Globe valves, recognized for their spherical body and superior throttling accuracy, are integral components in fluid control systems. Their unique design allows for both the regulation and the complete obstruction of fluid flow, making them indispensable in various industrial applications. This article compiles a list of frequently asked questions about globe valves, providing insights into their functionality, installation, and operational characteristics.

Part 1: Understanding Globe Valves

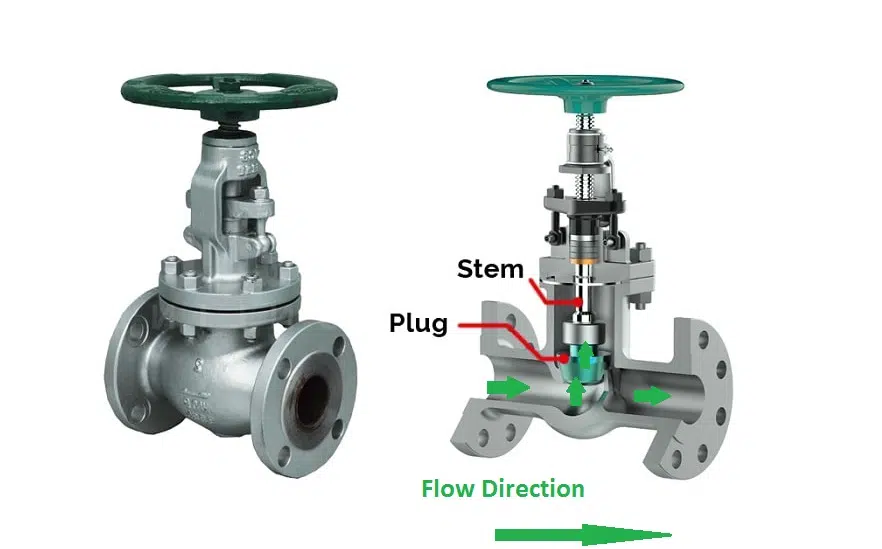

What is a globe valve

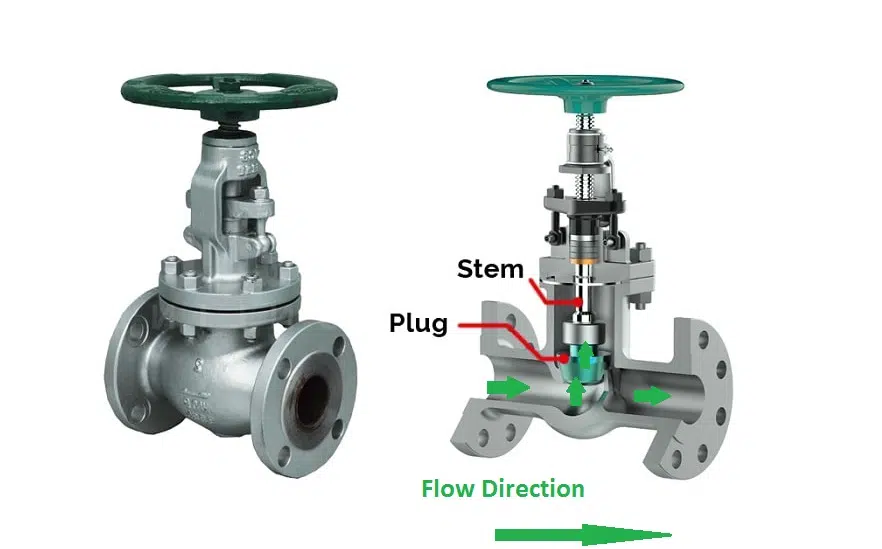

A globe valve is a linear motion valve designed to stop, start, and regulate flow. It has a spherical body with an internal baffle that houses a movable disk or plug which seals against a stationary seat.

