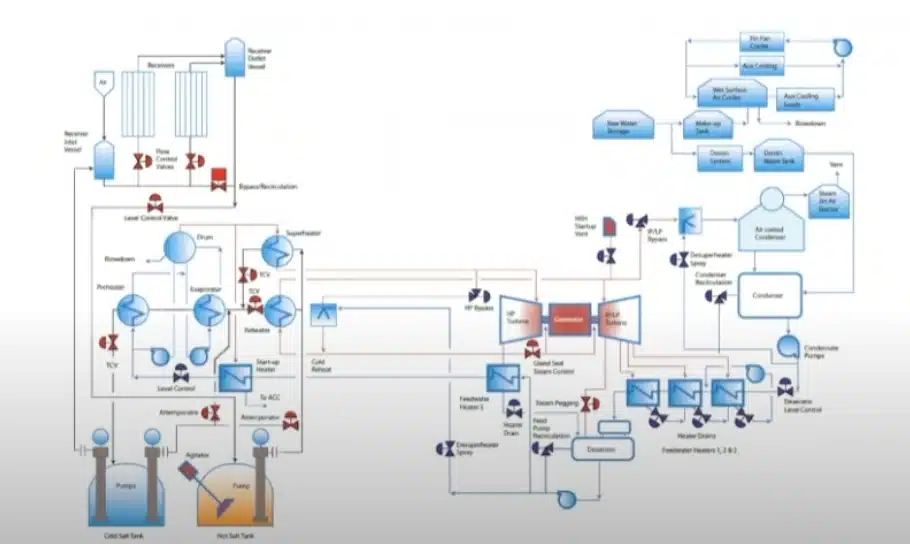

If you are a purchase manager or a mechanical engineer, an instrument named flow meter you will always meet, but not expert on it. The flow meter is used in mining, oil and gas, chemical, and power plants. The main purpose of the flow meter is used to measure the quantity of material flowing in the pipelines, it means to calculate the flow rate of a substance through a specified flow section.

Here’s everything you will learn in this guide:

- What is Flow Metering

- What are the Different Types of Flow Meters

- What Affects Flow Meter

- How is Flow Meter Measured

- What is Flow Metering

- Flow Meter Installation

- Why do We Measure Flow

- Which Type of Flowmeter is Most Accurate

The rate of flow across a specified flow segment is the primary metric for flow metering. In order to maximize the effectiveness of automated manufacturing, flow metering must be incorporated into every technical process flow chart.

Each kind has a unique method for determining the flow rate of a fluid. Today’s market offers five primary types of flowmeters, including differential pressure flowmeters, velocity flowmeters, positive displacement flowmeters, mass flowmeters, and open-channel flowmeters.

Existing flowmeters are classified as follows:

Flow meters are based on hydrodynamic methods: variable differential pressure, variable level, streamline flow, vortex method, as well as others.

Flowmeter with continuous motion objects: speed, power, etc.;

Flowmeters are based on various physical phenomena: thermal, electromagnetic, acoustic, optical, etc.

What are the Two Types of Flow Meters?

For Beginners, we just simply first categorize two types of flow meters based on the medium state: gas and fluid or liquid. Fluid flow meters have 5 subcategories: differential pressure flowmeter, velocity flowmeter, positive displacement flowmeter, mass flow flowmeter, and open-channel flowmeter.

What Affects Flow Meter?

Variables like temperature, viscosity, pressure, and conductivity may all impact the accuracy of specific types of flow meters. The quality of the water may also be a factor in determining the flow meter’s design. Knowing the properties of the flow being monitored is the next stage in selecting a flow meter.

What are the Different Types of Flow Meters?

In the previous paragraph, we learned that there are 5 main types of flow meters, and now we introduce them one by one.

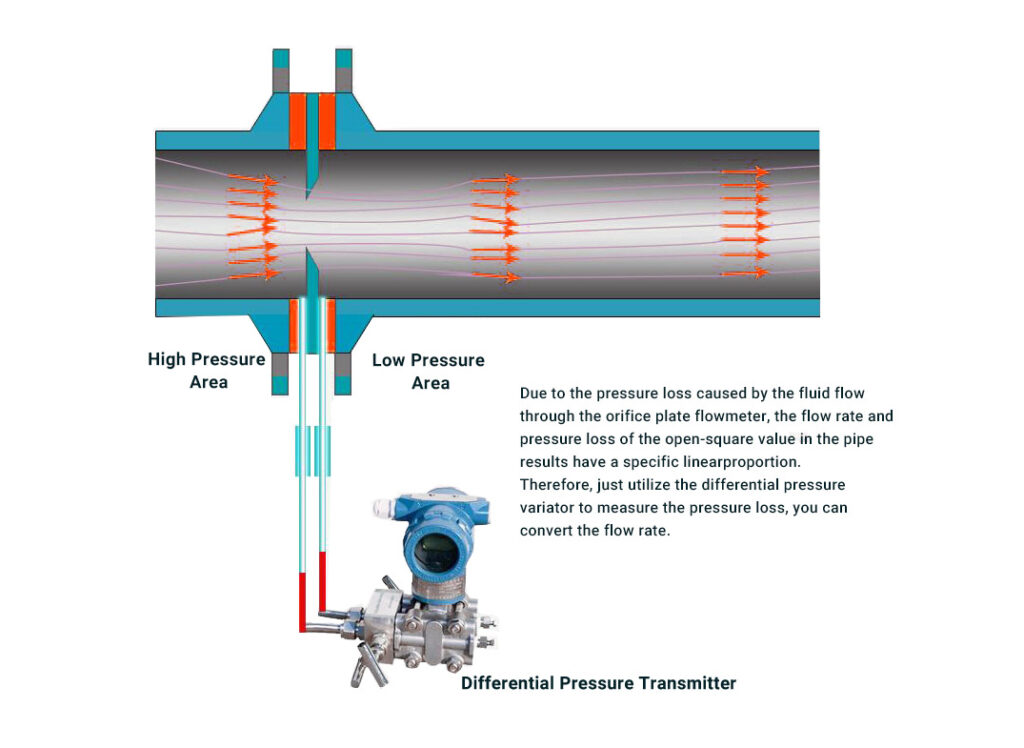

1. Differential Pressure Flow Meters

Most water and gas flow meters use differential pressure technology. Experience speaks for itself in the form of numerous appearances. Whether it’s gas, liquid, or steam, the differential pressure flow meter can detect the number of gases, steam, or liquids that are moving through a system. They find particular utility in applications where extremes of pressure, temperature, or diameter are present. You can find them in the petrochemical, natural gas, power plant, and chemical industries.

Typical Types of Differential Pressure Flow Meters Include:

