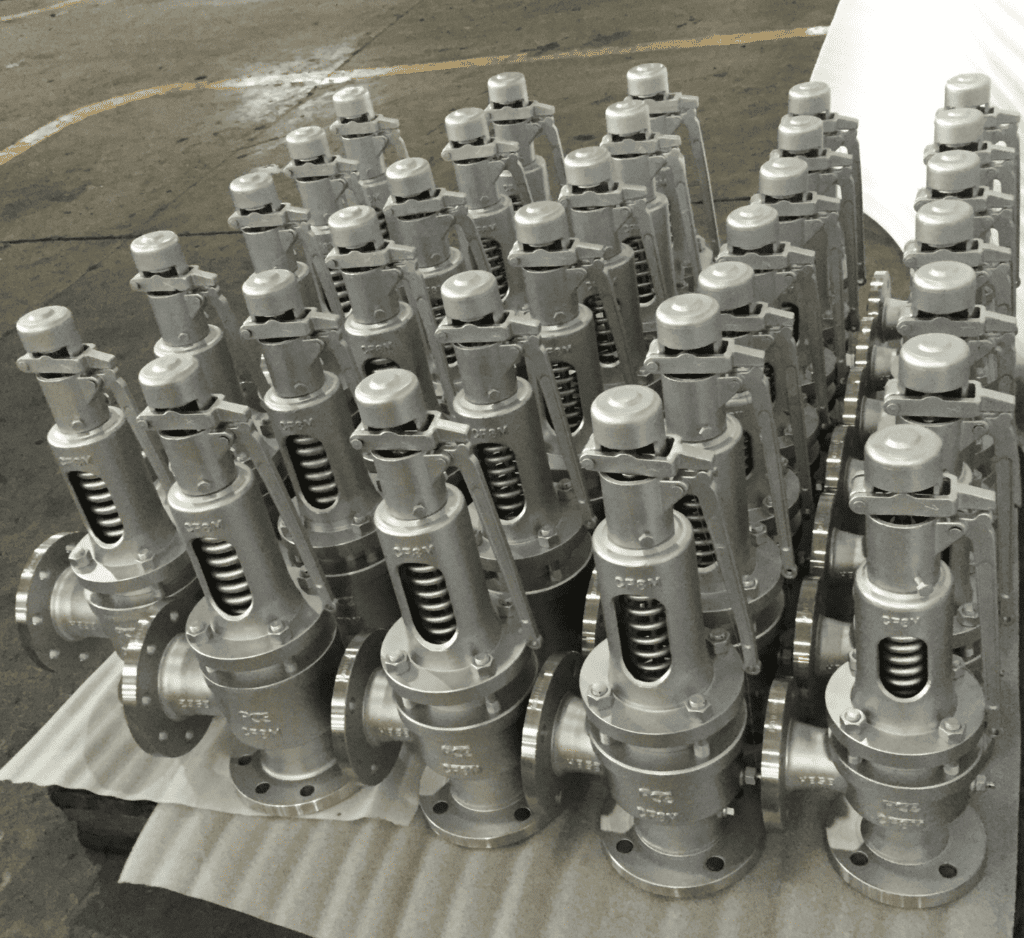

In high-temperature and high-pressure conditions, a safety valve’s reliability is very important for keeping a system safe and stable. If a safety valve does not work properly in these tough environments, it could cause serious problems, such as system failure, unexpected shutdowns, or even dangerous accidents. That is why THINKTANK works hard to design and improve safety valves that can handle extreme conditions.

Recently, our newest high-temperature safety valve successfully passed a Special Equipment Type Test, a strict certification process that checks the valve’s strength, sealing ability, and overall performance under difficult conditions. This official approval proves once again that THINKTANK’s products are built to perform well, even in the toughest working environments.

This achievement makes THINKTANK even more competitive in the market and gives engineering companies, valve distributors, and system owners a trustworthy and tested safety valve solution. Whether used in power plants, chemical factories, oil and gas systems, or high-temperature steam applications, THINKTANK’s high-temperature safety valves help improve safety, reduce risks, and make systems run more smoothly.

