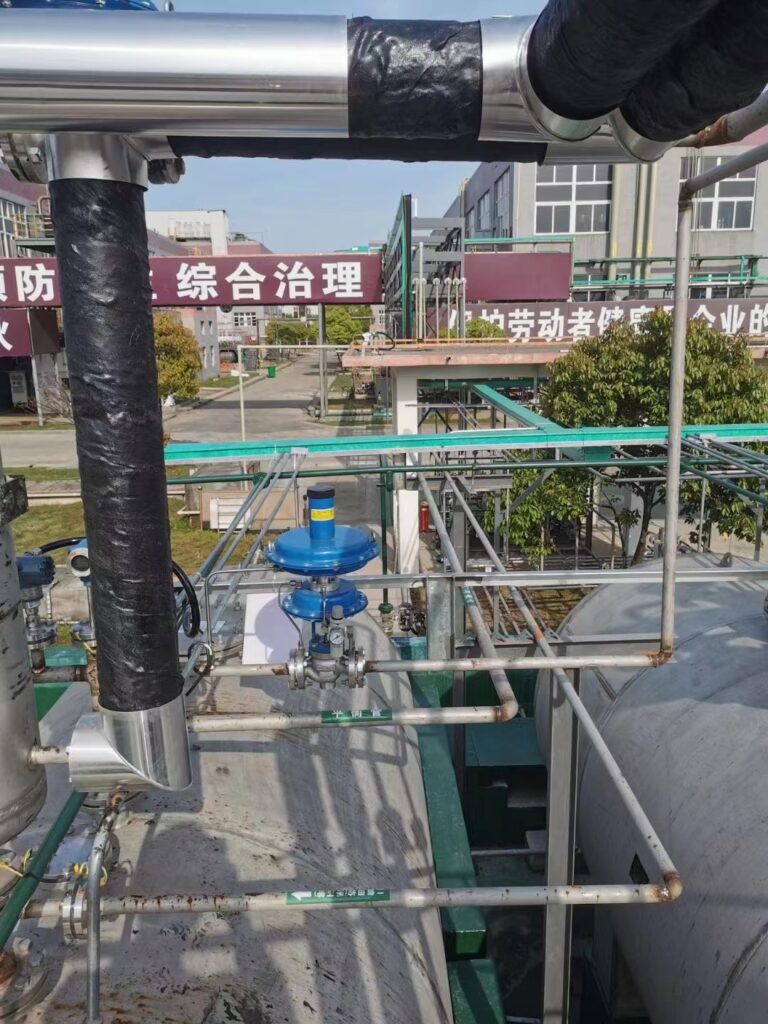

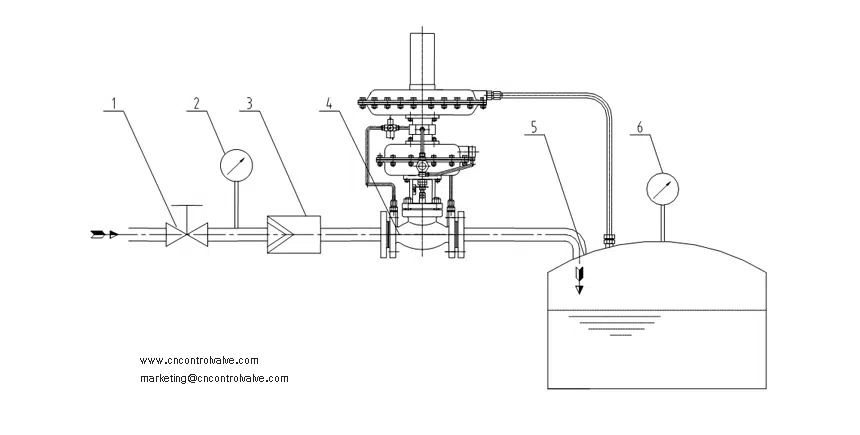

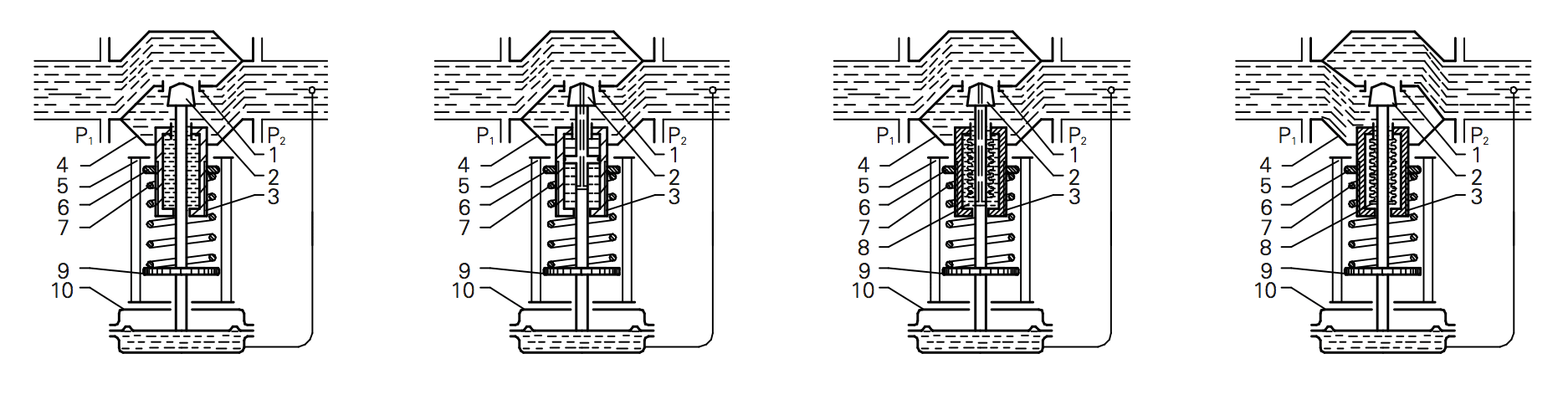

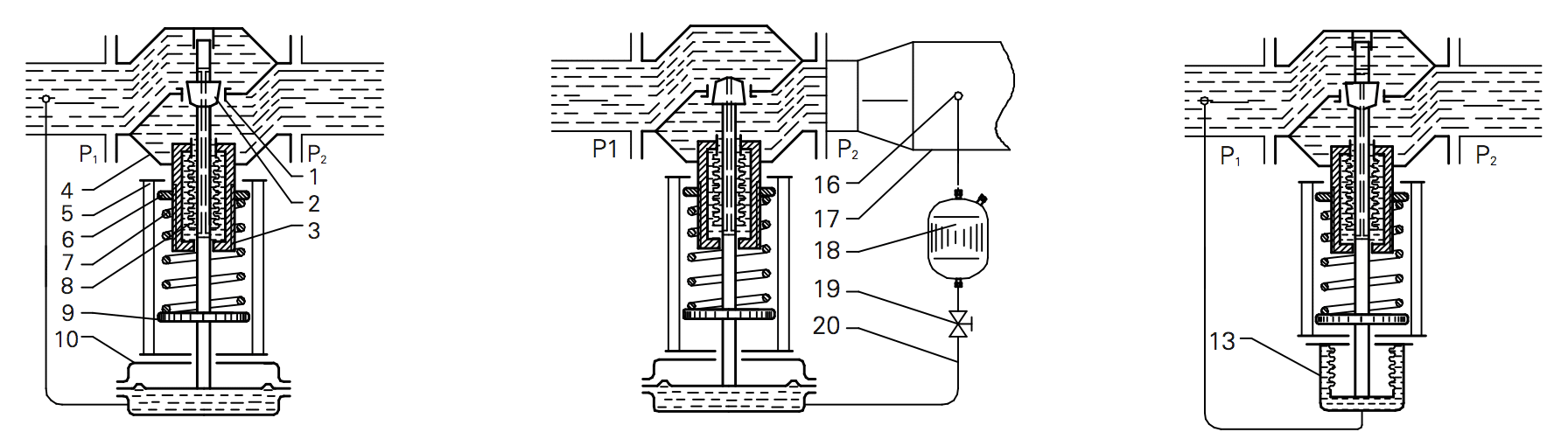