How does a globe valve work

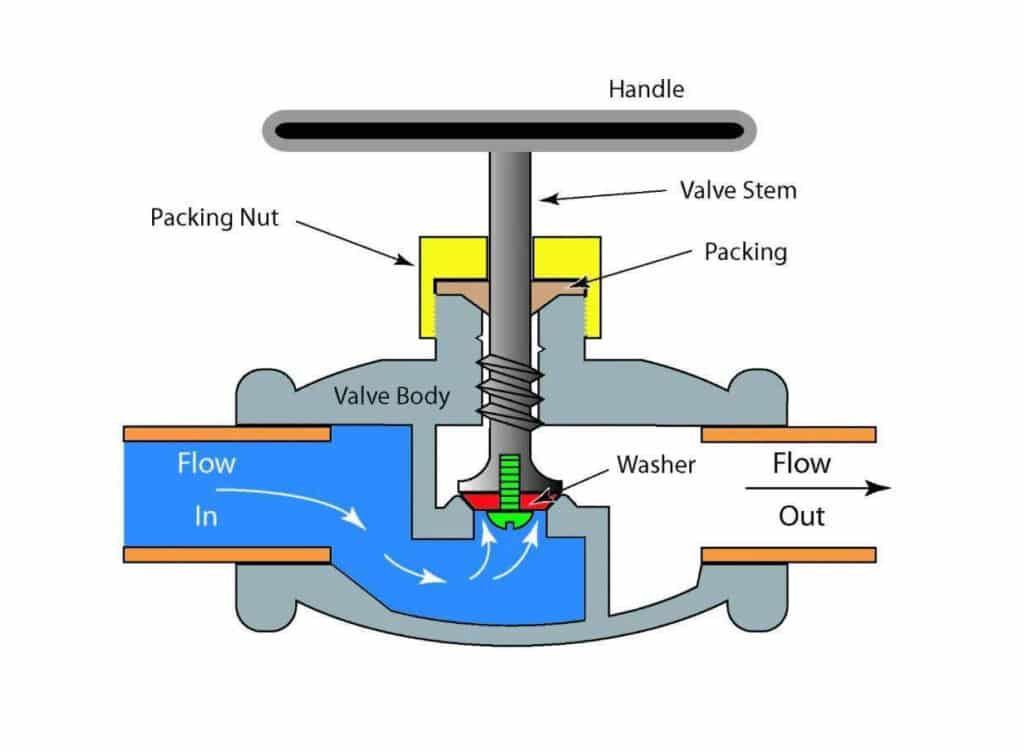

A globe valve works by the upward and downward movement of the valve stem. When the handwheel is turned, the stem moves the disc or plug toward or away from the seat, which is perpendicular to the flow path, thus controlling the flow of fluid through the valve.

What is the purpose of a globe valve

The primary purpose of a globe valve is to regulate flow in a pipeline. It is designed to throttle flow and can be used to completely shut off the fluid flow.

What does a globe valve do

A globe valve controls flow in a pipeline by adjusting the distance between a movable disk and a stationary ring seat, thus throttling the flow as needed.

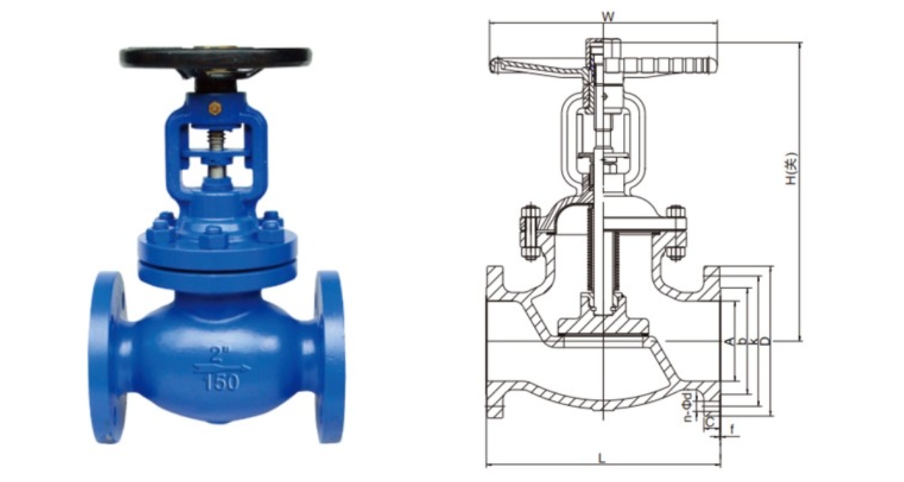

What does a globe valve look like

A globe valve typically has a spherical body with a protruding bonnet on top, housing the stem and handwheel. Internally, it has a baffle that splits the body with the seat on one side and the disk or plug on the other.

