What is Temperature Control Valve?

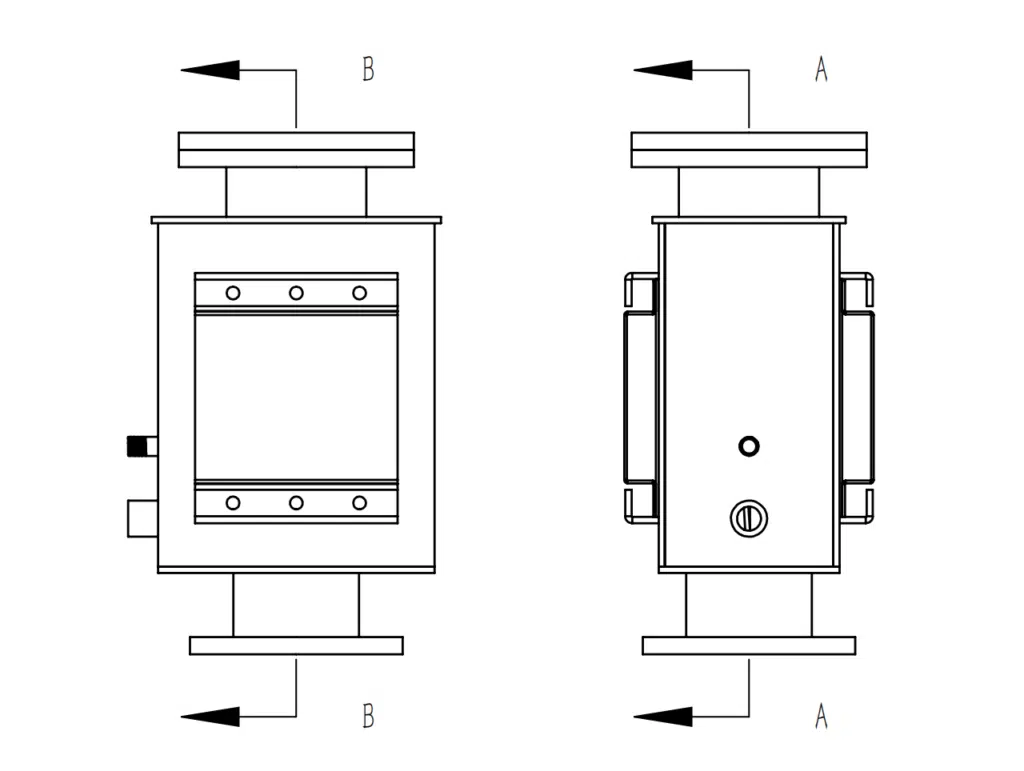

The Temperature Control Valve is a specialized valve designed to regulate temperatures in industrial piping systems. It typically consists of two distinct parts, a temperature regulating element and a control valve body, each providing different functions within the same piece of equipment. The temperature regulating element can be adjusted to set the desired flow rate and temperature, while the control valve body is used to redirect or shut off the flow of liquid as needed. With its reliable performance and precise temperature control capabilities, the Temperature Control Valve is an indispensable tool for many industries such as automotive, food production, pharmaceuticals and more.

Temperature control valves play a critical role in many industrial and residential applications, ensuring optimal temperature management and preventing damage to equipment or products. Selecting the right valve for your application can be a complex task. To make the process easier, we have compiled five expert tips to help you choose the perfect temperature control valve.

Tip 1. Understand the Basics of Temperature Control Valves

Before diving into the selection process, it’s essential to understand the different types of temperature control valves and their primary functions.

Types of Temperature Control Valves

1. Direct-Acting Temperature Valves

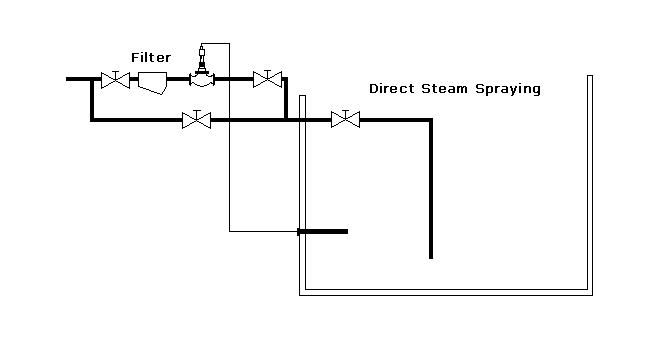

Direct-Acting Temperature Valves are valves that directly work with the temperature of a system, controlling the flow of fluids or gases in order to maintain a desired level. Unlike other types of valves, direct-acting valves do not require external forces such as electric signals or pneumatics to operate, instead relying solely on the thermal expansion and contraction of the material in response to changes in temperature. These valves operate without external power sources and use the process fluid’s pressure to control the temperature.