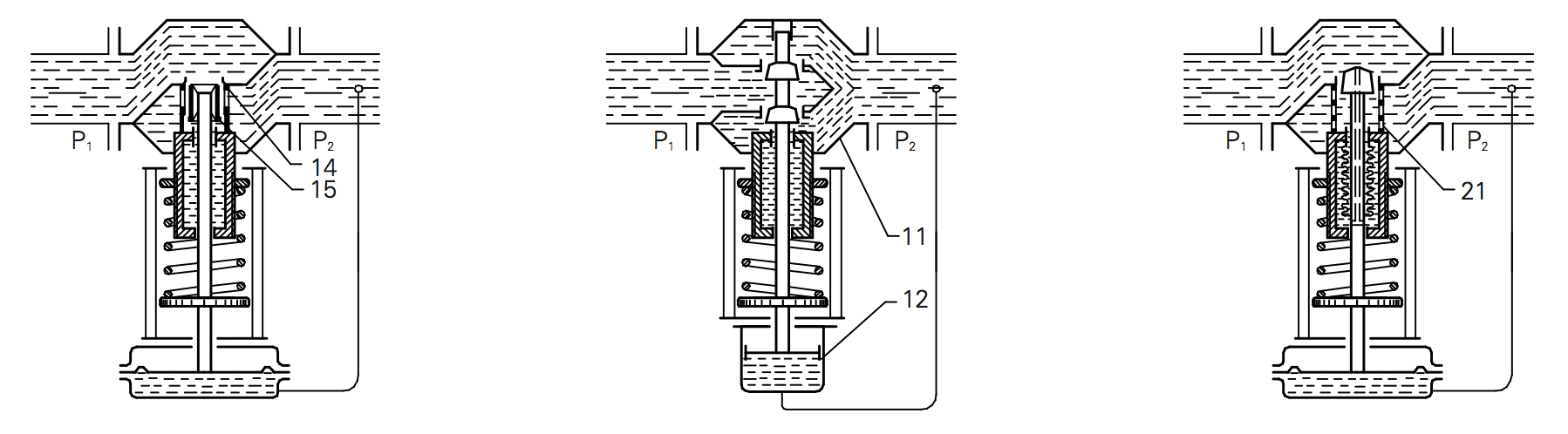

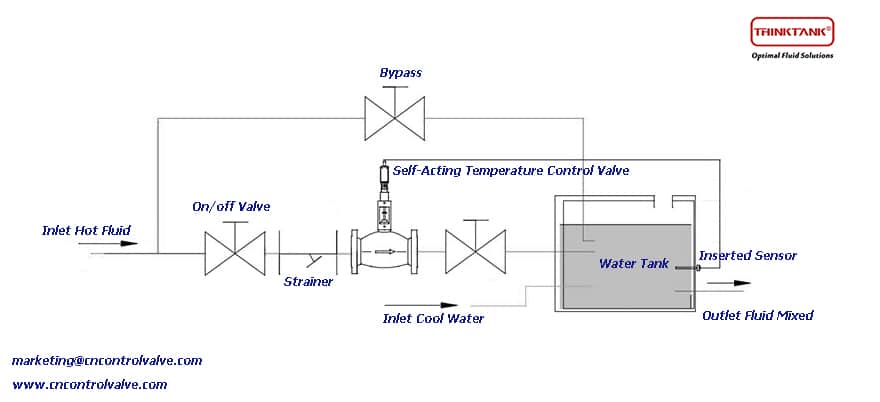

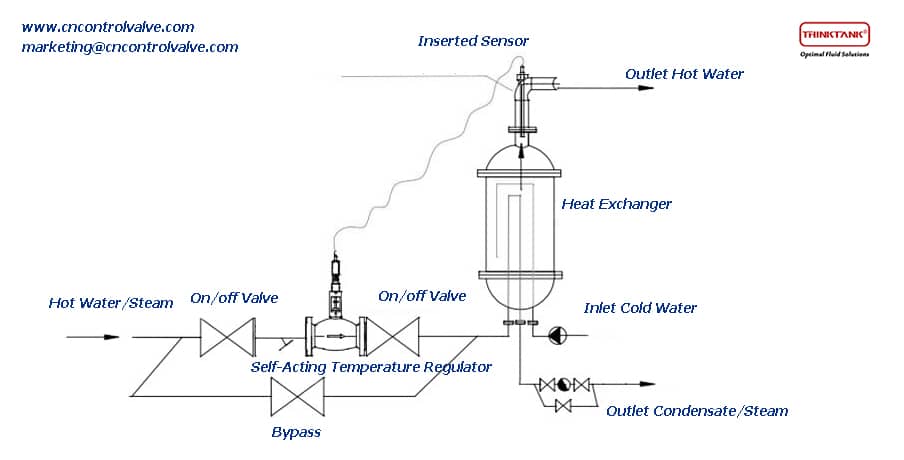

Step 1: Make sure the valve body is installed at the inlet of the primary heat medium with a horizontal position, and the valve stem upwards to ensure that the self-actuating actuator is positioning vertically.

