The oil and gas industry relies on a wide range of industrial valves to ensure the safe and efficient transport of hydrocarbon resources. Among these valves, ball valves have emerged as versatile and reliable choices due to their unique design and performance characteristics. In this article, we will explore how ball valves play a vital role in the oil and gas industry, and how leading brands Fisher, Samson, THINKTANK, Flowserve, Spirax Sarco, KOSO, Azbil, Masoneilan, ARI, and ARCA are contributing to this crucial sector.

I. Introduction

A. Brief overview of the importance of Ball valves in the oil and gas industry

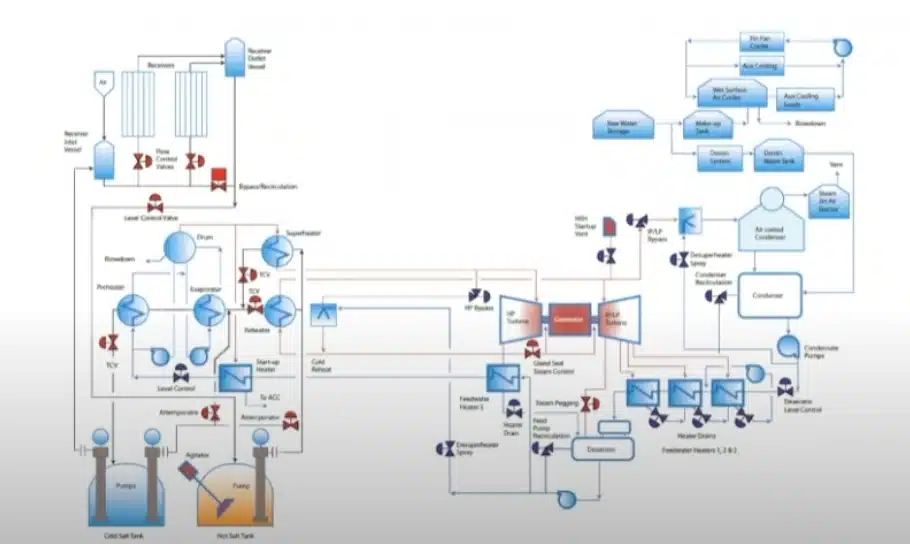

Valves play a critical role in the oil and gas industry, ensuring the safe and efficient operation of numerous processes in upstream, midstream, and downstream sectors. As a vital component of the industry’s infrastructure and piping system, valves regulate the flow of fluids, maintain pressure and temperature levels, and provide isolation and control in various applications.

