Industrial valves play a crucial role in controlling and regulating the flow of liquids, gases, and slurries in a wide range of industries. Their primary function is to maintain and control pressure, temperature, and flow in various systems. In this article, we will explore the different types of industrial valves, their applications, and how they function.

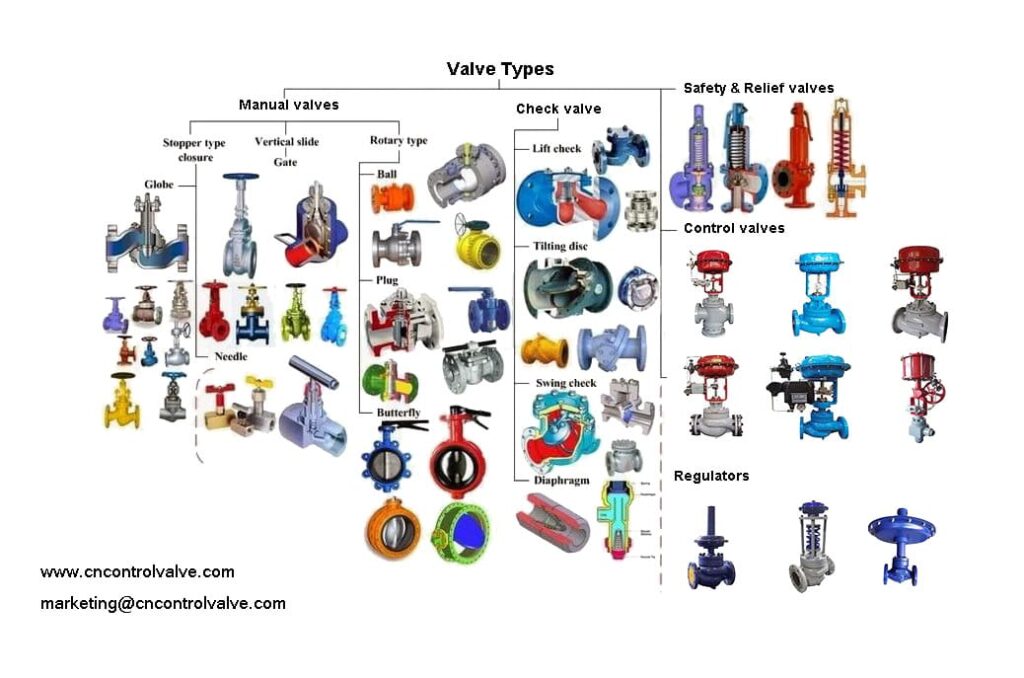

Classification of Industrial Valve Types

Industrial valve types can be broadly classified based on their design, function, and mode of operation. Here, we will discuss the most common valve types.

Gate Valves

Gate valves, also known as sluice valves, are designed for on/off service and are used to isolate or shut off flow in a pipeline. They consist of a movable gate or disc that slides to open or close the valve, providing a straight flow path with minimal resistance. Gate valves are widely used in the oil and gas industry, water supply, and other industrial applications.

Globe Valves

Globe valves are used for regulating and throttling flow in pipelines. They feature a spherical body with a movable disc or plug that sits on a stationary seat. By raising or lowering the disc, the flow can be adjusted to the desired level. Globe valves are commonly used in chemical, petrochemical, and power generation industries.

Ball Valves

Ball valves are characterized by a spherical ball with a hole through its center, which can be rotated to control the flow of fluid. They provide tight shutoff and fast on/off operation, making them suitable for high-pressure applications. Ball valves are commonly used in oil and gas, chemical, and petrochemical industries.

Butterfly Valves

Butterfly valves consist of a circular disc mounted on a rotating shaft, which opens and closes by rotating the disc at a 90-degree angle. They offer a compact design and are used for regulating flow in large pipelines. Butterfly valves are widely used in water and wastewater treatment, food and beverage, and HVAC systems.

Diaphragm Valves

Diaphragm valves use a flexible diaphragm to separate the valve body from the flowing medium. By compressing the diaphragm against a valve seat, flow can be controlled. These valves are known for their excellent sealing capabilities and are commonly used in the pharmaceutical, food and beverage, and biotechnology industries.

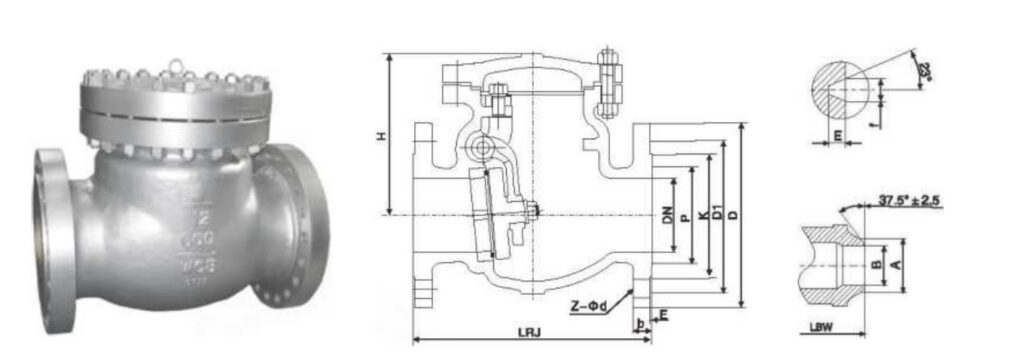

Check Valves

Check valves, also known as non-return valves, prevent backflow in a system by allowing fluid to flow in one direction only. They utilize a swinging, tilting, or lifting mechanism that automatically closes when the flow reverses. Check valves are commonly used in water supply systems, chemical processing, and power generation.

Plug Valves

Plug valves consist of a cylindrical or conical plug with a hole through its center, which can be rotated to control the flow. They offer excellent shutoff capabilities and are used in a variety of applications, including oil and gas, chemical, and petrochemical industries.

Pressure Relief Valves

Pressure relief valves protect systems from overpressure by releasing excess pressure when it exceeds a predetermined limit. They are essential safety devices in many industries, such as oil and gas, chemical, petrochemical, and power generation.

Needle Valves

Needle valves are characterized by a long, tapered needle-like stem that can be adjusted to control flow with precision. They are ideal for low flow rate applications and are commonly used in instrumentation, test equipment, and gas distribution systems.

Control Valves

Control valves regulate flow, pressure, and temperature in a system by responding to signals from a controller. They can be operated manually or automatically, using pneumatic, hydraulic, or electric actuators. Control valves are widely used in process control and automation across various industries.

Solenoid Valves

Solenoid valves are electrically operated valves that control the flow of fluids and gases by opening and closing a passageway in response to an electrical signal. They are commonly used in automation systems, fluid power systems, and various industrial processes.

Valve Material Selection

Selecting the right material for an industrial valve is crucial for ensuring optimal performance and longevity. Common materials used in valve construction include:

- Cast iron

- Ductile iron

- Carbon steel

- Stainless steel

- Brass

- Bronze

- Alloy steel

- Plastic

The choice of material depends on factors such as temperature, pressure, corrosion resistance, and the nature of the fluid being handled.

Conclusion of Industrial Valve Types

Industrial valves are essential components in a wide range of applications and industries. Understanding the different valve types, their functions, and their applications can help in selecting the right valve for a specific application. Proper valve selection and maintenance are crucial for ensuring the safety, efficiency, and reliability of industrial processes.