Control valves are useful for the regulation of fluid flow and pressure to maintain processes and set points. These setpoints are the basic rate of flow, temperature, and pressure. It also controls the product parameters such as density, liquid level, etc.

Component of Control Valves

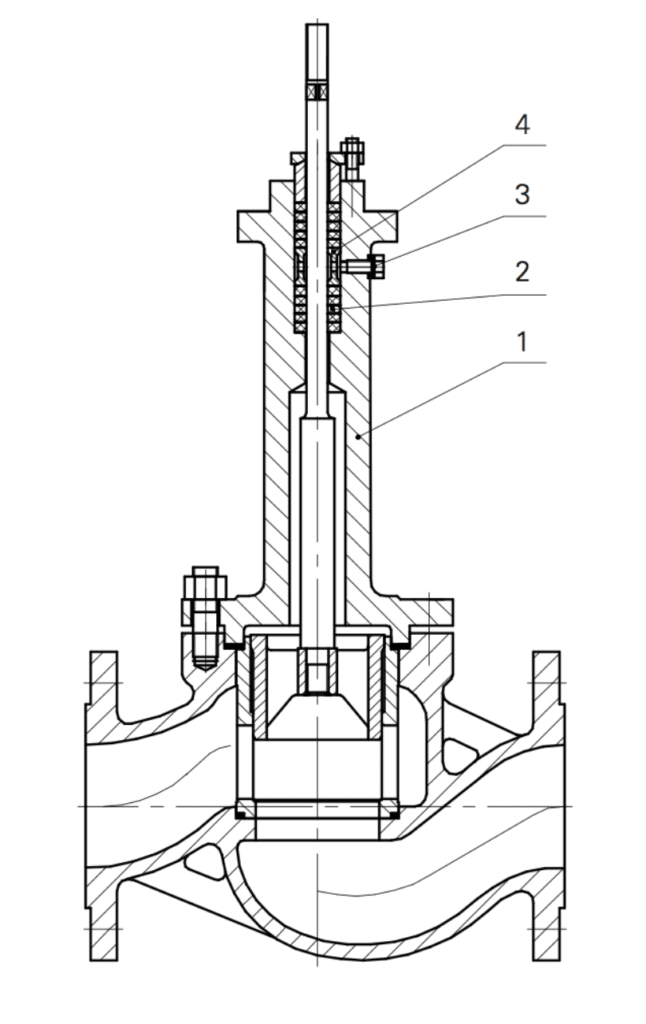

Valve Body

The body of a control valve has a bonnet and trim parts. It ensures both the static and differential fluid pressure and allows the flow. It also provides pipe connecting ends.

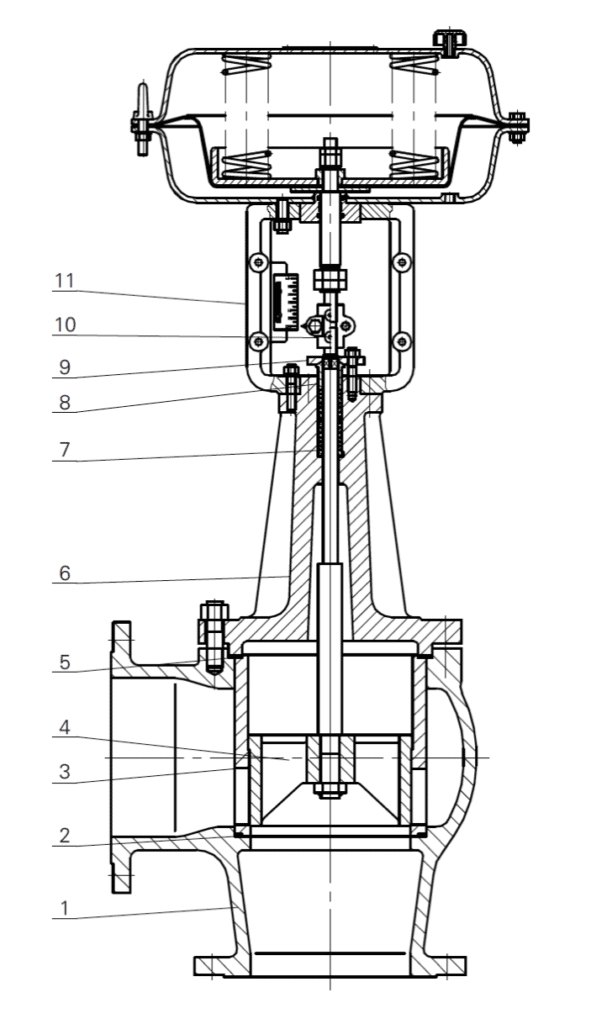

Actuator

The actuator is a pneumatic or hydraulic device that helps in the opening and closing of the control valve.