B. Definition and explanation of ball valves

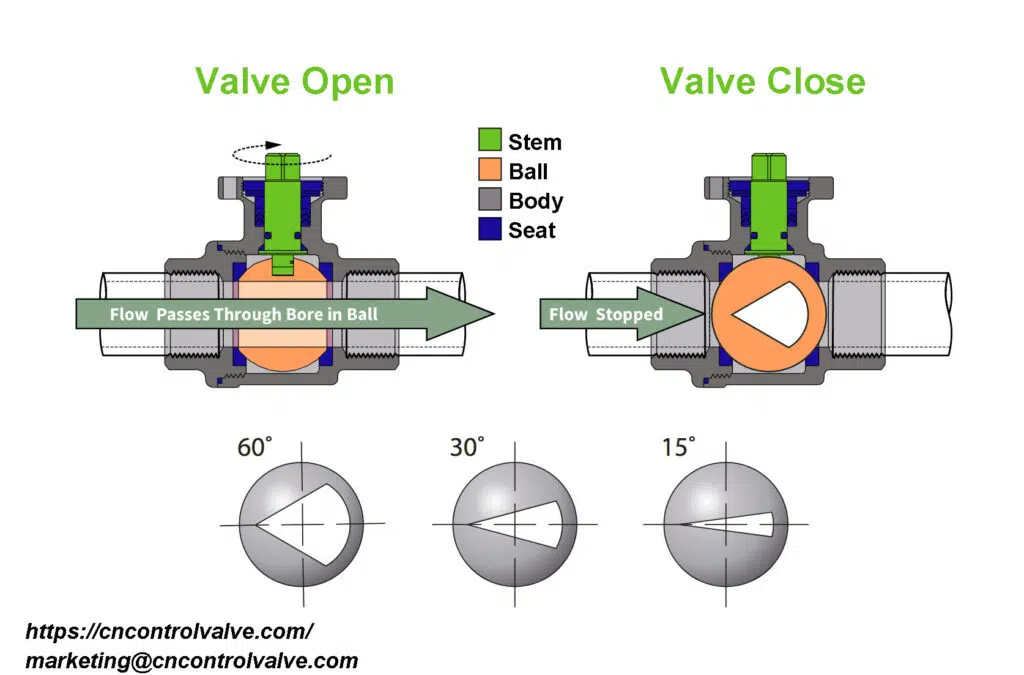

A ball valve is a quarter-turn type rotary, valve type, that has a hollow ball, through which the fluid passes, and then through a rotating 90° hollow ball (also called a “ball”) to control the flow of fluid through the valve. The ball has a hole or port through its center, which aligns with the pipeline when the valve is in the open position, allowing fluid to flow seamlessly. When the valve is closed, the ball rotates 90 degrees, and the hole is perpendicular to the flow path, effectively blocking the fluid and preventing any flow.

Ball valves are a popular choice in many industries because they are easy to use, have a straightforward design, dependable sealing capabilities. They are especially handy for situations that call for on or off control or when quick and sporadic operation is needed. Furthermore, they are incredibly long-lasting, don’t require much upkeep, and can withstand a wide variety of pressures and temperatures, making them a go-to choice for various fluid control valve applications.

C. Scope and purpose of the article

The scope and purpose of this article are to provide a comprehensive understanding of ball valves and their significance in the oil and gas industry. We will delve into the various types of ball valves, their key features, benefits, and specific applications in the different sectors of the oil and gas industry. Additionally, we will discuss the selection criteria for ball valves, ensuring compatibility with the operational requirements and industry standards. Finally, we will touch upon the challenges and innovations in ball valve technologies, highlighting their role in driving safety, efficiency, and sustainability in oil and gas operations.

By the time you finish reading this article, you’ll have a solid understanding of ball valves, their significance within the oil and gas field, and the recent advancements that are shaping their future. This information will be helpful to anyone interested in learning more about this essential component of oil and gas infrastructure as well as professionals, engineers, and decision-makers in the field.

II. Types of Ball Valve in Oil and Gas Industry

A. Floating ball valves

Floating ball valves feature a ball that is not rigidly fixed and instead floats between the two seats. When the valve is closed, the upstream pressure pushes the ball against the downstream seat, creating a tight seal.

Floating ball valves are typically used for smaller sizes and lower pressure applications, as the sealing performance may be compromised under high pressure and larger sizes.

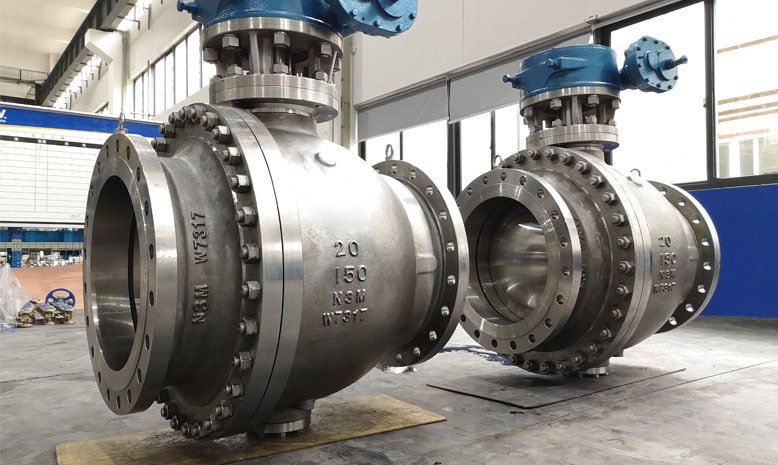

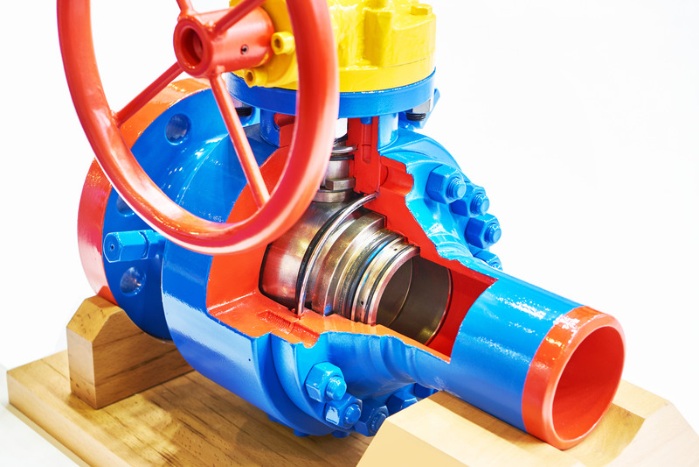

B. Trunnion-mounted ball valves

Trunnion-mounted ball valves have a ball supported by upper and lower bearings or trunnions, which absorb the line pressure and reduce the friction between the ball and seats.

