Every facility, industrial plant, and process system needs suitable valves to help them keep operations running smoothly. If you’re looking for a reliable valve solution that offers both precise controls and minimal costs, look no further than butterfly valves! In this ultimate guide to butterfly valves, we’ll cover everything about butterfly valves. You’ll gain all the knowledge you need to understand how these industrial valves work in different processes – so get ready to open up the wingspan on your understanding of butterfly valves!

FAQ about Butterfly Valves

Do you have a ton of questions about butterfly valves? Well, you’ve come to the right place!

Our FAQ about butterfly valves is here to help guide you through the decision-making process. We cover all the essential topics, from installation instructions to maintenance tips, ensuring you’ll have everything you need to make the right choice.

Don’t let your process get bogged down with a regular valve; choose butterfly valves and keep everything moving smoothly and quickly. With our FAQ about butterfly valves, you can be sure you’re getting all the information necessary to make an educated decision that will serve you well now and in the future.

What are butterfly valves?

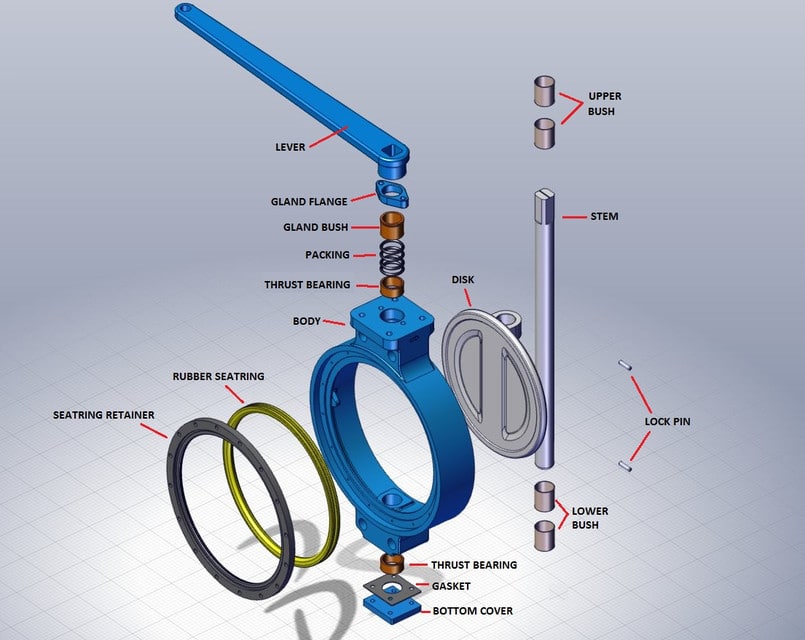

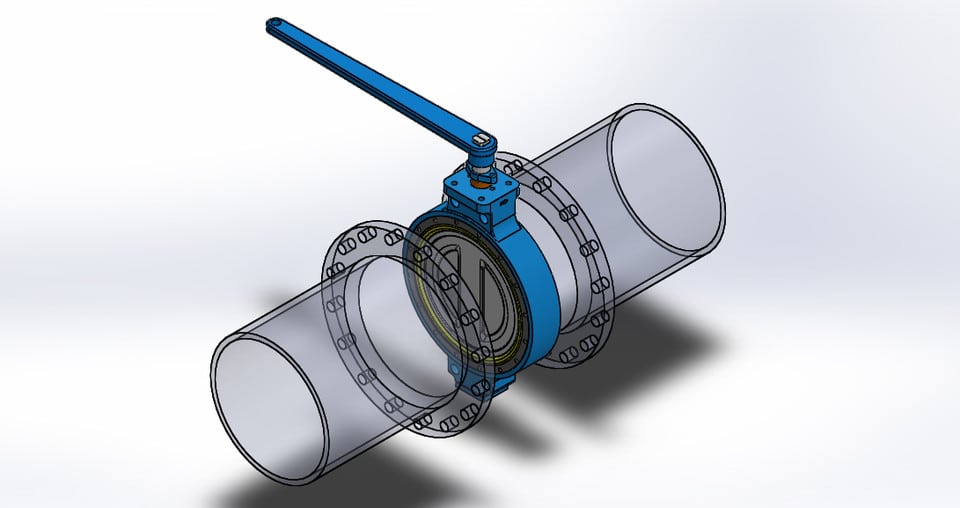

Butterfly valves are industrial valves consisting of a disc or vane that is rotated inside a ring seat to control the flow of liquids or gases. They’re usually made from resilient materials, such as rubber and plastic, to ensure tight seals and reduce maintenance costs.