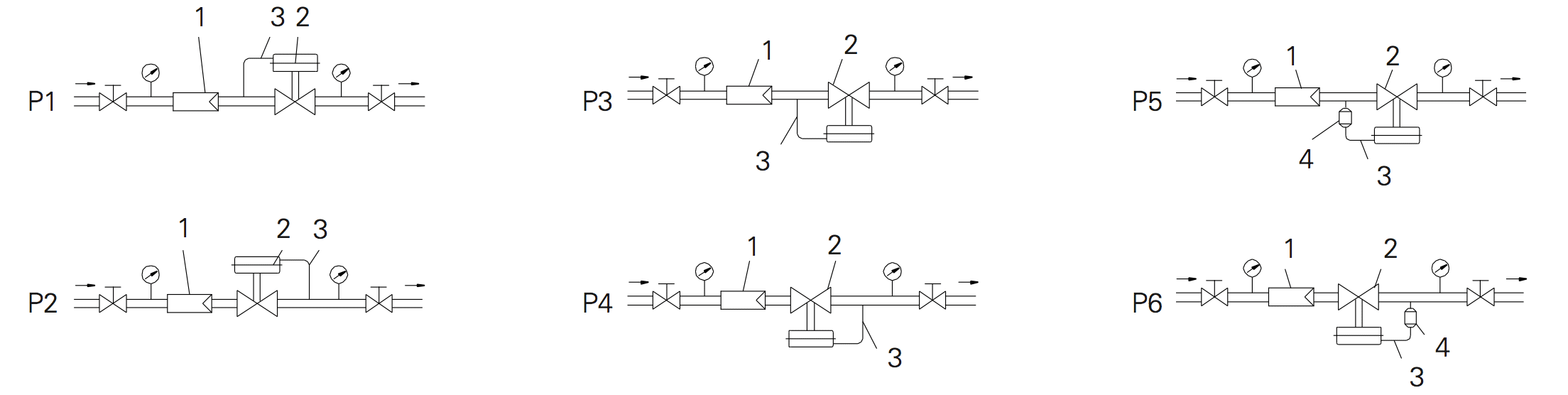

Step 2: At the inlet of the self-acting temperature control valve, it needs to install a strainer, and the required filter mesh corresponds with the medium.

Step 3: It should be installed on/off valve inlet and outlet of the self-acting temperature control valve. And install globe valve of bypass pipeline.