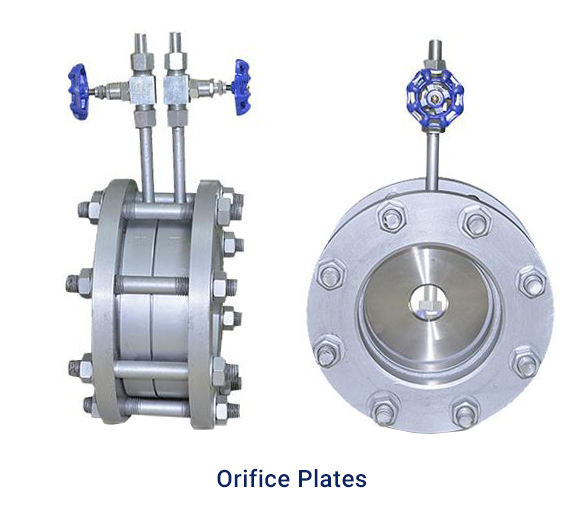

Orifice Plates

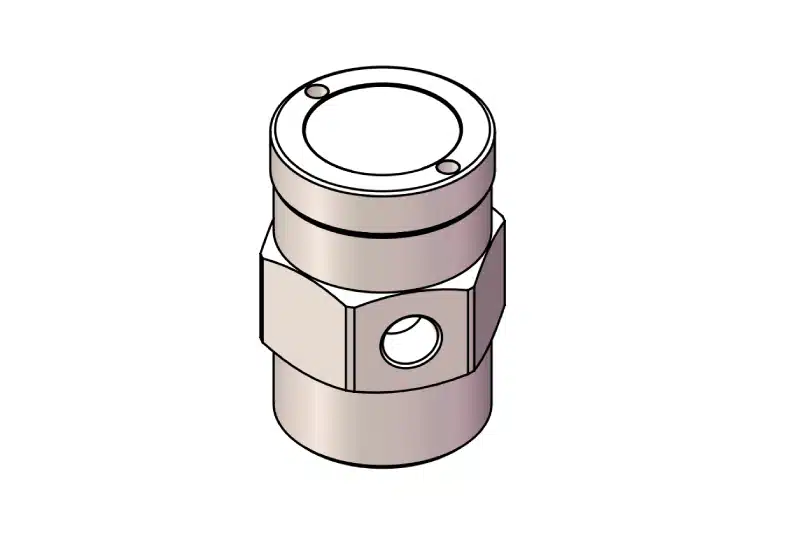

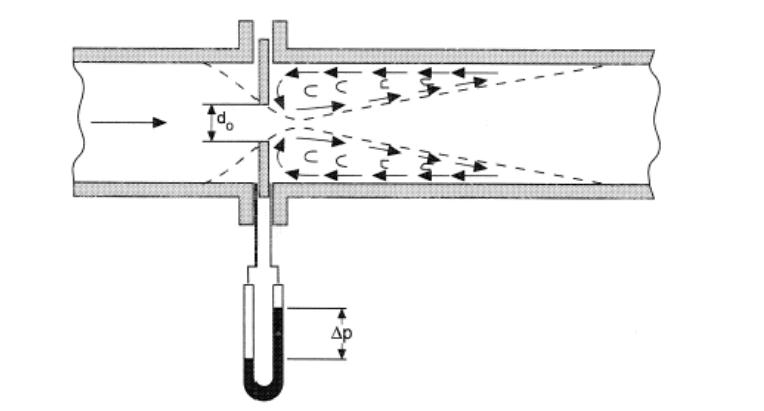

Orifice Plate Flow Meter Systems monitor the change in the flow’s pressure from upstream to downstream when the flow is partially obstructed in the pipe.

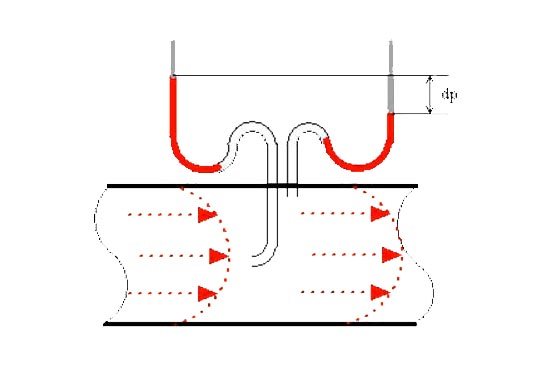

Flow Nozzles

A Flow Nozzle is an inexpensive and basic design of a venturi meter. The nozzle is fixed between the ends of the material-carrying pipe. A differential pressure sensor monitors pressure decreases in order to calculate the flow rate.

Venturi Tubes

Venturi Flow Meters monitor liquid flow rate and measure the change in pressure caused by a flow path’s cross-sectional flow area.

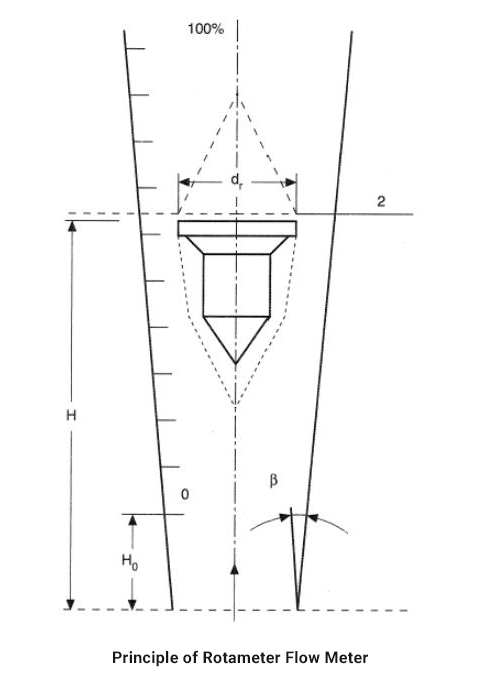

Rotameters

Rotameters are variable flow meters that measure the force of gravity acting on a fluid by rotating a float that travels vertically through a tapered tube. They are frequently employed for liquid and gas measurements. Rotameters are simple, affordable, monitor low pressure drops, and have linear output and a large variety of conditions.

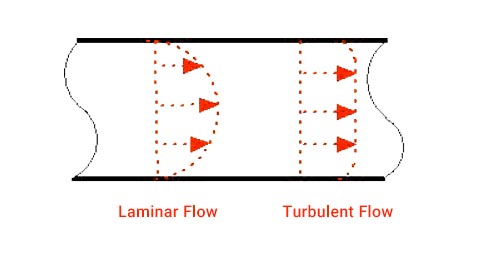

2. Velocity Flow Meter

Flow velocity is measured with velocity flow meters. They generate a reading by monitoring the flow’s depth and average air velocity, enabling engineers to maintain the appropriate flow throughout the stream. The range of velocity flow meters is higher than that of differential pressure flow meters. There are pilot tubes, calorimetric, turbines, and electromagnetic velocity flow meters.

Pilot Tube

Utilized in ventilation and HVAC systems, Pilot Tube Flow Meters measure flow velocity by converting kinetic energy to potential energy.

Calorimetric Flow Meters

Calorimetric Flow Meters, also known as thermal flow monitors, determine the distinction between continuous and controlled heating using the principles of heat transfer. The first sensor monitors the temperature of the heating element, while the second measures the temperature of the fluid.

Turbines

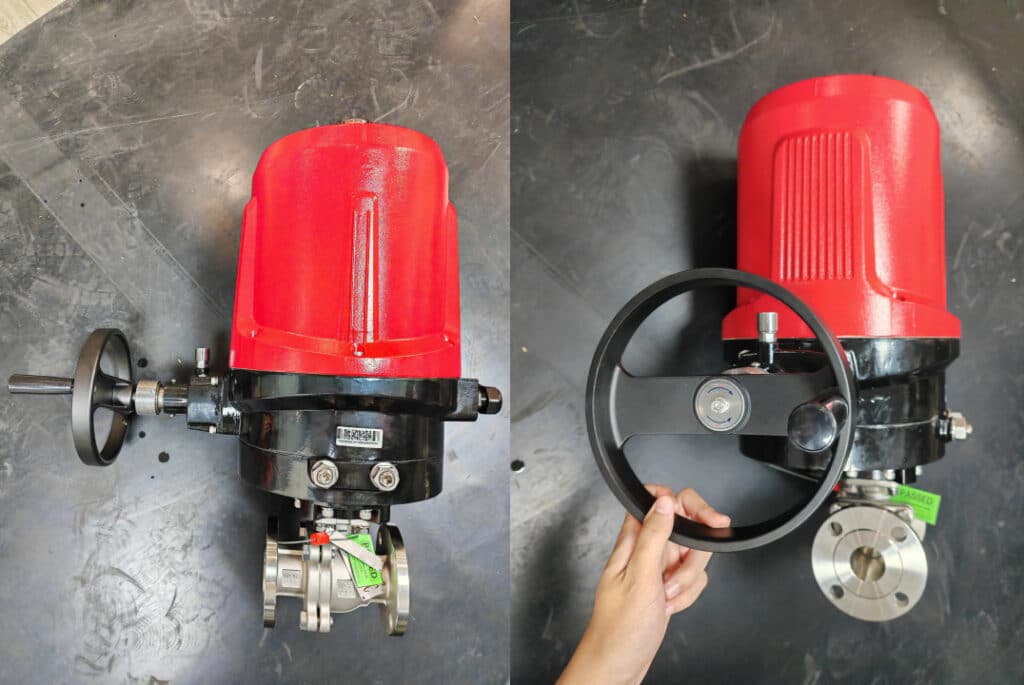

Turbine Flow Meters are used with clean and viscous liquids with an accuracy of 0.5% to measure the turbine’s speed. They have a rotor with many blades placed perpendicular to the flow. The output frequency is a sine wave or square wave. Signal conditioners can be put on them, but only on categories that are explosion-proof.

