If you are looking for the best industrial valve manufacturers in Thailand, you’ve come to the right place. In this post, we will list the top 10 companies in the industry. These businesses have years of experience and expertise in supplying Thailand’s factories with quality control valves. If you are looking for a reliable supplier, these are the businesses you should be considering!

The Top 10 Industrial Valves Companies in Thailand

The industrial valve market in Thailand is growing rapidly, and there are many good companies to choose from. If you are looking for a quality supplier, these are the top 10 businesses you should be considering:

1. Sirimongkol Engineering & Supply Limited Partnership

Sirimongkol is a recognized leader in the Electrical & Instrument service Provider industries, offering top-notch goods at affordable prices with prompt shipping. Direct shipments of the valve from manufacturers in Europe, the United States, Australia, Korea, India, and China will be made. (based on the different budgets of the end-users)

A recognized leader in the electrical and instrument service provider industries, Sirimongkol Engineering & Supply Limited Partnership offers top-notch goods at affordable prices with quick turnaround times.

Address: 48/77, Smet Daung Road, Tambol Tapma, Amphur Meang, Rayong

Phone: 098-250-9779

Tel: 062-651-0651

E-mail: [email protected]

2. K C MAHANAKORN CO.,LTD.

K C MAHANAKORN CO.,LTD is an engineering and industrial valve supplier established in 1990 with the mission “to be the best commercial and industrial valve supplier in Thailand. They provide customers with the best quality products at the most competitive prices and unparalleled service and support. They have authorized distributors of leading Japanese brands which renowned for their superior product quality.

Phone numbers: (+66)2678-2530

E-mail: [email protected] or [email protected]

Business hours: Monday – Friday 8:00am – 5:00pm

3. Thai Vista Enterprise Co., Ltd

Since 2002, Thai Vista Enterprise has been a leading distributor of industrial valve-related products in Thailand. They are not only a distributor but work closely with renowned valve manufacturers around the world to select, source, and deliver the most cost-effective industrial valves to the local Thai market.

Address: 23/4 Moo 11, Kratumban, Klongmadeu, Samutsakorn 74110

Tel: (+66-34)-875-908-10

Fax: (+66-34)-875-911

Email: [email protected]

Website: www.thaivista.co.th

4. SCI CORPORATION CO., LTD

SCI CORPORATION CO., LTD. (Formerly known as Siam Cast Iron Works) was founded in April of 1974 under a joint venture agreement between Thai and Japanese companies to produce high-quality cast iron and ductile iron valves using Japanese technology and know-how.

For water works and trash service, air conditioning, irrigation, power plant, and industrial application, SCI products are well recognized on both the local and international markets under the brand. All products are manufactured in accordance with AWWA, MSS Practice, BS, JIS, DIN, and ISO specifications, including sluice gates, gate valves, butterfly valves, check valves, and air valves.

Address: 1/12 Samutsakorn Industrial Estate, Soi 7, Tahsai, Muang, Samutsakorn 74000 Thailand

Export sales and shipping department: +66 (34) 410 491

Domestic sales department: +66 (34) 410 492

5. Action Engineering Co., Ltd

Action Engineering Co.,Ltd was founded by three engineers with ” OVER 37 YEARS ” of expertise in Process Instruments and Control Valves.

Established on August 15, 1985 with the primary purpose of being the market leader in Thailand for industrial Control and On/Off valves. Within five years, the firm attained its goal and ranked first in selection, supply, and after-sales service for Control & On-Off Valves.

Address: 8 Soi Krungthepkreetha 31 Yaek 4-1

Thabchang, Saphansung, Bangkok 10250

Tel.: (02) 752 0004-9

5. Azbil (Thailand) Co., Ltd

Since more than 15 years ago, Azbil (Thailand) Co., Ltd., the Thai subsidiary of the azbil Group, has provided maintenance services for valves placed at clients’ factories in Rayong Province, located in Thailand’s Eastern Economic Corridor. When the company’s ancient facility was rebuilt, it was also reincarnated as the Solution and Technology Center, which offers digital transformation (DX) and smart security to ASEAN clients. As the biggest valve repair facility within the azbil Group, it offers solutions for the safe and reliable running of plants.

