A pneumatic on/off valve is used for tight closing applications for liquids, gases, and vapors. It has standard options such as temperature extensions and metal bellows seals.

As this control valve is designed according to the modular assembly principle, so it can be assembled with a pneumatic actuator and an option with a handwheel, it also can be equipped with other accessories, such as limit switches, solenoid valve, and so on.

Modulating type control valves include single-seated control valves, double-seated control valves, angle type control valves, cage guided control valves, and so on.

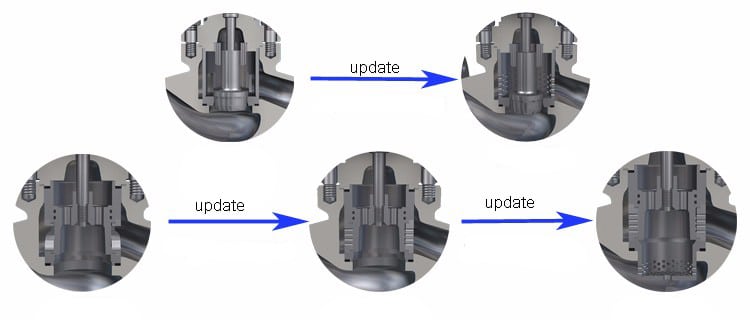

For example, cage guided type balanced trim, movement balanced ring, fission labyrinth type standard cage, optional movement seal ring, high strength structure. The 510D series is the most pointed control valve in the high differential pressure operating mode, has used the labyrinth type valve cage, has the characteristic which multistage falls pressure, the multilayered labyrinth gasket type valve can reduce the fluid noise and eliminate cavitation as well as the multi-hole cage valve. Moreover, reduces the volume greatly, the trim in the valve is interchangeable between the HCB series control valve with the HSC series Cage Guided control valve.

A self-acting control valve is also known as a self-operated pressure regulator, which doesn’t need any auxiliary power to drive the valve, the self-acting control valve through the medium energy to operate the valve itself, that’s why it is called self-acting or self-operated. A self-operated control valve can realize the adjustment of temperature, pressure, differential pressure, flow rate, and other parameters. It has the characteristics of simple structure, low price, reliable action, and so on. It is suitable for occasions where flow rate changes are small, adjustment accuracy is not high, or instrument air/power supply is difficult.

Low-pressure control valves are designed to regulate the flow of fluid in systems that operate under low pressures. The term “low pressure” can be relative and depend on the specific industry or application, but generally, it refers to systems operating under pressures of around 20 PSI (pounds per square inch) or lower.

These valves function much like any other control valves, in that they allow more or less fluid to pass through based on the position of the valve. The valve’s position can be controlled manually or automatically by an actuator, which can be electric, pneumatic, hydraulic, or manually operated.

Low-pressure control valves come in various designs, including globe, gate, ball, and butterfly valves. The choice of which type of valve to use depends on several factors, including the nature of the fluid being controlled, the required flow rate, and the specific requirements of the application.

While they may be similar in operation to control valves designed for higher pressures, low-pressure control valves are designed with materials and components that can provide a reliable seal and maintain control at low pressures. Ensuring a good seal at low pressure can be challenging, as even small leaks can represent a significant percentage of the total flow.

Low-pressure control valves are used in a wide variety of applications, including water systems, gas distribution networks, and many others where the pressure of the fluid is relatively low.

“Mid-pressure control valves” is a term used to describe control valves that are designed to operate effectively in applications with medium or mid-range pressure levels.

In industrial contexts, the definition of “low”, “mid”, and “high” pressure can vary widely depending on the specific application or industry. For example, in some industries, “mid-pressure” might refer to pressures in the range of a few hundred psi (pounds per square inch), while in others it might refer to pressures in the thousands of psi.

Mid-pressure control valves come in a wide variety of designs, including globe valves, ball valves, butterfly valves, and more, and can be actuated in a number of ways, including manually, or by using electric, pneumatic, or hydraulic actuators.

Regardless of their specific design, the primary function of these valves is to regulate the flow of fluid (which could be a liquid or a gas) under medium pressure conditions. They do this by changing the size of the opening that the fluid flows through, which can be adjusted to control the flow rate of the fluid.

As with all control valves, mid-pressure control valves are used in a wide range of industries and applications, anywhere that precise control over fluid flow is needed in a medium pressure context. This includes industries like oil and gas, power generation, water and wastewater treatment, chemical processing, and more.