What Are butterfly valves used for?

Butterfly valves are used in a variety of applications. They’re often used to regulate the flow of liquids and gases in industrial, commercial, and residential applications.

What are the advantages of butterfly valves?

Butterfly valves offer several advantages, making them a popular choice among engineers and plant managers.

First, they provide precise flow control in tight spaces. This makes them ideal for applications where space is limited, or access is difficult.

Second, they require minimal maintenance due to their resilient construction materials.

Third, butterfly valves are very cost-effective, especially when compared to other types of valves.

Finally, butterfly valves can be used for high-temperature applications due to their heat resistance.

These advantages make butterfly valves a great choice for any application with limited space and budget constraints.

What are the disadvantages of butterfly valves?

Like any valve, butterfly valves come with a few disadvantages.

First, they can be difficult to install due to their size and weight.

Second, they may not provide the same level of control as other types of valves due to their limited range of motion.

Finally, they’re prone to leaking if the disc or seat is damaged over time.

These disadvantages should be considered when selecting a butterfly valve for your application.

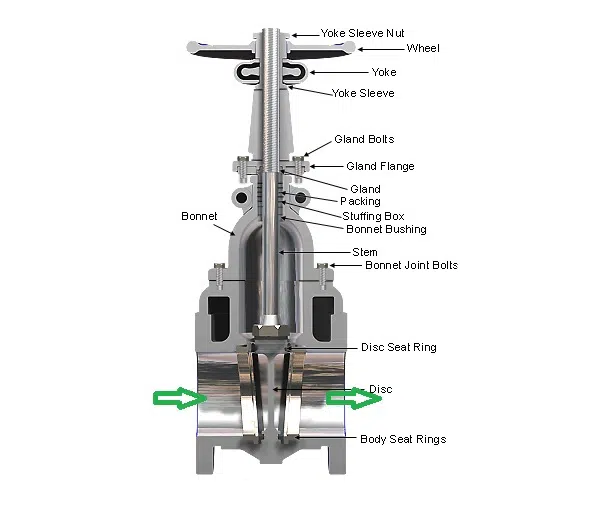

Are butterfly valves better than gate valves?

The answer to this question depends on the application and desired performance. Butterfly valves offer precision control in tight spaces, while gate valves are best for applications that require shutoff of the fluid flow.

Gate valves are often used in applications with large amounts of flow; however, they tend to be more expensive than butterfly valves due to their complexity.

Why do butterfly valves fail?

Butterfly valves can fail for several reasons, such as worn or damaged seals and components, incorrect installation, or inadequate maintenance. It’s important to inspect the valve regularly and ensure that all components are in good working order to avoid failure.

Now that you have all the information about butterfly valves, you can be sure to choose the right valve for your application! With their precise flow control, low maintenance costs, and heat resistance capabilities, butterfly valves can provide reliable performance in various applications.

Why is it called a butterfly valve?

The butterfly valve is named after its disc, which resembles a butterfly in shape. The disc rotates on an axis to open and close the valve, just like the wings of a butterfly move up and down when it flies.

What are the three types of butterfly valves?

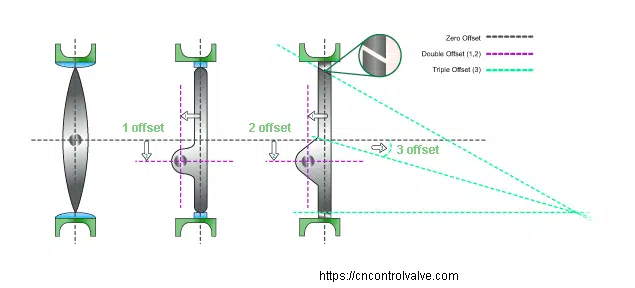

Butterfly valves come in three different types – high-performance butterfly valves, triple offset butterfly valves, and centerline butterfly valves. Each type provides its own unique advantages depending on the application.

