THINKTANK has been participating in many projects on liquid storage tanks, tank blanketing, natural gas, air/oil/gas utilities, pressure reduction, and food & beverage. Since our distributors ask for share knowledge of tank pressure control systems, based on our tank blanketing valve, gas back pressure regulator, gas pressure regulator, pressure reducing regulator, gas&tank blanketing regulator is perfect work at the site. This article is going to explain what a tank blanketing valve is, why we should use a tank blanketing system, how does blanketing works, and more associated knowledge of tank pressure control.

Learn About Tank Pressure Control

A main device or system for tank pressure control is blanketing, which is sensing the inert gas pressure and space of the storage tank, in case to control the flow capacity of nitrogen gas into the vapor space, therefore we can maintain the pressure of the storage tank within an acceptable range.

What is a Tank Blanketing Valve?

First, we need to know what tank blanketing is, tank blanketing is the process of filling the empty space of a liquid storage tank with inert gas, such as nitrogen gas. Why nitrogen gas? because nitrogen gas is a kind of inert properties and is a more available and relatively low-cost medium, it is an excellent choice for tank blanketing.

And tank blanketing valve is part of a device for the tank pressure protection system, which is used on low-pressure liquid storage tanks. Also, the tank pressure protection system will include a pressure vacuum relief valve, relief regulator, a flame arrestor, and emergency pressure vacuum relief work together to control the pressure inside and out of the tank.

Why is Tank Blanketing So Important?

Because tank blanketing is used to protect workers, equipment assets, and the environment and products. The most storage tank is for combustible media, so it’s very dangerous if the media meets oxygen by air. So tank blanketing storage system is designed for desirable to reduce the hazards connect with flammable liquids, or to minimize drawing air and oxygen in the tank to avoid combustion and flame.

For the food & beverage industry, the tank blanketing protects food, beverage, and other substances from oxidation, pollution, or evaporation. The vapor recovery regulator prevents harmful gas from escaping into the atmosphere. Also though oxidation will reduce corrosion to help keep the integrity of the tank.

How Does a Tank Blanketing Regulator Work?