The trunnion-mounted ball valve design offers superior sealing performance, and it is better to work for large sizes and high pressure conditions. Meanwhile, the trunnion has low operation and low torque is needed compared to others types to open or close the valve, which makes it easier to operate and saves more the costs for actuators.

C. Full port and reduced port ball valves

Full port ball valves have a bore size that perfectly matches the pipeline’s internal diameter, leading to minimal pressure drop and complete unrestricted flow. Such valves are best for applications demanding maximum flow rate. Conversely, reduced port ball valves have a restricted bore size, resulting in lesser flow area and higher pressure drop – they are usually smaller and lighter than full port valves.

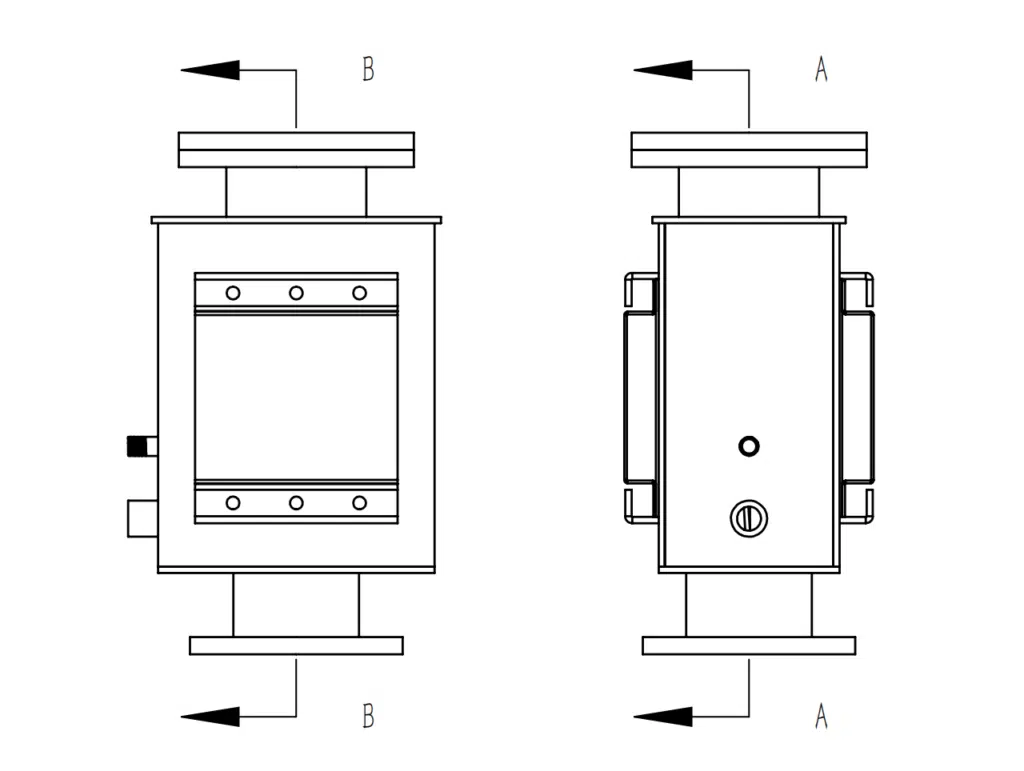

D. Multi-Port Ball Valves

Multi-port ball valves have multiple ports which offer various flow paths, allowing the user to easily switch between directions. This type of valve includes 3-way and 4-way ball valves, which can be used for diverting, mixing, or bypassing flow in any application. Furthermore, the structure of the ports and ball are customizable so they perfectly fit individual flow needs.

E. Top-Entry and Side-Entry Ball Valves

Top-entry ball valves have a one-piece body with a removable bonnet, allowing for easy maintenance and repair without removing the valve from the pipeline. This design is beneficial in applications where space is limited or disassembly of the pipeline is challenging.

Side-entry ball valves, conversely, have a two or three-piece body that is bolted together. To perform maintenance or repair, the valve must be removed from the pipeline. Side-entry ball valves are generally more economical and widely used compared to top-entry designs.

III. Key Features and Benefits of Ball Valves

A. Durability and Low Maintenance

Ball valves are known for their robust design and long service life. They are constructed using high-quality materials, which can withstand wear and tear, corrosion, and erosion. Due to their simple design and minimal moving parts, ball valves require low maintenance, making them a cost-effective solution for various applications.