High-performance butterfly valves are designed for applications that require precise control, such as those in power plants and refineries. Triple offset butterfly valves offer superior sealing capabilities to contain hazardous media and corrosive fluids. Lastly, centerline butterfly valves provide a low-cost solution for applications that don’t require precise control.

No matter the type of application or the process you need to control, butterfly valves can provide reliable performance at an affordable cost. From controlling water flow in municipal systems to regulating steam pressure in industrial plants, butterfly valves are a great choice!

Which gear is used in the butterfly valve?

A worm gear is typically used to rotate the disc of a butterfly valve, allowing for precise control over flow rate. The gear converts rotational motion into linear motion, allowing the user to precisely regulate the opening and closing of the valve.

Unfortunately, if this gear becomes damaged or worn out, it can lead to failure of the butterfly valve. Regular maintenance and inspection of the gear is critical to ensure the valve functions properly.

Can butterfly valves control flow?

Yes, butterfly valves are capable of controlling flow in applications ranging from water systems to steam plants. The precise control over flow rate allows users to regulate system pressure, temperature, and other variables depending on their specific needs.

How much pressure can a butterfly valve hold?

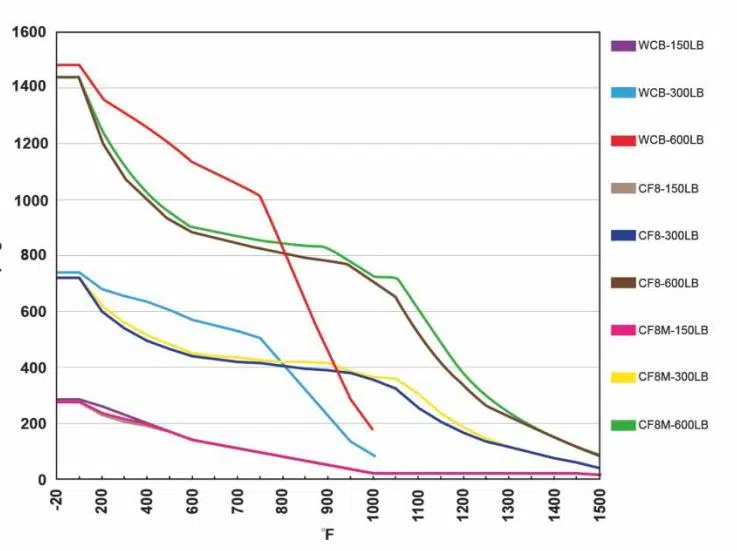

The pressure rating of a butterfly valve depends on its size, materials used, and features such as seal design. Centerline butterfly valves can handle pressures up to 150 psi (1 MPa), but high-performance butterfly valves and triple offset butterfly valves can meet class 1500lb, even higher.

It’s important to select the right butterfly valve for your application in order to ensure it can withstand the pressure of your system.

Do butterfly valves need lubrication?

Some butterfly valves require lubrication in order to function properly. Generally, it’s recommended that you use a light oil or grease for regular maintenance and inspection of the valve. This will help ensure all parts are working correctly and reduce wear on the seals.

It’s important to refer to the manufacturer’s instructions when lubricating butterfly valves to ensure proper use and safety.

How long do butterfly valves last?

The lifespan of a butterfly valve will depend on the application, materials used, and frequency of maintenance. Generally, butterfly valves can last for many years if they are properly cared for and maintained regularly.

Regular inspection of butterfly valves is essential in order to identify any potential issues before they become larger problems. This will help ensure your system works at its optimum performance for many years to come.

No matter what type of application you’re using butterfly valves for, proper maintenance and inspection will help ensure reliable performance and extend the life of your valve.

How do you maintain a butterfly valve?

The best way to maintain a butterfly valve is through regular inspection and cleaning. It’s important to inspect the seals, shaft, and other parts for wear or damage on a regular basis. Additionally, you should clean the valve periodically with soap and water to remove any dirt or debris that could interfere with its operation.

Finally, if the butterfly valve is exposed to high temperatures or corrosive fluids, it’s important to regularly lubricate the seals and other parts. This will help ensure optimal performance of your butterfly valve for many years.

With proper maintenance and inspection, butterfly valves can provide reliable performance at an affordable cost. Whether you’re controlling water flow in a residential system, or regulating pressure in an industrial plant, butterfly valves are a great choice!

