In the world of machines and systems that keep things running smoothly, one thing we always keep an eye on is system pressure. Imagine system pressure as a sort of constant force that needs careful handling to make sure it doesn’t exceed the set pressure limit. Now, meet the most important component to manage pressure – safety relief valve. You might also hear them called safety valve, safety relief valve or pressure safety valve. These valves swiftly respond, automatically opening to relieve excess pressure and prevent potential damage. Acting as the guardians against excessive pressure, safety relief valves are a crucial component in averting catastrophic scenarios like rupture, cooling system failure, or any unexpected surge in system pressure. In this blog, brought to you by THINKTANK, we’ll uncover the details of these crucial components and how they play a key role in making sure industrial processes are safe and reliable.

Functionality of Safety Relief Valves by THINKTANK

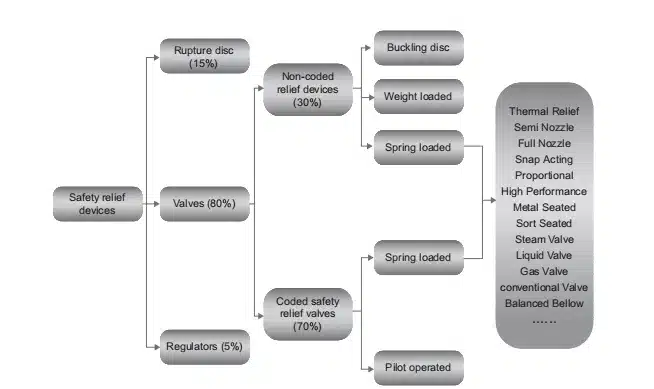

As THINKTANK, a professional manufacturer of safety relief valves, we understand the critical importance of these devices in industrial settings. The safety relief valve (SRV) is an essential component for ensuring the safety and efficiency of various systems. what differentiate safety relief valve from pressure relief valves is instead of regulating pressure in a system, safety valves are designed to immediately release pressure during emergencies or system failures to avoid any catastrophic disaster. Here’s why they are so important:

1. Overpressure Protection

Our SRVs are designed to automatically release pressure from a system when it exceeds a predetermined limit. This is vital to prevent potential equipment failures, such as ruptures or explosions in pipelines, vessels, and boilers.

2. System Safety

The primary purpose of our SRVs is to protect the integrity of equipment and ensure operational safety. By relieving excessive pressure, these valves prevent accidents and protect both the workforce and the environment from hazardous incidents.

3. Regulatory Compliance

In the manufacturing of SRVs, we adhere to stringent industry standards and regulations. This compliance is not just about following laws; it’s about ensuring that every SRV we produce is reliable and effective in safeguarding industrial operations.

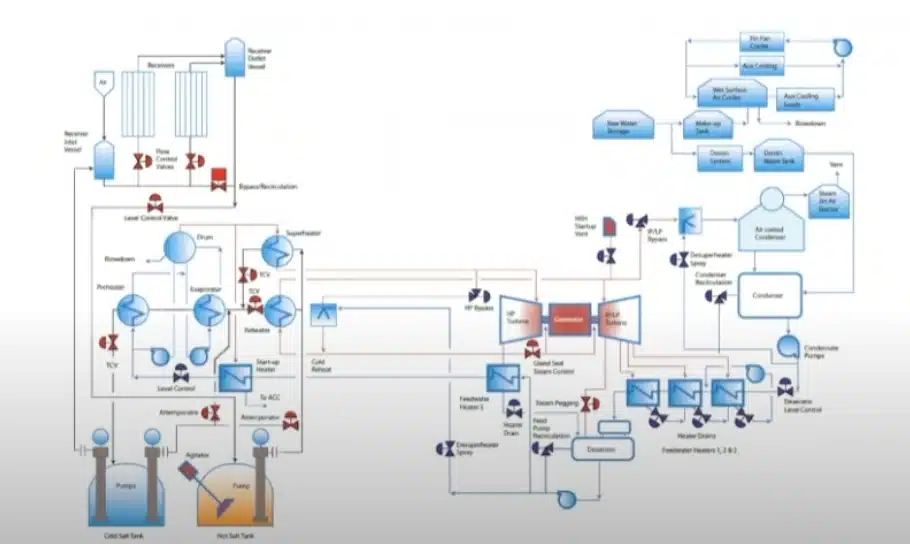

4. Operational Efficiency

By maintaining pressure within safe limits, our SRVs help ensure that industrial processes run smoothly and efficiently. This prevents downtime and productivity losses caused by overpressure incidents.

