Quality is Guaranteed

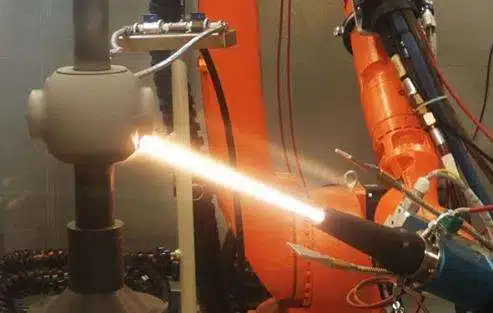

The non-rubbing resilient metal-to-metal sealing system of the THINKTANK‘s Triple Offset Valve assures bidirectional zero leakage shutoff in even the most demanding applications, and we also manufacture high-performance(double offset design) butterfly valves which have rugged reliability and extremely easy maintenance in the field, this high-performance valve provide the highest quality and highest value available for the snowmaking requirements.

1. Butterfly Valve Flow Control

THINKTANK is one of the leading manufacturers and suppliers of a quality range of butterfly control valves and other types of control valves. The most two common types of control butterfly valves are high-performance butterfly valves and triple offset butterfly control valves.

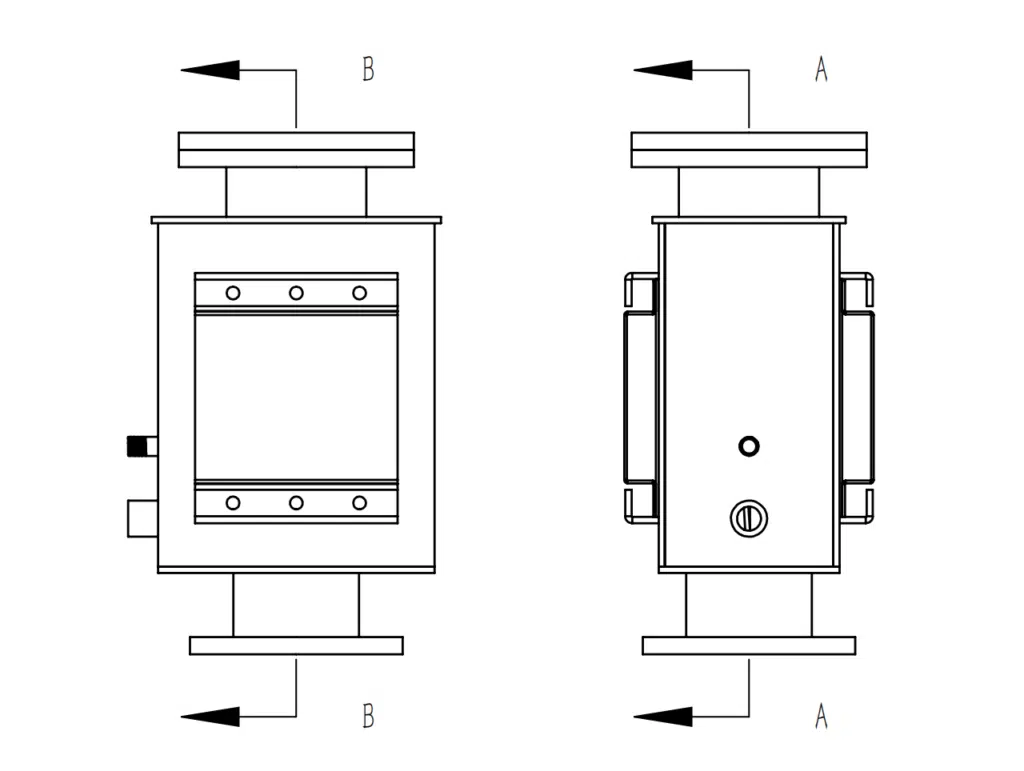

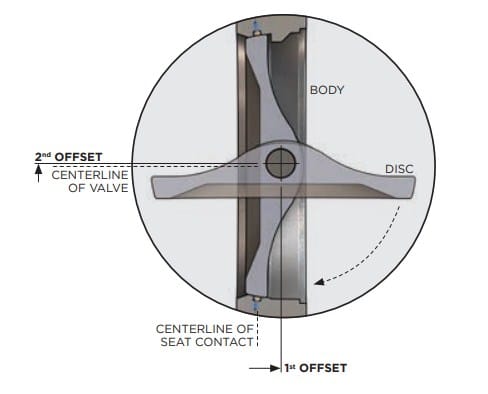

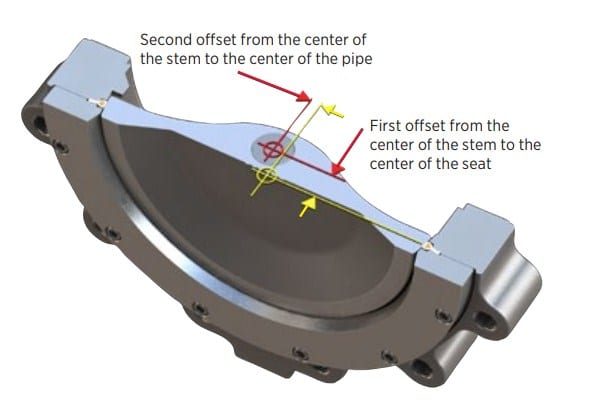

High-performance butterfly control valves

High-performance butterfly control valves have a double eccentric design, first offset from the center of the stem to the center of the valve seat, and the second offset from the center of the valve stem to the center of the pipe.