6. YOSHITAKE WORKS(THAILAND) LTD

With the introduction of an integrated manufacturing system from casting to final product, YOSHITAKE WORKS(THAILAND) LTD. is able to significantly improve quality, cost, and delivery time. In addition, the corporation encourages the use of ductile iron for standard items in an effort to improve product safety.

Addess: 222 M.3 T.Banbueng A.Banbueng Chonburi 20170, Thailand

Tel: 038-110-003~009

Fax: 038-110-012

7. CEO CORPORATION Co., Ltd.

CEO Fluid Services Ltd. is a leading valve trading company that services and distributes industrial valves. It is one of the leading valve trading companies in Thailand, providing service and distribution of industrial valves, piping, fittings, and instruments.

Founded in 2005 as a privately owned company, CEO Fluid Services Ltd. has grown into a medium-sized company providing sales, service and technical support in Bangkok and the eastern region of Thailand. CEO valves are imported in accordance with API and ISO requirements from many countries, such as the United States, Europe, Japan, Korea and China, with materials of construction that meet ASTM standards and are pressure tested.

8. AZ Armaturen Thailand Co. Ltd

AZ is one of the leading manufacturers of cavity-free plug valves and special valves for production plants in the chemical, petrochemical, pharmaceutical, paper and food industries as well as for nuclear power plants and many other areas. together with its customers, AZ designs and develops special valves for the highest requirements in the field of high working pressures and corrosive, toxic or abrasive media.

Address: 19/2 Wad Khodhin-Kaophai Road

Tambon Tabma, Amphur Muang Rayong

Rayong 21000

Tel: +66 33 218 011

Email: [email protected]

9. EBRO VALVES TRADING (THAILAND) CO LTD

EBRO Thailand Trading specializes in the import of EBRO’s industrial automation valves and is able to offer customized solutions for automation valves to end customers. A dedicated business unit ensures the precise coordination of valves, actuators and automation technology. The result is an end-to-end product portfolio that also meets all process engineering requirements in terms of energy efficiency. The coordinated combination of high quality valves and pneumatic actuators can also be precisely matched to specific applications. This matching of components reduces air and energy requirements, while also simplifying the overall cost of such solutions.

10. THAIPOINT GLOBAL TECHNOLOGY CO., LTD

THAIPOINT GLOBAL TECHNOLOGY is a trading firm that specializes in process control instrumentation and safety equipment valves, valve replacement parts, thermocouples, and technical solutions support and services for the power plant, oil and gas, and petrochemical sectors. Its company strategy is to provide these sectors with the superior goods and dependable services they seek.

Address: 119/59 Moo3 T. Tabma,A.Muangrayong, Rayong, Thailand 21000

Phone: +6638-691-899

Mobile: +6681-618-6643

Email: [email protected]