Pneumatic top guided single-seated angle control Valve applied with an unbalanced plug, this top guided single seated angle control valve requires a large actuator output force. The size is reduced by incorporating a fine designed multi-spring diaphragm actuator. This series is a good application for slurry polymer crystallization and high-temperature fluid as the pressure balanced structure is not used here.

510D Model is adopted cage guided type balanced trim, movement balanced ring, fission labyrinth type standard cage, optional movement seal ring, high strength structure. The 510D series is the most pointed control valve in the high differential pressure operating mode, has used the labyrinth type valve cage, has the characteristic which multistage falls pressure, the multilayered labyrinth gasket type valve can reduce the fluid noise and eliminate cavitation as well as the multi-hole cage valve. Moreover, reduces the volume greatly, the trim in the valve is interchangeable between the HCB series control valve with the HSC series Cage Guided control valve.

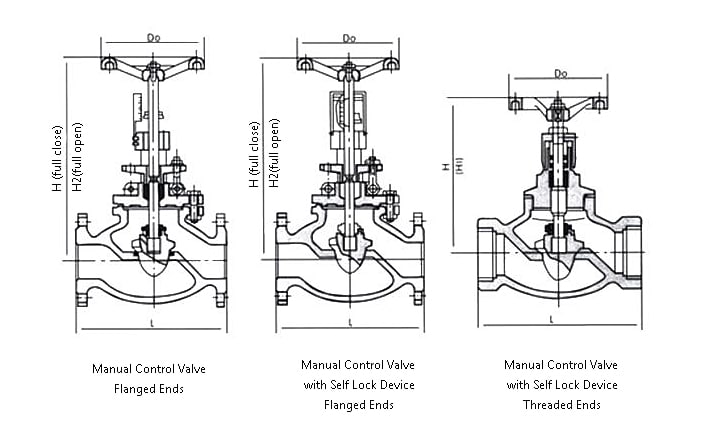

Manual Control Valves are valves that are operated by manual input, typically by turning a handwheel, lever, or crank. The operator manually adjusts the position of the valve to control the flow of a fluid through a system. This control valve is still globe type, and they are used for both throttling and shut-off. A disc or plug inside the valve can be moved closer to or further away from the valve seat to adjust flow.

Electric/Motorized Control Valves, also known as Electric Actuated Control Valves, are valves that can be controlled remotely or automatically by an electric actuator. The actuator uses an electric motor to control the valve’s position, which in turn controls the flow of fluid through the valve.

These types of valves are commonly used in various industrial applications where precise control of fluid flow is needed. They can be found in water treatment plants, oil and gas pipelines, chemical processing facilities, HVAC systems, and many other settings.

The operation of an Electric/Motorized Control Valve can be modulating or on/off:

Modulating control: In this mode, the valve can be adjusted to any position between fully open and fully closed to control the flow rate of the fluid. This is useful in applications where flow rates need to be adjusted dynamically based on changing process conditions.

On/Off control: In this mode, the valve is either fully open or fully closed. This is useful in applications where flow needs to be completely stopped or allowed to flow freely, such as in safety shut-off applications.

The electric actuator typically receives a signal from a control system, such as a PLC (Programmable Logic Controller) or DCS (Distributed Control System), which tells it what position to move the valve to. This allows for precise, automatic control of fluid flow rates based on the needs of the process.

Pneumatic or Cylinder Control Valves are control valves that use a pneumatic actuator for operation. The actuator uses air pressure to control the position of the valve, which in turn controls the flow of fluid through the valve.

In a typical pneumatic actuator, air pressure is applied to a diaphragm or a piston, which then moves a stem attached to the valve. The stem movement can either open or close the valve, or move it to any position in between for modulating control.

Pneumatic control valves can be “normally open”, which means they stay open when no air pressure is applied, or “normally closed”, meaning they stay closed when no air pressure is applied. They can also be double-acting, meaning that air pressure can be used to both open and close the valve.

These valves are widely used in various industries such as oil and gas, water and wastewater, power generation, and chemical processing. Pneumatic control valves are popular because of their reliability, low maintenance, and because they can be easily integrated into control systems.

Pneumatic actuators also have the advantage of being safe to operate in explosive environments, as they do not create sparks like some electrical devices can. They also can deliver a high amount of force, which can be useful for operating larger valves.

In this type, the flow of the fluid is modified by the closure member in rotary motion. Rotary motion valves are of three types.