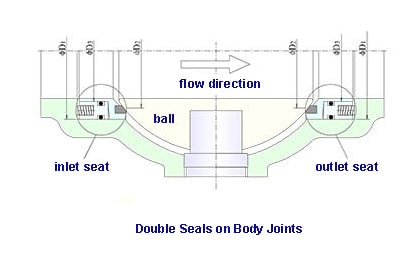

B. High-Performance Sealing

Ball valves offer excellent sealing performance, thanks to the tight contact between the ball and the valve seats. This design minimizes the risk of leaks and ensures reliable operation, even under high pressure and temperature conditions. The use of soft and hard seat materials enhances the sealing capabilities, catering to different application requirements.

C. Quick and Easy Operation

One of the key advantages of ball valves is their quick and easy operation. The quarter-turn design allows for rapid opening and closing, providing efficient on/off control of fluid flow. This feature is particularly useful in emergency situations where quick response is crucial. Moreover, ball valves can be easily automated, offering remote control and monitoring capabilities.

D. Wide Range of Sizes and Pressure Ratings

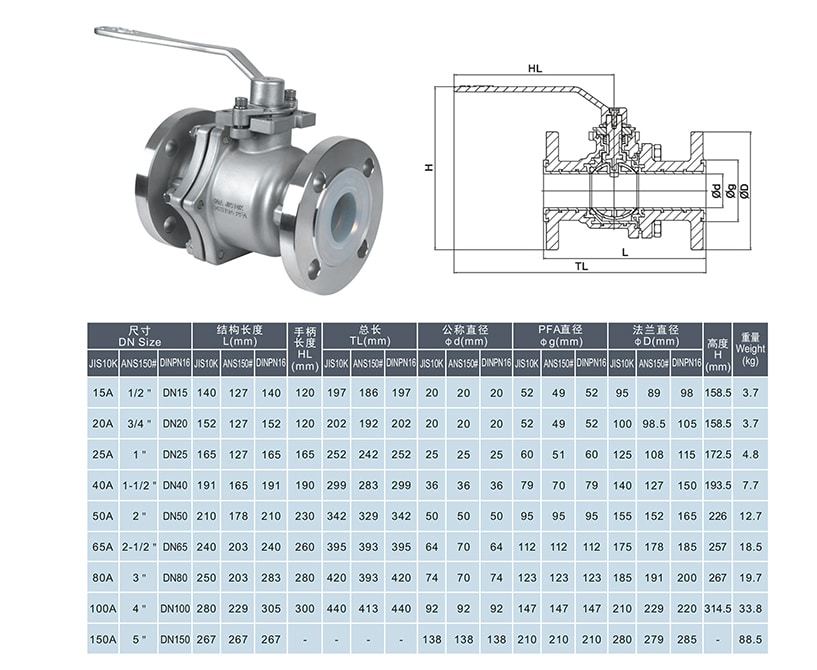

Ball valves are available in a wide range of sizes, from small to large bore, making them suitable for various applications within the oil and gas industry. Additionally, they can handle a broad spectrum of pressure ratings, from low to high pressures, ensuring compatibility with different operational requirements and environments.

E. Versatility in Applications

Ball valves are versatile and can be used in a multitude of applications across the oil and gas industry. Their ability to handle different types of fluids, including corrosive and abrasive substances, makes them suitable for upstream, midstream, and downstream operations. Furthermore, their compatibility with various end connections, such as threaded, flanged, or welded, allows for easy integration into existing infrastructure.

IV. Applications of Ball Valves in the Oil and Gas Industry

Ball valves are used across various applications in the oil and gas industry, some of which include:

1. Pipeline Transportation

Ball valves are commonly used in pipeline transportation systems due to their ability to provide tight shutoff, high flow capacity, and quick operation. These valves can be used in pipelines for the transportation and distribution of natural gas, crude oil, and other refined products.

2. Wellhead Control

Ball valves are often employed in wellhead control systems to isolate and manage the flow of oil and gas from production wells. It has a high performance for high pressure conditions, resists corrosion, and supply tight sealing and emergency shutoff make ball valves suitable for wellhead control.

3. Processing Plants

THINKTANK has rich experience of working with industrial plants, we know that ball valves are very commonly used in processing plants, such as the refinery industry, and gas processing facilities. They are main function is to controlling the flow of fluids through various stages of the production process, and suitable for managing flows in distillation units, heat exchangers, and other critical equipment.