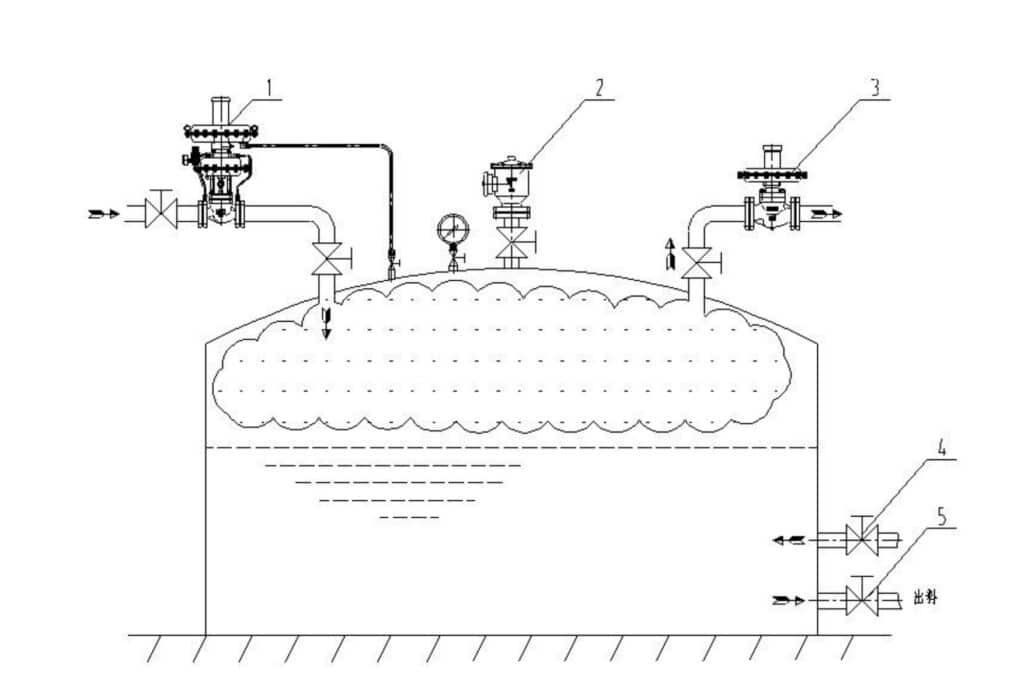

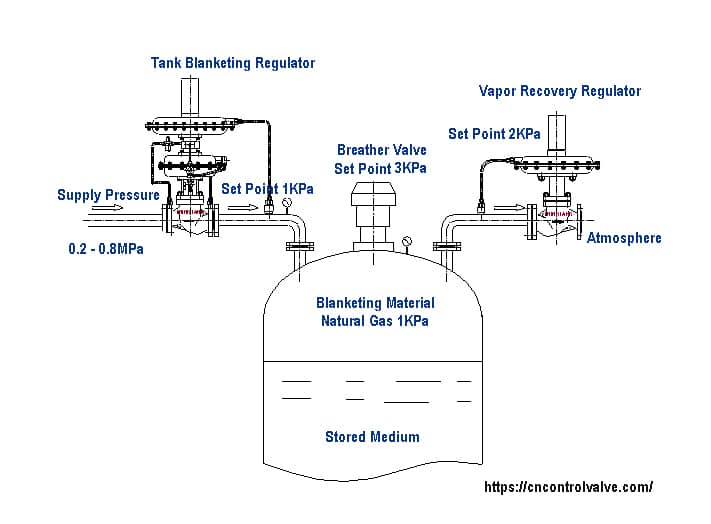

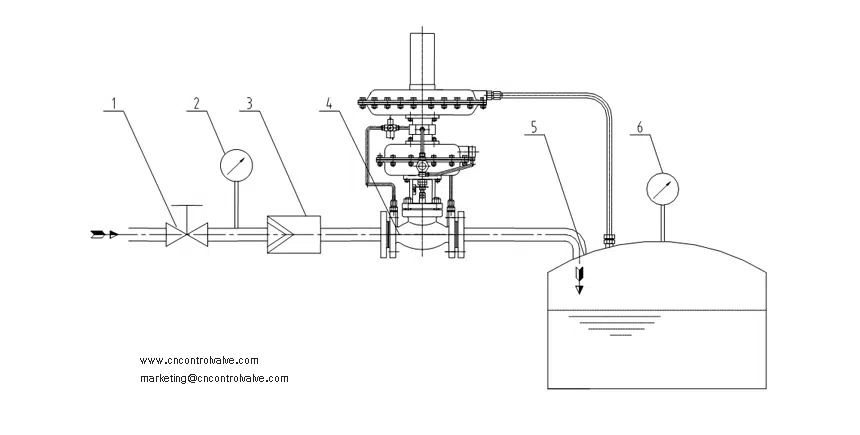

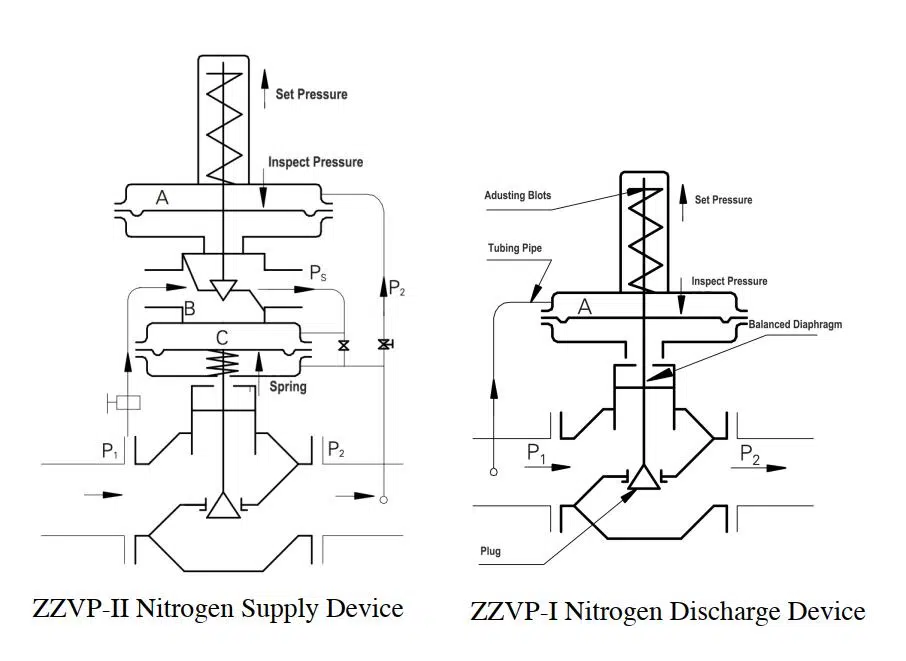

Tank blanketing systems include two types of regulators, tank blanketing regulator and vapor recovery regulator.

The tank blanketing pad regulator is a kind of pressure reducing valve(PRV) which controls the pressure inside the tank. The main function is to ensure there is sufficient pressure in the tank.

The vapor recovery regulator is a kind of relief pressure valve/backpressure reducing valve(BPRV) which also controls the pressure in the tank, but its main function is to make sure the tank is not over-pressurized.

Normally the set pressure of the vapor recovery regulator should be a bit higher than the tank blanketing regulator.

