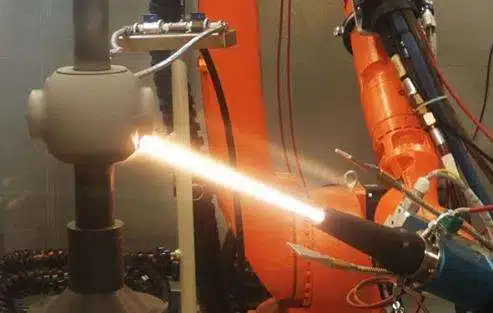

In the constantly shifting landscape of industrial safety dynamics, precision takes center stage, and at THINKTANK, we’re all about safeguarding high pressure environments. Picture this: pressure relief valve, your undercover safety shield, ensuring a secure industrial environment by releasing extra pressure precisely in a variety of critical applications when system pressure exceeds set pressure limit. These valves, often referred to as pressure relief valves or relief valves, Take on a crucial first responder role in safeguarding and preventing potential damage from excessive pressure. From chemical plants to power generation, pressure relief valves are typically installed to ensure the well-being of machinery and preventing the high risk of a catastrophic failure. As we dive on this journey to unravel the secrets behind pressure relief valves and there specific applications, we discover their crucial roles and the precise design that goes into each unit, proudly designed by industry leaders like THINKTANK.

Importance of Pressure Relief Valve

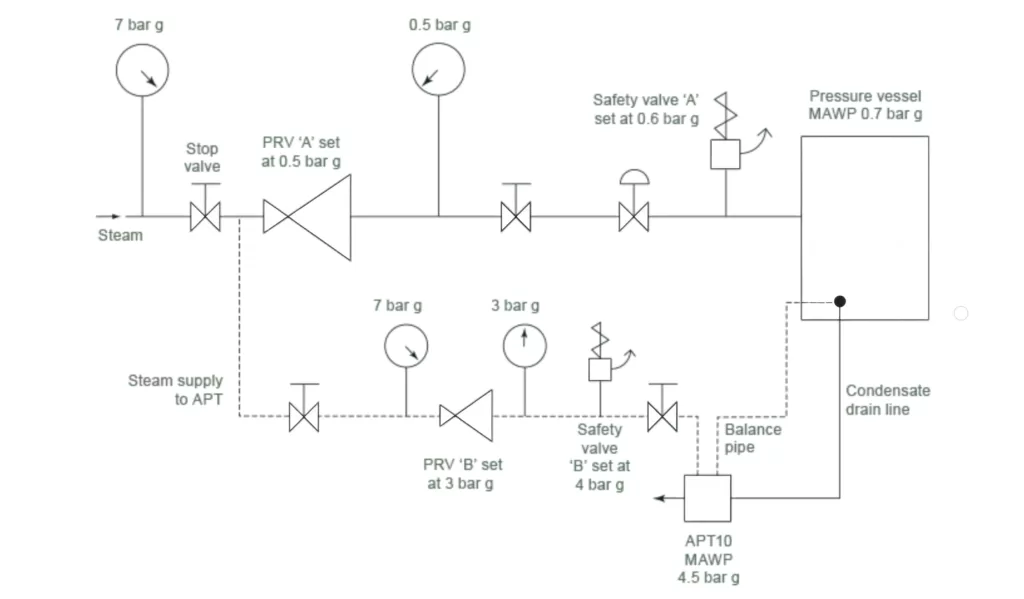

Pressure relief valves play a pivotal role as a safety net that keep machinery and systems secure and their system pressure under control and in safe pre set level. Their fundamental purpose? To prevent disorder when pressure in a system experiences unexpectedly surge. pressure relief valve opens to ease the building pressure by allowing it to escape, the valve then closes when pressure drops to a stable level. Think of them as pressure watchful protectors, always ready to step in when overpressure situations threatens trouble.

Picture a chemical plant or power facility—without pressure relief valve installed, it’s a risky game with no safety measures. These valves act as protective watchers, automatically releasing excess pressure before it becomes a real issue. Whether labeled as safety valves, safety relief valves, or relief valves, their role remains the same: safeguarding against potential damage and maintaining a safe level system pressure.