High-Temperature Safety Valve Key Technical Parameters & Structure Highlights

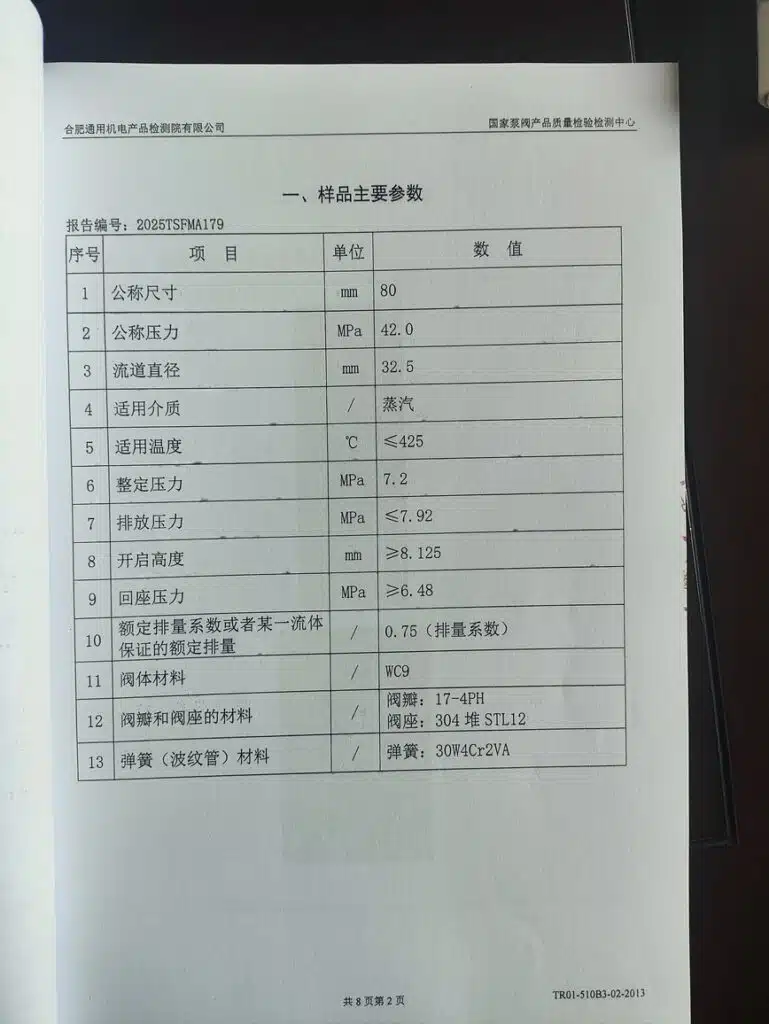

1. Sample Key Technical Parameters

THINKTANK’s high-temperature safety valve is designed to work under extreme conditions like high-temperature and pressure working, we making sure the system stays safe and runs smoothly.

Here are the main features for our certified sample.

| Serial No. | Item | Unit | Value |

| 1 | Nominal Size | mm | 80 |

| 2 | Nominal Pressure | MPa | 42.0 |

| 3 | Flow Path Diameter | mm | 32.5 |

| 4 | Applicable Medium | / | Steam |

| 5 | Operating Temperature | °C | ≤425 |

| 6 | Set Pressure | MPa | 7.2 |

| 7 | Relief Pressure | MPa | ≤7.92 |

| 8 | Lift Height | mm | ≥8.125 |

| 9 | Reseating Pressure | MPa | ≥6.48 |

| 10 | Discharge Coefficient | / | 0.75 (Discharge Coefficient) |

| 11 | Valve Body Material | / | WC9 |

| 12 | Valve Disc & Seat Material | / | Disc: 17-4PH, Seat: 304+STL12 |

| 13 | Spring Material | / | 30W4Cr2VA |

These numbers show that this safety valve can handle high pressure and high temperatures, making it suitable for power plants, steam systems, and heavy industries.

2. Safety Valve Structure Highlights

To ensure strong performance and long-lasting use, this safety valve is made with high-quality materials and smart design features.

- Durable Valve Body: Made from WC9 alloy steel, which resists high heat and pressure.

- High-Quality Trim Materials:

- Valve Disc: 17-4PH stainless steel, known for strength and corrosion resistance.

- Valve Seat: 304 stainless steel with STL12 (Stellite) coating, which reduces wear and extends lifespan.

- Strong Spring System

- The Spring (30W4Cr2VA) is made for high-pressure use, helping the valve stay stable over time.

- Reliable Lift Mechanism:

- Designed to lift at least 8.125 mm, making sure pressure is released safely when needed.