4. Storage and Transfer Facilities

We are also to see ball valves everywhere in storage and transfer facilities, they often manage the flow of oil and gas into storage tanks and other vessels. Ball valves provide tight shutoff and withstand harsh operating conditions makes them ideal for these applications.

5. Offshore Platforms

In offshore oil and gas platforms, ball valves are usually to on-off the flow of hydrocarbons and other fluids during production and drilling activities. They are a great solution for these demanding conditions due to their sturdy build and low maintenance needs.

based on different working positions, it can be divided into upstream, midstream, and downstream operations conditions

1. Upstream Operations

Wellhead Isolation

Ball valves are used for isolating wellheads during the drilling, completion, and production phases, ensuring safety and control over the flow of oil and gas.

Subsea Installations

In subsea applications, ball valves provide reliable control over the flow of fluids under extreme pressures and temperatures, as well as corrosive environments.

Christmas Tree Assemblies

Ball valves are integral components of Christmas tree assemblies, used for controlling and monitoring the production of oil and gas from wells.

2. Midstream Operations

Pipeline Transportation

Ball valves are employed in pipeline transportation systems for flow control, isolation, and pressure regulation of oil and gas.

Gas Processing Plants

In gas processing facilities, ball valves are used to control the flow of natural gas during various stages of processing, such as separation, dehydration, and sweetening.

3. Downstream Operations

Refineries

Ball valves are utilized in refineries for controlling the flow of crude oil and refined products during various processes, including distillation, cracking, and blending.

Petrochemical Plants

In petrochemical plants, ball valves help manage the flow of chemicals and feedstocks during the production of plastics, fertilizers, and other products.

Storage and Distribution Facilities

Ball valves are essential for controlling the flow and maintaining safety in storage and distribution systems for oil, gas, and petrochemical products.

Selection Criteria for Ball Valves

A. Material Compatibility

Select appropriate materials for the valve body, ball, and seats that are compatible with the fluids being handled and the operating conditions.

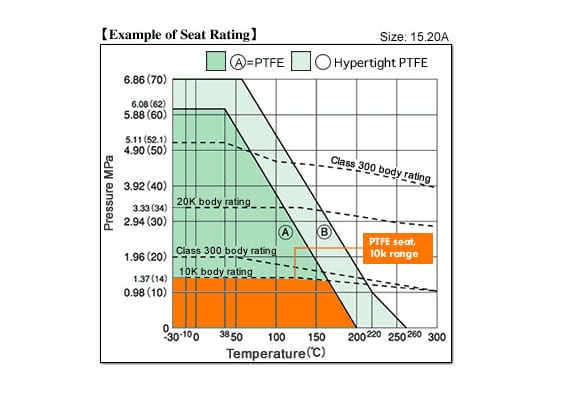

B. Pressure and Temperature Ratings

Choose ball valves with suitable pressure and temperature ratings to ensure safe and reliable operation under specific application requirements.

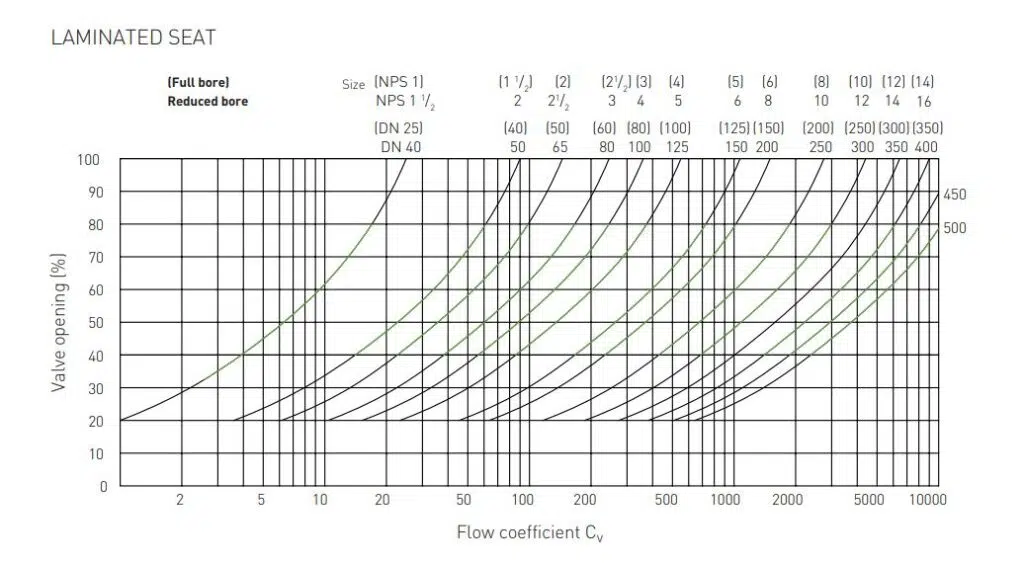

C. Flow Coefficient (Cv) and Valve Size

Consider the flow coefficient (Cv) and valve size based on the desired flow rate and pressure drop across the valve.