As the name suggests, the shape of the valve is like a ball with a container for fluid flow. Right at the opening, this valve enables the flow and after being rotating at 90° it stops the flow. Ball valve has good resistance towards high temperature & high pressure. The advantage of the ball valve is easy to maintain and has low torque. On the other hand, it also has the disadvantage of causing corrosion when the fluid gets trapped inside the valve mainly during a closed position.

Butterfly valve has a disc rotating at 90˚ inside the pipe. The disc allows the stem to pass through it and is supported by both ends. Similar to the ball valve, the butterfly valve also stops with a right-angle rotation. The butterfly valve has the capacity of controlling large flow and low-pressure applications. It is affordable and has a quick opening. It has only one disadvantage of loose shut-off.

The plug valve is available in both cylindrical and tapered shapes. At the time of opening of this valve, both inlet and outlet ends of this valve, are connected to give a flow line. This valve is suitable for both chemical and petrochemical industries. The plug valve has advantages like less maintenance, fewer requirements of headroom, and quick opens. It has a low-pressure drop and doesn’t provide loose shut-off like a butterfly valve. The plug valve also has disadvantages like not affordable and is not useful for throttling action.

In high temperatures, the gate valve is used for on/off applications. This is also recommended for non-throttling services because of its fully closed or fully open designs. It has a sliding gate to control the flow. It works well at the time of straight-line flow of liquid with minimum restrictions. Based on shape, the gate valve is further divided into two categories: Parallel and wedge.

The gate valve starts working when the stem is rotated either clockwise to close motion or clockwise to open motion. As you move the stem, the gate valve moves up and down. The advantage of a gate valve is it comes with a tight sealing. Gate valve also has the disadvantage of requiring more actuating force.

Due to the globular shape, this valve is named a globe valve. Its closure member is a plug with a button, located right at the center. When the plug is raised, the globe valve allows the fluid flow. Globe valve mainly has 3 body designs as Z, Y, and angle body. The advantage of the globe valve is it has better throttling characteristics than other valves. It also has the disadvantage of having a high-pressure drop.

The diaphragm valve has a compressor that is connected to a flexing diaphragm. This diaphragm is lifted at the time of opening of this valve and allows the fluid flow. When the valve is closed, it closes the path tightly. The diaphragm valve works at low temperature and low pressure and is highly suitable for corrosive liquids. The advantage of the diaphragm valve is it is easy to maintain and has a simple construction. It also has disadvantages like it can’t be used in high temperatures and high pressure.

A pinch valve is more cost-effective than other valves. This valve is used for slurries or liquids having minimal solid particles. It is similar to a diaphragm valve but uses flexible elements like rubber to turn off the fluid flow. To actuate the pinch valve, hydraulic pressure is placed on the elastomer sleeve. The pinch valve doesn’t have any internal obstructions and hence it has a low-pressure drop. This is a good advantage of the pinch valve.

Normally the industrial process is by open-loop control or closed-loop control to maintain the desired data such as flow capacity, pressure, or temperature.

Generally, the open-loop control system that controls action only depends on the input signal without its output response.

The closed-loop control system that controls action depends on both of input signal and a feedback signal from the valve controllers.

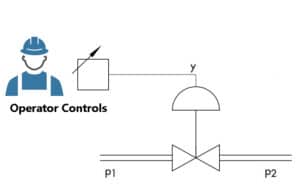

Operator controls the process variable p2 via remote adjuster

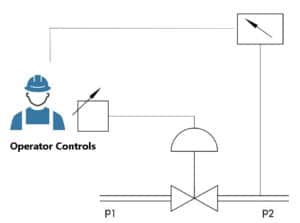

Operator controls the process variable p2 an a closed-loop

Controlling system: Controller and actuator

Controlled system: Final control element, pump, pipeline, heating system, etc.

Input signal: It is the signal from the control room/operator controls to the valve positioner.

Output signal: It is the signal from the valve positioner then feedback to the control system.

Pneumatic globe type control valves: Globe valve, actuator, valve positioner, air filter regulator.

Actuator: It is the device to provides the power to activate the valves.