Electromagnetic Flow Meters

Electromagnetic Flow Meters sometimes referred to as magnetic flow meters, are volumetric devices that employ Faraday’s law of electromagnetic induction.

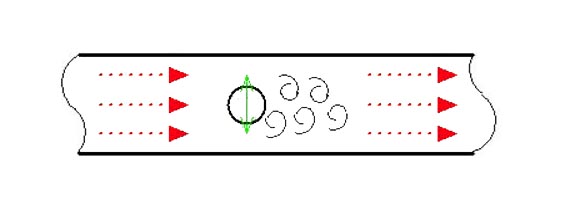

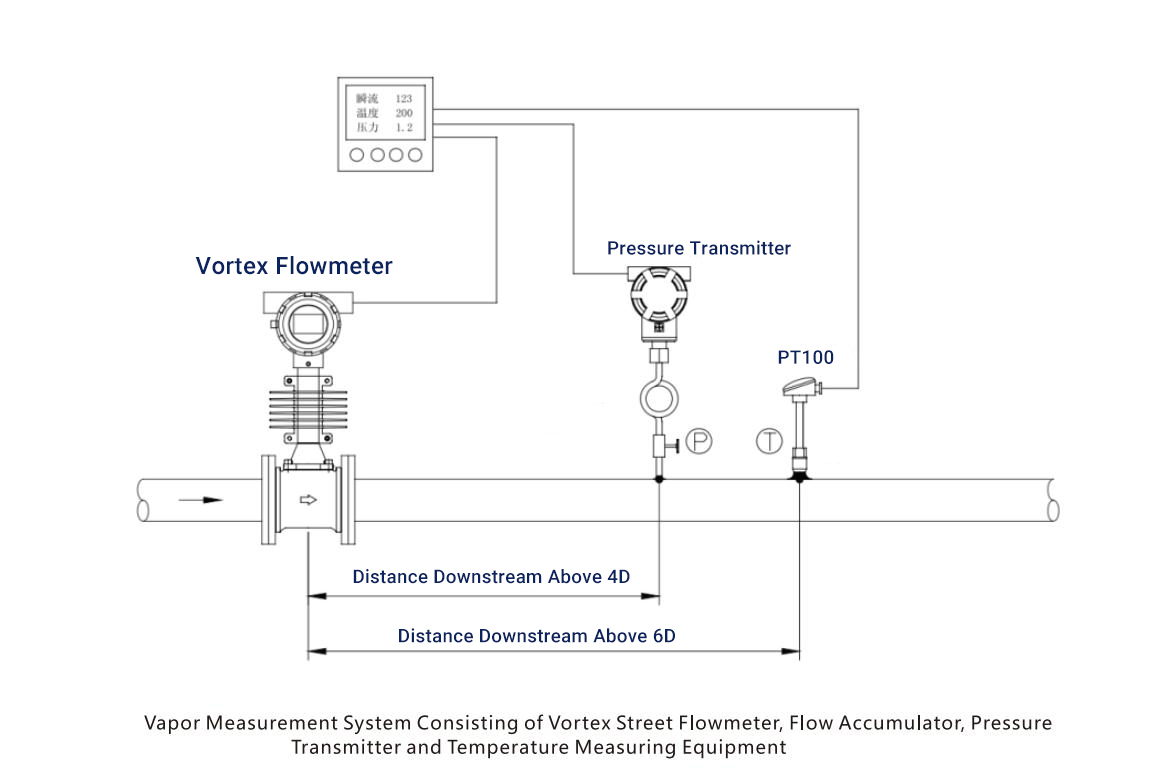

Vortex Flow Meters

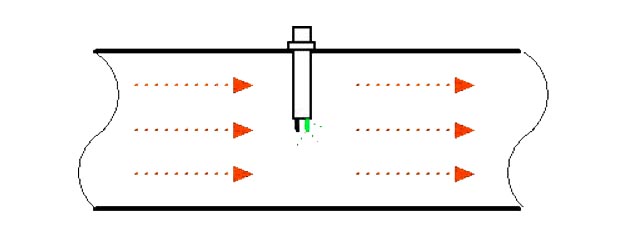

Vortex Flow Meters assess flow rate by placing a barrier directly in the flow channel, causing liquids or gases to go around the impediment. Flow around the barrier generates two symmetrical vortices on the opposite side, altering the flow’s pressure. Between the vortices, a flow sensor records pressure fluctuations.