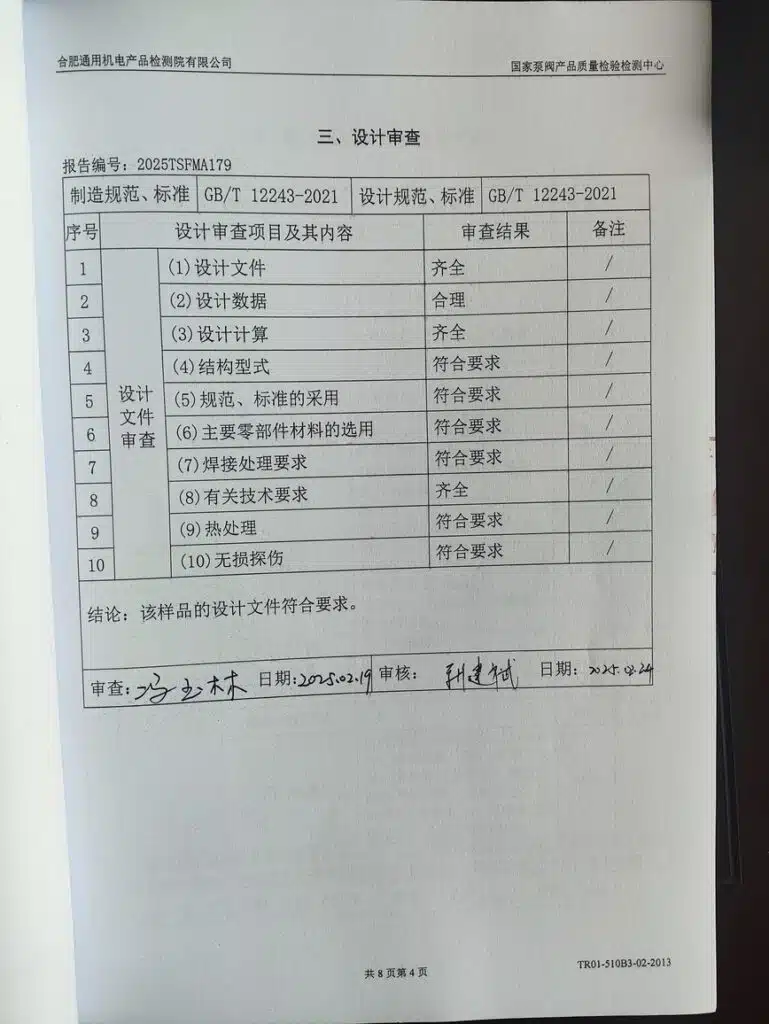

Design Review Approval

The design was carefully checked following GB/T 12243-2021 standards. The review confirmed that:

✅ The design documents and calculations are complete.

✅ The structure, materials, welding, and heat treatment meet all requirements.

✅ Non-destructive testing shows the valve is free of defects.

This means the THINKTANK high-temperature safety valve has passed strict quality checks and is ready for safe use in demanding industries.

