As we explore the world of food and beverage processing, we come across the critical role of valves in maintaining the quality and safety of products. In this comprehensive guide, we’ll dive into the details of selecting the most suitable valves for food and beverage applications, ensuring that your processing system is efficient, hygienic, and cost-effective.

Types of Valves Used in Food and Beverage Applications

1. Butterfly Valves

Butterfly valves are versatile and offer a compact design, making them a popular choice in the food and beverage industry. They are ideal for applications involving liquid or semi-liquid products.

2. Ball Valves

Ball valves provide excellent shut-off capabilities and are ideal for applications requiring precise flow control. They are suitable for high-pressure systems and can handle a wide range of temperatures.

3. Diaphragm Valves

Diaphragm valves offer exceptional cleanliness and are designed for sterile applications. They are ideal for handling viscous fluids or those containing particulates, making them perfect for dairy, brewery, and other food processing applications.

4. Check Valves

Check valves are used to prevent backflow in processing systems, ensuring the integrity of the product and the safety of the equipment.

5. Globe Valves

Globe valves offer precise flow control and are suitable for high-pressure systems. They are commonly used in applications involving steam, water, and other process fluids.

Applications of Valves in the Food and Beverage Industry

Valves are used in various applications in the food and beverage industry, including:

Processing

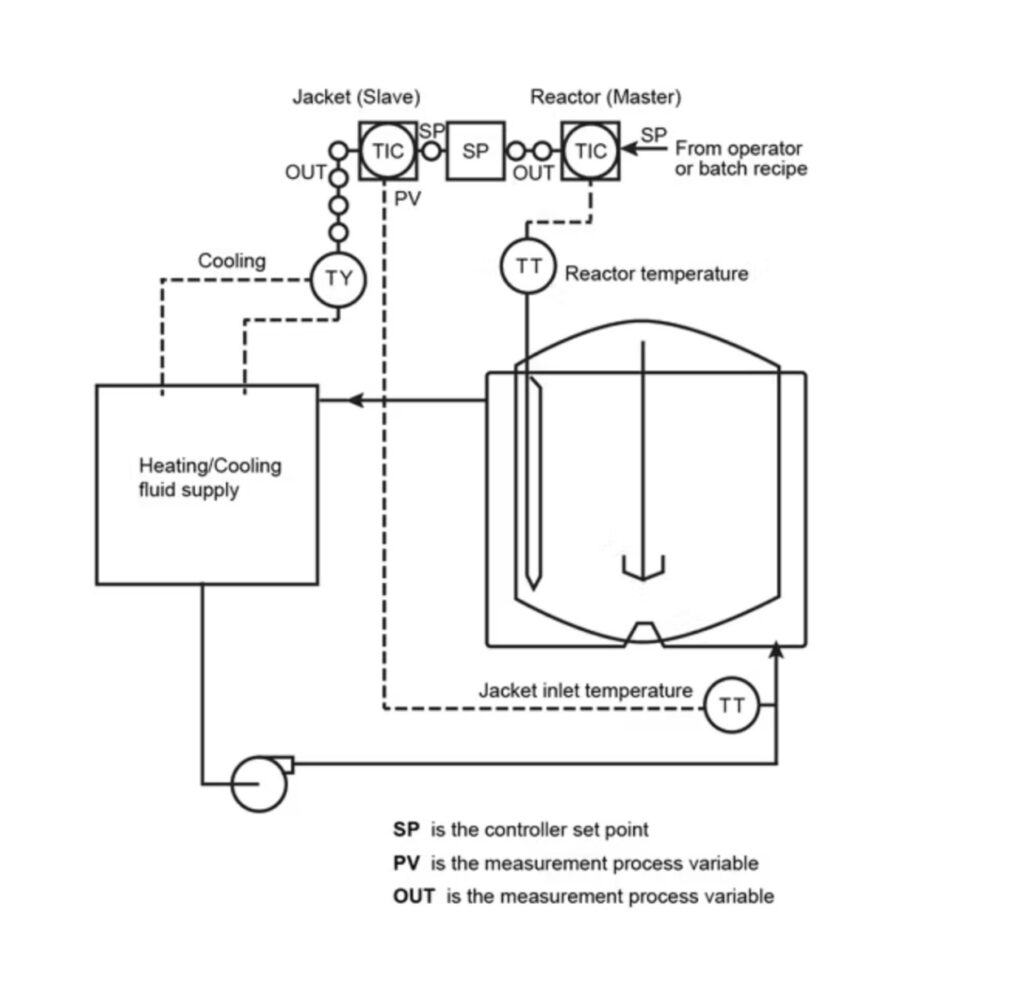

Valves are used to control the flow of ingredients, such as liquids, powders, and gases, in processing equipment, such as blenders, mixers, and reactors.

Packaging

Valves are used to control the flow of products into packaging machines, such as bottling, canning, and bagging machines.

Storage

Valves are used to control the flow of products in storage tanks and vessels.

Transport

Valves are used in pipelines to control the flow of products during transportation.

Key Considerations for Control Valve Selection in the Food and Beverage Industry

1. Material Selection

The materials used to construct control valves must be compatible with the fluids and gases they will come into contact with in the food and beverage industry. This ensures that there is no risk of contamination or corrosion, which could compromise product quality or safety. Stainless steel is a popular choice for control valve construction due to its corrosion resistance and ability to withstand frequent cleaning and sanitizing processes. However, it is crucial to consult a valve material guide to select the most suitable material for your specific application.