Web: www.thaipointglobal.co.th

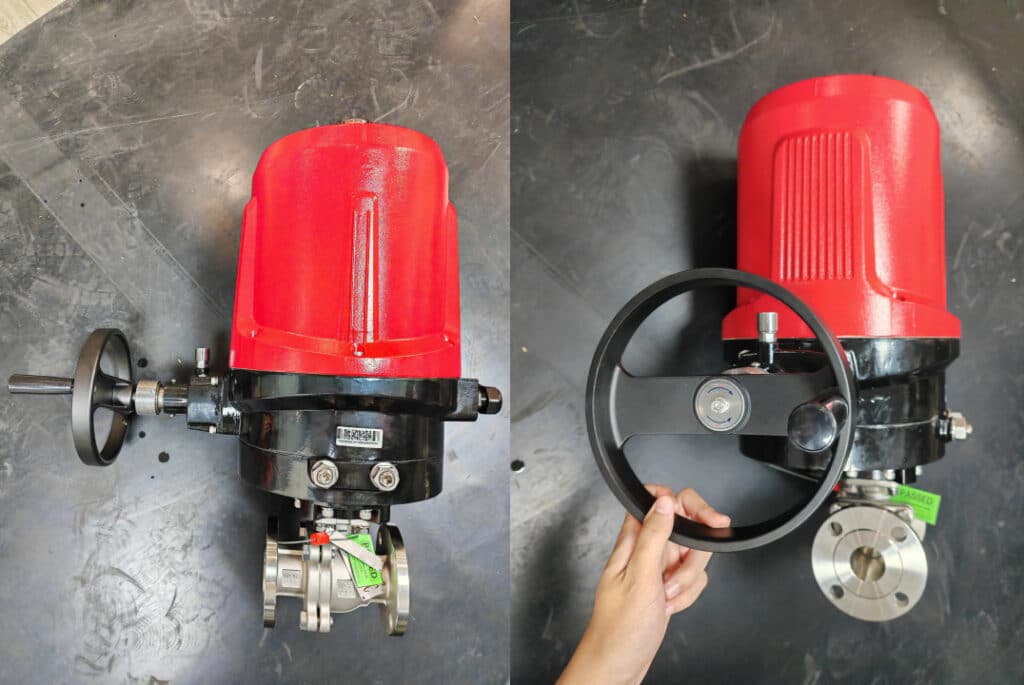

THINKTANK: A Leading Manufacturer of Quality Industrial Valves

If you’re looking for a quality industrial valve manufacturer in China, look no further than THINKTANK. We have been in the business for over 30 years and have a reputation for excellence. Our industrial valves are used in a variety of industries, including oil and gas, water treatment, chemical processing, and more. We offer a wide range of valves, including globe valves, gate valves, control valves, check valves, ball valves, safety valves and pressure regulators. We also have a team of experts who can help you choose the right valve for your needs.

At THINKTANK, we are committed to providing our customers with top-notch quality products and services. We use only the highest grade of raw materials during production to ensure that the valves manufactured meet industry standards. Our experienced engineers inspect each valve before it leaves our facility in order to maintain product reliability and performance. We also offer competitive pricing and prompt delivery.

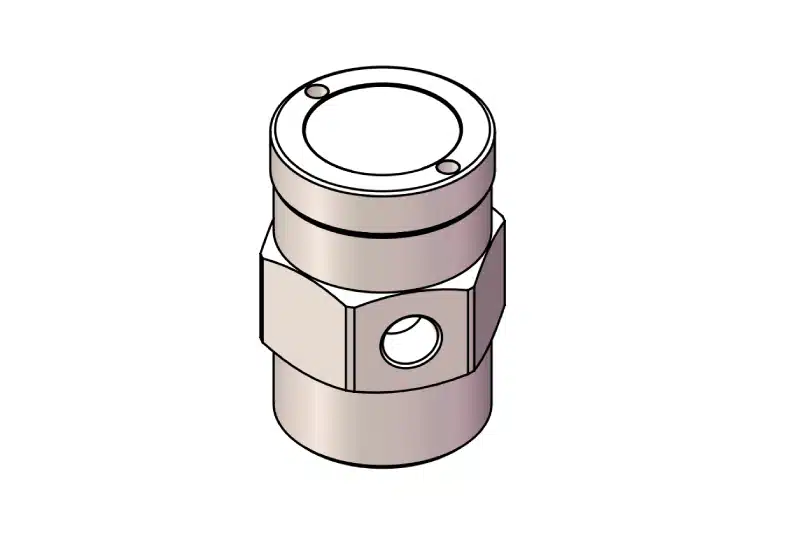

Industrial Valve Process Manufacturing

The manufacturing process for valves can vary depending on the type of valve and the materials it is made from. In general, however, the process typically involves the following steps:

- Design and development: This step involves creating a detailed design for the valve, taking into account factors such as the materials to be used, the desired size and shape of the valve, and the specific application it will be used for.

- Raw materials: Once the design is finalized, the necessary raw materials are procured. This may include materials such as steel, brass, bronze, or plastic, depending on the type of valve and its intended use.

- Cutting and machining: The raw materials are then cut and machined to the precise dimensions specified in the design. This may involve using a variety of tools and machines, such as lathes, mills, and grinders, to shape the materials to the desired specifications.