3. Design Review

| Serial No. | Design Review Items & Contents | Review Result | Remarks |

| 1 | Design Documents | Complete | / |

| 2 | Design Data | Reasonable | / |

| 3 | Design Calculations | Complete | / |

| 4 | Structural Form | Meets Requirements | / |

| 5 | Adoption of Standards & Codes | Meets Requirements | / |

| 6 | Selection of Major Component Materials | Meets Requirements | / |

| 7 | Welding Process Requirements | Meets Requirements | / |

| 8 | Related Technical Requirements | Complete | / |

| 9 | Heat Treatment | Meets Requirements | / |

| 10 | Non-Destructive Testing | Meets Requirements | / |

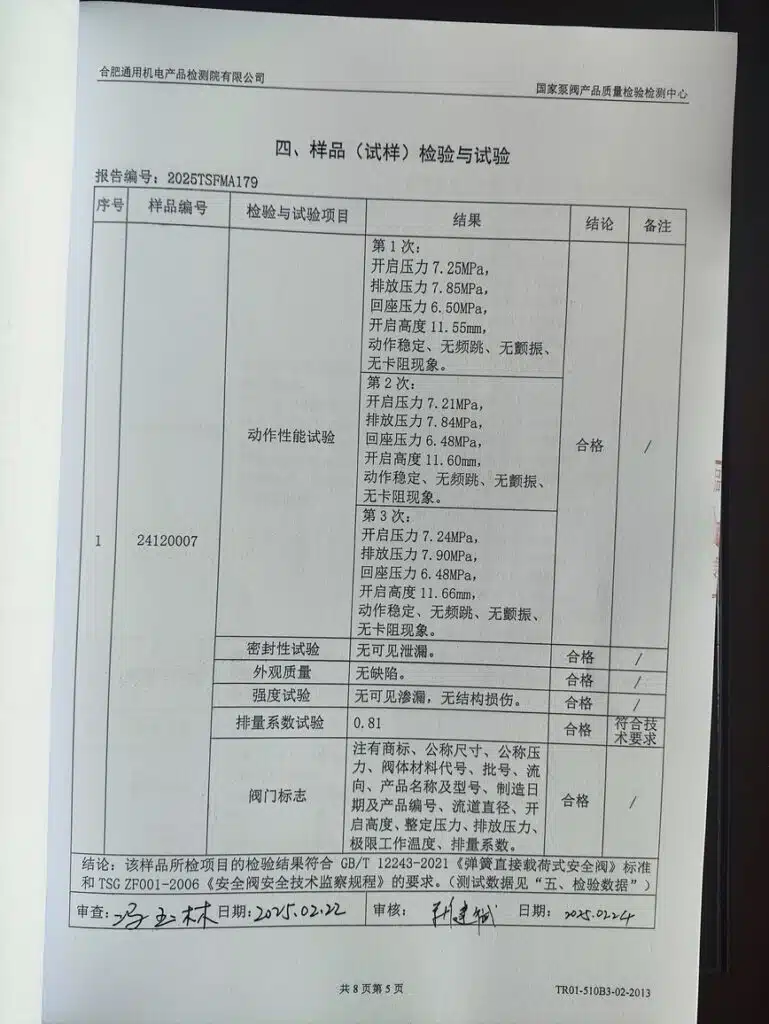

4. Sample Inspection & Testing Report

To ensure the highest level of safety and reliability, THINKTANK’s high-temperature safety valve through a comprehensive set of tests. Below are the key findings from the inspection and performance evaluation.

Operational Performance Test

The valve was tested multiple times for its opening pressure, discharge pressure, reseating pressure, and lift height to verify its stability and responsiveness under high-pressure conditions.

The results confirm:

| Serial No. | Sample No. | Inspection & Test Items | Results | Conclusion | Remarks |

| 1 | 24120007 | Operational Performance Test | Test 1: · Opening Pressure: 7.25 MPa · Discharge Pressure: 7.85 MPa · Reseating Pressure: 6.50 MPa · Lift Height: 11.55 mm · Performance: Stable, no frequency jumping, no vibration, no obstruction. | Pass | / |

| Test 2: · Opening Pressure: 7.21 MPa · Discharge Pressure: 7.84 MPa · Reseating Pressure: 6.48 MPa · Lift Height: 11.60 mm · Performance: Stable, no frequency jumping, no vibration, no obstruction. | |||||

| Test 3: · Opening Pressure: 7.24 MPa · Discharge Pressure: 7.90 MPa · Reseating Pressure: 6.48 MPa · Lift Height: 11.66 mm · Performance: Stable, no frequency jumping, no vibration, no obstruction. | |||||

| 2 | Sealing Test | No visible leakage. | Pass | / | |

| 3 | External Quality Inspection | No defects. | Pass | / | |

| 4 | Strength Test | No visible seepage, no structural damage. | Pass | / | |

| 5 | Discharge Coefficient Test | Measured discharge coefficient: 0.81 | Pass (Meets technical standards) | / | |

| 6 | Valve Marking Inspection | The valve body and nameplate include all required information: · Manufacturer logo and name · Nominal size and pressure · Valve body material code · Heat treatment batch number · Flow direction marking · Product name and model · Date of production and batch number · Opening height · Set pressure · Discharge height · Working pressure · Temperature limits · Discharge coefficient | Pass | / |

Test Result

The tested sample meets the requirements of GB/T 12243-2021 and TSG ZF001-2006 (Safety Technical Supervision Regulations for Safety Valves). The test data has been documented in the “Test Data” section.

