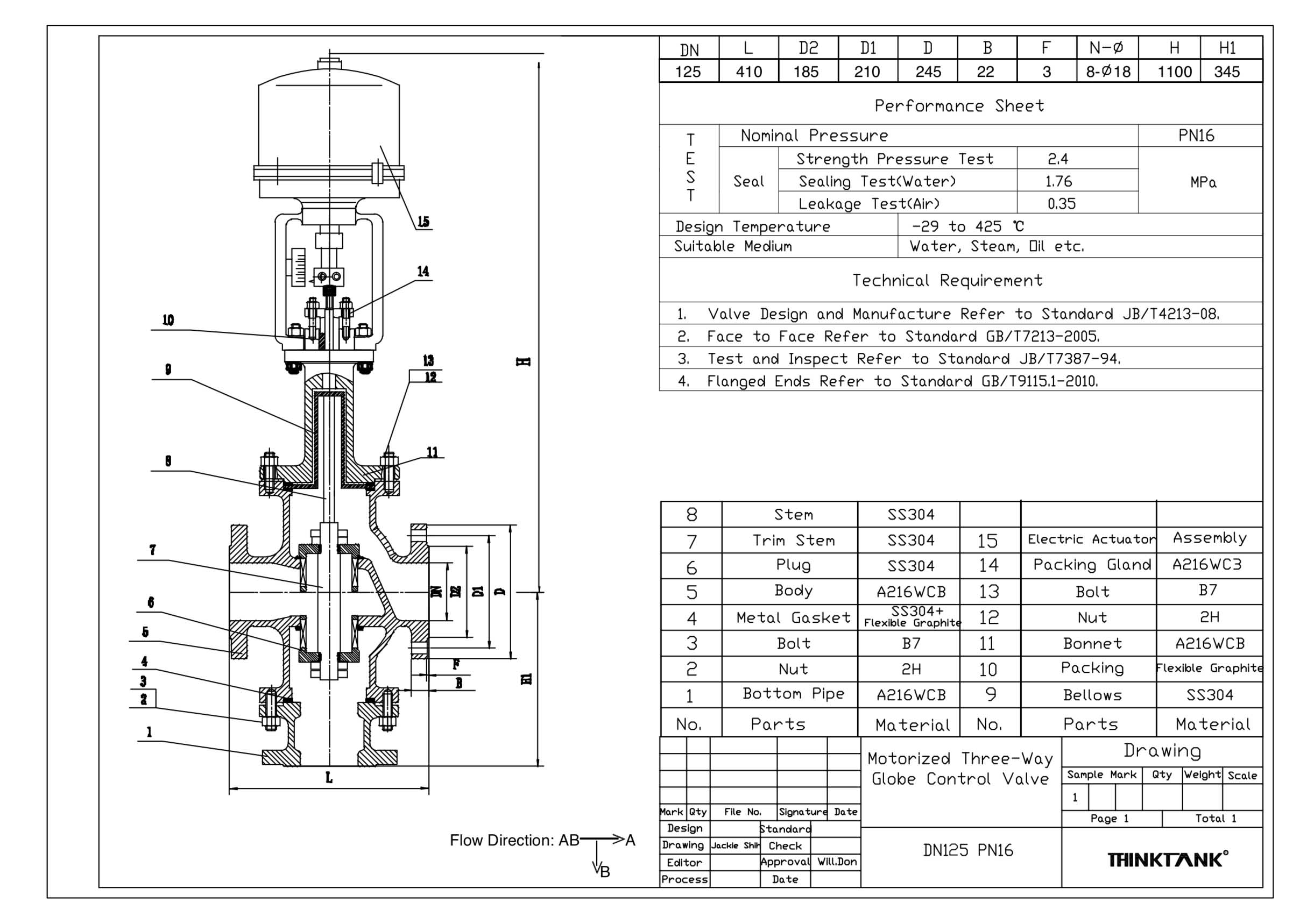

For thermal oil conditions required three-way control valve should bear a high temperature, around 350-degree centigrade, so it makes a more different design than other 3-way globe valves.