A globe valve’s characteristics can be changed by altering

A globe valve’s characteristics can be changed by altering the shape and material of the disk and seat, stem packing, and by choosing the appropriate size for the intended flow rate and pressure.

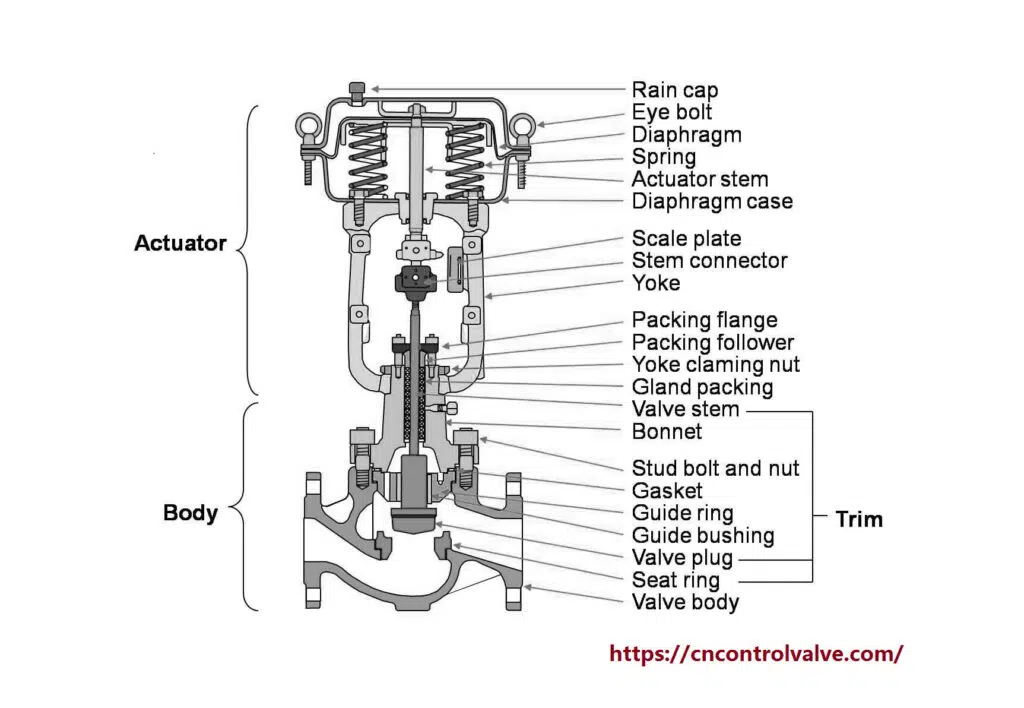

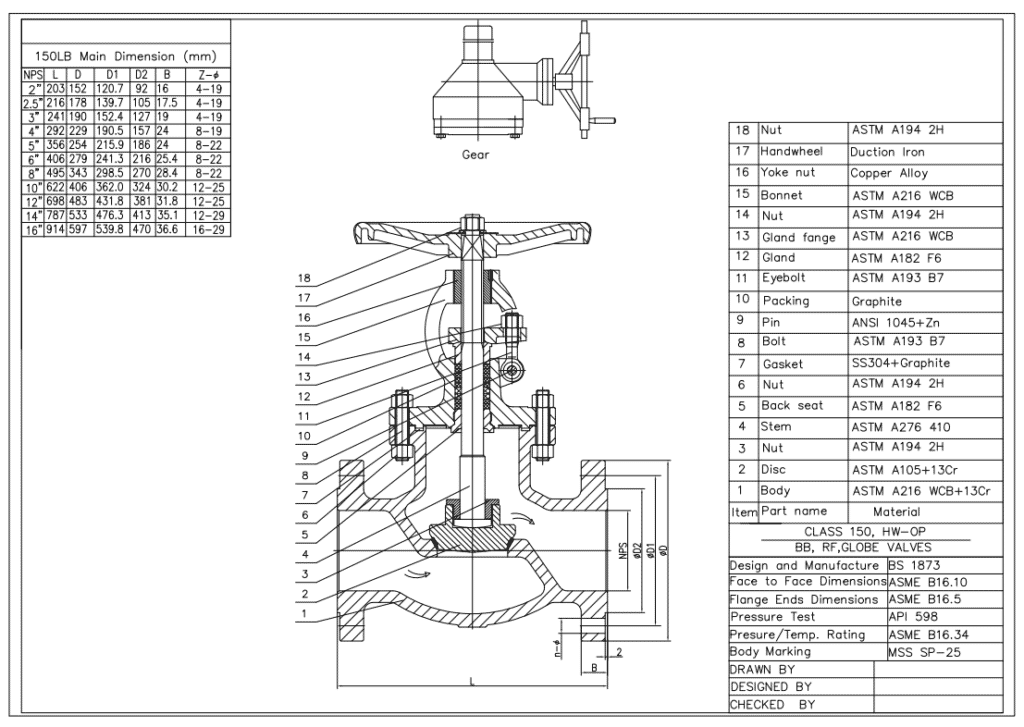

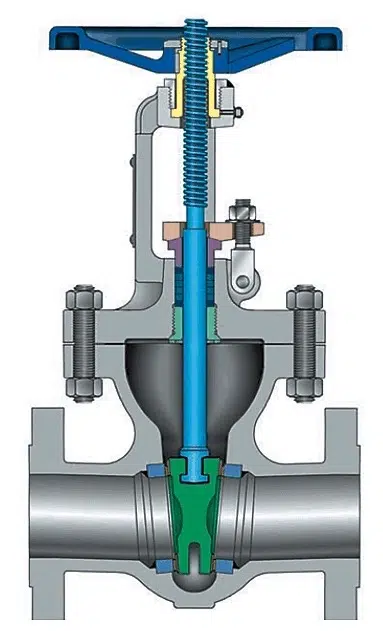

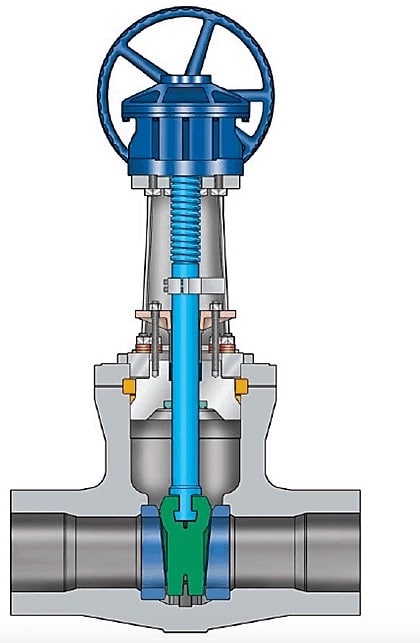

A globe valve diagram

illustrate the baffle that separates the two halves of the body and the bonnet, which houses the stem and packing that prevents leaks along the stem. The diagram may also detail the valve’s flow arrows, indicating the correct installation orientation to ensure proper operation.

Are all shutoff valves globe valves

No, not all shutoff valves are globe valves. There are several types of shutoff valves including ball valves, gate valves, plug valves, and butterfly valves, each with their own operational characteristics.

Are globe valves appropriate for slurries or suspensions

Globe valves are generally not recommended for slurries or suspensions because the particles can cause wear on the valve seat and the disk, leading to leakage. There are special valves used for this application, we THINKTANK has rich experience of slurry field, please feel free to contact us for an instant quote and solution.

Are Globe Valves WOG in Air Conditioning

WOG stands for Water, Oil, and Gas, which are the fluids a valve is rated to handle. Globe valves can be used in air conditioning systems for these fluids, provided they meet the system’s pressure and temperature requirements.

How CV is Calculated For Globe Valves

CV, or flow coefficient, is calculated for globe valves by determining the flow rate in gallons per minute (GPM) of water at 60°F that will flow through the valve with a pressure drop of 1 psi.

How does a 3 way globe valve work

A 3-way globe valve has three ports and can be used to mix flow from two inlets or divert flow to two different outlets. The valve’s operation allows for changing the flow path within the valve body to the desired outlet.

How does a globe check valve work

A globe check valve works by allowing flow in one direction and automatically closing to prevent backflow when the flow reverses, typically using a swinging disc or piston.

How does a globe stop check valve work

A globe stop check valve combines the functions of a globe valve and a check valve. It allows the valve to be closed, even if flow is going in the intended direction, to stop flow entirely, or to act as a check valve and prevent backflow.