In simple terms, the importance of pressure relief valves is crystal clear: they ensure a balanced stability, preventing disasters, and keeping machinery and industrial setups running smoothly. It’s not just about machines; it’s about providing a safe environment where operations unfold seamlessly without unexpected disruptions. These pressure relief valves emerge as crucial crucial components, maintaining the delicate balance of safety and reliability.

Functionality of Pressure Relief Valve

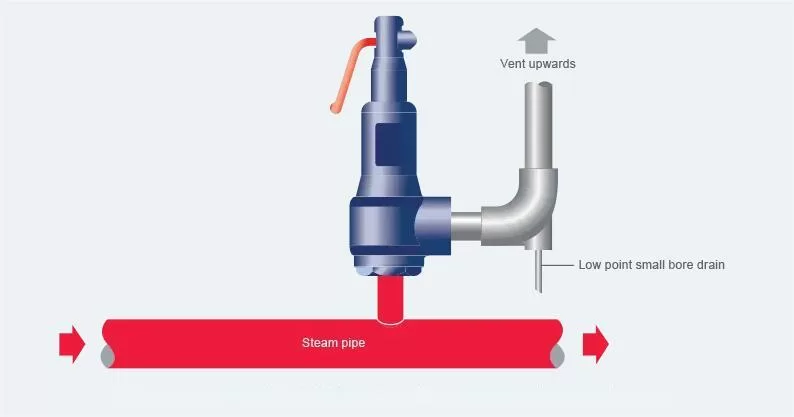

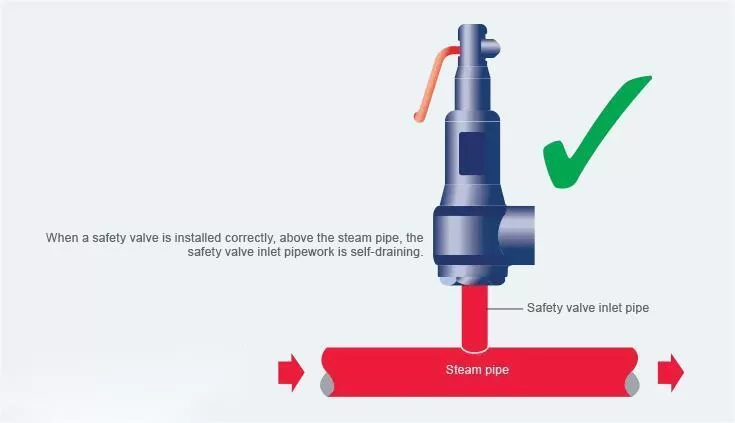

At their core, pressure relief valves are the problem-solvers of industrial systems, designed to tackle one crucial task: managing pressure with high accuracy. Think of them as the guardians of stability, ready to get into action when pressure in a system escalate. These valves operate on a simple principle—automatically opening to release excess pressure and promptly closing once the system pressure returns to a safe state. It’s like having a watchful eye on a pressure cooker; when things get too intense, the valve ensures a controlled release, preventing any potential disasters. In essence, pressure relief valves act as the silent guides, coordinating a careful balance in system pressures, ensuring smooth operations in the complex interactions of industrial machinery.