Three-Way Control Valves for Thermal/Heat Oil

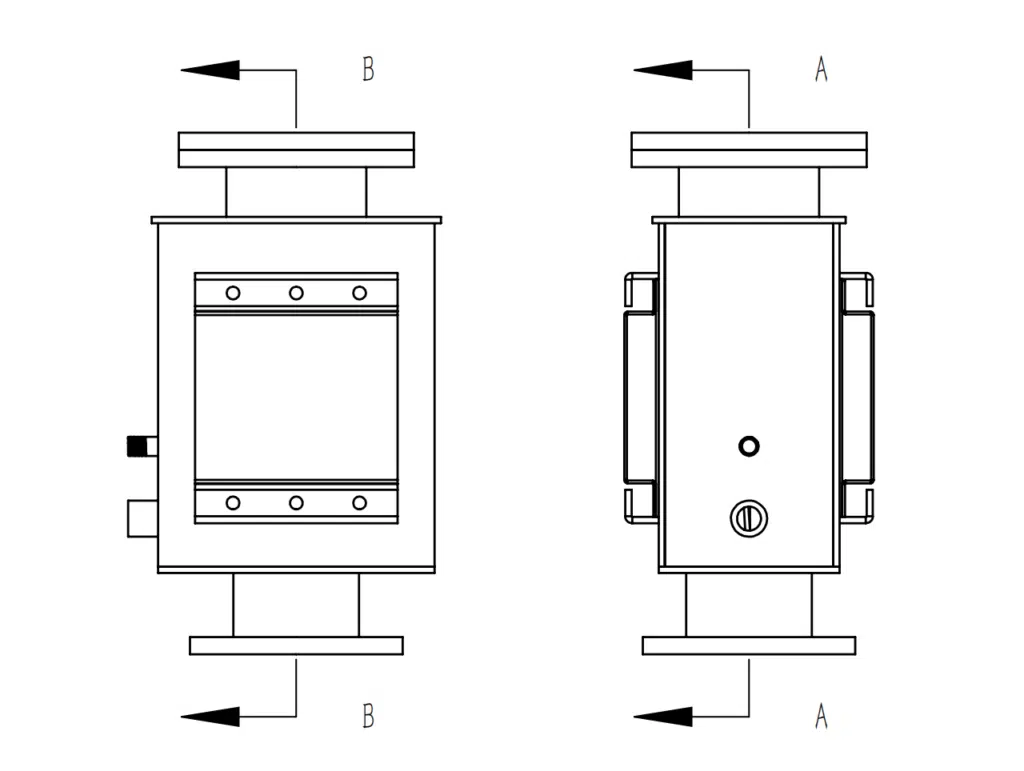

Three-way control valves are designed with three flow ports, AB, A and B port. This type of control valve modulates flow capacity and can be diverting flow to two outlet ports or mixing two inlets to one outlet port with different temperatures or pressures.