With this knowledge about butterfly valves, now you know why they’re such a popular choice for controlling flow and regulating pressure in many different applications. With proper maintenance and inspection, butterfly valves can provide reliable performance at an affordable cost.

6 Factors to Consider When Choosing a High-Performance Butterfly Valve

To ensure that you have the most appropriate butterfly valve for your application, please consider the following 6 factors when selecting a butterfly valve.

1. Functional – Body Type

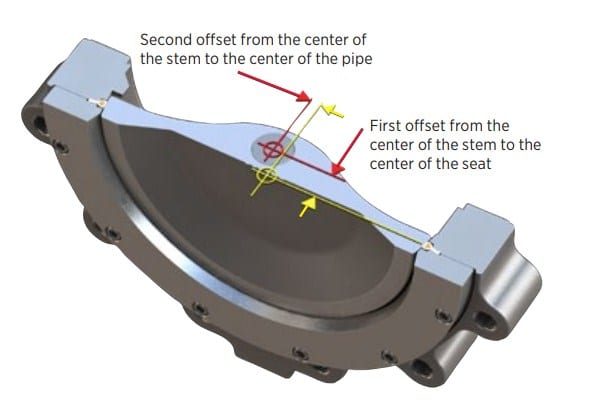

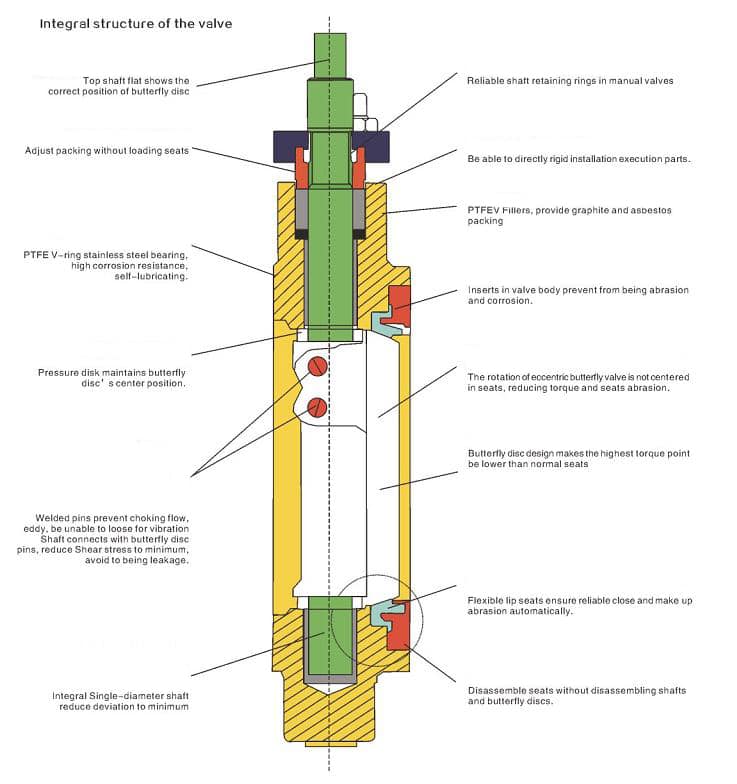

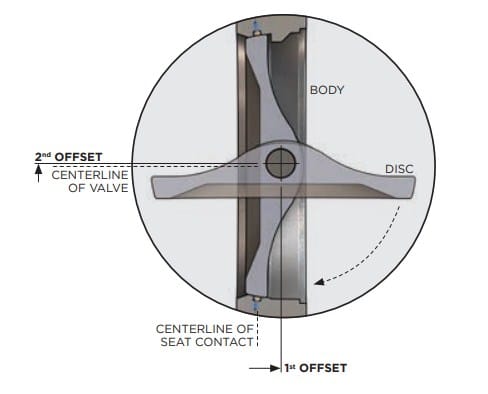

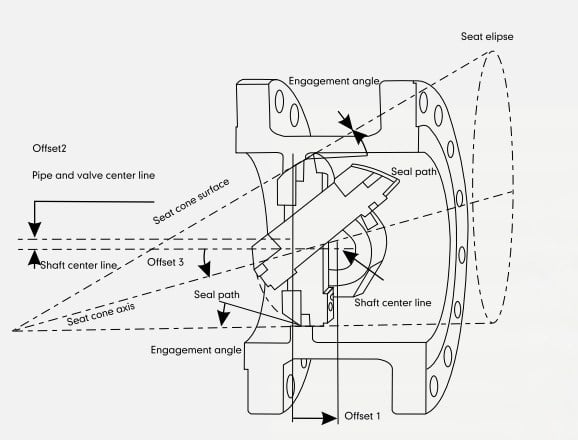

According to the design structure, the butterfly valves can be divided into centerline butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valve. The centerline butterfly valve is generally used for on-off functions, while the double eccentric and triple eccentric butterfly valves can achieve both on-off and flow control functions.

2. Environment – Body Material

Butterfly valves can be made from a variety of materials, and when choosing a butterfly valve material, it is important to consider the role of these materials in the environment. Butterfly valves can be non-metallic or metallic. The most common butterfly valve materials are ductile iron or carbon steel, as they are readily available and inexpensive. However, these materials are not corrosion resistant, so in applications that are prone to corrosion, we should choose a stainless steel or alloy steel butterfly valve. Although stainless steel or alloy steel costs more, it is resistant to both corrosion and high temperatures. In extreme conditions, such as high pressure drop, strong corrosion, and the presence of solid particle impurities may require the use of a special material butterfly valve.

3. Media – Seat Material

When selecting a butterfly valve, it is critical to know what fluid is passing through your application, whether it is a gas, liquid or slurry. The type of medium will affect the sealing performance of the valve. Butterfly valves used in gas systems require a minimum specified leak rate at a specific operating temperature and pressure. Valves used for liquids require a tight seal to prevent liquid leakage. And butterfly valves for slurry media need to have a reliable wear resistance to ensure tight closure.

Slurry fluids, because they contain solid media, require a seal that is flush and smooth with the inside of the pipe to avoid fluid obstruction and prevent media buildup at the valve seal from affecting valve closure. In addition the media containing solid class is easy to wear the valve seat, these materials are easy to be stuck between disc and seat, therefore, in this condition, butterfly valve should try to choose metal to metal design.

4. Connection Type

There are three types of connection for butterfly valves, lug type, wafer type, and flange type. According to the engineering system requirements, we provide the right connection type to meet pipeline installation.