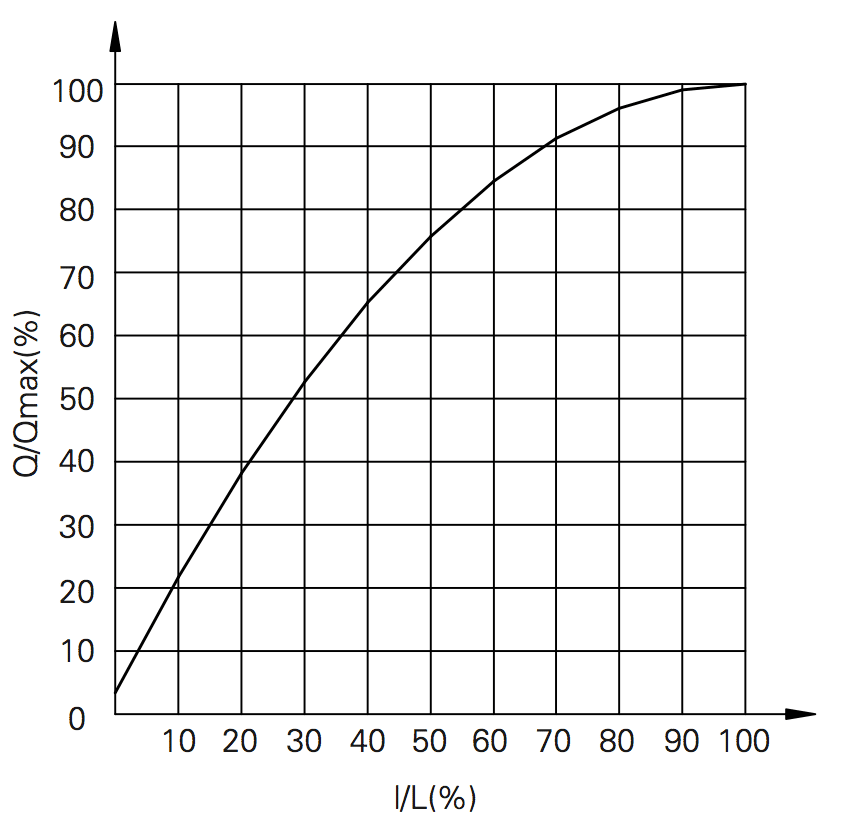

Please refer to figure 2 for installation layout, and kindly noted that the optimum working range of the inlet stream is around 3.0 to 7.0 bar. Any information just feel free to contact us representative marketing at cncontrolvalve.com

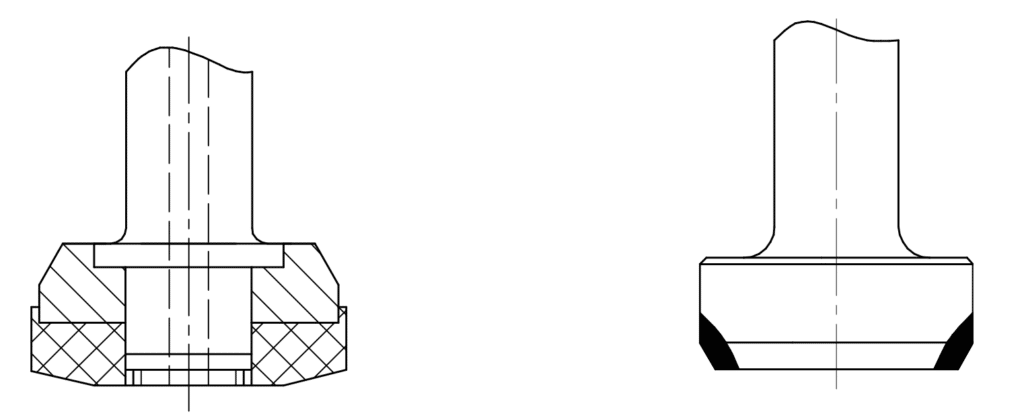

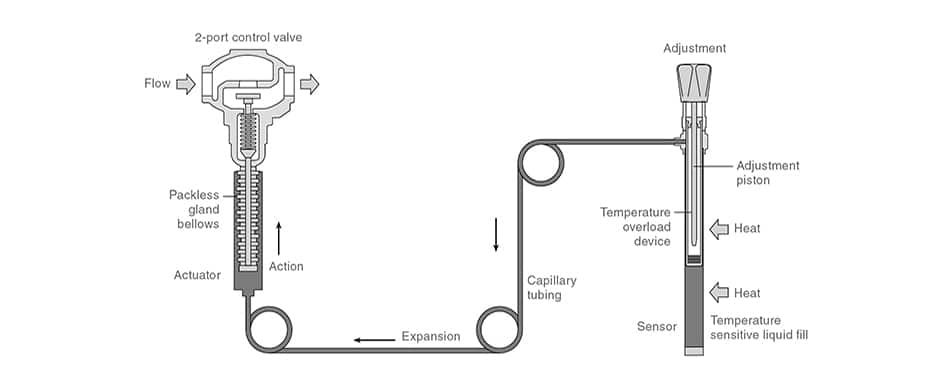

The sensor is inserted around the outlet of the heat exchanger or outlet pipe of water. Be careful of the valve stem and capillary tube during installation. Drilling a hole in the pipeline to insert the sensor, then welding without any leakage from this connect part.