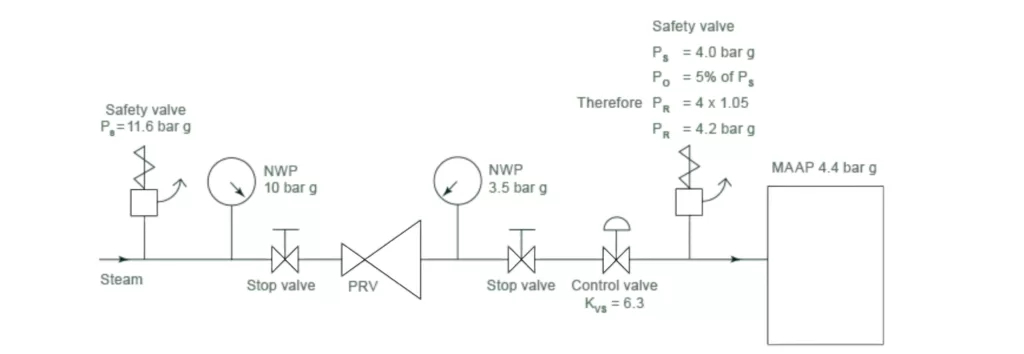

Steam control valves with pneumatic actuators are widely used for industrial processes, such as sugar mills, power plants, chemical industry, oil, and gas.

Usually, it is assembly with E/P or P/P valve positioner to receive an input signal from the controller room, 4-20mA or 3-15psi.

Steam control valves with pneumatic actuators are designed to regulate the flow of steam in various industrial applications. They use pneumatic actuators to control the opening and closing of the valve.

Here’s how they work:

Pneumatic Actuator: The pneumatic actuator uses air pressure to create motion that opens or closes the valve. It typically operates via a diaphragm or a piston mechanism. When pressurized air is introduced, it moves the diaphragm or piston, which in turn moves the valve stem and changes the position of the valve. These actuators can be spring return (single acting – where air pressure opens or closes the valve and a spring returns the valve to its original state when the air pressure is released) or double acting (where air pressure can both open and close the valve).

Steam Control Valve: The valve component of this system is specifically designed to handle the high temperature and pressure of steam. It might be a globe, gate, or ball valve, depending on the specific needs of the system. When the valve is opened or closed by the actuator, it allows more or less steam to pass through, effectively controlling the flow rate of steam in the system.

These valves are used in a variety of industries and applications, including power plants (where steam is used to generate electricity), food processing facilities, and any other application where the flow of steam needs to be precisely controlled.

In a system with these valves, the pneumatic actuator typically receives signals from a control system, which tells it how far to open or close the valve. This allows for automatic and precise control of steam flow based on the current requirements of the system.

Description

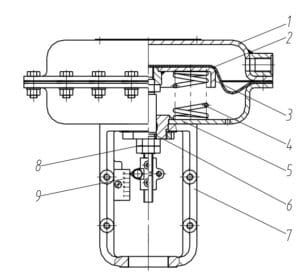

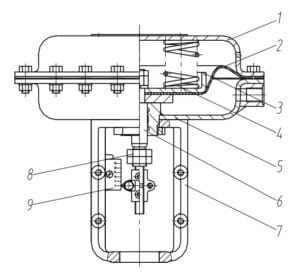

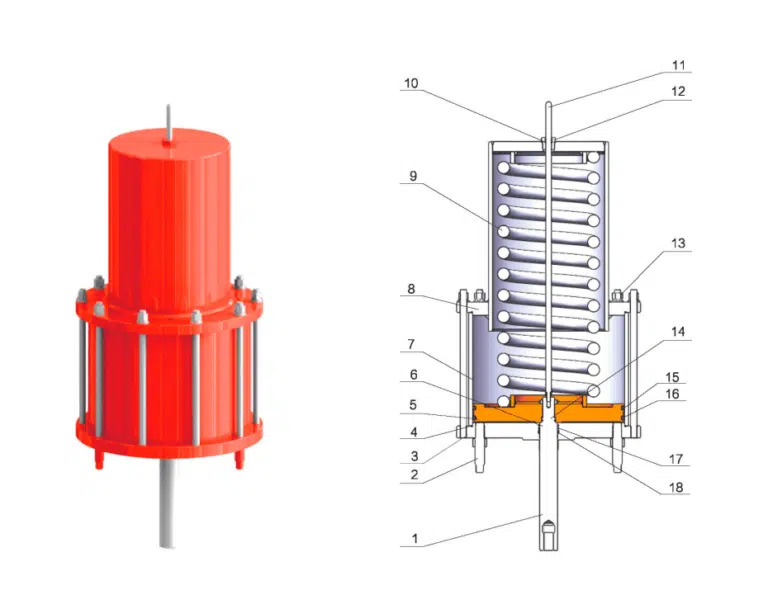

The multi-spring membrane pneumatic actuators of P/R type are applied for control operation of control valves and other positioning elements in automatic industrial systems. There are two following design options of the actuator:

– Direct action (air – advances the stem)

– Reverse action (air – retracts the stem)

Features

1. Up diaphragm castings 2. Diaphragm

3. Diaphragm plate 4. Spring

5. Down diaphragm castings 6. Actuator stem

7. Yoke 8. Adjust nut 9. Travel indicator

1. Up diaphragm castings 2. Diaphragm

3. Diaphragm plate 4. Spring

5. Down diaphragm castings 6. Actuator stem

7. Yoke 8. Adjust nut 9. Travel indicator

Model TT-667 actuator is a reverse-acting, spring-opposed diaphragm actuator. The actuator positions the valve plug in response to varying pneumatic loading pressure on the actuator diaphragm.

Description

Our Model TT-667 diaphragm actuator with a single spring is 100% to replace Fisher 667 actuators, which are designed to ensure stable on/off or throttling operation of the control valve. These spring-balanced membrane actuators respond to the pneumatic output signal of the controller or valve positioner to determine the position of the valve plug. 667 diaphragm actuator is a reverse-acting.

Specifications:

It could be a single-seated, double-seated, cage-guided, top-guided globe type trim design for the industrial engineering process. The control valve body assembly with a pneumatic actuator to modulate or shut off downstream pressure, flow rate, or temperature.

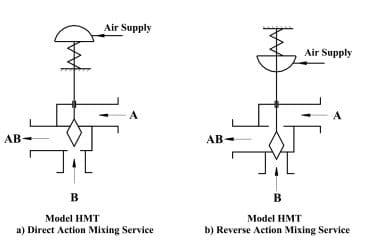

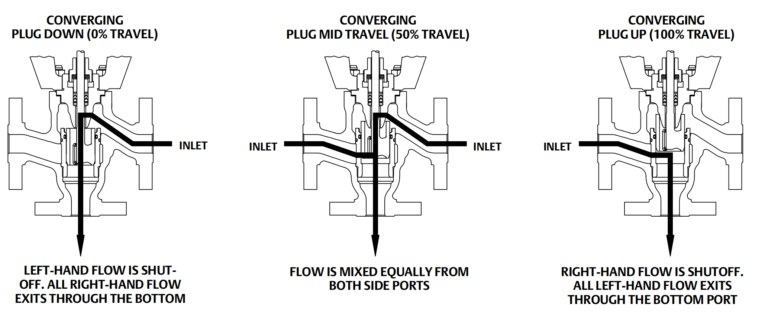

Three ways control valves are service for diverting or mixing service. The pneumatic actuator is designed as a rubber diaphragm with multi-springs, or piston/cylinder type pneumatic actuator with single-acting or double-acting.

Three-way globe type control valves are specialized control valves that have three ports and two valve seats, which allow the valve to connect two ports together at a time in different combinations. This allows them to perform several functions that would otherwise require multiple two-way valves.

Here’s a general idea of how they work:

Mixing Application: In the ‘mixing’ configuration, fluid can enter the valve from two different ports and then mix together and exit through the third port. This configuration is often used in heating and cooling systems where there is a need to mix hot and cold fluids to achieve a specific temperature output.

Diverting Application: In the ‘diverting’ configuration, fluid enters the valve from one port and can be directed to either of the other two ports. This is often used where a fluid needs to be directed towards two different paths in a system.

Three-way globe type control valves are typically actuated (opened and closed) using a manual wheel, an electric motor, a pneumatic or hydraulic cylinder, or a solenoid. The actuator can adjust the position of the internal mechanism (typically a disc or a ball) to change the path of the fluid through the valve, allowing for precise control over the fluid flow.

Like all globe valves, three-way globe type control valves have good throttling abilities, which means they can adjust the flow rate of the fluid very precisely. This makes them ideal for applications where precise control over fluid flow is important. However, they also have a higher pressure drop than other types of valves due to the more complex flow path, which can be a consideration in system design.

Control Valve Failure Position 101

We are looking for valuable brand customers with long-term cooperation. Only with high quality and service can bring our customers more market share and stable business.

Avoid your inquiry is delay response, please enter your WhatsApp/Wechat/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 185 1656 9221, or WeChat: +86 199 2125 0077. or call +86 189 5813 8289 directly.

Just leave your name, email, and simple message or requirements, We will contact you within 1 hour.

WhatsApp: +86 199 2125 0077

Skype ID: sowell85

Wechat ID: +86 199 2125 0077

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 199 2125 0077, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.