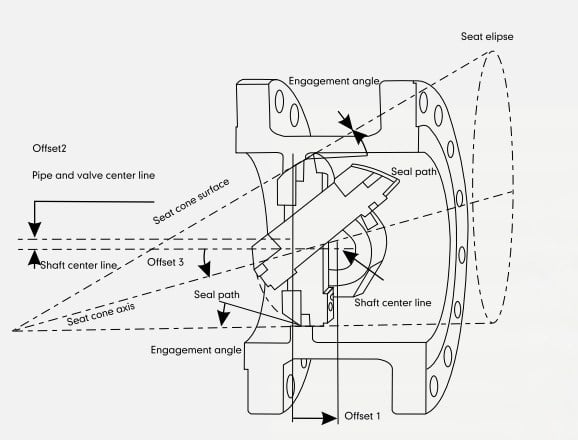

Triple offset butterfly control valves

The Triple offset butterfly control valves based on the double eccentric of high-performance butterfly valve added extra third eccentric, which consists of an inclined conical profile machined into the valve sealing surface, allowing rotary engagement and disengagement of the seat and seal ring without interference. This triple offset eliminates all rubbing between the seat and seal ring during valve travel, reducing seat and seal wear and extending cycle life.

Download Triple Offset Butterfly Control Valves Brochure

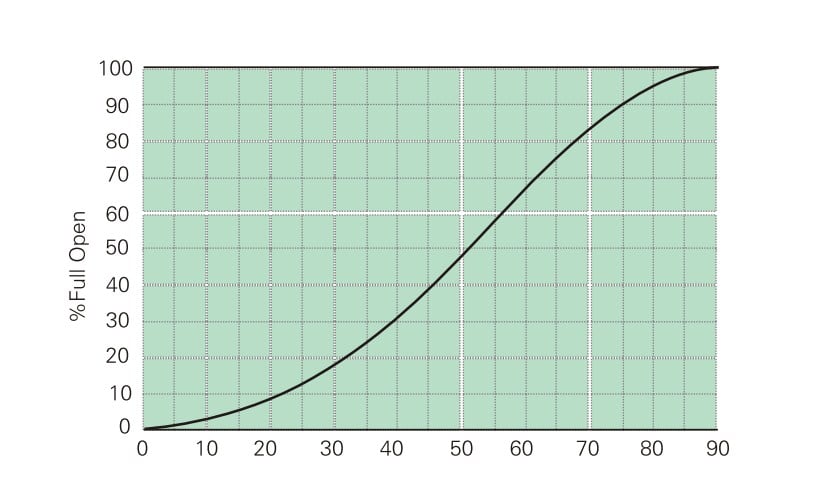

2. Butterfly Control Valve Flow Characteristics

The butterfly control valves are suitable for throttling control high capacity flow process and small pressure drop. As a control valve, the butterfly valve just needs to be operable through 90 degrees to operate the valve open and close. For throttling function, a high-performance butterfly control valve and triple offset control butterfly control valve provide linear flow characteristics and approximate equal percentage flow characteristics.