How much does a globe sprinkler valve cost

The cost of a globe sprinkler valve can vary widely depending on size, material, and specifications. It is best to consult with suppliers for specific pricing.

How to calculate the globe valve system curve

The globe valve system curve is a graphical representation of the head loss versus flow rate through the valve. It is calculated by measuring the pressure drop across the valve at various flow rates and plotting these values on a graph. The valve’s inherent flow characteristic curve can be superimposed on the system’s flow requirement curve to understand how the valve will perform within the system.

Simply to say, to calculate the globe valve system curve, you need to chart the relationship between the flow rate through the valve and the resulting pressure drop, considering the valve’s CV and the specific system characteristics.

How to calculate CV of globe valve

CV is calculated for globe valves by measuring the flow rate in gallons per minute (GPM) that passes through the valve with a pressure drop of one pound per square inch (PSI) when the valve is fully open.

Is a trim valve a globe valve

Trim refers to the internal parts of a valve that come in contact with the fluid, not a specific type of valve. Globe valves have trim parts, including the disc, seat, stem, and cage.

Is ball valve and globe valve the same

No, ball valves and globe valves are not the same. Ball valves use a spherical ball with a hole through the center to control flow, while globe valves use a movable disc or plug to regulate flow.

Is control valve a globe valve

A control valve can be a globe valve if it is used for the purpose of controlling flow. However, ‘control valve’ is a broad category that can include other types of valves as well, such as butterfly type, plug type, V notch type, eccentric plug type, v-ball type, segment type and so on.

Is gate valve and globe valve the same

No, gate valves and globe valves are different; gate valves are designed primarily for on/off control with minimal pressure drop, while globe valves are used for regulating flow.

Is globe valve a normally closed valve

Globe valves can be normally closed (NC) or normally open (NO), depending on the design and the needs of the system they are installed in. Normally closed means the valve is closed when no actuating force is applied.

Is globe valve bidirectional

Typically, globe valves are not bidirectional. They are designed to be used with the flow in one direction, which is usually indicated by an arrow on the valve body.

Is globe valve unidirectional

Yes, globe valves are unidirectional and are designed to be installed with the flow in a specific direction to function correctly and to ensure a proper seal when closed.

What are angle globe valves

Angle globe valves are a type of globe valve where the inlet and outlet ports are at a 90-degree or other angle to each other. This design can facilitate a change in the direction of flow and reduce the number of elbow fittings required in the piping system.

What are globe valves used for

Globe valves are used for throttling or regulating flow in pipelines. They are also used for on/off service and are effective for frequent cycling and control of fluids anywhere in the amount or volume of flow.

What is a globe angle irrigation valve

A globe angle irrigation valve is a valve used in irrigation systems that combines the features of a globe valve and an angle valve, often used to control the flow of water at a 90-degree angle, which is beneficial in certain irrigation system layouts.

What is a globe check valve

A globe check valve is a type of check valve with a globe-shaped body that allows fluid to flow in one direction only, preventing backflow and typically using a swinging disc or piston for closure.

What is a globe stop check valve

A globe stop check valve is a type of valve that serves as a stop valve and a check valve. It can stop flow like a globe valve and prevent backflow like a check valve, even when the flow is in the correct direction.

What is a globe valve in plumbing

In plumbing, a globe valve is used to regulate the flow of water, allowing for precise control of water supply within a building or system.