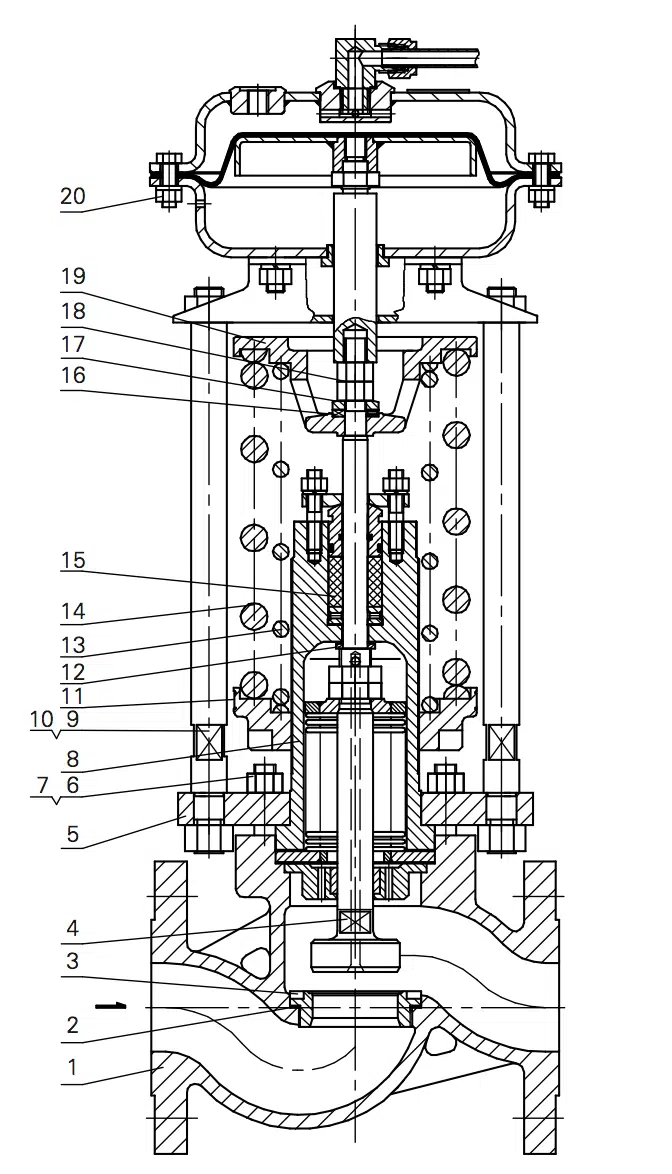

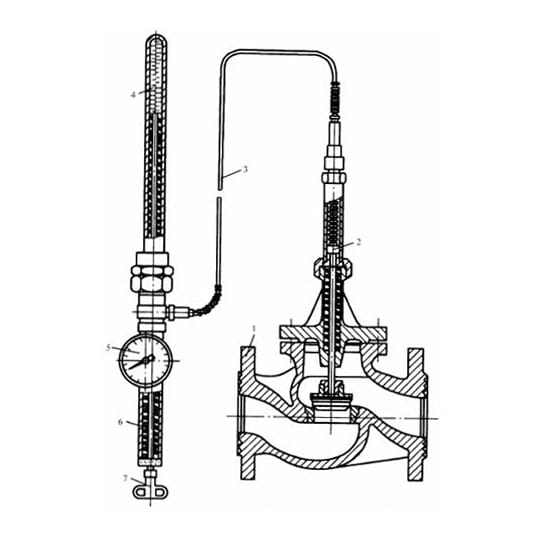

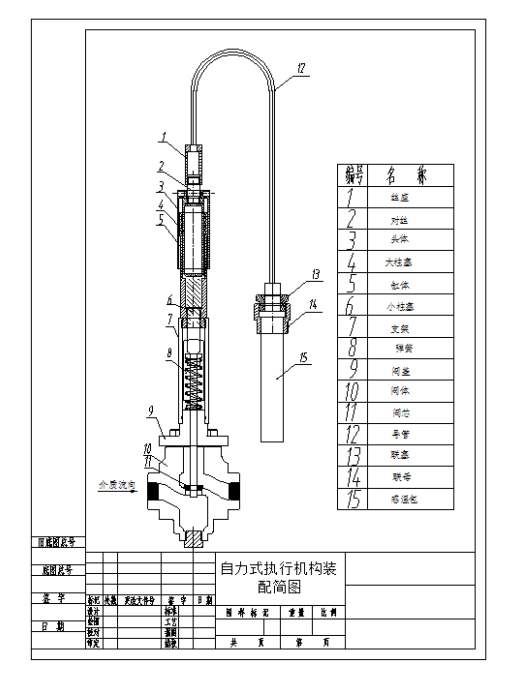

THINKTANK supply the complete self-acting temperature control valve before shipment, so the actuator has already assembly on the valve body, all you need to do is tighten the nuts between the sensor and temperature overload device.