Difference Design of Three-Way Control Valve for Hot Oil

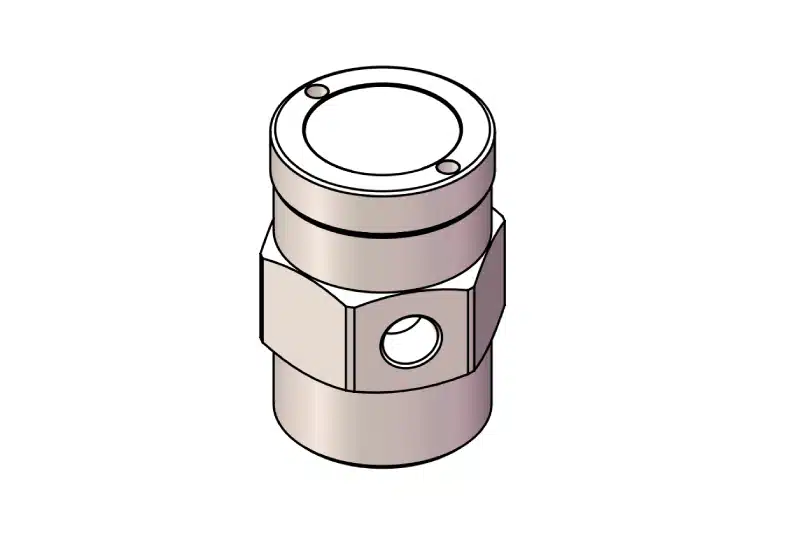

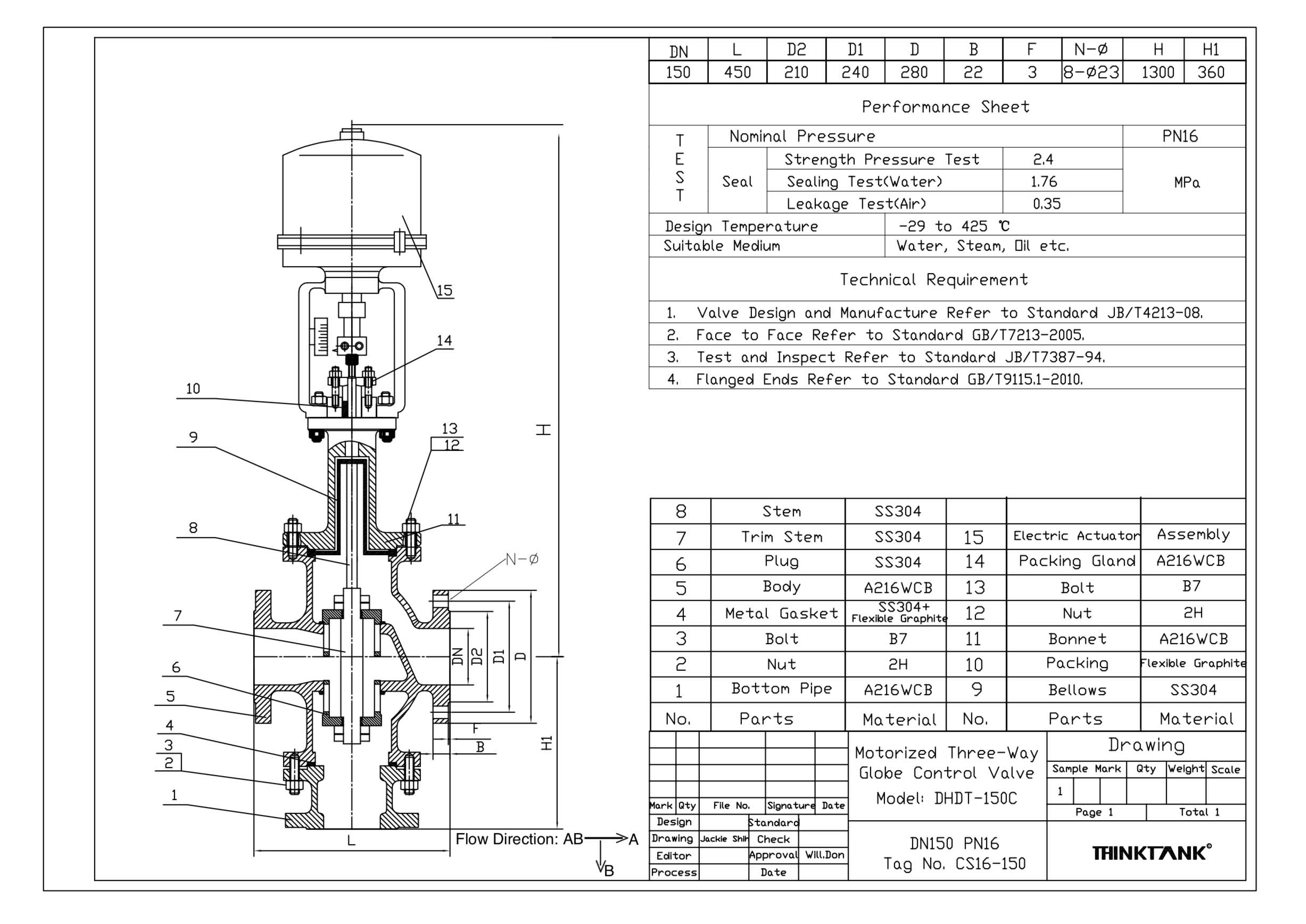

- Bonnet design. THINKTANK uses stainless steel bellows bonnet and flexible graphite packing as double sealing to protect the actuator performance and effectively isolate the medium in the pipeline from the outside, significantly improving the safety and reliability of the product seal.

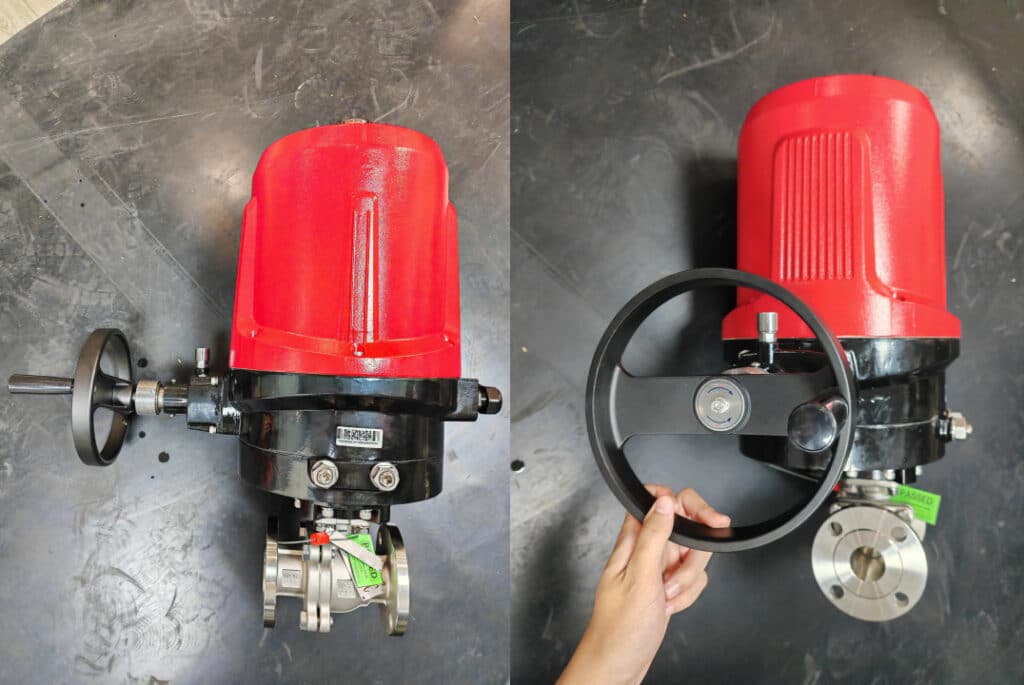

This 3-way control valve was specially developed for the oil furnace temperature control system of the heat setting machine in the textile machinery industry. - It usually assembles a pneumatic or electric actuator with a 4~20mA input signal or on/off control signal to change the valve opening. At the same time, the isolation signal of the valve opening will provide feedback to the control system.

- The thermal oil 3-way control valves generally flow to open, so their stability is better than others.

- The servo amplifier adopts deep dynamic negative feedback to improve adjustment accuracy.

- The electric/pneumatic three-way control valve used for heat-conducting oil saves automation. Compared with single-seat, double-seat, or sleeve/cage type globe control valves, the same system can save one unit valve, simplify the design and save cost for the end-users.