5. Cost-Effectiveness

By preventing overpressure-related damages, our SRVs help industries avoid costly repairs and maintenance. This makes them a cost-effective solution for long-term operational stability.

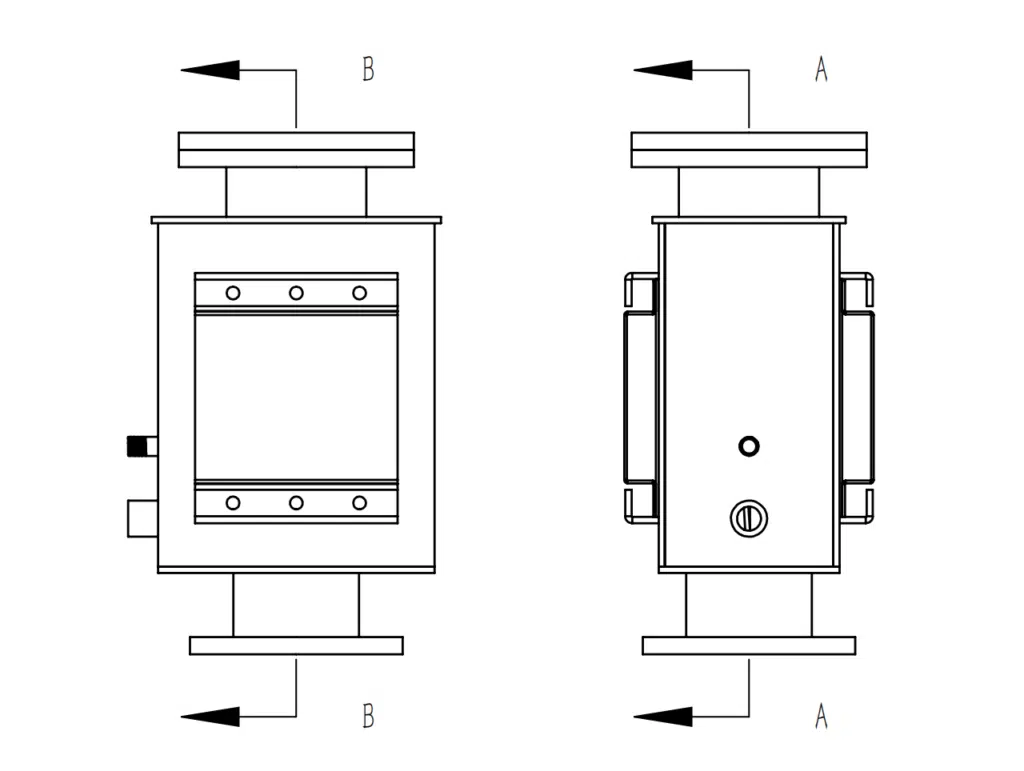

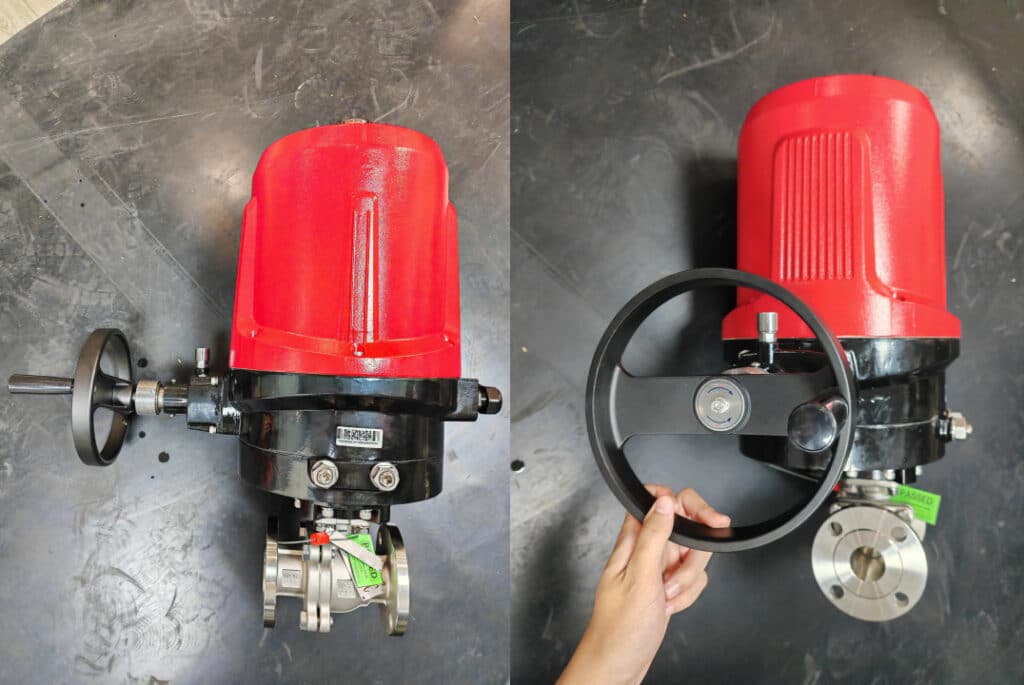

6. Customization for Specific Needs

We understand that different industries have unique requirements. That’s why we offer customized SRV solutions to meet specific operational parameters, ensuring optimal performance in any application.

Safety Relief Valves as Preventive Measures

Catastrophic Scenarios

Unprotected pressurized system face potential risks when pressure levels exceed safe limits. Safety relief valves, expertly designed by THINKTANK, play a pivotal role in preventing catastrophic scenarios by automatically releasing excess pressure, to protect equipment and protect life in general.

Keystone in Process Safety

Considered a keystone in process safety, safety relief valves are crucial elements in the industrial landscape. With their proactive design, these valves are indispensable safeguards, maintaining optimal system conditions and preventing potential risks.

Unraveling the Mysteries

Safety relief valves serve as protectors, uncovering the secrets of overpressure events. By foreseeing and minimizing risks, THINKTANK’s valves guarantee smooth operations, guarding against disruptions and maintaining the delicate balance between safety and reliability.

The Importance of Safety Relief Valves

A Plant Manager’s Priority

For plant managers, ensuring facility and employee safety is paramount. In this crucial responsibility, Safety relief valves (SRVs) emerge as indispensable tools, carefully designed by THINKTANK to protect against overpressure events and maintain optimal system conditions.