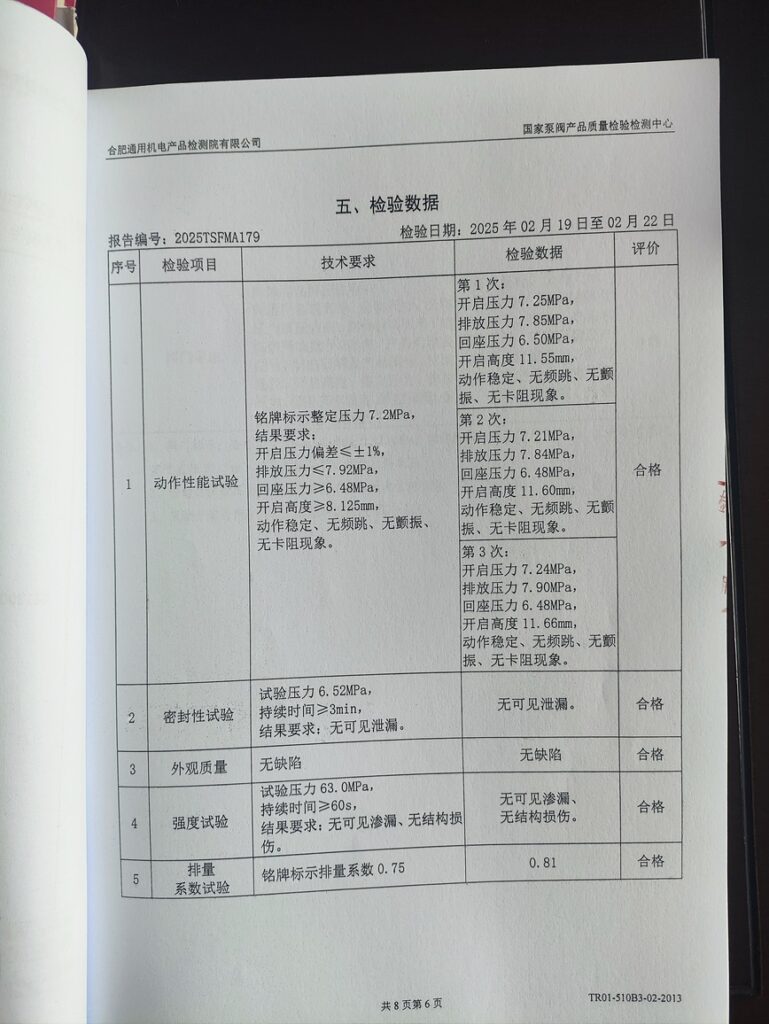

5. Inspection Data

| Serial No. | Test Item | Technical Requirement | Test Data & Results | Evaluation |

| 1 | Operational Performance Test | – Nameplate Set Pressure: 7.2 MPa – Opening Pressure Deviation: ±1% – Discharge Pressure: ≤7.92 MPa – Reseating Pressure: ≥6.48 MPa – Lift Height: ≥8.125 mm – Performance must be stable with no frequency jumping, vibration, or obstruction. | Test 1: – Opening Pressure: 7.25 MPa – Discharge Pressure: 7.85 MPa – Reseating Pressure: 6.50 MPa – Lift Height: 11.55 mm – Performance: Stable, no frequency jumping, no vibration, no obstruction. | Pass |

| Test 2: – Opening Pressure: 7.21 MPa – Discharge Pressure: 7.84 MPa – Reseating Pressure: 6.48 MPa – Lift Height: 11.60 mm – Performance: Stable, no frequency jumping, no vibration, no obstruction. | ||||

| Test 3: – Opening Pressure: 7.24 MPa – Discharge Pressure: 7.90 MPa – Reseating Pressure: 6.48 MPa – Lift Height: 11.66 mm – Performance: Stable, no frequency jumping, no vibration, no obstruction. | ||||

| 2 | Sealing Test | Test Pressure: 6.52 MPa, Duration: ≥3 min | No visible leakage. | Pass |

| No visible leakage allowed. | ||||

| 3 | External Quality Inspection | No visible defects such as cracks, dents, or deformations. | No defects found. | Pass |

| 4 | Strength Test | Test Pressure: 63.0 MPa, Duration: ≥60s | No visible seepage, no structural damage. | Pass |

| No visible seepage or structural damage allowed. | ||||

| 5 | Discharge Coefficient Test | Nameplate Indicated Discharge Coefficient: 0.75 | Measured Discharge Coefficient: 0.81 | Pass |