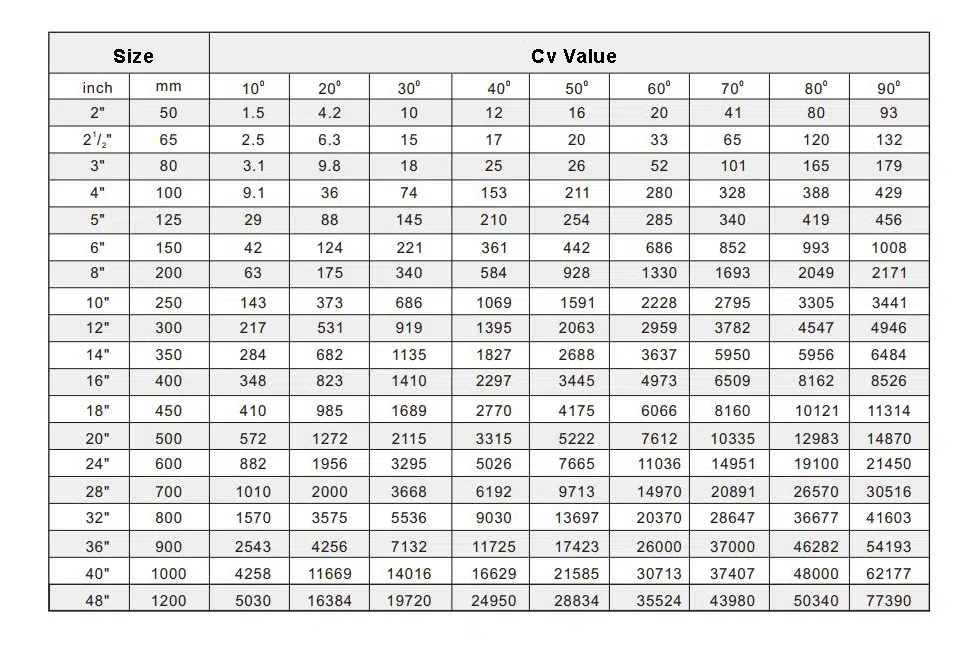

5. Pressure Drop – Valve Size

The on/off butterfly valve generally follows the size of the pipeline to select the corresponding valve size, but for the control type butterfly valve, the parameter of pressure drop needs to be considered in the selected size. Pressure drop refers to the change in medium pressure between the valve inlet and outlet. For example, for regulating flow conditions, if the butterfly valve is fully open, but the pressure drop is not large enough, this means that the valve cannot control or change the fluid flow well until it is in a position close to fully closed (the pressure drop change does not occur until the small opening). In this case, we need to choose a smaller diameter butterfly valve to meet the actual pressure drop or flow requirements.

6. Operation Speed – Operated Type

In many working conditions, there are requirements for valve closing time, in order to ensure the safety of the whole system operation and cost saving. So when selecting a butterfly valve, we need to consider the system’s operating speed and application requirements for the butterfly valve. If the system requirements must be quickly isolated or stopped, the butterfly valve needs to be equipped with fast-acting actuators. For example, by hydraulic or pneumatic actuators combined with solenoid valves to meet the fast action requirements. Some electric actuators have relatively high motor speeds, and it can also provide reasonably fast action. However, in most cases, where fast closing conditions are required, we give preference to pneumatic or hydraulic actuation structures. Quick-opening butterfly valves are not suitable for regulating the flow of fluids.

If the fast isolation function is not required, then refer to the energy source that can be provided on-site, and if the air source is convenient, then use a pneumatic actuator. If it is easier to provide a power source, then use an electric actuator.

Maximizing Efficiency Through High-Performance Butterfly Valves

High-performance butterfly valves offer the highest level of efficiency due to their ability to open and close quicker than other valve types. Their single-piece construction reduces installation time and allows for higher operating speeds. Triple offset butterfly valves provide increased resistance to vibration, as well as a greater range of pressure settings than standard models. This improved performance requires less energy to operate, allowing for cost savings across the board. Butterfly valves are beginning to replace the more traditional gate and globe valves due to their improved performance properties. Although butterfly valves have a higher initial cost than other types of valves, they provide greater long-term value due to their energy efficiency and reduced maintenance requirements. Butterfly valves can be used in a wide range of industries and applications, making them a great choice for any system.

For more detailed information about butterfly valves, contact one of THINKTANK’s experienced engineers today to learn how they can help you optimize your process. With the right high-performance butterfly valve, you can maximize efficiency while minimizing costs.

Increase Productivity By Utilizing a High Quality, High-Performance Butterfly Valve

The key to achieving maximum efficiency lies in selecting the right valve for your system. High-performance butterfly valves are designed specifically to handle the rigors of industrial production and deliver reliable, high quality results. Their improved performance over other types of valves makes them a must-have component in any piping system. From controlling air flow to regulating temperatures, butterfly valves are capable of providing precise control while reducing energy costs.

In addition, butterfly valves require less maintenance and provide longer service life than other types of valves making them an ideal choice for any production environment. With their superior performance capabilities, butterfly valves can increase productivity by ensuring product quality and minimizing downtime.

Conclusion

Now you know all the essential information about butterfly valves, you can be sure to make the right choice for your specific application! With their precise flow control, low maintenance costs, and heat resistance capabilities, these valves can provide reliable performance in various applications.

If you’re in the market for a valve, the butterfly valve is your go-to! From on/off and throttling needs, our butterfly valves are sure to be the perfect addition to your system. Cut through your competition with these reliable yet efficient valves.

Our butterfly valves stand out with their ability to provide just the right pressure for any system. Our range of capabilities makes them one of the most versatile valve options – designed for whatever challenge you may face. On top of that, our butterfly valves are highly reliable and aesthetically pleasing – with both manual and automated versions to choose from. Whether you’re looking for convenience or need something tough enough to withstand even the toughest conditions, our valves are sure to meet your needs.

For an extra bit of flare, all our valves come with compact and unique design choices, making them great fits for modern systems! With such a wide array of possibilities and benefits, it’s no question why so many people swear by our butterfly valves. So don’t wait another moment—just freely contact us for an instant quote.