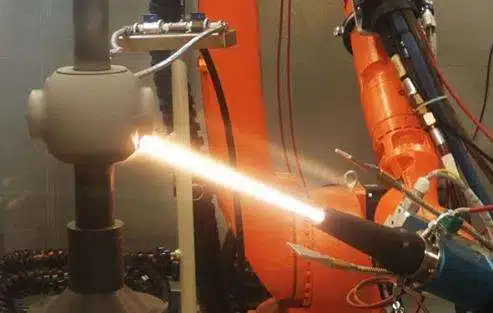

Design Dynamics

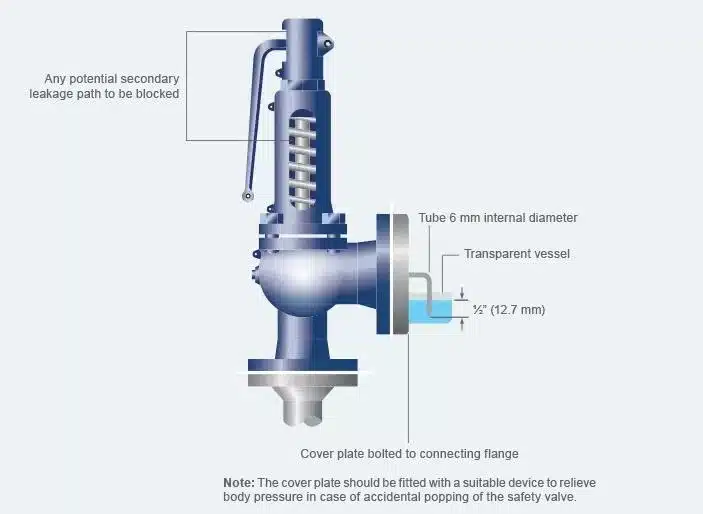

A safety relief valve, often serving as the last line of defense for a system, is paramount in these situations. Certification and capability to operate under all circumstances are non-negotiable aspects, highlighting the crucial responsibility these valves bear in ensuring the safety and reliability of industrial operations. These valves come to life when faced with system overpressure, triggered by various factors such as blocked discharge, exposure to external fire (often referred to as the “Fire Case”), thermal expansion, chemical reactions, or heat exchanger tube ruptures.

How THINKTANK Selects the Right Safety Valve for You

Choosing the most suitable safety valve involves a meticulous process, and at THINKTANK, we prioritize your system’s safety and efficiency. Our selection is based on various factors:

1. Media Type

Careful consideration of the media (air, gas, steam, liquid) involved in your application.

2. Pressure Parameters

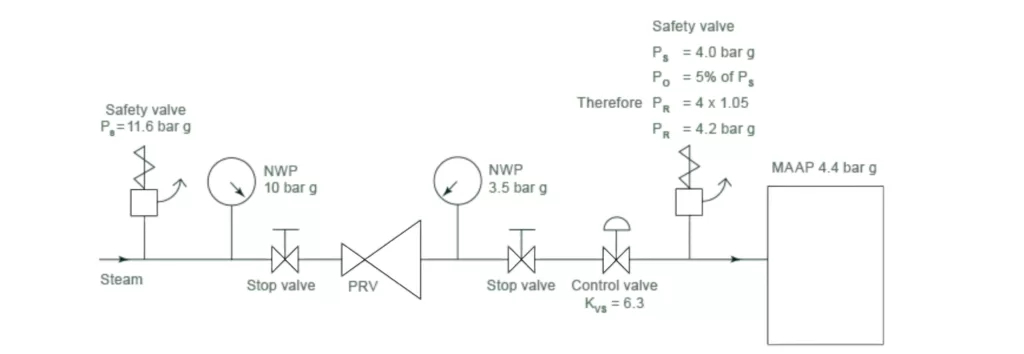

Determining the set pressure, popping pressure, and relieve pressure tailored to your system’s needs.

3. Capacity Requirements

Assessing the required capacity for your specific application to ensure optimal performance.

4. Environmental Considerations

Factoring in elements such as temperature, back pressure, and the nature of corrosive media or the operating environment.

5. Operational Characteristics

Aligning with your system’s normal working pressure and understanding the maximum allowable working pressure under standard conditions.

6. Set Pressure Precision

Defining the set pressure, which marks the point at which the valve initiates its protective function.

7. Overpressure Safeguards

Ensuring the valve’s capacity to handle overpressure scenarios, preventing any potential risks.

At THINKTANK, our commitment is to deliver safety valves tailored to your unique operational demands, providing a comprehensive solution that guarantees the reliability and protection of your industrial processes.

Summary

In conclusion, THINKTANK underscores the vital role played by safety relief valves in upholding industrial safety. These valves contribute significantly to regulatory compliance, boost operational efficiency, and offer cost-effective solutions for effectively managing overpressure risks across diverse systems. It’s crucial to note that, in contrast to pressure relief valve, safety valve promptly and fully open, prioritizing the prevention of disasters rather than managing system pressure.