- There are many electric operators, which can be applied to 4~20mA or 0~10mA DC or 1 ~5V DC, 0 ~10V DC, with power supply 380V AC, 220V AC, 24 V DC, or just simply air supply 2 ~ 6 bars.

- If using an electronic actuator to control the valve opening by the current signal, no need servo amplifier.

- The bellows seal type bonnet will completely seal the moving stem, preventing any fluid leakage.

- The hot-oil 3-way control valve is not only guided by the bushing at the valve bonnet but also guided by the side of the valve plug and the inner surface of the valve seat, with a sizeable guiding area and reliable operation.

Case Study of Heat Oil Application(Motorized 3-Way Control Valve)

This liquid solution is for an Indian customer on a heat oil project. There is no control equipment such as a controller on-site, so we provide the integral solution according to the customer’s parameters.

Process Parameters

- Flow volume approx.: 120 m³/h

- Pressure head, approx.: 45 m l. c.

- Medium: Therminol 66

- Operation temperature: 280 °C

- Max. acceptable operating temperature: 335 °C

- Control valve with the actuator in 3-way execution with flanges and bellow sealing

- Nominal size: DN150

- Nominal pressure: PN16

- Valve function: Distribution function

- Actuator: Electric actuator prefer (ARI)

Solution & Valve Principle

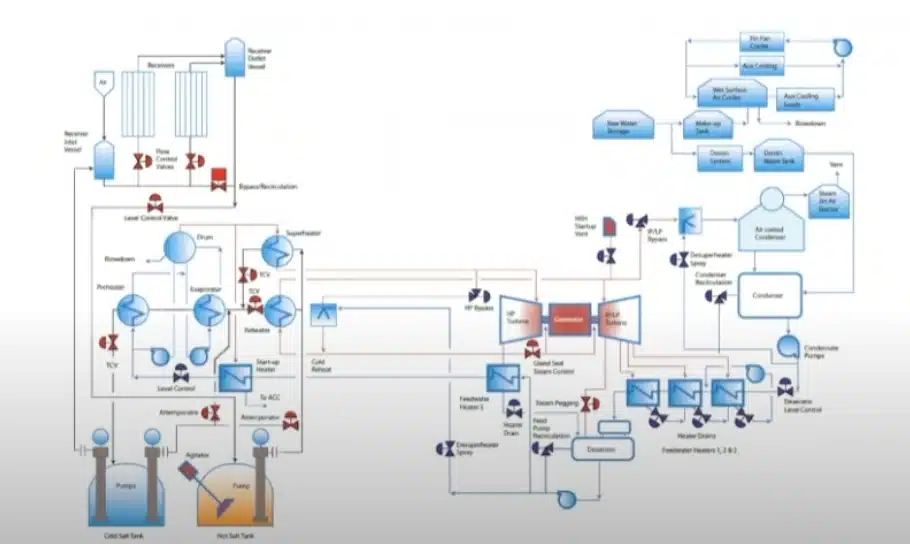

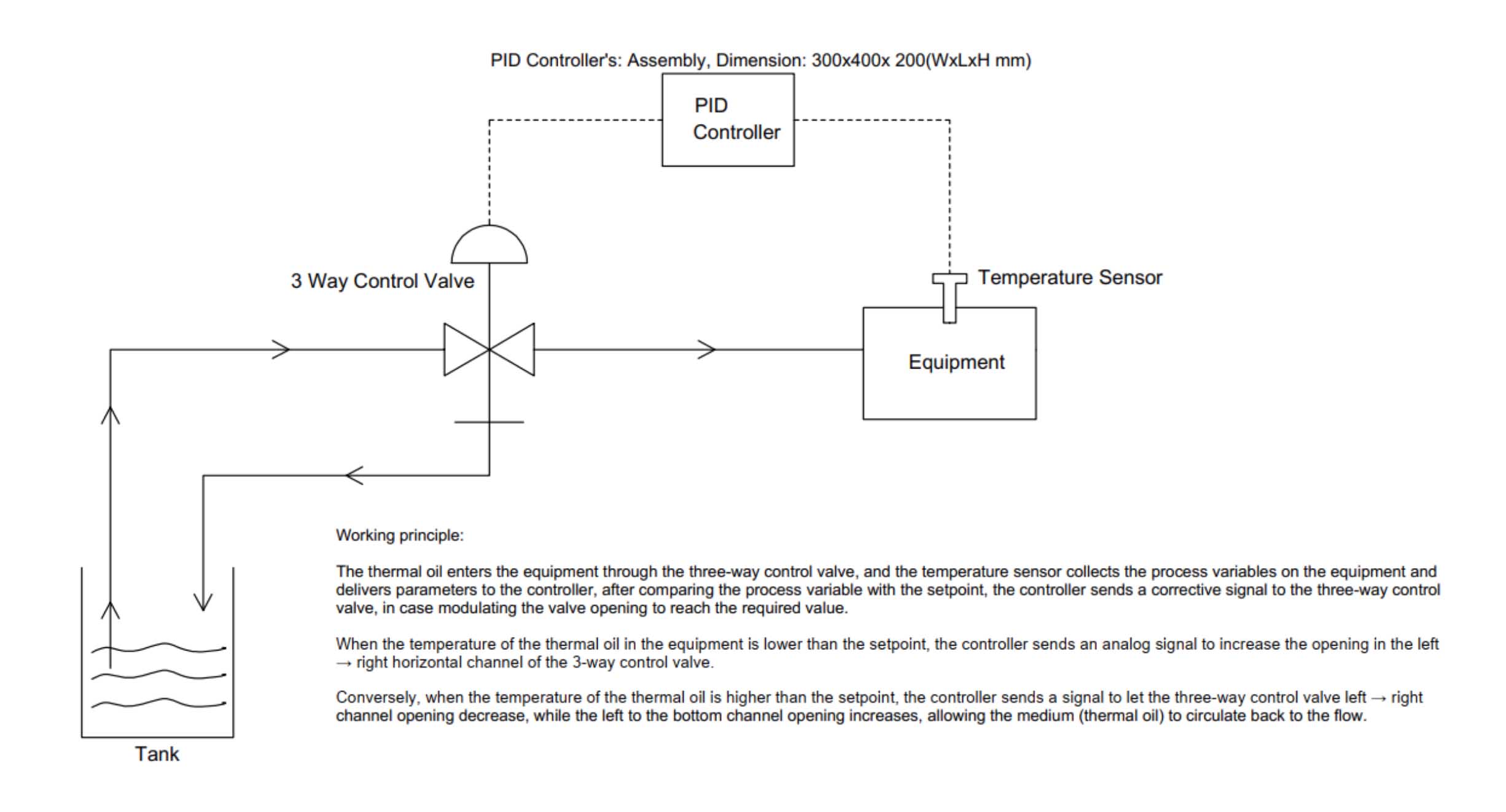

The thermal oil enters the equipment through the three-way control valve, and the temperature sensor collects the process variables on the equipment and delivers parameters to the controller. After comparing the process variable with the setpoint, the controller sends a corrective signal to the three-way control valve, in case modulating the valve opening to reach the required value.

When the thermal oil temperature in the equipment is lower than the setpoint, the controller sends an analog signal to increase the opening in the left → right horizontal channel of the 3-way control valve.

Conversely, when the temperature of the thermal oil is higher than the setpoint, the controller sends a signal to let the three-way control valve left → right channel opening decrease, while the left to the bottom channel opening increases, allowing the medium (thermal oil) to circulate back to the flow.