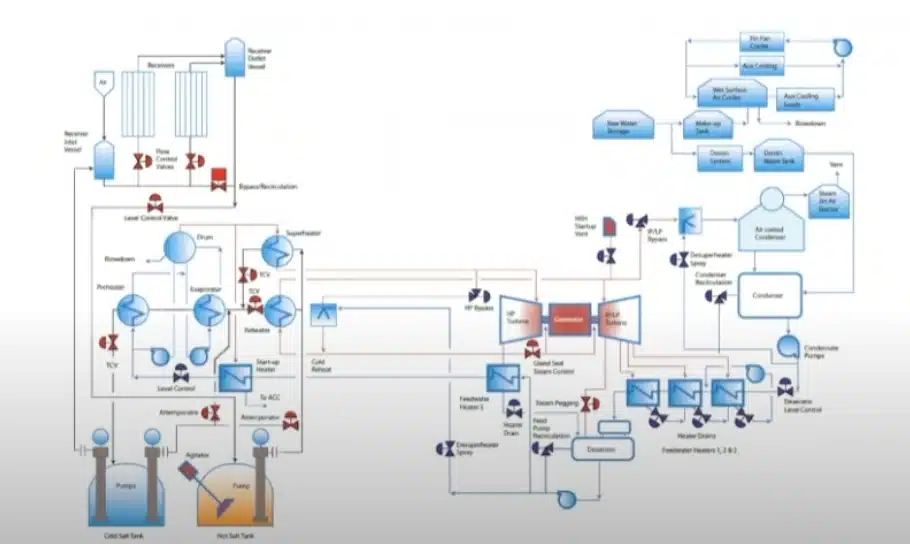

Applications in Different Industries

A pressure relief valve (PRV) is a critical safety component in various industrial and mechanical systems. Pressure relief valves are like safety superheroes that show up in different industries to save the day. Imagine them as protectors in chemical plants, preventing disasters by releasing extra pressure. Power places, like where electricity is made, rely on these valves to keep everything stable. Even in the oil and gas world, they make sure pressure doesn’t cause trouble. But here’s the cool part—they’re not just for big places. From your water heater at home to the big air systems in stores, these valves quietly keep things safe and working right. So, pressure relief valves are like everyday heroes, fitting into different jobs and making sure everything runs smoothly. The pressure relief Valve (PRV) serves to:

1. Prevent Overpressure: It automatically release pressure that is caused by gas, steam, or liquid when the pressure within a system exceeds a predetermined set pressure limit. By doing so, it prevents potential damage to pipes, vessels, and other equipment.

2. Ensure Safety: By controlling the high pressure systems, pressure relief valves help in preventing catastrophic failures and explosions, which could lead to property damage, environmental hazards, and loss of life.

3. Maintain Operational Integrity: Consistent and safe pressure levels are essential for the smooth and efficient operation of many industrial processes. PRVs help in maintaining these levels, ensuring that systems operate within their designed parameters.

4. Compliance with Regulations: In many industries, the installation of PRVs is mandated by safety regulations and standards to ensure safe operation of pressure systems.

5. Cost-Effective Maintenance: By preventing overpressure incidents, PRVs reduce the need for costly repairs and downtime, thus playing a role in maintaining the economic efficiency of operations.

As a professional valve manufacturer at THINKTANK, we specialize in designing and producing high-quality pressure relief valves (PRVs). Our expertise lies in crafting PRVs that meet specific industry standards and address diverse customer needs. Here’s an overview of our role and contributions:

- Expertise in Pressure Relief Valve (PRV) Design and Manufacturing: At THINKTANK, we leverage our deep knowledge and technical skills to produce PRVs suitable for a wide range of applications and pressures. Our valves are designed to ensure versatility and reliability across various industrial settings.

- Innovation and Technology Integration: We are committed to innovation and continually integrate the latest technologies into our pressure relief valves(PRVs). This includes using advanced materials and precision engineering techniques, along with incorporating smart features to enhance valve performance and reliability.

- Quality Assurance and Compliance: Ensuring that our pressure relief valves (PRVs) comply with international safety and quality

In conclusion, the role of a pressure relief valve is indispensable in industrial settings, serving as a fail-safe mechanism to guard against the potential dangers stemming from excessive pressure. Pressure relief valve play a pivotal role in safeguarding the well-being of both operational processes and personnel while contributing to environmental protection. As critical components, their significance role lies in maintaining a delicate balance in system pressures, preventing catastrophic failures. In essence, pressure relief valve stand as an important component, ensuring a harmonious and secure industrial environment where safety remains paramount. Please do not hesitate to contact THINKTANK’s technical engineer if you have any questions, we are pleased to support your business.