- Assembly: The various parts of the valve are then assembled, using methods such as welding, brazing, or threading, depending on the type of valve and the materials it is made from.

- Testing: Once the valve is fully assembled, it is subjected to a series of tests to ensure that it functions properly and meets all of the design specifications. This may include pressure tests, flow tests, and other types of performance tests.

- Finishing: Finally, the valve is given any necessary finishes, such as painting or plating, to protect it from corrosion and improve its appearance. It is then packaged and shipped to the customer.

FAQs about industrial valves

Here we have listed a few common questions about industrial valves, if there are other questions you have, feel free to contact us for advice.

What is an industrial valve?

An industrial valve is a mechanical device that controls, regulates, or directs the flow of gases, liquids, or other materials by opening, closing, or partially obstructing passageways. Valves are used in a wide range of applications, including oil and gas production, water and sewage treatment, power generation, and chemical manufacturing. They are typically made of metal, such as steel or brass, and are designed to withstand high pressure and temperature.

What are the 4 types of valves?

There are several different types of valves, and the specific types used can vary depending on the specific application. Some common types of valves include gate valves, globe valves, ball valves, and butterfly valves. Each of these types of valves operates differently and has its own specific advantages and disadvantages.

Why are industrial valves important?

Industrial valves are important because they are used to control the flow of liquids, gases, and other materials in industrial systems. They are critical components in a wide range of industries, including oil and gas, chemical processing, water treatment, and many others. Valves are used to regulate the flow of materials in these systems, ensuring that they operate safely and efficiently. In addition to their practical functions, industrial valves are also important because they can help prevent accidents and minimize the risk of damage to equipment and the surrounding environment.

How many valves are there in the industry?

There are many different types of valves used in various industries. Some common types of valves include ball valves, butterfly valves, gate valves, globe valves, and check valves. Each of these types of valves has a specific purpose and is designed to control the flow of fluids or gases in a particular way. The exact number of different valve types used in industry can vary depending on the specific application and the needs of the system in which the valve is used.

If you are interested in furthermore types of valves and applications, you can read the following post.

What are the 6 types of industrial valves?

There are several different types of valves, including gate valves, ball valves, butterfly valves, check valves, globe valves, and plug valves. Each type of valve has a specific function and is used in different applications. Gate valves are used to stop and start the flow of liquids and gases, while ball valves are used for regulating flow. Butterfly valves are used to control the flow of fluids, while check valves allow fluid to flow in only one direction. Globe valves are used to regulate the flow of fluid by restricting the flow path, and plug valves are used to stop and start the flow of fluids.

What are the three main types of valves?

There are many different types of valves, but some of the most common ones include gate valves, ball valves, and globe valves. Gate valves are used to regulate the flow of liquid or gas by opening, closing, or partially blocking the passage through a pipe. Ball valves, on the other hand, use a hollow, perforated, and pivoting ball to control the flow of fluid. Globe valves, meanwhile, use a movable disk to regulate the flow of fluid. Other common types of valves include butterfly valves, diaphragm valves, and check valves.

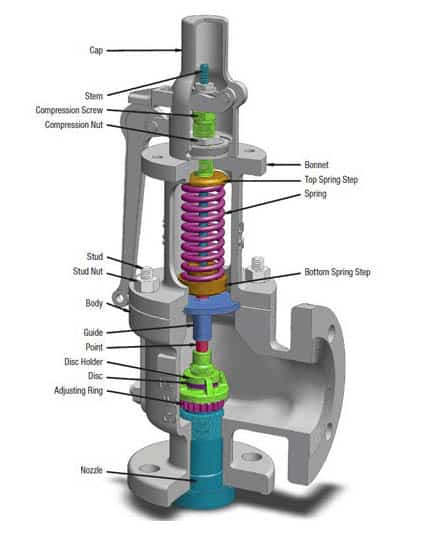

What are PSV and PRV in the industry?