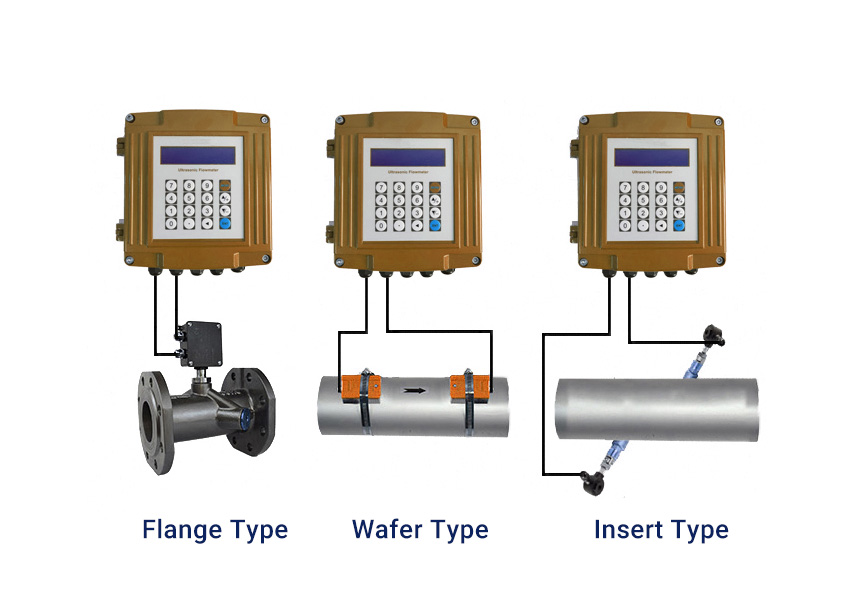

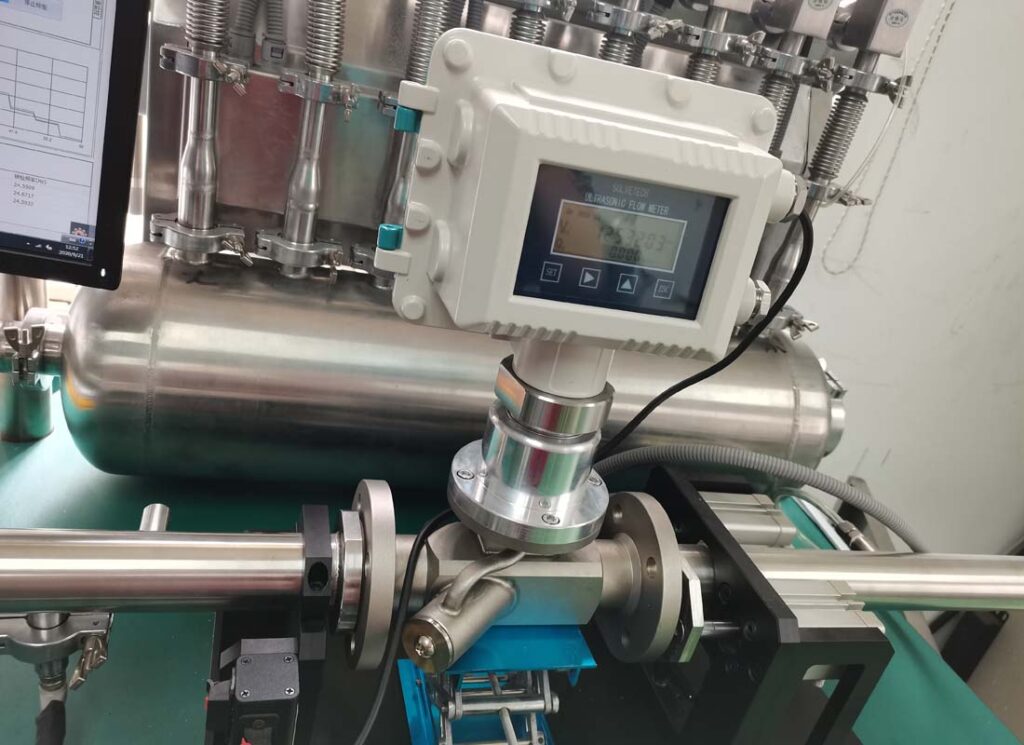

Ultrasonic Flow Meters

Ultrasonic Flow Meters compute flow volume by measuring fluid velocity using ultrasound. There are two varieties of ultrasonic flow meters: in-line and clamp-on. In-line ultrasonic meters consist of two sets of ultrasonic devices oriented in opposition and put into the flow pipe. Clamp-on devices utilize the same two components, but neither device is placed into the pipe.

Hydraulic Flow Meters

Hydraulic Flow Meters are utilized for testing, diagnosing, and maintaining hydraulic systems by measuring the flow rate or volume of a liquid within a hydraulic system. They evaluate the system’s efficiency and effectiveness and fix any issues that arise.

Air Flow Meters

Air Flow Meters monitor air pressure and velocity. They are suitable for obtaining rapid, consistent measurements of ventilation systems and for process monitoring.

3. Positive Displacement Flow Meter(PD flow meters)

Positive displacement flow meters use rotors as sensors to detect viscous liquid flow. By using vanes, gears, pistons, or diaphragms, airflow is displaced. The rotation of the rotors is proportional to the flow volume. They are utilized for measurements when a straight pipe is unavailable or as a substitute for turbine meters and paddlewheel sensors when the flow is too turbulent.

4. Mass Flow Meters

The volumetric flow rate is calculated by dividing the mass flow rate by the fluid’s density using a mass flow meter. It employs the Coriolis Effect, an inertial force that operates on moving objects inside a given reference point. The thermal Mass Flow Meter employs two sensors to monitor temperature, an active heat sensor to measure heat loss in the liquid, and a flow meter to calculate the flow rate.

Mass Gas Flow Meters or Coriolis Flow Meters are based on motion mechanics and the Coriolis Effect. When fluid enters a sensor, it is divided, causing the sensor’s tubes to vibrate and produce a sine wave. The mass flow rate is determined by the time delay between the oscillations of the two tubes. They are used for checking for leaks and measuring low flow rates.

5. Open Channel Flow Meters

Digital Flow Meters are any devices with a digital display that measures flow. Power providers utilize a standard digital meter to monitor the flow of energy to your home and to transmit your usage statistics to the electrical company, which uses the information to bill you.

Additional Types of Flow Meters

Slurries, water, and other closed-pipe fluids are measured using water flow meters. Liters or cubic meters are used to express the flow rate.

Fuel flow meters count the volume of liquid being moved. The user may see on a mechanical or digital display how much fuel has been transferred during a transaction.

Peak flow meters evaluate lung capacity and are used to treat breathing problems. By breathing into the mouthpiece, which records the volume of air taken in per minute in liters, the portable, low-cost gadget assesses lung capacity.

An operator can see a liquid as it passes through a pipe thanks to flow indicators. They are a component of an industrial process that requires an instantaneous inside view of the flow within a pipe and are sometimes referred to as sight flow indicators. The mass or speed of the flow is not calculated or measured by flow indicators. They are the most basic type of flow meter and have no moving components, they are often referred to as plain sight indicators.

How is Flow Meter Measured?

Different type of meter measure has different working principles, so let’s learn how each type of flow meter is measured.

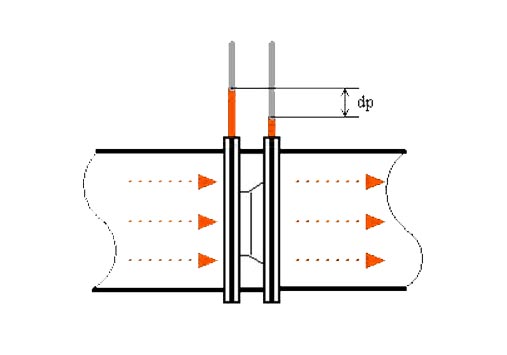

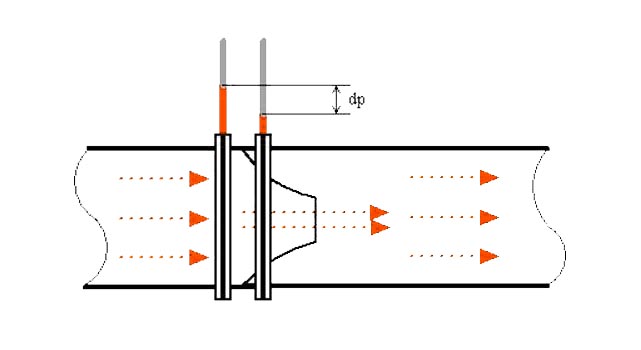

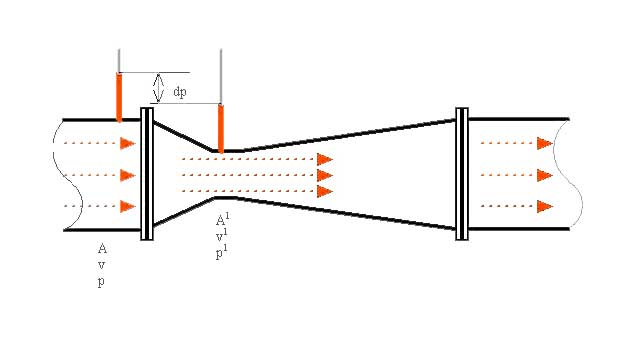

1. Principle of Differential pressure flowmeter/Orifice

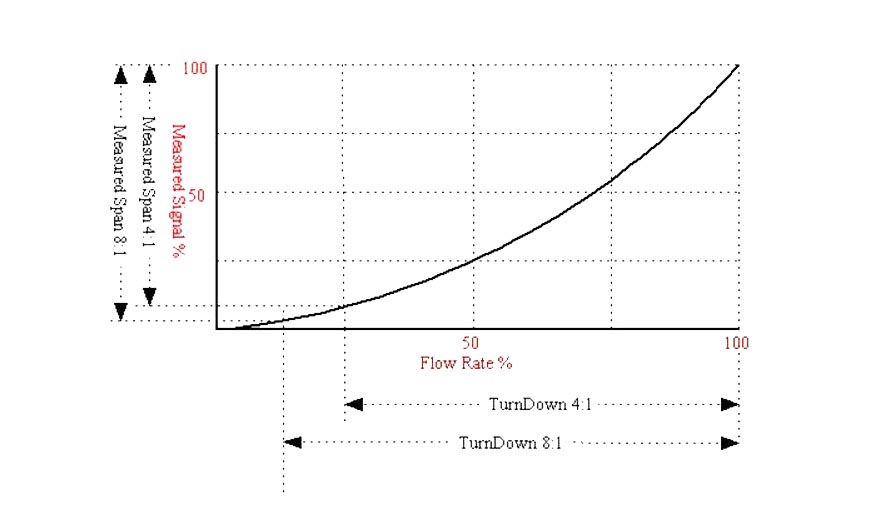

The flow is determined in a differential pressure drop device by measuring the pressure drop over blockages inserted in the flow. The differential pressure flow meter is based on the Bernoulli Equation, which states that the pressure drops and subsequently measured signal are functions of the square flow speed.