Positioner

The positioner helps to maintain the movement of the actuator and gives the desired set point.

Other Accessories

The accessory parts of the control valve such as electro-pneumatic transducers, position indicators, etc also help to maintain the work of other valve parts.

Valve control is used to control the fluid flow by changing its shape as directed by the given signal. It sets focuses on the fluid flow rate, temperature, and pressure applied. Its controls are based on fluid density, concentration, levels, and many more. Its installation requires a valve body, positioner, actuator, and some necessary accessories.

Types of Control Valves Based on Functions

Depending on the different conditions, control valves serve many functions within the system.

On/off Type Control Valves

Modulating Type Control Valves

Self-Operated Pressure Control Valves

Types of Control Valves Based on Pressure, Actuator, or Action Direction

Control valves play a critical role in controlling the flow of fluids in various industrial applications. These valves can be categorized based on pressure, actuator, or action direction. Below, we delve into these classifications:

Type of Control Valves Based on Working Pressure

- Low-Pressure Control Valves

- Mid-Pressure Control Valves

- High-Pressure Control Valves

Type of Control Valves Based on Actuator Type

- Manual Control Valves

- Electric/Motorized Control Valves

- Pneumatic Control Valves

- Hydraulic Control Valves

Type of Control Valves Based on the Closure Member’s Movement

- Rotary Motion Control Valves

- Linear Motion Control Valves

Here we are discussing the types of control valves based on movement.

Rotary Type of Control Valves

Rotary motion valves – In this type, the flow of the fluid is modified by the closure member in rotary motion. Rotary motion valves are of three types.

Ball Valve

As the name suggests, the shape of the valve is like a ball with a container for fluid flow. Right at the opening, this valve enables the flow and after rotating at 90° it stops the flow. The ball valve has good resistance toward high temperature & high pressure. The advantage of the ball valve is easy to maintain and has low torque. On the other hand, it also has the disadvantage of causing corrosion when the fluid gets trapped inside the valve mainly during a closed position.

Butterfly Valve

The butterfly valve has a disc rotating at 90˚ inside the pipe. The disc allows the stem to pass through it and is supported by both ends. Similar to the ball valve, the butterfly valve also stops with a right-angle rotation. The butterfly valve has the capacity of controlling large flow and low-pressure applications. It is affordable and has a quick opening. It has only one disadvantage loose shut-off.

Plug Valve

The plug valve is available in both cylindrical and tapered shapes. At the time of opening of this valve, both inlet and outlet ends of this valve, are connected to give a flow line. This valve is suitable for both chemical and petrochemical industries. The plug valve has advantages like less maintenance, fewer requirements of headroom, and quick opens. It has a low-pressure drop and doesn’t provide a loose shut-off like a butterfly valve. The plug valve also has disadvantages like not being affordable and it is not useful for throttling action.

Linear Type of Control Valves

Linear motion valves – In this type, the closure member moves in a linear direction and modifies the fluid flow rate. Linear motion valves are of four types.

Gate Valve

In high temperatures, the gate valve is used for on/off applications. This is also recommended for non-throttling services because of its fully closed or fully open designs. It has a sliding gate to control the flow. It works well at the time of straight-line flow of liquid with minimum restrictions. Based on shape, the gate valve is further divided into two categories: Parallel and wedge.

The gate valve starts working when the stem is rotated either clockwise to close motion or clockwise to open motion. As you move the stem, the gate valve moves up and down. The advantage of a gate valve is it comes with tight sealing. Gate valve also has the disadvantage of requiring more actuating force.