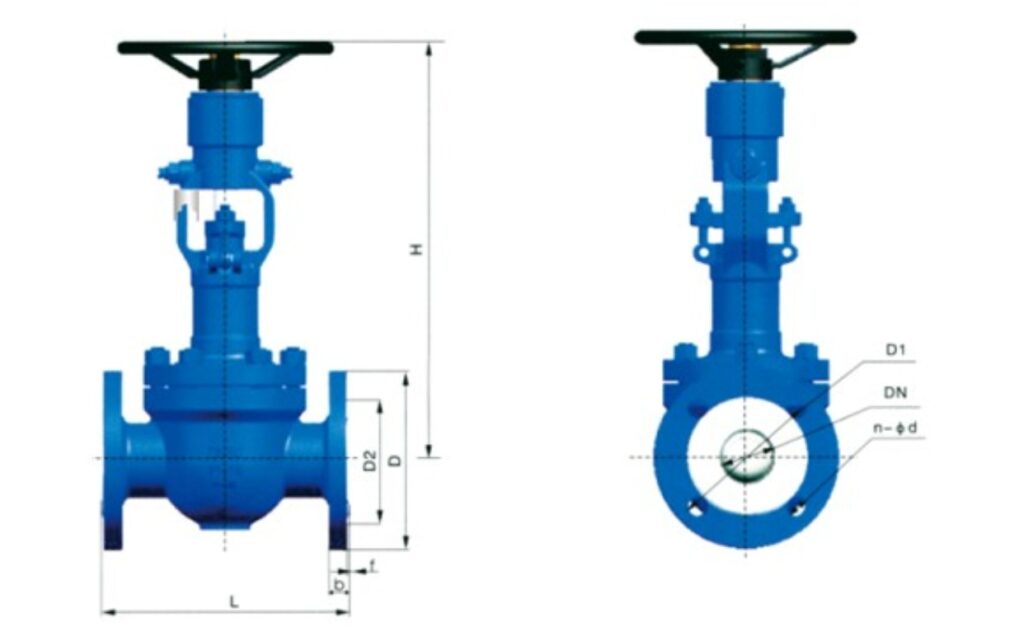

D. End Connections and Installation Requirements

Determine the appropriate end connections (threaded, flanged, or welded) for easy integration into the existing various pipeline systems and infrastructure.

E. Industry Standards and Certifications

Ensure the selected ball valves meet relevant industry standards and certifications, such as API, ASME, or ISO, to guarantee quality and performance.

Challenges and Innovations in Ball Valve Technologies

A. Addressing High-Pressure and High-Temperature Applications

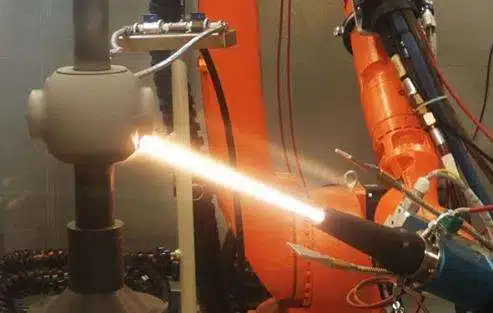

Innovations in materials, sealing technology, and valve design enable ball valves to withstand extreme pressure and temperature conditions in challenging oil and gas environments.

B. Corrosion and Erosion Resistance

Advanced materials and coatings enhance the corrosion and erosion resistance of ball valves, increasing their service life and reliability.