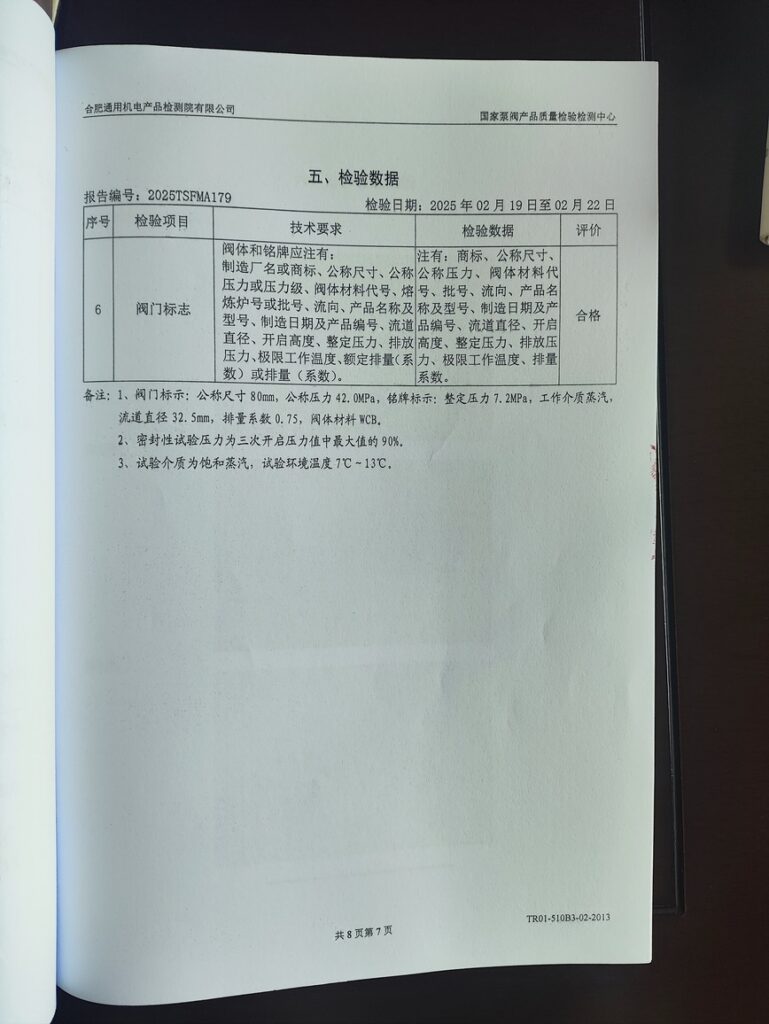

| 6 | Valve Marking Inspection | The valve body and nameplate must include: – Manufacturer logo and name – Nominal size and pressure – Valve body material code – Heat treatment batch number – Flow direction marking – Product name and model – Date of production and batch number – Opening height, set pressure, discharge height, extreme working pressure, temperature limits, and discharge coefficient. | The nameplate and markings meet all required specifications. | Pass |

Notes

- Valve Marking

- Nominal Size: 80 mm

- Nominal Pressure: 42.0 MPa

- Nameplate Marking

- Set Pressure: 7.2 MPa,

- Working Medium: Steam

- Flow Path Diameter: 32.5 mm

- Discharge Coefficient: 0.75

- Valve Body Material: WCB

- Sealing Test Pressure

- The test pressure is 90% of the maximum opening pressure value among the three tests.

- Test Medium & Environment

- The test medium used is saturated and superheated steam.

- The test ambient temperature ranges from 7°C to 13°C.