DP(△P) = ρv2 / 2 (1)

where

DP(△P) = Differential Pressure (Pa, psi)

ρ = Fluid Density (kg/m3, slugs/ft3)

v = Flow Velocity (m/s, in/s)

Note that it is common to use “head” instead of “pressure”

h = DP / γ (2)

where

h = Head (m, in)

γ = Specific Weight (N/m3, lb/ft3)

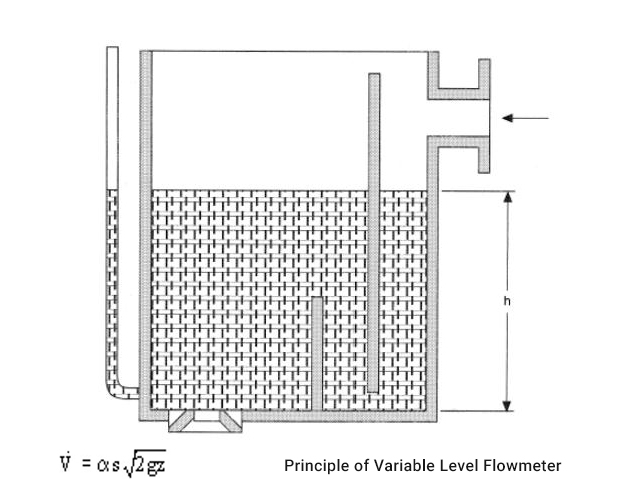

2. Principle of Variable Level Flowmeter

A liquid is continuously pumped into the vessel while simultaneously flowing out of a hole in the bottom or a side wall. Variable-level flowmeters are based on the relationship between flow rate and the height of the level in the vessel. The main transformer is a container with an aperture of area S. The liquid level in the vessel’s height is what is being measured, and the flow rate, which is the flow rate coefficient, is determined from the relationship ![]() and is independent of the liquid’s density.

and is independent of the liquid’s density.

Slit flowmeters, which are tiny weirs in the wall of a vessel into which a liquid is continuously delivered, are frequently used to measure the flow rate of liquid in open channels (trays). The height of the liquid level over the lower edge of the slit determines the flow rate. A flowmeter of this type has the following characteristics, which are determined by the shape of the slit cross-section: The flow rate ![]() for a rectangular slit that is b1 wide and b2 high, profiles b1(b2) have been designed on which they are applied and a linear relationship

for a rectangular slit that is b1 wide and b2 high, profiles b1(b2) have been designed on which they are applied and a linear relationship ![]() is established.

is established.

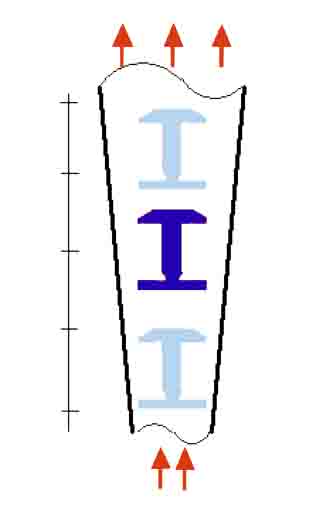

3. Principle of Rotameter Flow Meter

The primary transformer in streamlined flow flowmeters absorbs the dynamic pressure of the flow and moves under its action by a value proportional to the flow rate. The most common are constant pressure differential flowmeters, in which a streamlined body glides vertically and the weight of the body produces a counterforce.

Among these are Rotameters flowmeters, as well as floating and piston-type (slide valve) flowmeters. The rotameters are manufactured in the shape of a vertical conical (conicity, 0.001-0.01), upwards diverging glass pipe on which the graduations are created, a float travels inside the pipe with inclined ribs on its upper rim.

The float rises and spins in response to the flow, ensuring that the float is centered in the center of the flow. The height z of the float lift determines the volume flow rate of the liquid. ![]() It is proportional to the size of the circular gap Sc(z) between the pipe walls and the float and is dependent on the float parameters (volume Vf, midsection area Sf = (/4)df2 and density of the float material (f).

It is proportional to the size of the circular gap Sc(z) between the pipe walls and the float and is dependent on the float parameters (volume Vf, midsection area Sf = (/4)df2 and density of the float material (f).

In specific measurement settings![]() , the relationship Sc(z) is virtually linear for tiny pipe taper angles. Where A is determined by an initial calibration Float flowmeters work in the same way. Under the operation of a dynamic head, the piston in a piston-type flowmeter travels in a bush with specially formed windows through which the liquid flows out at a flow rate

, the relationship Sc(z) is virtually linear for tiny pipe taper angles. Where A is determined by an initial calibration Float flowmeters work in the same way. Under the operation of a dynamic head, the piston in a piston-type flowmeter travels in a bush with specially formed windows through which the liquid flows out at a flow rate ![]() .

.

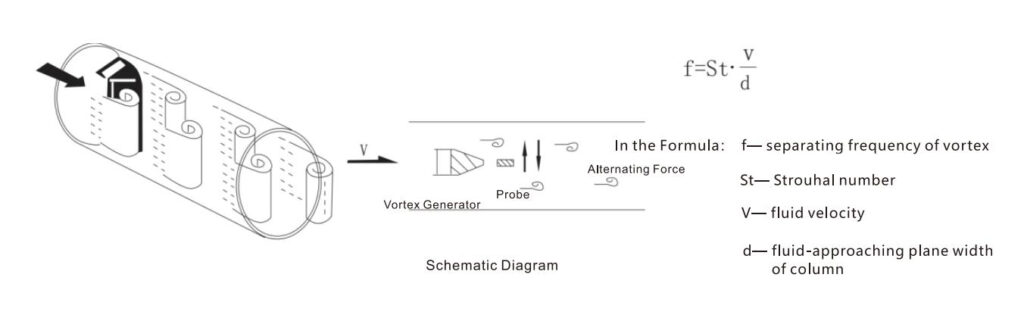

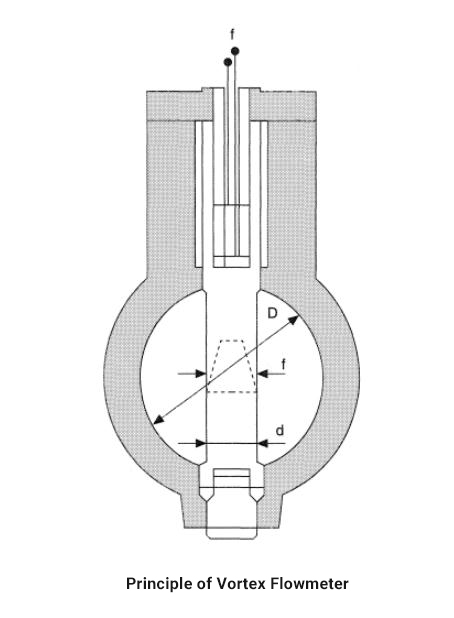

4. Principle of Vortex Flowmeter

The frequency of fluctuations in pressure or velocity that occur in the cross-flow across a body (cylinder, prism, plate) is calculated and depends on the flow rate in vortex flowmeters. The Strouhal number Sr = du-1f relates the frequency f to the mean streamlining velocity u and the body size d. The flow rate for a flow section area S = (π/4)D2 is determined by the relation![]()

Sr = const ensures proportionality between ![]() and f, which is attained when the cylinder is streamlined across the range 104 ≤ Ro ≤ 2 × 105 (Ro = ωd/u is the Rossby number). This guarantees that the observed flow rate has a wide range

and f, which is attained when the cylinder is streamlined across the range 104 ≤ Ro ≤ 2 × 105 (Ro = ωd/u is the Rossby number). This guarantees that the observed flow rate has a wide range![]() .

