You may need to select an automatic control valve compatible with your particular type of application. There are three common choices of benefits, Pneumatic, electric, or self-acting? All three of these choices are available, but you don’t know which is the best option for your case. This article discusses selecting the proper control valves for your steam systems. It also provides you with a step-by-step guide to choosing the correct valve for your specific needs.

Indeed We can’t list all the considered factors in one article. Still, based on my 14 years of experience in the control valve industry, I will separate two significant steps for you quickly understand. You can follow the guided step-by-step from your application.

Step 1: Defined Your Application

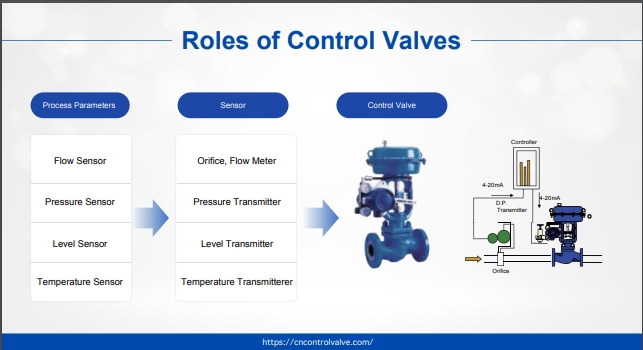

Understanding well your application and process variable data required.

This step is essential, and only you – the engineer of the end-user know what exactly you want. For a quick review of the specification, make a list for your check.

① Controlling

- Temperature

- Pressure

- Flow Rate

- Level

② Failure Safety Position

- Valve Close

- Valve Open

- None

③ Medium Information

- Density

- Temperature

- Physical Properties

④ Process Pressure

- Maximum/Normal/Minimum Upstream Pressure

- Maximum/Normal/Minimum Downstream Pressure

- Maximum Drop Pressure

- Differential Pressure

⑤ Flow Rate

Maximum/Normal/Minimum Flow Capacity

⑥ Valve Material

⑦ End Connection Type

⑧ Which Power is available on the site, compressed air power, electricity, or non-power driving?

⑨ What’s the working environment? corrosive, hazardous area, dirty dust area, or atmosphere?

⑩ For the control temperature function, setpoint fixed or variable temperature set for your case?

Above ten questions need you to check carefully, and it will help you define your application well. The next step is to base the driving force you have in site on selecting control valves for the steam system. (You can refer to last step no.8 questions.)

Generally, the control valve is usually driven by electric power, compressed air, or no auxiliary power.

The fluid itself drives self-acting control valve. Electric power could be 220V AC, 24 V DC, 380 V AC, and other custom power. And compressed air power from 1.4 to 10.0 Bar is available to choose.

If on/off function just power is enough, for modulating function then need an input signal to control transmitter 4-20mA, 3-15PSI, 1-10V or others.

Self-acting control valves do not require external auxiliary power. They use energy by themselves to generate fluid power.

Step 2. Select Power Source of Control Valves for Steam Systems

Check the in-site power you can provide and a description of the advantage and disadvantages of each drive option before you make a final decision on control valves for the steam system.

① Compressed Air Power for Control Valves

Using a diaphragm or piston/cylinder pneumatic actuator to operate the control valve. Often this control loop system consists of a valve, pneumatic actuator, controller, sensors or transmitter, and converter or electro-pneumatic positioner, pneumatic-pneumatic positioner.

Advantages:

- Precision control

- Fast response

- Tight shutoff

- Large rangeability

- High capacity

- No extra cost for fail to open or fail to close the safety position required

Disadvantages:

It requires compressed air power for this system. Not every industry system has compressed air in-site and needs air tubing and piping to transfer this air power.

② Electric Power for Control Valves

Electric power to drive the control valve is more effortless than a pneumatic actuated control valve. The controller and power are combined inside the actuator, so just wiring the terminal is simply designed.

Advantage:

- Highly accurate control.

- Multifunction with an on-off or modulating shift.

Disadvantages:

- Compared with the pneumatic control valves, electric valves are relatively slow to operate., which means they are not always suitable for sudden changes in process parameters such as pressure control of rapidly changing loads.

- Due to electric power being an independent source and needing wiring to the control valves, the costs have to be considered.

- Electric actuators have higher costs than pneumatic actuators. More functional makes high extra costs, such as safety position, limit switches, loading speed, etc.

- Less smooth operation than pneumatic control valves.

- If control valves are used in a hazardous environment, it will request an electric actuator or any electrical device that has explosion-proof performance. And it will cause higher costs than pneumatic control valves because pneumatic control valves only need to improve valve positioner explosion-proof grade.

③ Self-Actuated Control for Steam System

Self-actuated control valves usually refer to self-operated pressure regulators, self-operated temperature regulators, and differential pressure regulators. These control systems do not require external power to operate.

Advantages:

- Low cost

- Simple operation

- Easy to install and start-up

- Provide proportional control with wide rangeability

- They are safe for use in hazardous areas

Disadvantages:

- Due to the self-actuated regulator operated by medium energy itself, it will be relatively slow to respond if data variables change fast.

- It can’t transmit the data to the controller system. The self-acting valve doesn’t have a feedback signal to the control room.

If you are interested in more knowledge about self-acting control valves, please refer to this page.

So when you finished the above two steps, I think you will know which type of control valve you need, and then you can contact your local distributors for valve manufacturers to inform them what your steam system requires.

In conclusion, for steam systems or other industrial applications, we should know our specifications deeply, then submit your process parameters to the experts. According to your requirements, they will size the proper control valves for you. The above two steps are crucial for whether the steam system is running well, related precision, service life, total cost, saving energy and wide rangeability, etc. I hope this article can help you know the correct type of control valves for your steam system quickly.