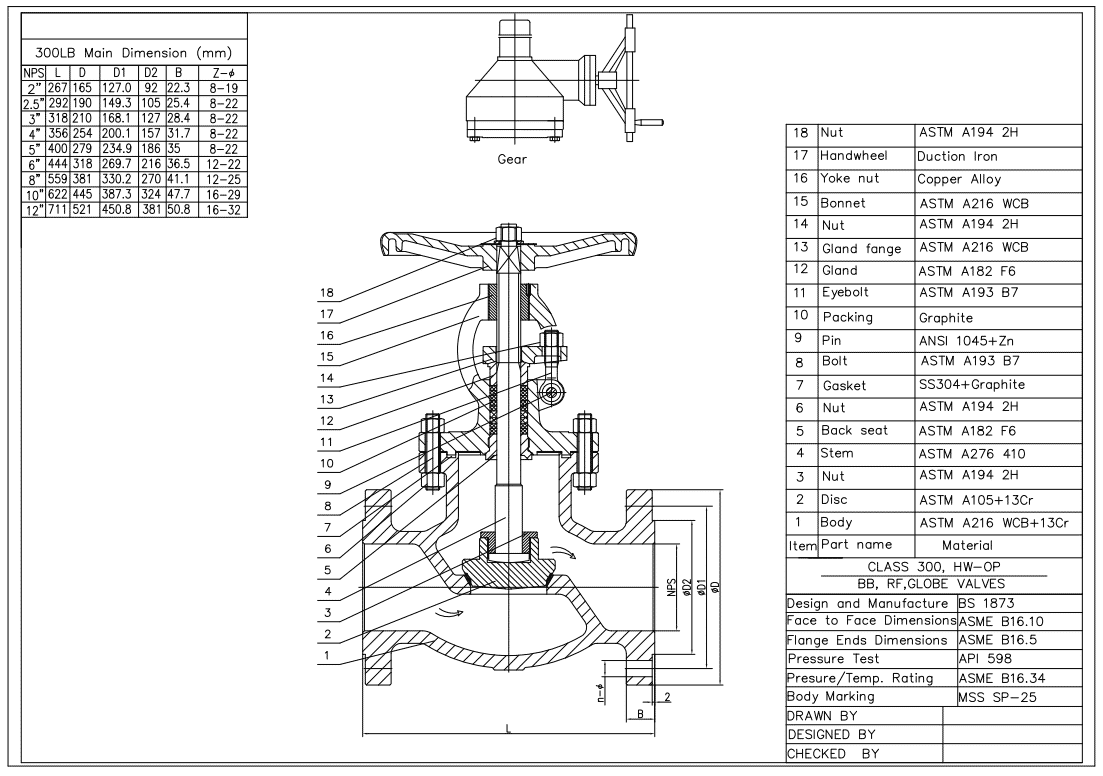

What is a globe valve made of

Globe valves can be made of various materials, including cast iron, cast steel, stainless steel, bronze, brass, PVC, special alloy steel, and other materials suitable for the specific application and the type of fluid being controlled.

What is a manual globe valve

A manual globe valve is operated by hand, using a handwheel or a similar device to open and close the valve, as opposed to an automated or actuated valve.

What is a needle and globe valves

Needle valves are a type of globe valve with a small port and a threaded, needle-shaped plunger. They provide precise flow control. When referring to “needle and globe valves,” it typically points to both being used in applications where precise flow regulation is needed.

What is a pneumatic globe valve

A pneumatic globe valve is controlled by pneumatic actuator rather than manual operation, which uses air pressure to open or close the valve.

What is a reciprocating globe valve

This term is not standard in valve terminology. Reciprocating refers to a back-and-forth movement, which is not characteristic of globe valves. If referring to a valve used in a reciprocating pump system, then it would simply be a globe valve used within that context.

What is a stop globe valve

A stop globe valve is another term for a globe valve that is specifically used to stop flow. It emphasizes the valve’s ability to completely shut off the flow when needed.

What is the trim of a globe valve

The trim of a globe valve includes the internal parts that come into contact with the process fluid, such as the seat, disc, stem, and sleeve. The trim material is selected based on the fluid characteristics to ensure proper function and durability.

What is bellow seal globe valve

A bellow seal globe valve incorporates a metallic bellow welded to the stem and bonnet of the valve, which creates a hermetic seal and prevents leaks through the stem area, commonly used in applications where leakage into the atmosphere must be minimized.

What is a globe control valve

A globe control valve is a type of globe valve that is used to regulate flow in a pipeline. It is designed to respond to signals from a control system and can be used for throttling or modulating flow.

What is an SDNR globe valve

SDNR stands for Screw Down Non-Return. An SDNR globe valve combines the functions of a globe valve and a check valve. It can be screwed down to stop flow like a globe valve and also allows flow in only one direction like a check valve. BTW, SDSL globe valve means Screw Down Screw Lift globe valve.

What is the advantage of a globe valve

The advantages of a globe valve include good throttling capability, high rangeability, and the ability to maintain and regulate high-pressure drops. They also provide a better shut-off than gate valves.