3. Triple Offset Control Butterfly Valve Control Range

The control range of butterfly control valves is approximately 10 to 70% opening, general its 1/3 opening flow capacity is a similar full capacity of the same size for globe type control valves or eccentric plug rotary control valves. So it saves much cost for the end-user at large pipeline flow control process.

4. Butterfly Control Valve Cv Values

Different butterfly valve openings correspond to different CV values (150LB)

| inch | mm | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° |

| 2″ | 50 | 1.5 | 4.2 | 12 | 16 | 20 | 41 | 80 | 93 | 93 |

| 21/ “ 2 | 65 | 2.5 | 6.3 | 15 | 20 | 33 | 65 | 120 | 132 | 132 |

| 3″ | 80 | 3.1 | 9.8 | 18 | 25 | 26 | 52 | 101 | 165 | 179 |

| 4″ | 100 | 9.1 | 36 | 74 | 153 | 211 | 280 | 328 | 388 | 429 |

| 5″ | 125 | 29 | 88 | 145 | 210 | 254 | 285 | 340 | 419 | 456 |

| 6″ | 150 | 42 | 124 | 221 | 361 | 442 | 686 | 852 | 993 | 1008 |

| 8″ | 200 | 63 | 175 | 340 | 584 | 928 | 1330 | 1693 | 2049 | 2171 |

| 10″ | 250 | 143 | 373 | 686 | 1069 | 1591 | 2228 | 2795 | 3305 | 3441 |

| 12″ | 300 | 217 | 531 | 919 | 1395 | 2063 | 2959 | 3782 | 4547 | 4946 |

| 14″ | 350 | 284 | 682 | 1135 | 1827 | 2688 | 3637 | 5950 | 5956 | 6484 |

| 16″ | 400 | 348 | 823 | 1410 | 2297 | 3445 | 4973 | 6509 | 8162 | 8526 |

| 18″ | 450 | 410 | 985 | 1689 | 2770 | 4175 | 6066 | 8160 | 10121 | 11314 |

| 20″ | 500 | 572 | 1272 | 2115 | 3315 | 5222 | 7612 | 10335 | 12983 | 14870 |

| 24″ | 600 | 882 | 1956 | 3295 | 5026 | 7665 | 11036 | 14951 | 19100 | 21450 |

| 28″ | 700 | 1010 | 2000 | 3668 | 6192 | 9713 | 14970 | 20891 | 26570 | 30516 |

| 32″ | 800 | 1570 | 3575 | 5536 | 9030 | 13697 | 20370 | 28647 | 36677 | 41603 |

| 36″ | 900 | 2543 | 4256 | 7132 | 11725 | 17423 | 26000 | 37000 | 46282 | 54193 |

| 40″ | 1000 | 4258 | 11669 | 14016 | 16629 | 21585 | 30713 | 37407 | 48000 | 62177 |

| 48″ | 1200 | 5030 | 16384 | 19720 | 24950 | 28834 | 35524 | 43980 | 50340 | 77390 |

5. Butterfly Control Valve Applications

Butterfly control valves have a wide application in industrial processes. Here is the typical industry in which THINKTANK butterfly control valves are used for.