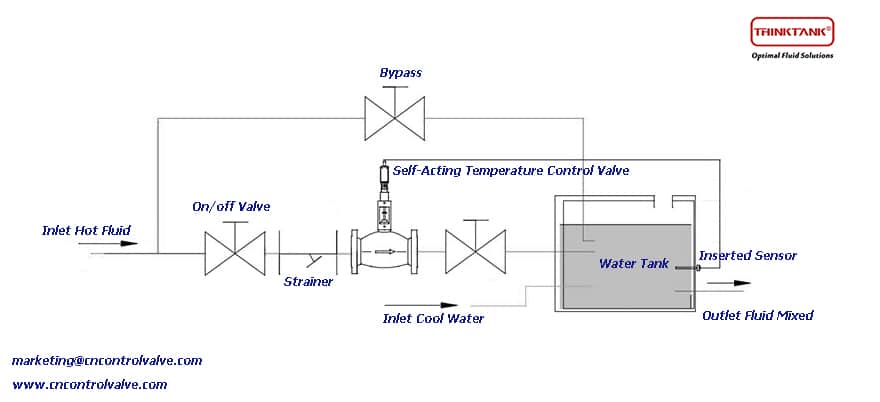

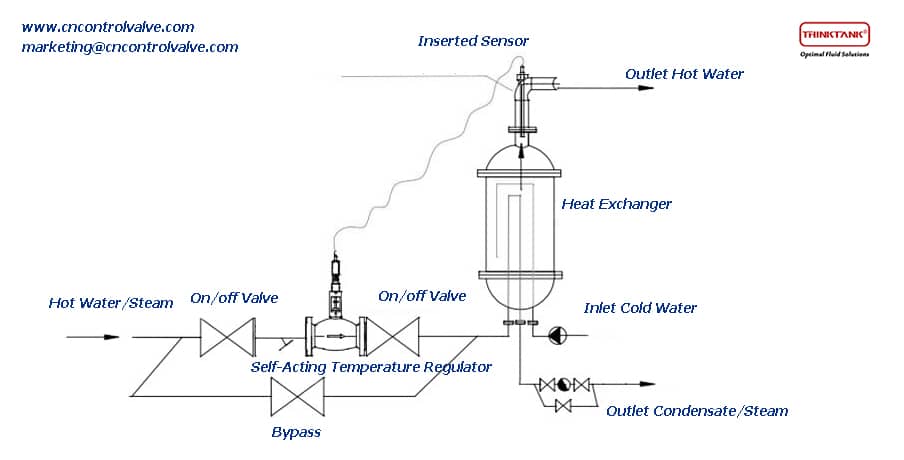

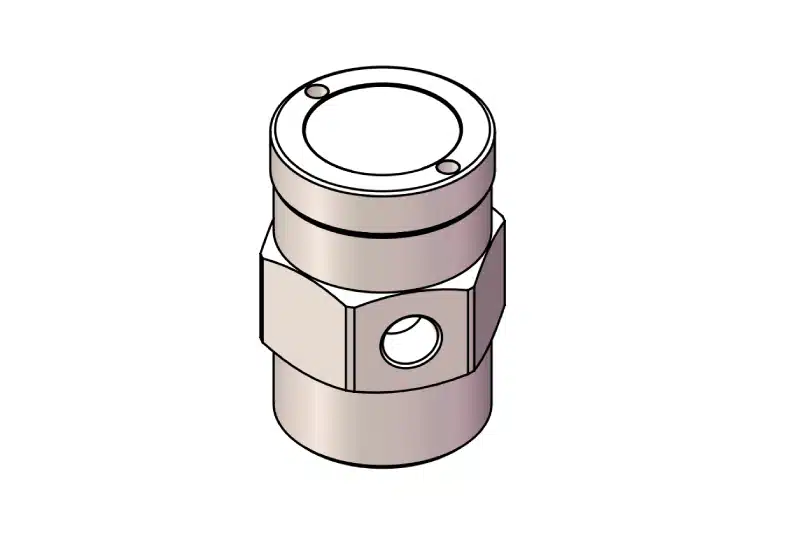

2. Self-Operated Temperature Valves

Self-Operated Temperature Valves are valves that use an internal relief system to regulate the flow rate and temperature of fluid or gas. They are commonly used in applications where a consistent and reliable temperature is required, such as industrial cooling, air conditioning, and heating systems. These valves use a built-in spring system to adjust their setting and open/close based on changes in pressure or temperature, meaning that they can effectively maintain a desired level at all times. Additionally, self-operated temperature valves typically require little to no maintenance over time. These valves use an integrated thermal actuator to control the temperature by sensing changes in the process fluid’s temperature.