.

However, ![]() is constrained by the circumstances of sustained vortex formation (for example, water u > 0.2 m/s). Typically, primary transformers with d/D values between 0.15 and 0.2 are utilized (D is the diameter of the pipeline). The pressure pulsations are converted into an electric signal using piezo ceramic pressure pickups. Flow rate measurement error is estimated to be 0.5-1.5%.

is constrained by the circumstances of sustained vortex formation (for example, water u > 0.2 m/s). Typically, primary transformers with d/D values between 0.15 and 0.2 are utilized (D is the diameter of the pipeline). The pressure pulsations are converted into an electric signal using piezo ceramic pressure pickups. Flow rate measurement error is estimated to be 0.5-1.5%.

5. Principle of Turbine Flowmeter

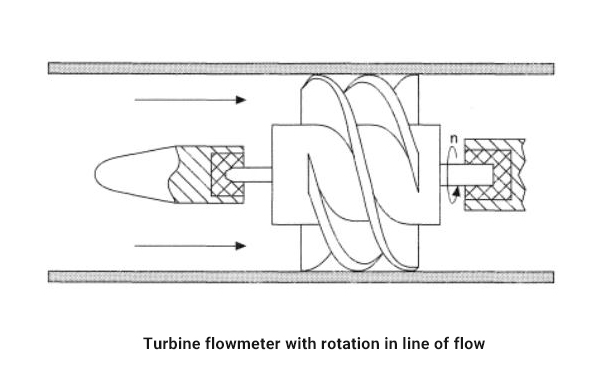

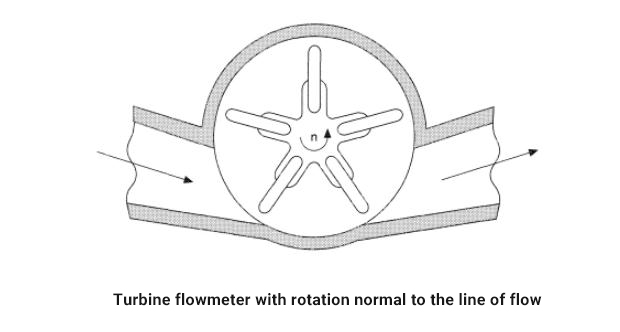

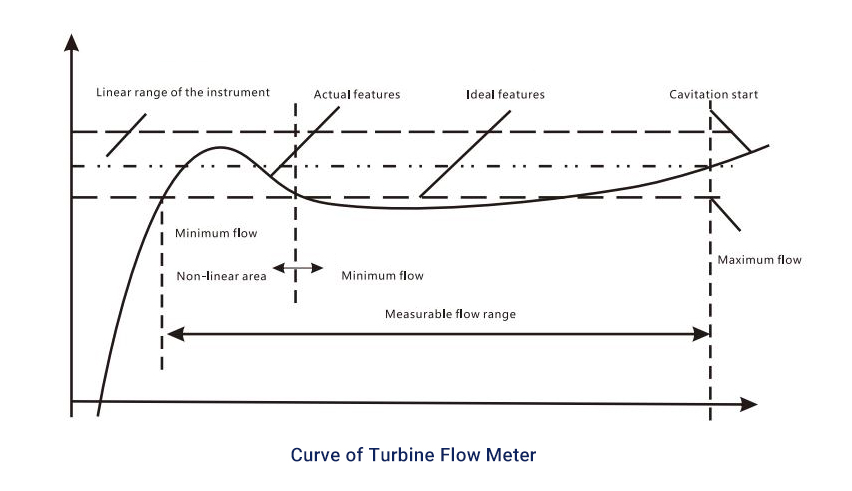

Tachometric flowmeters have a rotary element whose measuring velocity is proportional to the volume flow rate.

Flowmeters in the shape of a miniature turbine have found wide applications, with the rotational speed of the turbine being determined by the frequency meter’s measurement of the number of electric pulses per unit of time. Turbine flowmeters are built as either an axial small turbine (Turbine flowmeter with rotation in the direction of flow) with variable helix angle propeller blades or a tangent small turbine (Turbine flowmeter with rotation normal to the direction of flow) with flat, radially placed blades. As the moving element of ball-type flowmeters, a ball is moved around the circuit by the swirling flow with the assistance of a propeller guide.

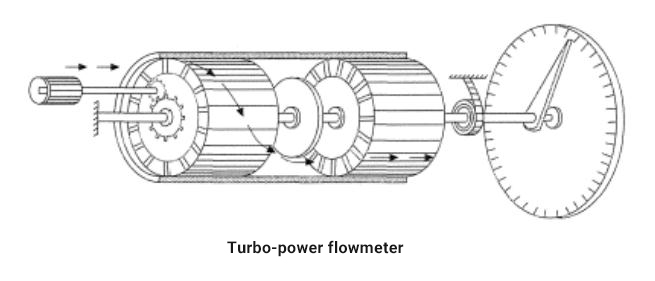

Power flowmeters measure the value of a parameter that describes how a force acts on the flow, with the force’s impact being proportional to the mass flow rate. The force increases the flow’s speed. The flowmeters are divided into three categories based on the type of acceleration: turbo-power flowmeters, Coriolis flowmeters, and gyroscopic flowmeters.

- The turbo-power flowmeters either use a stationary auger or an external action (such as a rotor with an electric motor) to swirl the flow.

- Coriolis flowmeters experience Coriolis acceleration as a result of force.

- Gyroscopic flowmeters that measure the gyroscopic moment.

The torque on the rotating shaft is monitored and inversely proportional to the mass flow rate in the flowmeter depicted in the Turbo-power flowmeter.

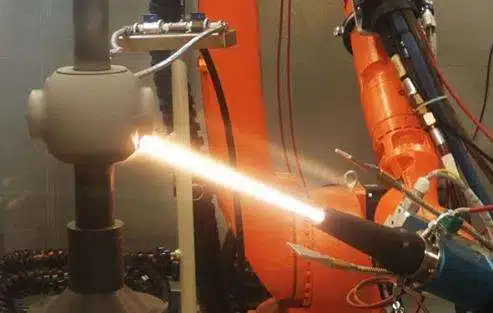

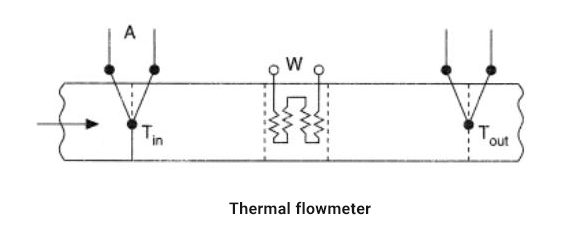

6. Principle of Thermal Flowmeter

Thermal flowmeters are based on the flow rate of the amount of heat received by a liquid flowing from a heater. A heater (typically an electric one) is injected into the flow on the pipeline portion, and its power W is recorded, as well as the difference in flow temperatures ΔT = Tout – Tin at the upstream and downstream. The mass flow rate ![]() is hence proportional to the heating power W with ΔT held constant. Because the coefficient K is affected by heat losses into the surroundings, the nonuniform distribution of velocity throughout the pipeline cross-section, and other factors, a preliminary calibration was done. When the flowmeter is thoroughly made and calibrated, it can provide an accurate flow rate measurement of ±(0.3-0.5)% and can be used as a reference for inspecting and calibrating other flowmeters. The thermoanemometric technique determines local velocity by measuring the temperature of a hot wire or hot film supplied with a continuous current. Using existing relationships, this local velocity may then be connected to the mean velocity.

is hence proportional to the heating power W with ΔT held constant. Because the coefficient K is affected by heat losses into the surroundings, the nonuniform distribution of velocity throughout the pipeline cross-section, and other factors, a preliminary calibration was done. When the flowmeter is thoroughly made and calibrated, it can provide an accurate flow rate measurement of ±(0.3-0.5)% and can be used as a reference for inspecting and calibrating other flowmeters. The thermoanemometric technique determines local velocity by measuring the temperature of a hot wire or hot film supplied with a continuous current. Using existing relationships, this local velocity may then be connected to the mean velocity.