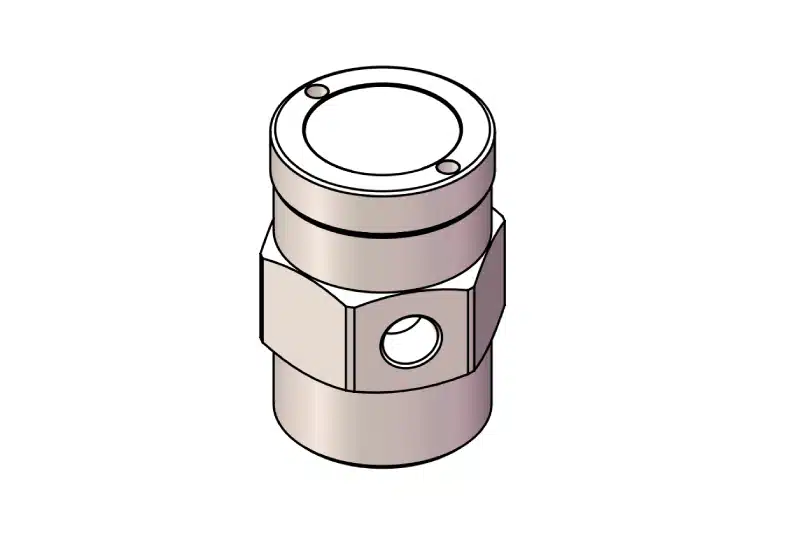

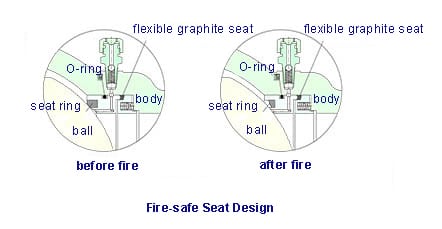

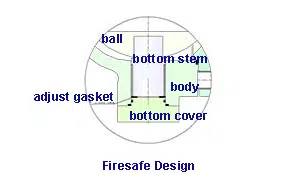

C. Enhanced Sealing Technologies

Developments in soft and hard seat materials, as well as advanced sealing designs, improve the sealing performance of ball valves, reducing the risk of leaks and fugitive emissions.

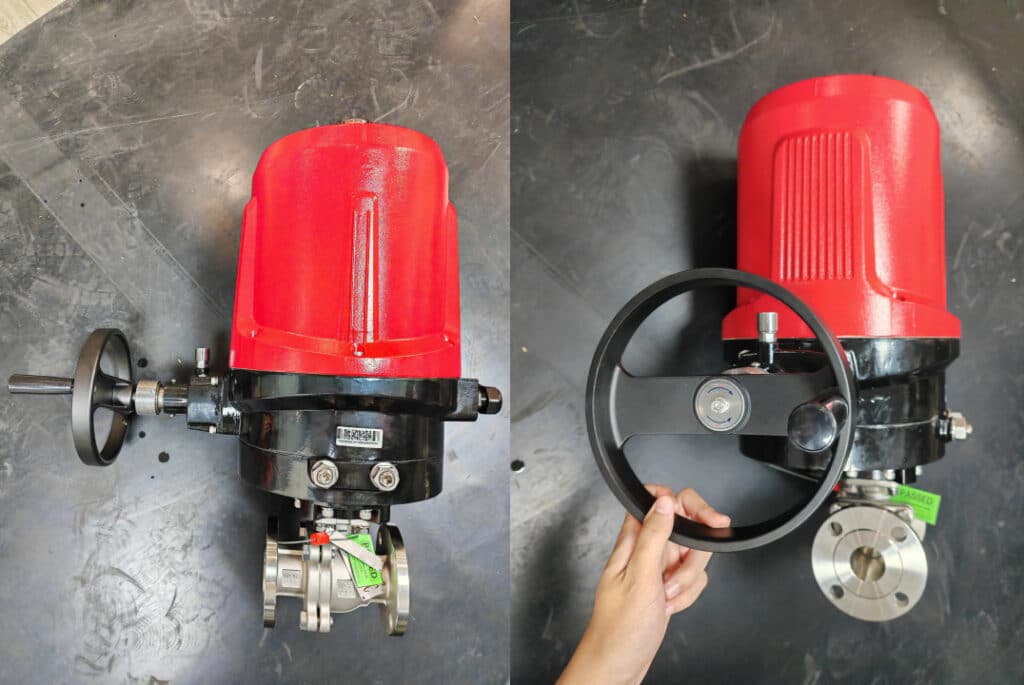

D. Development of Smart Valve Systems and Remote Monitoring

Integration of smart technologies, such as sensors, actuators, and communication systems, allows for remote monitoring and control of ball valves, enhancing operational efficiency and safety.

Advantages of Ball Valves in the Oil & Gas Industry

Ball valves offer several advantages that make them an ideal choice for various applications in the oil and gas industry:

1. High Flow Capacity

Ball valves are ideal for use in the oil and gas industry due to their full-bore design which provides a high flow capacity with a minimal pressure drop across the valve. This means that operations can be conducted with optimal efficiency. For more information on this subject, you can consult this guide on Cv values.