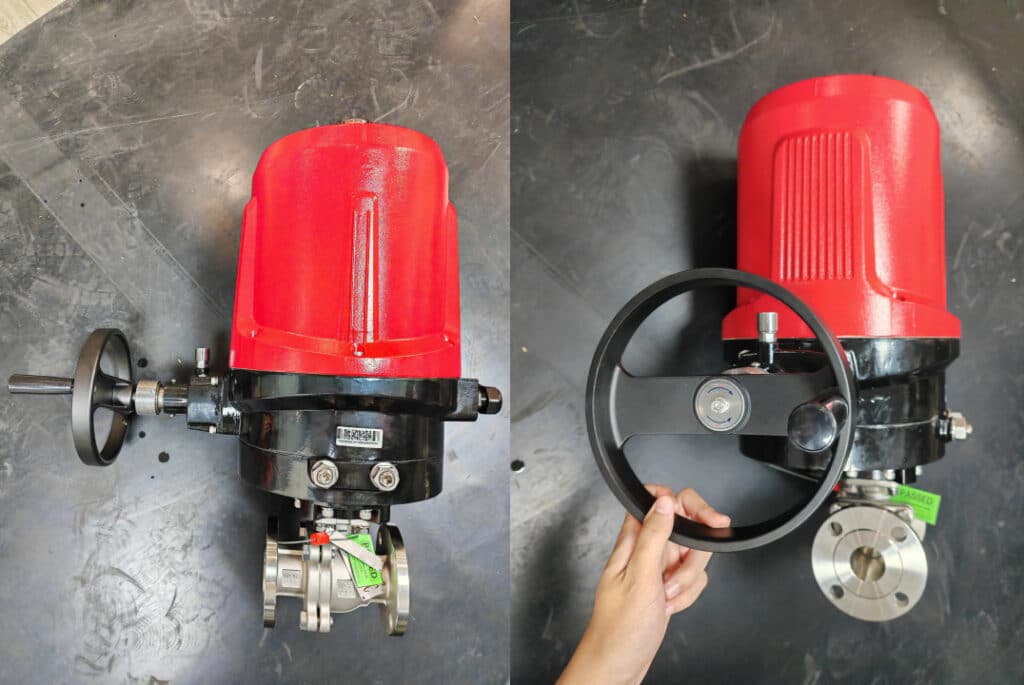

3. Electric Temperature Control Valves

Electric Temperature Control Valves are valves that utilize electric signals to control the flow of fluids or gases in a system. They are commonly used in applications such as industrial cooling, air conditioning, and heating systems where precise control over temperatures is required. These valves use electrical signals to open and close, meaning that they can more precisely regulate the flow rate and temperature of fluid or gas. Additionally, electric temperature control valves typically have a wider range of adjustable settings than manual valves, allowing for greater flexibility in controlling temperatures.