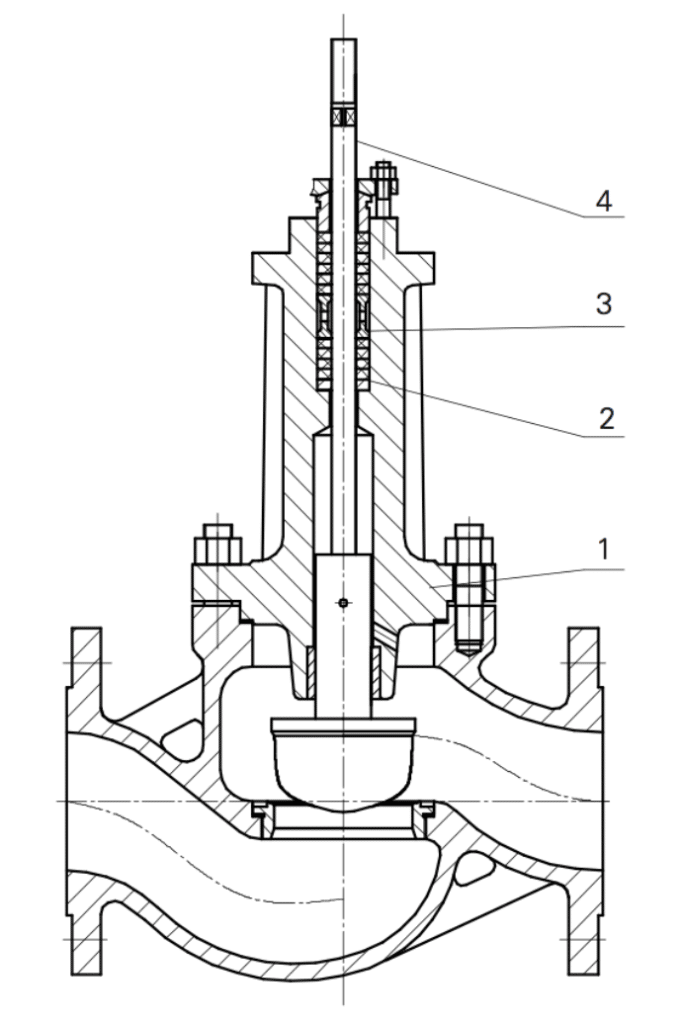

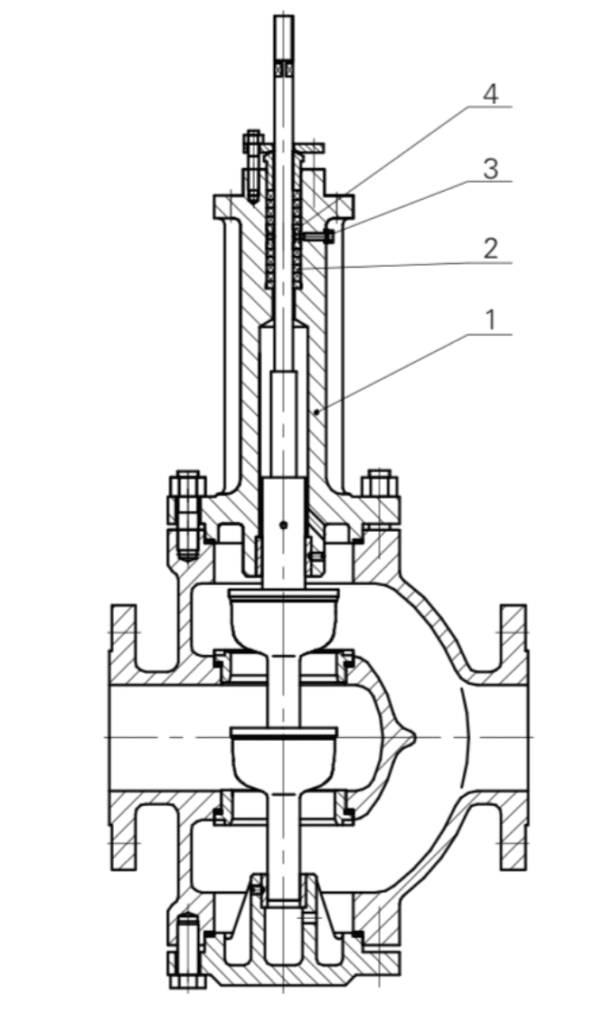

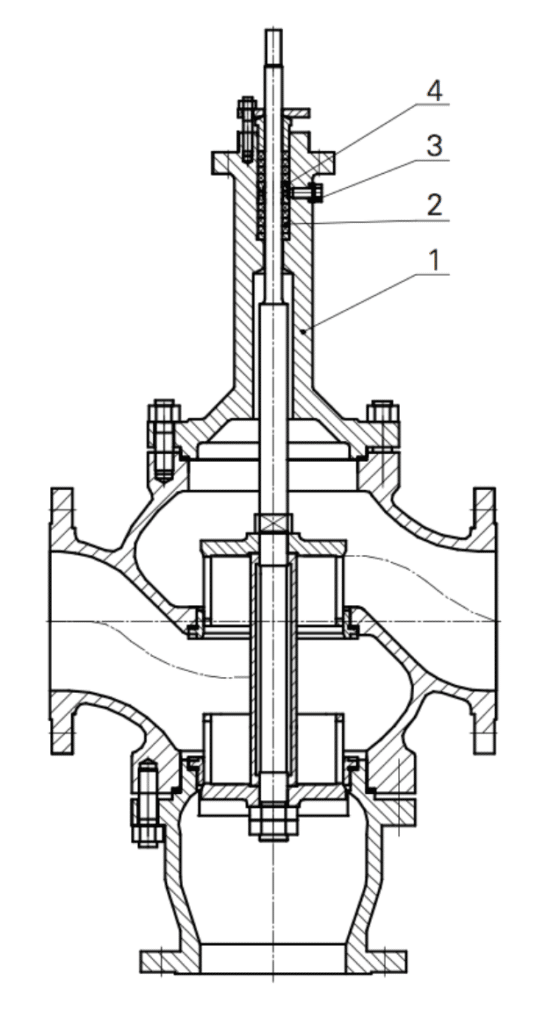

Globe Valve

Due to the globular shape, this valve is named a globe valve. Its closure member is a plug with a button, located right at the center. When the plug is raised, the globe valve allows the fluid to flow. Globe valve mainly has 3 body designs as Z, Y, and angle body. The advantage of the globe valve is it has better throttling characteristics than other valves. It also has the disadvantage of having a high-pressure drop.

Diaphragm Valve

The diaphragm valve has a compressor that is connected to a flexing diaphragm. This diaphragm is lifted at the time of opening of this valve and allows the fluid flow. When the valve is closed, it closes the path tightly.

The diaphragm valve works at low temperatures and low pressure and is highly suitable for corrosive liquids. The advantage of the diaphragm valve is it is easy to maintain and has a simple construction. It also has disadvantages like it can’t be used in high temperatures and high pressure.

Pinch Valve

A pinch valve is more cost-effective than other valves. This valve is used for slurries or liquids having minimal solid particles. It is similar to a diaphragm valve but uses flexible elements like rubber to turn off the fluid flow. To actuate the pinch valve, hydraulic pressure is placed on the elastomer sleeve. The pinch valve doesn’t have any internal obstructions and hence it has a low-pressure drop. This is a good advantage of the pinch valve

In Conclusion

The control valve is the key part of the control circuit. People who work in the industrial field talk about control valves are actually referring to a complete assembly control valve. It usually includes the valve body, trim, actuators, and a variety of other valve accessories. The actuator provides power to operate the valve, and it could be pneumatic driving, electric driving, or hydraulic driving. And for accessories, according to the control system to assembly sensor, valve positioner, transducer, air filter regulator, limit switches or handwheel, etc.

There are two main types of control valves designed according to the function of the closing part: The sliding-stem control valve and the rotary control valve. Sliding-stem means the closure member acts as a linear motion, but a rotary valve uses rotational motion to turn a closure member into and out of a seating surface.

Rotary type control valves include full-port ball control valve, segmented ball control valve, segmented V-notch control valve, butterfly control valve(conventional disk), eccentric butterfly control valve/high-performance butterfly valve, and eccentric plug control valve.

Sliding-stem control valves include single-port globe type valves, cage-guided globe type, double-ported, three-way valves, and angle type control valves.

So this is everything you should know about the various types of flow control valves. If you have any questions just feel free to contact us.