What is the face on a globe valve

The face on a globe valve typically refers to the surface where the valve connects to the flanges or pipe ends, known as the face-to-face dimension, which is important for proper installation and compatibility with the piping system. You can freely contact us for drawing or catalogs to check the standards of face to face dimension.

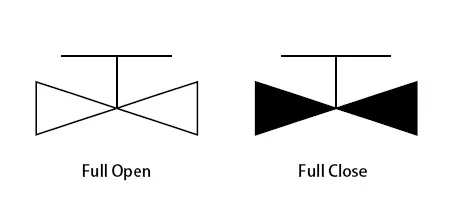

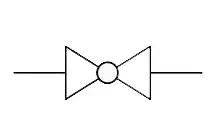

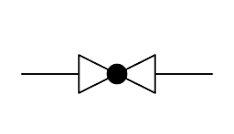

What is the symbol for a globe valve

The symbol for a globe valve in piping and instrumentation diagrams (P&ID) usually consists of a circular representation with a solid line through it at an angle, indicating the valve seat, with two lines for the pipe connections on either side.

What model valves have globe and angle configurations combined

Valves that have both globe and angle configurations are usually known as angle globe valves. They have the flow-regulating feature of globe valves but with an angled body, which allows for a 90-degree or other degree turn in the flow path.

What type of flow does a globe valve give

A globe valve gives a throttled flow which can be finely adjusted. It is not designed for full, unobstructed flow, so it will always cause some pressure drop even when fully open.

Why are globe valves shaped

Globe valves are shaped with a spherical body to house the internal mechanism that requires space to accommodate the disk, seat, and stem assembly, which provides a good seal and allows for the precise regulation of flow.

Why is it called a globe valve

It is called a globe valve because of the spherical shape of its body, which is divided by an internal baffle housing the valve’s seat and controls the flow within the spherical chamber.

Why use globe valve

Globe valves are used because they offer precise control of flow, are excellent for throttling, and provide a reliable shut-off. They are suitable for applications where flow needs to be adjusted regularly or maintained at a certain level.