Thermal/Heat Oil Three-Way Control Valve Drawing

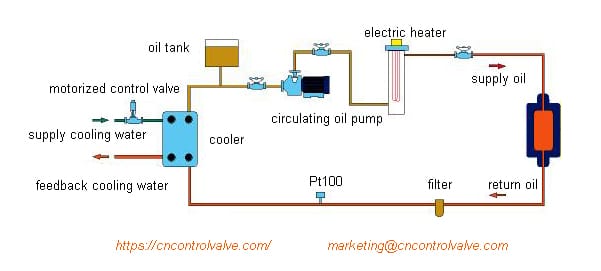

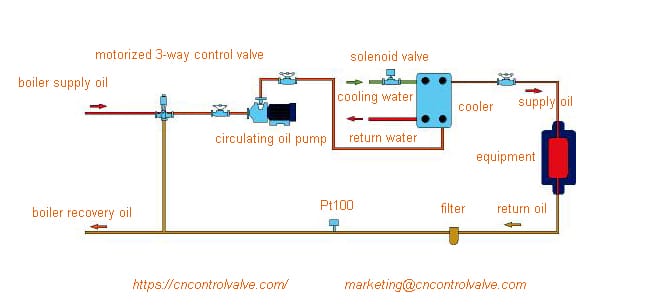

Principle and Composition of Thermal Oil Temperature Control Device

The thermal oil temperature control device comprises a circulating oil pump, electric heater, cooler, cooling valve, temperature sensor, oil tank, valve set, and controller panel. The temperature control device is especially suitable for high-temperature cooling needs (below freezing temperature) and is based on heating as the primary purpose, and the device is often cooling as a supplement.

The temperature control unit of the control panel (PLC or temperature control meter) is used to detect the return oil temperature through the temperature sensor, control (PID) the electric heater and cooling valve, and then control the heating and cooling process: after the oil is heated by the heater, the heat is transferred to the equipment through the forced circulation of the oil pump, and the oil is discharged in the equipment and heats up the equipment. After exothermic and heating the equipment, the temperature drops and then circulates to the heater for circulating heating; when the temperature exceeds the set temperature, the heater stops, and the cooling valve (or fan) is opened for cooling to keep the device temperature constant at the set working temperature.

The independently installed oil tank has three functions oil replenishment, exhaust, and expansion to ensure the stable operation of the thermal oil temperature control device.

Device Features

- Take thermal oil as a working medium, and realize high-temperature operation under normal pressure. The commonly used temperature range is 0~400℃.

- Nickel-chromium alloy electric heating tube, PT100 temperature sensor.

- The heat-conducting oil pump adopts a high-temperature mechanical seal.

- The control cabinet adopts a SIEMENS touch screen and PLC, FUJI temperature control meter, and Schneider electric apparatus.

- PID automatic adjustment function of temperature control process can realize temperature control accuracy: ±1℃, working temperature can be set at any time.

- The control panel has over-temperature, oil shortage, dry burn, overload protection, and automatic exhaust function.

- Temperature control device entire skid-mounted factory, each temperature control independently.

In conclusion

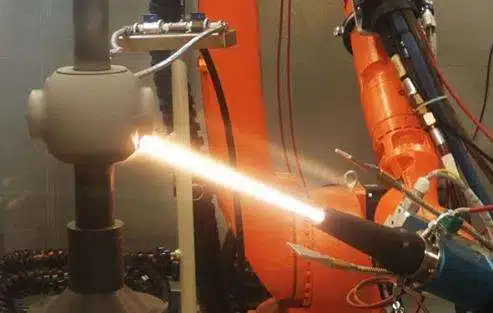

As a reliable valve manufacturer, THINKTANK provides many valve solutions for our customers, such as expansion cooling tubes, stainless steel bellows bonnet, and balanced/unbalance cage guided trims to satisfy unique conditions. Generally, our stainless steel bellows are suitable for the valve operating temperature range of 662 °F efficiently. So, these control valves can regulate thermal oil or heat oil, hot oil, high-temperature water, steam, and other critical media. If you are interested in more information, please just feel free to contact us by email marketing at cncontrolvalve.com