2. Valve Type

There are different types of control valves used in the industry, each with unique features and benefits. For example, globe valves offer precise control, while butterfly valves are more suitable for large flow applications. It is crucial to select a valve that meets the specific requirements of your application. For example, globe control valves are widely used in the food and beverage industry due to their excellent throttling capabilities, while butterfly valves offer a compact and cost-effective solution for flow regulation.

3. Sanitary Design

Control valves used in the food and beverage industry must meet strict hygiene and sanitation requirements to minimize the risk of contamination. Select valves that have a sanitary design, with smooth internal surfaces and minimal dead zones where contaminants can accumulate. Additionally, make sure the valve is easy to disassemble for cleaning and maintenance purposes.

4. Temperature and Pressure Ratings

The control valve should be able to withstand the temperature and pressure ranges encountered in your specific application. Consult the control valve pressure-related chart to ensure that the valve you choose meets these requirements.

5. Flow Characteristics

Control valves have different flow characteristics, such as linear, equal percentage, and quick opening. It is essential to select a valve with a flow characteristic that matches the requirements of your application. For more information on flow characteristics, consult the definition of linear and equal percent characteristic guide.

6. Cv Value

Proper valve sizing is crucial to ensure optimal performance and prevent issues such as cavitation, noise, and excessive wear. The Cv value of a control valve indicates its flow capacity under specific conditions. It is essential to calculate the Cv value required for your application and select a valve with an appropriate Cv value to ensure efficient operation. Consult the control valve sizing guide for more information on valve sizing and Cv calculation.

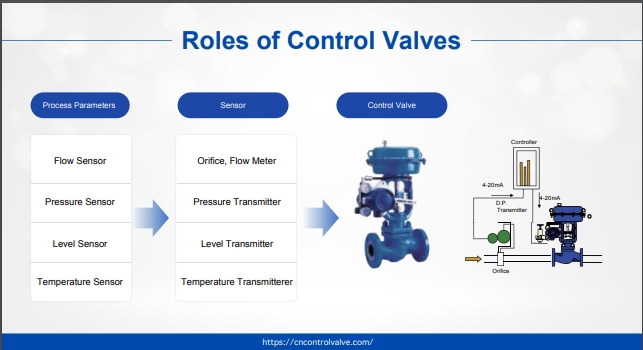

7. Actuators and Positioners

Select the appropriate actuator and positioner for the control valve, considering factors such as speed, torque, and control signal compatibility.

Control valves are often paired with actuators, which convert an input signal into mechanical motion to control the valve position. There are various types of actuators, including pneumatic, electric, and hydraulic. It is essential to choose the right actuator for your application by considering factors such as power source, response time, and control signal compatibility. To learn more about actuator selection, read the 3 steps to installing your new actuator of valve guide.

8. Sanitary and Hygienic Requirements

In the food and beverage industry, control valves must meet strict sanitary and hygienic standards. Ensure that the valve design, materials, and sealing components comply with industry regulations.

9. Noise and Vibration Control

Control valves can generate noise and vibration, which can cause issues with nearby equipment and operators. It is essential to choose a valve with noise and vibration control features, such as a cage-guided trim design or a low-noise cage, to minimize these effects.

10. Maintenance and Support

Select a control valve from a reputable manufacturer that offers comprehensive support and maintenance services. This ensures that you will have access to spare parts, technical assistance, and other resources necessary to keep your control valve operating efficiently and reliably throughout its service life.

11. Cost and Lifecycle

Finally, consider the initial cost of the control valve, as well as ongoing maintenance and lifecycle costs. While a more expensive valve may have a higher upfront cost, it may offer better performance, durability, and support, resulting in a lower total cost of ownership over time.

Conclusion

In conclusion, selecting the right control valve for your food and beverage application requires careful consideration of various factors, such as valve type, material compatibility, sanitary design, temperature and pressure ratings, flow characteristics, actuator selection, valve sizing, noise and vibration control, maintenance and support, and cost and lifecycle. By taking these factors into account, you can make an informed decision and select a control valve that will provide efficient and reliable performance in your specific application. THINKTANK is a reliable control valve manufacturer in China, Welcome to contact our expert for a free consultation.

FAQs

1. Why are valves important in food and beverage applications?

Valves are crucial for maintaining safety, hygiene, and efficiency in food and beverage processing systems.

2. What are the most common types of valves used in food and beverage applications?

Butterfly, ball, diaphragm, check, and globe valves are commonly used in food and beverage processing.

3. What factors should I consider when selecting valves for my food and beverage processing system?

Material selection, valve size, flow rate, pressure and temperature requirements, certifications, and maintenance are some of the key factors to consider when selecting valves for food and beverage applications.

4. How do I ensure the chosen valve meets industry standards and certifications?

Make sure that the valve complies with industry standards such as FDA, 3A, and EHEDG, which guarantee hygiene and safety in food and beverage applications.

5. Why is material selection important when choosing valves for food and beverage processing?

The material used in valve construction plays a critical role in ensuring hygiene and durability. Materials like stainless steel are preferred due to their corrosion resistance and easy-to-clean surface.