2. Quick and Easy Operation

Now we know ball valves can be quickly opened and closed with a simple 90-degree turn of the handle or actuator, which makes them suitable for fast and efficient process control. This swift operation also reduces any possible of leaks and other issues that can generate from prolonged valve actuation. To learn more about different types of actuators, check out this article.

3. Low Maintenance

Ball valves require minimal maintenance due to their simple design and robust construction. They are less prone to wear and tear, ensuring a longer service life and reducing downtime for maintenance activities. For more information on valve maintenance, read this guide.

4. Tight Shutoff

Ball valves have a tight shutdown performance due to the ball and seat special design, which stops any leaks while the valve is in the closed position. Special elastic compensation design, even if wear or fire melts the soft seat of the ball valve, the compensation sealing will immediately close to the steel of the floating ball valve, maintaining a tight cut-off function. This is particularly significant in the oil and gas sector, where stopping leaks is essential to maintaining environmental and safety standards. See this page for additional information on valve seat leakage requirements.

5. Wide Range Material Opt

Ball valves are suitable for a wide range of oil and gas applications, such as high-pressure, high-temperature, and corrosive conditions. The body material can be made from various materials, such like stainless steel, carbon steel, and even alloys steel, which makes them a versatile choice for being used in the oil and gas industry. If you are interested in learning more about selecting the right valve material, just feel free to read this guide.

VII. In Conclusion

A. Recap of the importance of ball valve in oil and gas industry

In recap, ball valves are of paramount importance in the oil and gas industry due to their versatile design, durability, and exceptional sealing performance. They are essential components in various applications across upstream, midstream, and downstream sectors, providing reliable control, isolation, and regulation of fluid flow.

Meanwhile, we know ball valves are a popular choice among those working in the oil and gas industry due to their ability to handle a wide range of pressure, temperature, and fluid types. This makes them versatile enough to be used in many applications, while their easy operation and low maintenance requirements add to their appeal as they help streamline operations while ensuring safety.

Innovation and advancements in ball valve technologies continue to address industry challenges, such as high-pressure and high-temperature applications, corrosion and erosion resistance, and the development of smart valve systems. These ongoing improvements further reinforce the crucial role of ball valves in the oil and gas industry.

B. Emphasis on proper selection and maintenance for optimal performance

Emphasizing proper selection and maintenance of ball valves is critical for achieving optimal performance, efficiency, and safety in the oil and gas industry. The right choice of ball valve depends on several factors, including material compatibility, pressure and temperature ratings, flow coefficient (Cv), valve size, end connections, and adherence to industry standards and certifications. By considering these aspects, one can ensure the selected ball valve is suitable for the specific application and operational conditions.

Maintenance is equally important in maintaining the performance and longevity of ball valves. Although these valves are known for their low maintenance requirements, periodic inspection and servicing can help identify potential issues and prevent unexpected failures. Regular maintenance activities may include checking for leaks, inspecting sealing components, verifying proper operation, and lubricating moving parts as needed.

By placing emphasis on proper selection and maintenance, one can maximize the benefits of ball valves in the oil and gas industry, ensuring reliable and efficient control of fluid flow throughout various processes and applications.

C. Future outlook and ongoing innovations in ball valve technologies

The future outlook for ball valve technologies in the oil and gas industry appears promising, with ongoing innovations addressing key challenges and improving their overall performance, efficiency, and sustainability.

🟢 Advanced Materials

The development of advanced materials and coatings will continue to enhance the durability, corrosion, and erosion resistance of ball valves, making them suitable for more demanding applications and environments.

🟢 Enhanced Sealing Technologies

Research and development efforts are focused on improving sealing performance, with new designs and materials reducing the risk of leaks and fugitive emissions, thus contributing to environmental protection and safety.

🟢 Smart Valve Systems and Remote Monitoring

The integration of sensors, actuators, and communication systems into ball valves is expected to drive the adoption of smart valve systems. This will allow for remote monitoring and control, enabling predictive maintenance, and improving operational efficiency.

🟢 Energy-efficient Solutions

As the industry moves towards greener operations, energy-efficient ball valves with reduced pressure drops and optimized flow control will gain prominence, contributing to lower energy consumption and reduced emissions.

🟢 Customized and Application-specific Designs

As the oil and gas industry diversifies and explores new frontiers, customized and application-specific ball valve designs will become more prevalent, catering to unique operational requirements and challenges.

With over three decades of experience, THINKTANK is a reliable valve supplier in China, offering a wide range of valve solutions to meet the demanding requirements of the oil and gas sector. Our commitment to quality, innovation, and customer satisfaction has earned us a reputation as a trusted partner for clients worldwide, helping to enhance the performance and safety of their operations.