Fusible Link Valves are critical safety components in industrial settings, designed to automatically shut off the flow of hazardous materials in the event of a fire. This guide provides comprehensive insights into their function, types, applications, and selection criteria.

Fusible link valves are a type of safety device used in industrial piping systems to prevent the spread of fire by automatically shutting off the flow of flammable liquids or gases. These valves are designed to close rapidly in the event of a fire, cutting off fuel supply to the fire and thereby helping to contain it.

In the event of a fire, the fusible link melts, causing the valve to snap shut and stop the flow of flammable or hazardous materials.

The core component of these valves is the fusible link, which is a mechanical element designed to melt at a specific temperature.

In the event of a fire, the heat causes the fusible link to melt.

Once the link melts, it triggers a mechanism that rapidly closes the valve, stopping the flow of hazardous materials.

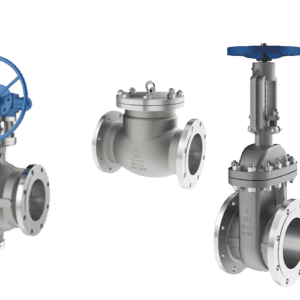

Fusible link valves come in various types and designs, each suited to specific applications and operational requirements. These valves are integral to safety in environments where there’s a risk of fire, especially in industries dealing with flammable materials. Here’s an overview of the common types and designs of fusible link valves:

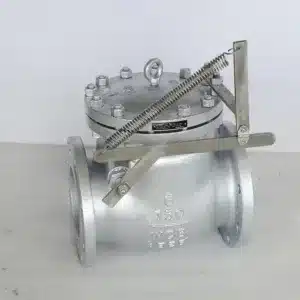

Fusible link check valves are a specialized type of check valve integrated with a fusible link mechanism. They are designed to prevent reverse flow in piping systems and, in the event of a fire, to shut off the flow of potentially hazardous materials automatically. Here’s a detailed look at fusible link check valves:

Check Valve Operation: These valves allow fluid to flow through them in only one direction. They have a gate or flap that opens with forward flow and closes if the flow is reversed, preventing backflow.

Fusible Link Mechanism: In addition to the check valve functionality, they have a fusible link which is designed to melt at a specific temperature. When exposed to excessive heat, as in a fire, the fusible link melts, triggering the valve to lock in a closed position, thus preventing the flow of flammable or hazardous materials.

Fusible Link Composition: The choice of material for the fusible link is crucial. It must have a melting point that is appropriate for the specific fire-risk scenario of the installation.

Response Time: The design ensures that the valve reacts swiftly to the melting of the fusible link to promptly stop the flow of flammable materials.

Flow Characteristics: Depending on the type of valve, the flow characteristics (like linear or equal percentage) will vary, affecting the overall control of the system.

Pressure and Temperature Ratings: These valves are rated for different pressure and temperature conditions, which should match the specifications of the application.

Resetting Mechanism: Some designs allow for the valve to be manually reset after activation, while others may require replacement of the fusible link or other parts.

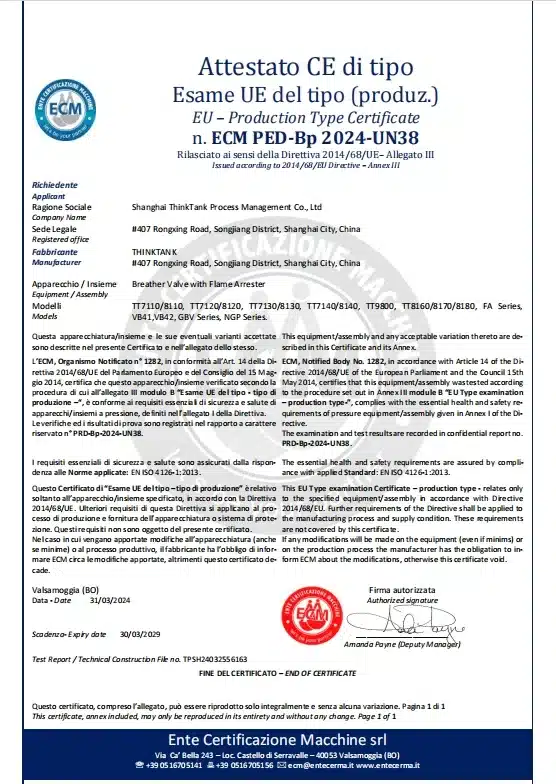

Safety and Compliance: Designs must comply with relevant safety standards and certifications appropriate for the industry and region of use.

Fusible link valves are predominantly used in high-risk industries such as oil and gas, petrochemical, pharmaceutical, and in various manufacturing processes involving flammable or hazardous materials.

We are looking for valuable brand customers with long-term cooperation. Only with high quality and service can bring our customers more market share and stable business.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 185 1656 9221, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.

Just leave your name, email, and simple message or requirements, We will contact you within 1 hour.

WhatsApp: +86 185 1656 9221

Skype ID: sowell85

Wechat ID: +86 199 2125 0077

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 185 1656 9221, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.