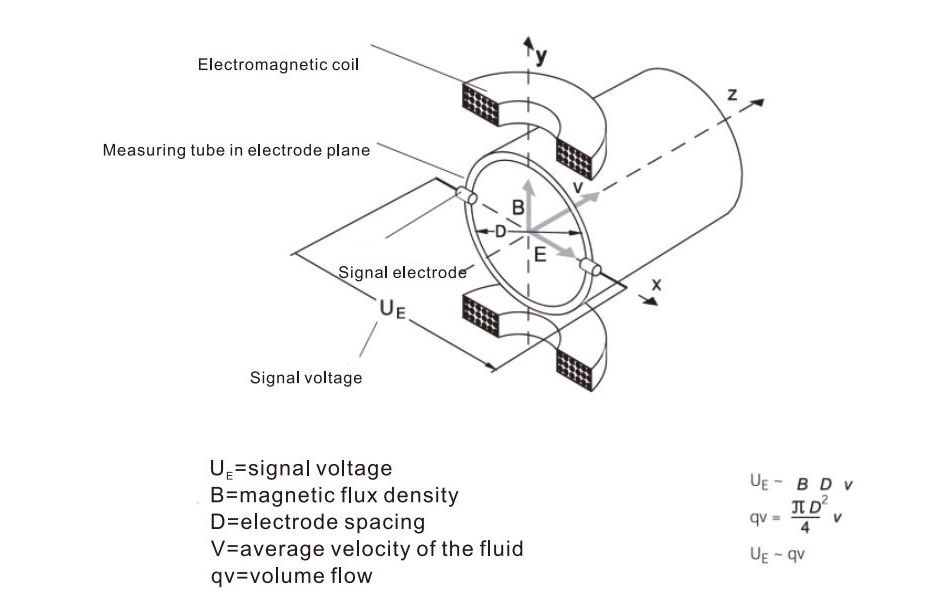

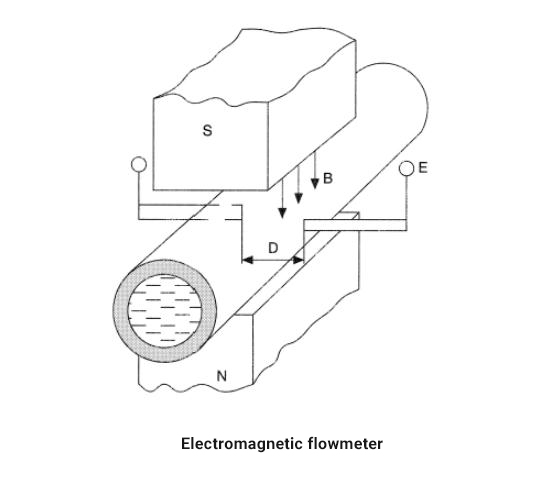

7. Principle of Electromagnetic Flowmeter

When measuring the flow rate of a liquid, electromagnetic flowmeters typically require a conductance of at least 103 Ohm/m. Their operation depends on the interplay of the transverse magnetic field and the moving current-conducting liquid. In this instance, the magnetic induction of the transverse field B, the liquid flow rate V, and the distance D between the electrodes all contribute to the electromagnetic force E that is produced in the liquid (located along the normal both to the velocity vector of the liquid and to the vector of the magnetic field intensity). D is the same as the inner diameter of the pipe.

The source of the current (E) is indicated by ![]()

The benefits of the electromagnetic flowmeter include its ability to measure abrasive, extremely viscous, and aggressive liquids as well as its independence from the viscosity and density of the material, lack of pressure loss, scale linearity, and high-speed response. But, It is unable to measure the flow rates of gases, vapors, or dielectrics.