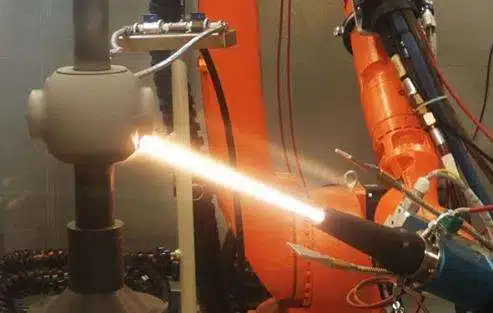

4. Pneumatic Temperature Control Valves

Pneumatic Temperature Control Valves are valves that use external forces, such as compressed air and use input signals to operate. They are commonly used in applications where temperature control is required and the precision of electric valves is not necessary. These valves rely on the force of compressed air or vacuum to open and close, allowing for less precise but still effective temperature regulation. Additionally, pneumatic temperature control valves are typically much easier to install and maintain than other types of valves.

Tip 2: Determine the Application Requirements

Understanding your application requirements is crucial in selecting the right temperature control valve. Consider the following factors:

1. Temperature Range

Identify the desired temperature range for your application to ensure the valve can accommodate these requirements.

2. Pressure Range

Determine the pressure range of your system, as this will impact the valve’s performance and durability.

3. Flow Rate

Calculate the flow rate required for your application, as this will help you choose a valve with the appropriate capacity.

4. Media Compatibility

Consider the type of fluid being used in your system, as this will influence the valve’s material and compatibility.

Tip 3: Consider Valve Sizing and Selection

Proper valve sizing and selection are critical for optimal performance and efficiency. Keep these factors in mind:

- Cv Value: The Cv value is a measure of the valve’s flow capacity. Ensure the selected valve has a Cv value that matches your application’s requirements.

- Valve Material: Select a valve material that is compatible with the process fluid and can withstand the system’s temperature and pressure.

- Connection Type: Choose a connection type that is compatible with your system’s piping and fittings, ensuring a secure and leak-free connection.

Tip 4: Evaluate Maintenance and Installation Factors

Consider the installation process and long-term maintenance requirements when selecting a temperature control valve:

Installation Process

Choose a valve that is easy to install and integrates seamlessly with your existing system, reducing the risk of errors and downtime.

Maintenance Requirements

Opt for a valve with minimal maintenance needs, ensuring the valve’s longevity and reducing overall costs.

Tip 5: Consult with an Expert

When in doubt, consult with a temperature control valve expert THINKTANK. We can provide valuable insights, recommendations, and support to ensure you select the perfect valve for your application.

As a professional temperature control valve manufacturer in China, THINKTANK boasts over 30 years of experience in producing a wide range of industrial valves. Our extensive product line includes control valves, gate valves, globe valves, check valves, ball valves, butterfly valves, pressure regulators, and more. Trust THINKTANK for unparalleled expertise and exceptional quality in valve manufacturing.

Conclusion

Choosing the perfect temperature control valve requires a thorough understanding of your application requirements, the different types of valves available, and factors such as sizing, maintenance, and installation. By following these five expert tips, you can confidently select the ideal temperature control valve to meet your specific needs.

FAQs Temperature Control Valves

Q1: How do I calculate the Cv value for my application?

A1: The Cv value can be calculated using flow rate, pressure drop, and specific gravity of the process fluid. Consult with an expert or use online tools to help determine the appropriate Cv value for your application.

Q2: Can I use one type of temperature control valve for all applications?

A2: No, different applications have unique requirements, and using a single type of valve may not be suitable. It’s essential to consider factors such as temperature range, pressure range, and media compatibility when selecting a valve. These process parameters are very important for choosing the right valve for your application, and they will highly affect the valve service time.

Q3: How often should I perform maintenance on my temperature control valve?

A3: Maintenance frequency depends on factors such as valve type, material, and operating conditions. Consult with the valve manufacturer or an expert for specific maintenance recommendations. If your valves are bought from THINKTANK, you can ask us for a free maintenance manual for your application.

Q4: Can I use a temperature control valve in a high-pressure application?

A4: Some temperature control valves are designed to handle high-pressure applications, while others may not be suitable. Normally if for high-pressure application, we recommend you choose pneumatic or electric temperature control valves, contact THINKTANK to ensure the selected valve is rated for the pressure range of your system.

Q5: What are some common temperature control valve materials?

A5: Common materials used in temperature control valves include cast iron, brass, stainless steel, bronze, and carbon steel. The choice of material depends on factors such as media compatibility, temperature range, and pressure range. You are welcome to contact our representative for a free consultation.