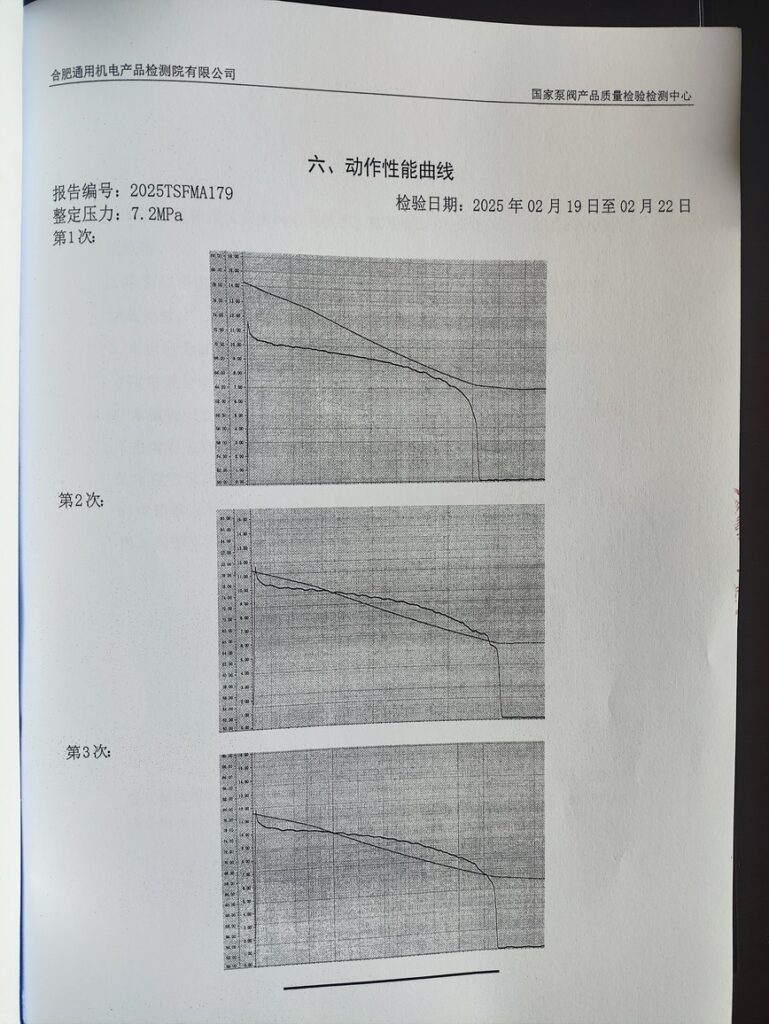

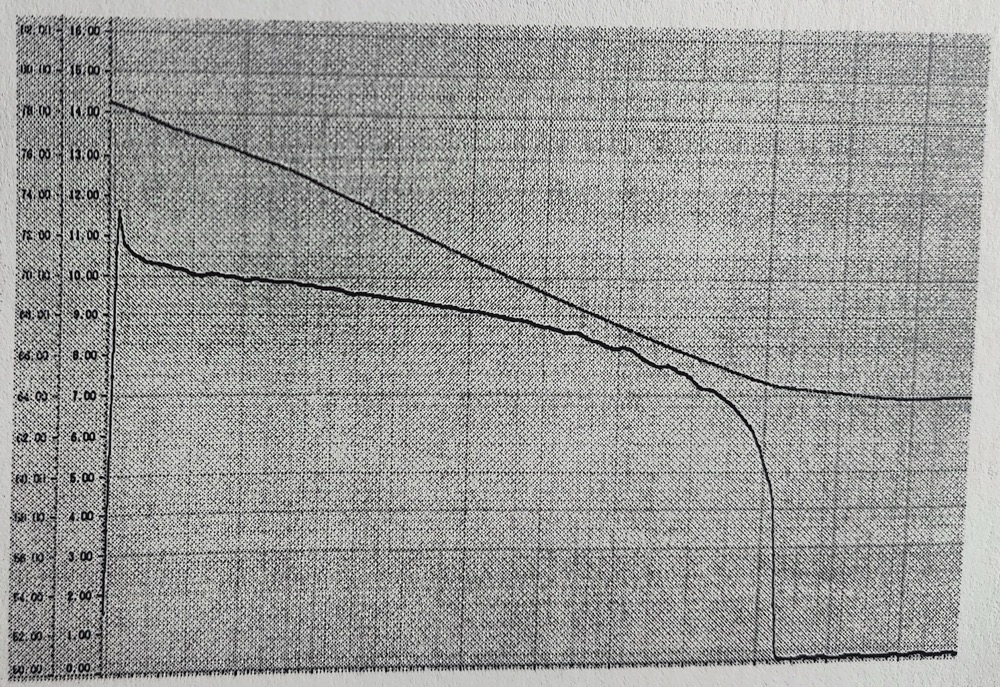

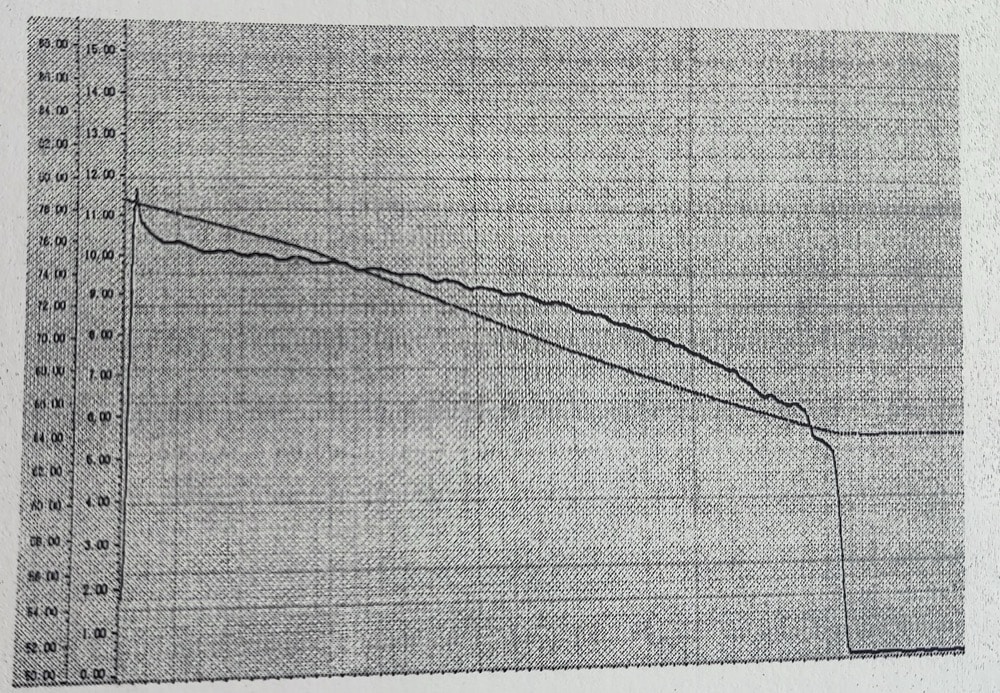

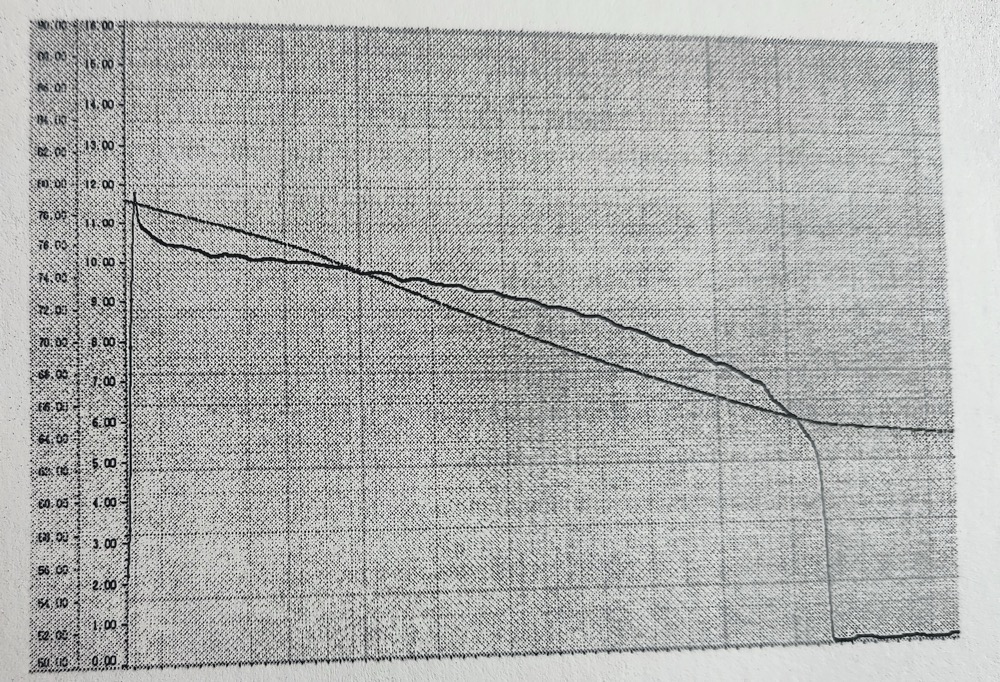

6. Operational Performance Curve

- Report No.: 2025TSFMA179

- Set Pressure: 7.2 MPa

- Inspection Date: February 19, 2025 – February 22, 2025

Test 1. Safety Valve Performance Curve

Test 2. Safety Valve Performance Curve

Test 3. Safety Valve Performance Curve

Certified Quality & Market Advantage

After strict testing by National Pump and Valve Product Quality Inspection and Testing Center, the most authoritative valve identification and testing agency in China, THINKTANK’s high-temperature safety valve has met and exceeded international safety standards. It is now certified for high-temperature and high-pressure applications, further proving its reliability and strengthening its competitiveness in the market.

We perform hydraulic shell tests, sealing pressure tests, reseating pressure tests, discharge pressure tests, and set pressure tests on each safety relief valve before shipment to ensure 100% compliance with specifications and customer requirements.

In addition, we conduct dimensional inspections and provide full documentation, including casting quality certificates, forged material certificates, spring certificates, valve wall thickness calculation sheets, inspection reports, and mechanical property reports for key components.

These measures ensure every detail and parameter meets the customer’s expectations and application standards.

Where It Can Be Used & Why It Helps

THINKTANK high-temperature safety valves are perfect for industries that need strong and safe pressure control. These industries include:

- Oil and gas plants – Protects steam and gas systems from overpressure.

- High-temperature steam systems – Used in power plants and industrial steam pipes.

- Power boilers – Helps keep pressure stable in thermal power plants.

- Molten salt energy storage – Used in renewable energy storage.

- Steel factories – Ensures safe operation in high-heat production.

Contact Us – Get a Quote or More Info

THINKTANK’s high-temperature safety valve is certified and ready to protect your systems. If you are an engineer, buyer, or valve brand owner, we can help with:

📌 Product details and pricing

📌 Free technical advice

📌 Custom solutions for your needs