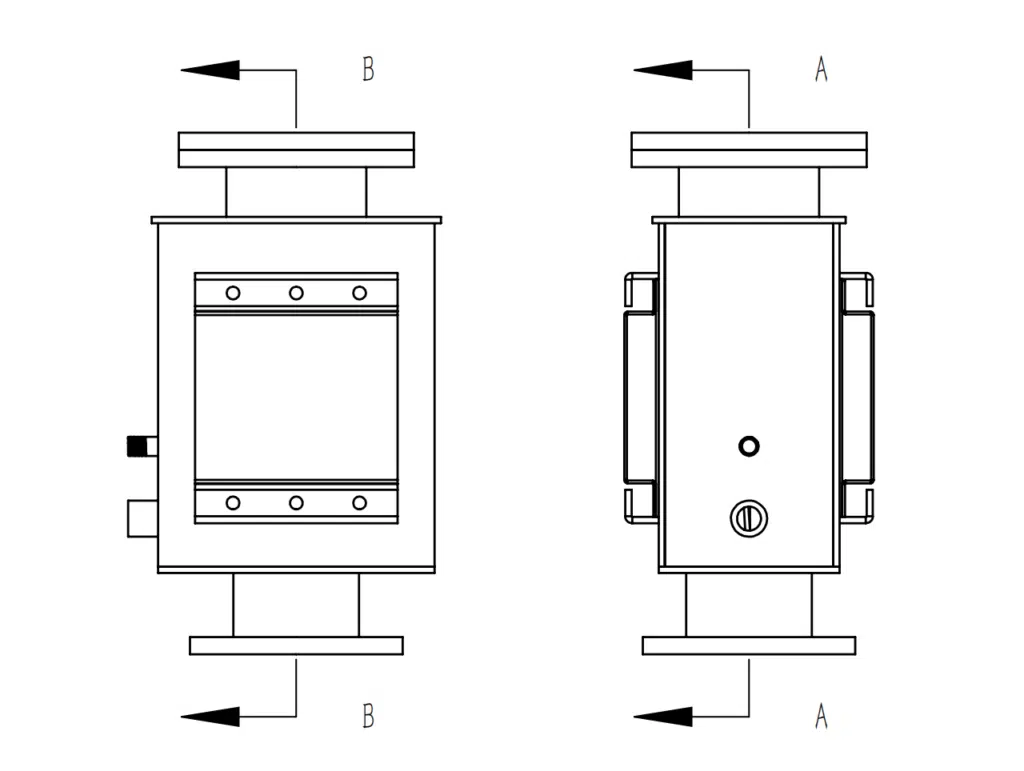

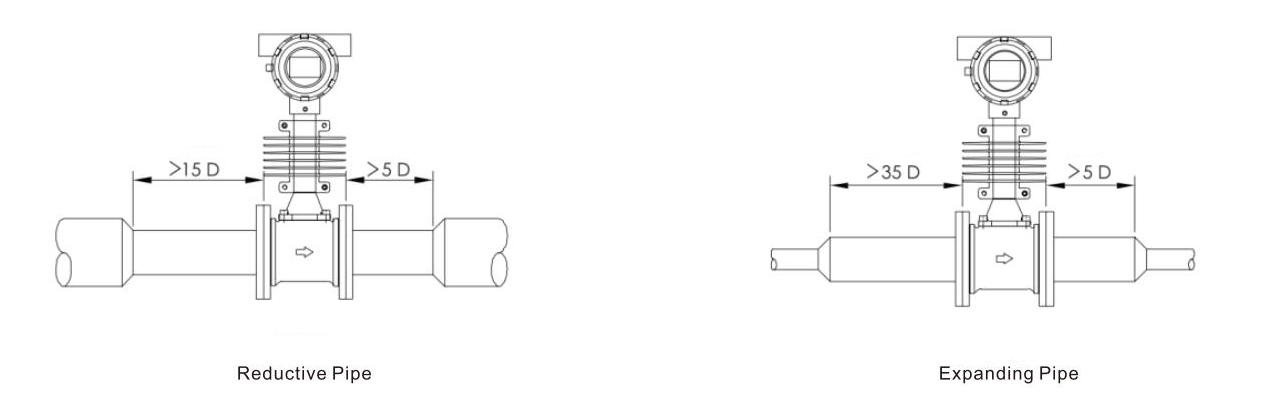

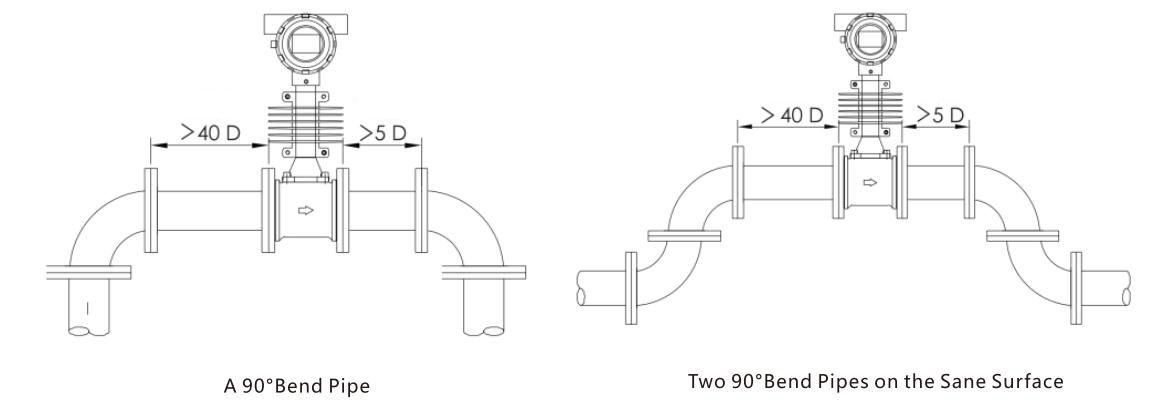

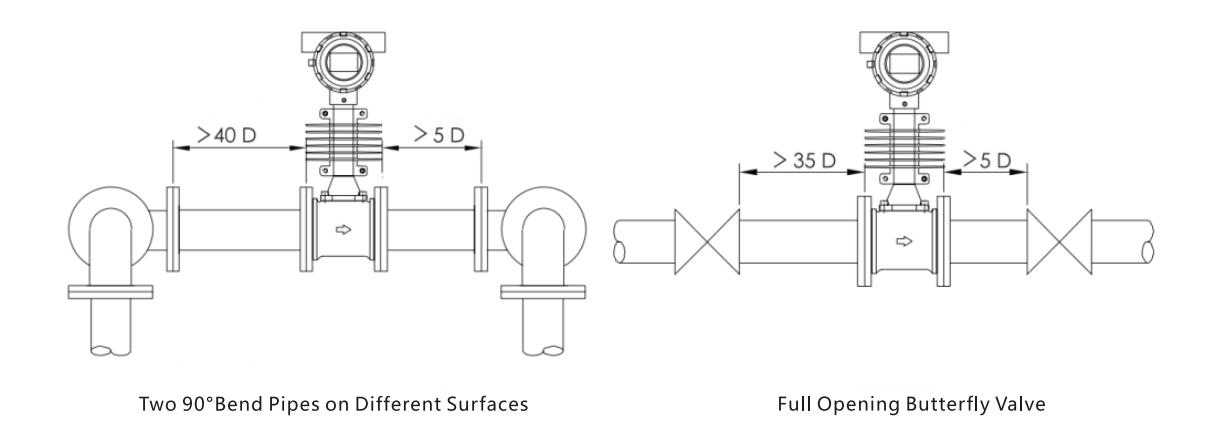

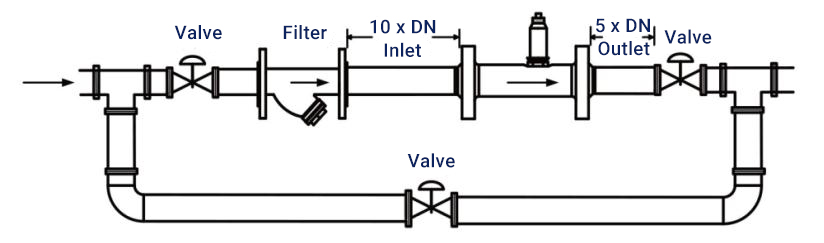

Flow Meter Installation

Flow measurement is a continual responsibility for each sector, which is why flow meters have grown so important. A flow meter must be properly placed in order to provide accurate and trustworthy data.

The following are some of the most important measures to take while installing a flow meter:

- Understand the location where it will be installed.

- It cannot be installed in areas with high vibrations or magnetic fields.

- Understand the flow’s direction.

- Avoid downward flow in liquid operations.

- It must be mounted on a straight pipe.

- Verify that it is totally filled with fluid.

- Inspect liquids and gas lines for the presence of vapors or air and droplets, respectively.

- A filter should be installed upstream of the meter to trap particulates if at all practicable.

- Allow for pipe expansion.

- Maintain a bypass line in case a repair is required.

Why do We Measure Flow?

The volume of fluid that travels through a certain cross-sectional area per unit of time is defined as flow rate. Accurate flow rate measurement with a suitable flowmeter is critical to ensure fluid control systems work smoothly, safely, and economically.

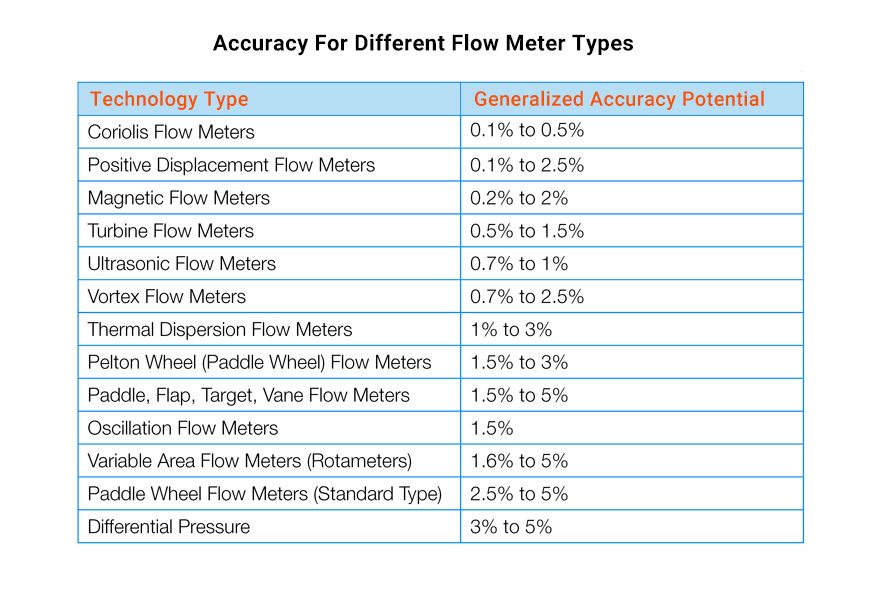

Which Type of Flowmeter is Most Accurate?

The most repeatably accurate flow meters now available are thought to be ultra-high accuracy flow meters like Coriolis flow meters. When great precision is essential for maintaining a continuous level of product quality, safety, and profitability, Coriolis meters are the best choice. in general cost more than any other flow technology. A flow meter with an accuracy of 5% which is much less expensive than another flowmeter with an accuracy of 0.2% could provide sufficient results for your process to function smoothly and give large cost savings. Understanding the precise accuracy requirements for your application and accuracy vs budget concerns might be challenging at times. You can get free assistance from our sales engineers in locating the ideal solution for your application.

Final Thoughts

The flow meter isn’t that complicated. You just need to learn basic terminology, category, and work principles. Go deep and learn if you needed from the real selection or use the application as much as you, you will quickly handle or expert soon.

Looking to learn more about industrial valves? Reading the following articles will help you expand your automation process knowledge.