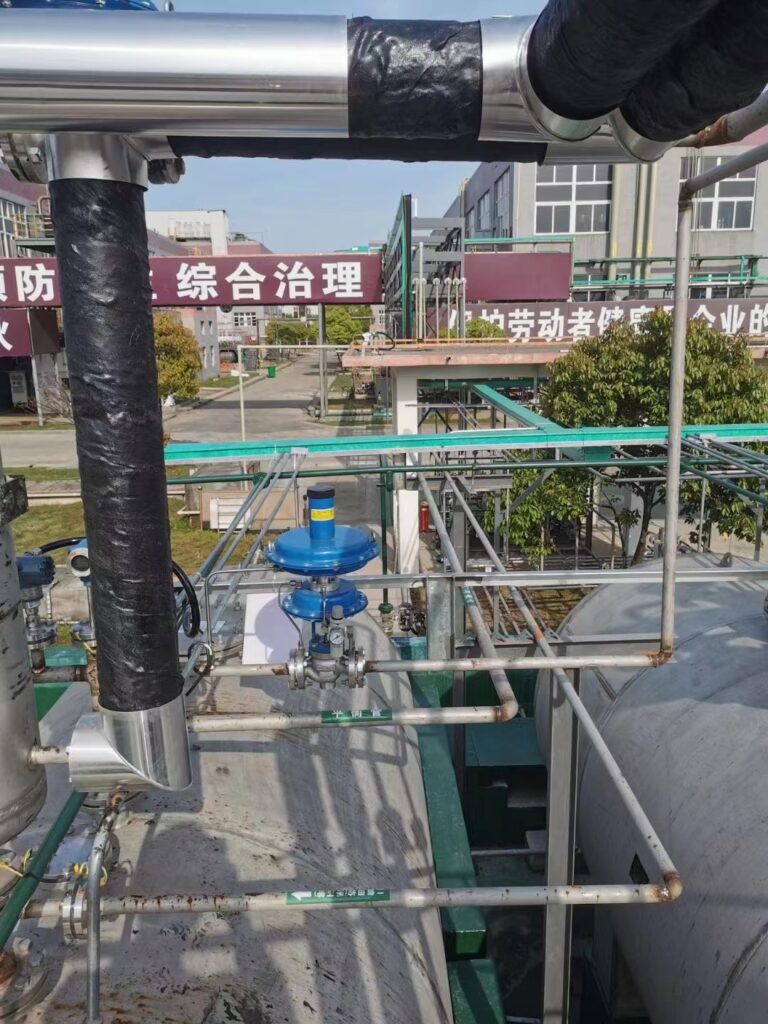

The tank blanketing regulator and vapor recovery regulator are typically installed on the top of the storage tank.

The natural gas supply piping is connected with the inlet of the tank blanketing regulator, and the outlet is connected to the storage tank. For most engineering designs, a sensing line is designed to the regulator’s sensing port from the tank. When the tank blanketing regulator senses the pressure decrease from the storage tank, then the regulator opens to supply more natural gas or other inert gas to the tank, until the tank pressure reaches the desired set pressure. When the tank inside pressure trigger or exceed the set point, the tank blanketing regulator closed and pressure returns to the desired set point.

Since there are lots of factors that will affect the volume of media in the tank, such as temperature changes, air entering the storage tank, vapor escaping from the tank, pumping medium in and out, and so on. When the volume of liquid changes, it will respond to the vapor space in the tank immediately. If higher pressure vapors, the vapor recovery regulator moves the plug away from the seat to relieve the pressure and vapor to flow out of the storage tank.

Tank Blanketing Application & Industry

- Tank Blanketing

- Natural Gas

- Oil&Gas

- Pressure Reducing

- Food & Beverage

- Pharma

- Chemical

- Petrochemical

Technical Parameters for Pressure Regulator

Size: DN20 ~ DN100

Pressure Rating: PN1.6 ~ PN6.4MPa, 150 ~ 300LB

Flange Standard: JB/T79.1-94. 79.2-94, ANSI B16.

Body Material: Bronze, Carbon Steel, Stainless Steel

Plug type: Single Seated, Double-seat, Cage Guided

Stem material: Stainless Steel

Pressure balancing: Stainless Steel Bellows

Flow characteristic: Quick Open

Working temperature: ≤ 80°C

End Connection: Threaded, Flanged

Actuator

Pressure Setting Range KPa: 0.4~0.5, 5~10, 9~14, 13~19, 18~24, 22~28, 27~33, 36~44, 42~51, 49~58, 56~66

Diaphragm Cover Material: Teflon coated A3, A4 steel sheet

Diaphragm Material: NBR, EPR, fluorine rubber, oil-resistant rubber

Benefits

- 100% completely self-operated for the system, no need external power source required.

- Due to its soft seat for the regulator, so the shutoff is tightened with ANSI Class VI standard.

- Assembly with an extra-large diaphragm that provides greater sensitivity and accuracy for natural gas.

The model ZZVP pressure regulating valve is a nitrogen sealing device composed of the control valve, actuator, pressure spring, pilot, pulse pipe, and other parts.

It is mainly used for maintaining the pressure of the gas (generally nitrogen) at the top of the vessel constant so as to prevent the materials in the vessel from contacting the air, volatilizing and being oxidized, and ensuring vessel safety.

It is especially suitable for gas seating protection systems of various large-sized storage tanks. The product has such features as energy-saving, agile action, reliable running, convenient operation, maintenance, etc. It is widely used in petroleum, chemical industry, etc.

In Conclusion

The tank blanketing pressure regulator and back pressure regulating valve play import role in the storage tank blanketing system. As a professional regulator manufacturer in China, THINKTANK provides free consultation, sizing, and selection service for our customers, if you are in the field of tank blanketing systems, please do not hesitate to contact us.

If you are interested in more industrial valves for industry and applications, you can read the following article.