Petrochemical Plants

- Brine, CO2 Vapor

- Propylene Plants

- Steam Service

- Propane Gas

- Maniford Flare Inlet & Manifold Isolation

- Ethylene Plants

- PSA & Molecular Service

- Ethylene Crackers

- Coker Plants

Petroleum Refinning

- Oil Storage Isolation

- Steam Service

- Desulphurization System & Tail Gas Treaters

- Flare Gas, Sour Gas Isolation

- Hot Cracking Gas

- Catalytic Cracker Units

Nuclear Power Plants

- Containment Isolation

- Saltwater Service

- Core Spray Systems

- Pump Isolation

- Seawater Desalination System

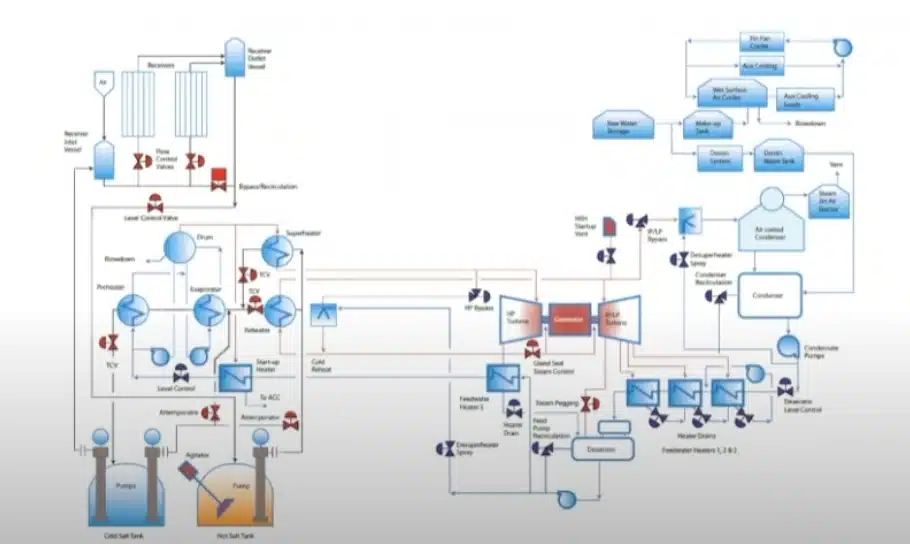

Fossil Power Plants

- Pump Isolation

- Condenser Cooling

- Pump & Steam Extraction Isolation

- Heat Exchanger, Condenser Cooling Isolation

Central Heating

- Thermal Power Plant

- Heat Exchange Station

- Boiler System

- Hot Water Pipeline

- Steam Service

Cryogenics

- Liquid Gases

- Natural Gas Service

- Oil Field Recovery System

- Gasification Plants & Storage

- LNG Service

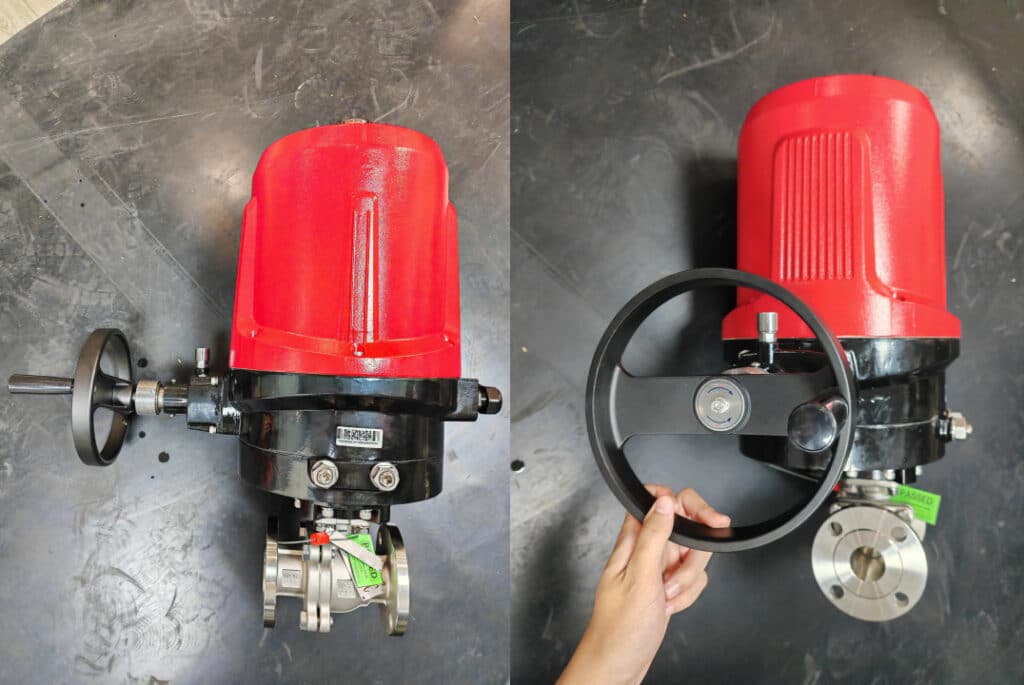

6. How a Pneumatic Butterfly Valve Works?

The working principle of the pneumatic butterfly control valve is derived by compressed air power to the pneumatic actuator and rotating the stem or shaft of the butterfly valve to the open or close through the disc.