PSV and PRV are abbreviations for pressure valves. PSV and PRV stand for “Pressure Safety Valve” and “Pressure Relief Valve,” respectively. These are types of valves that are used in various systems to regulate pressure and prevent accidents or damage.

A pressure safety valve is a type of safety valve that is used to protect a pressure vessel or other system from overpressure. The valve is designed to automatically open and release excess pressure when the pressure in the system exceeds a predetermined safe level. This helps to prevent accidents and damage to the system, and ensures that the system operates within safe limits at all times.

A pressure reducing valve is a type of valve that is used to reduce the pressure of a fluid or gas in a system. The valve works by allowing a small amount of the fluid or gas to pass through it, which reduces the overall pressure in the system. This can be useful in a variety of applications, such as regulating the pressure of water in a plumbing system, or controlling the pressure of gas in a gas line. The valve typically has a calibrated spring or diaphragm inside that is used to adjust the pressure setting, and it can be adjusted as needed to maintain the desired pressure in the system.

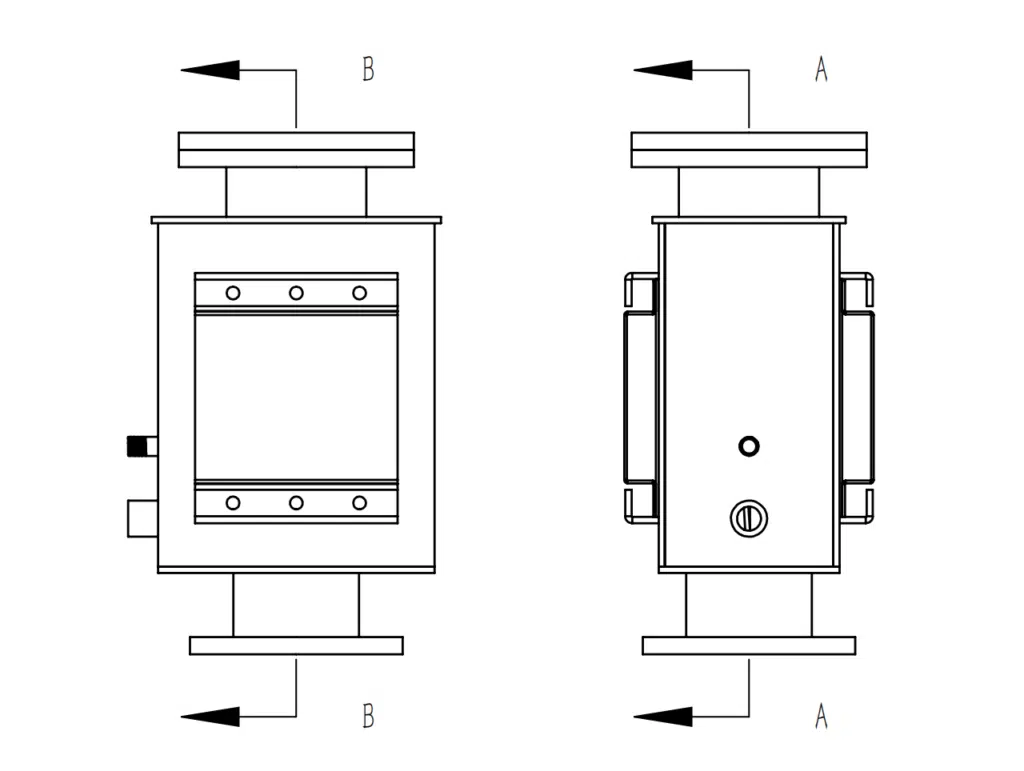

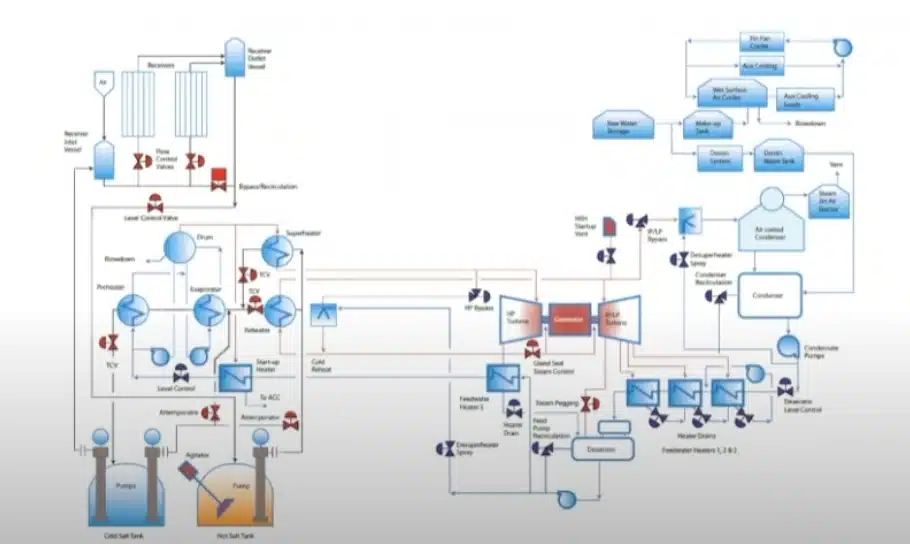

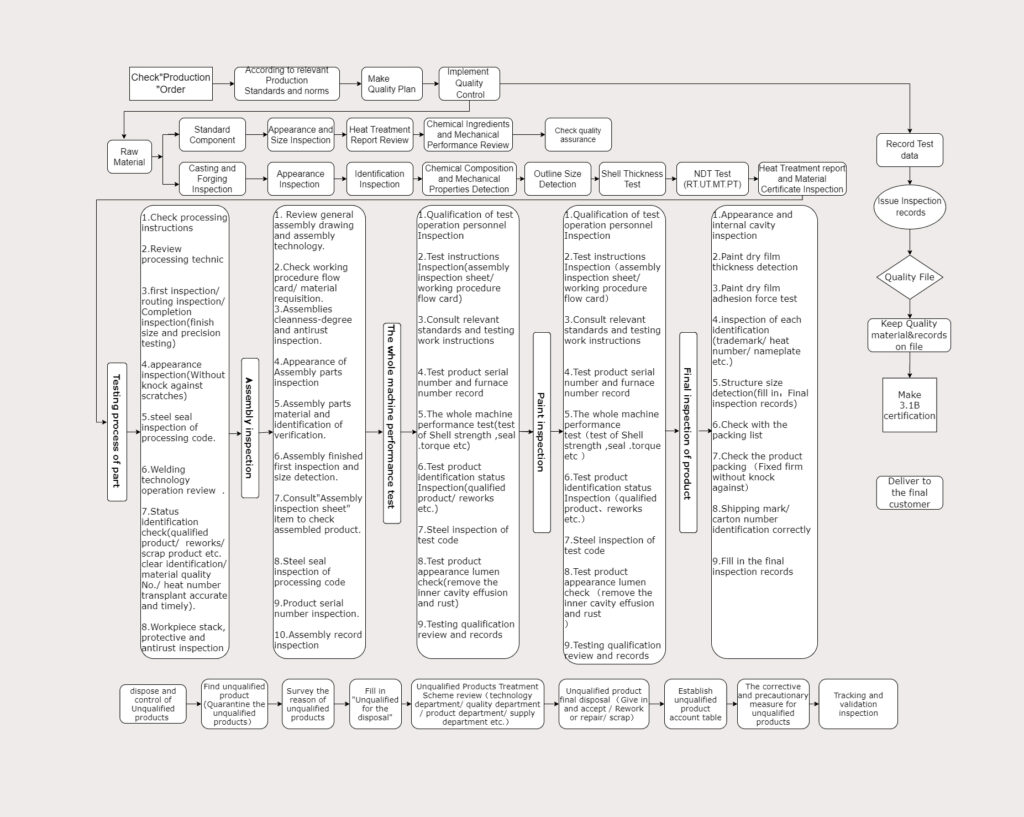

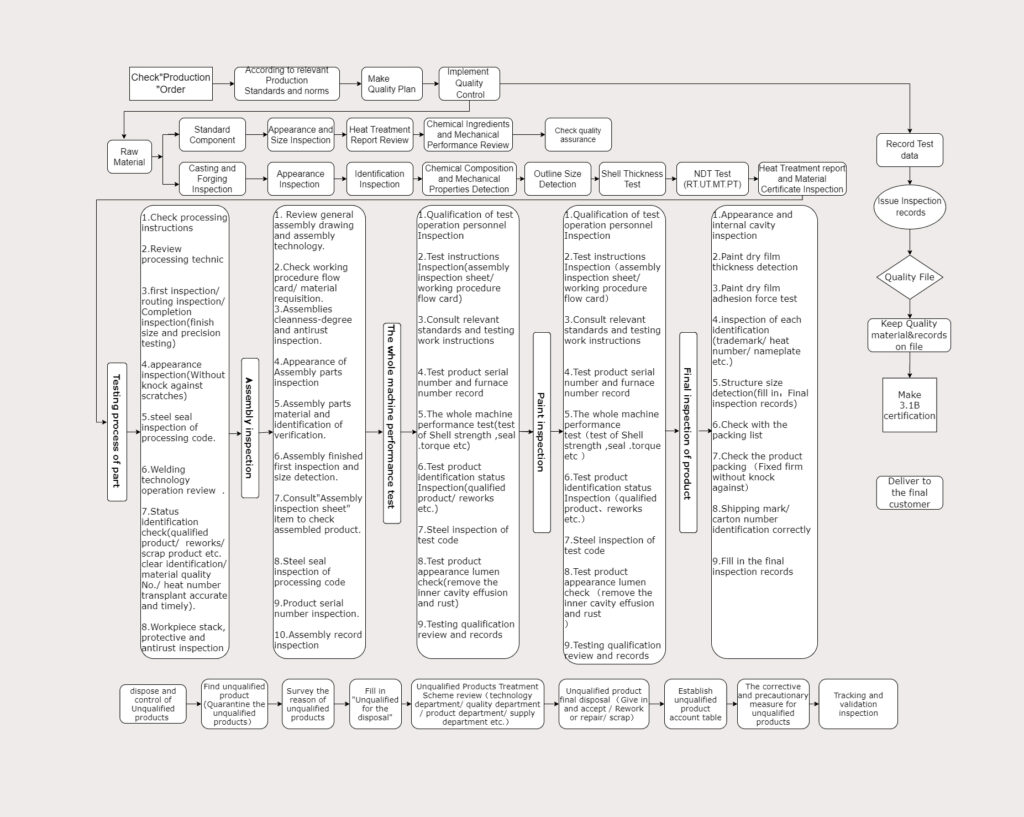

Control Valve manufacturing process flow Chart

Control Valve Manufacturing

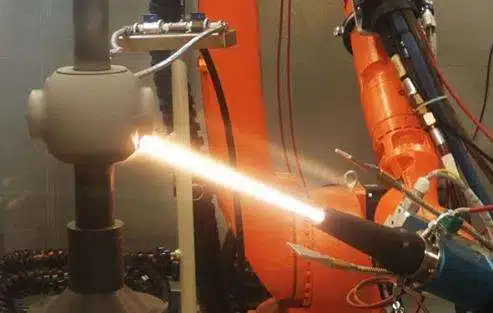

Control valves are used in various industries to regulate the flow of fluids such as gases, liquids, and slurries. These valves are typically manufactured using materials such as brass, stainless steel, and carbon steel, depending on the specific application and requirements. The manufacturing process for control valves typically involves several steps, such as casting, machining, and assembly. In the casting process, the valve body is formed by pouring molten metal into a mold. The machining process involves shaping and finishing the valve body and other components using tools such as lathes, mills, and grinders. Finally, the assembled valve is tested to ensure that it meets the required specifications and performance standards.

Conclusion

Now we know these companies offer a wide range of products and services that should be able to meet the needs of your application in Thailand. Also, we list the frequent questions about industrial valves for your reference. Should you have any questions, welcome to send us to get a free consultation.