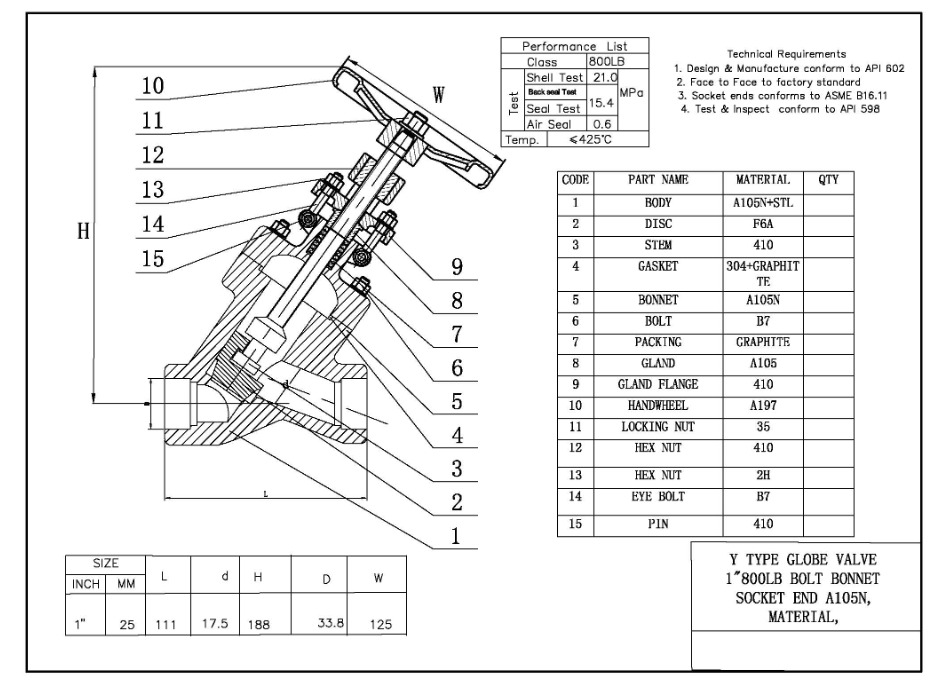

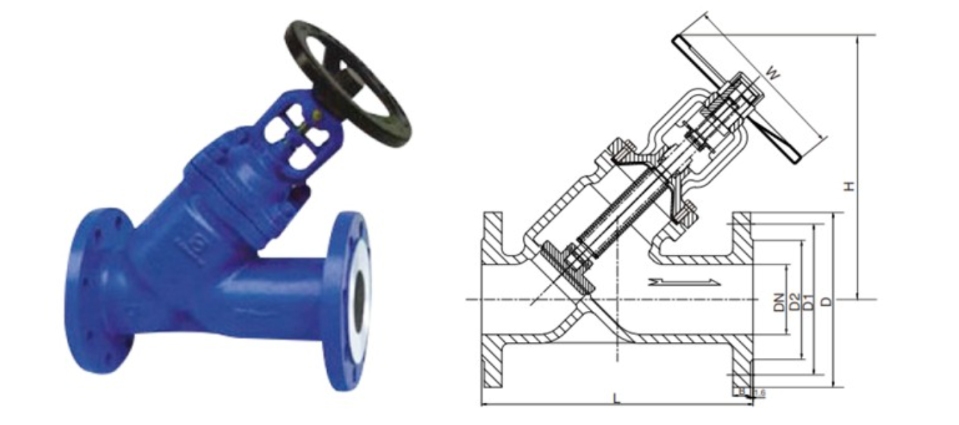

Why Y-type globe valve used

A Y-type globe valve is used because its design reduces the flow resistance and pressure drop across the valve, which makes it more suitable for high-pressure applications. The angled path through the valve also allows for a smoother flow transition.

Part 2: Installation Queries

Orientation and Flow Direction Considerations

Are globe valves directional

Yes, globe valves are directional due to their design and must be installed with the flow direction in mind to function properly.

Can a globe valve be installed vertically

Yes, a globe valve can be installed vertically as long as the flow direction is maintained and the valve is supported adequately.

Why is a globe valve unidirectional

A globe valve is considered unidirectional because it is designed to be used with the flow in one direction, which allows for the proper operation of the valve and effective shut-off.

Can a globe valve be installed on its side

Yes, a globe valve can be installed on its side, but the flow direction must be maintained as per the manufacturer’s instructions, and the actuator must be accessible.

Can a globe valve have no friction

No mechanical valve can be entirely without friction because there will always be some resistance when moving the parts against each other, especially the disk against the valve seat. However, well-designed valves can have minimal friction.

Part 3: Operational Capabilities

Throttling and Pressure Management in Globe Valves

Where should the pressure enter a globe valve

The pressure should enter the globe valve from under the seat. This assists in closing the valve and helps in achieving a tight seal when the valve is closed.

Can you throttle a globe valve

Yes, globe valves are particularly well-suited for throttling and regulating flow, making them ideal for applications where flow control is necessary.

Can globe valve be used for throttling

Yes, globe valves are particularly suitable for throttling purposes due to their ability to control flow precisely.

Can globe valves be installed upside down

It is not recommended to install globe valves upside down because it can complicate maintenance and may affect the performance due to the orientation of the stem and actuator.

How to fix a globe valve

Fixing a globe valve involves isolating the valve from the system, disassembling it to inspect for worn or damaged parts such as the seat, disc, stem, or packing, and replacing them as necessary. Reassembly should follow the manufacturer’s guidelines to ensure proper function.

How to flush a line before the drip globe valve

To flush a line before the drip globe valve, you should open the valve fully to allow water to flow at maximum capacity, thereby flushing out any debris or sediment. Some systems may have dedicated flush valves or ports for this purpose.

How to hydrotest a globe valve

Hydrotesting a globe valve involves filling the valve with water and pressurizing it to a specified test pressure, which is usually higher than the valve’s normal operating pressure. The valve is then inspected for leaks or deformities. Safety precautions must be strictly observed during hydrotesting.

How to install a globe valve

To install a globe valve you can following the blew steps.

Step 1: Ensure the pipeline is depressurized and drained.

Step 2: Check the flow direction indicated on the valve body.

Step 3: Place the valve in the pipeline with the flow direction matching the system’s flow.

Step 4: Use flanges or threads to secure the valve in place according to the type of valve ends.

Step 5: Tighten bolts or fittings evenly to prevent damage.

How to lap a globe valve

Lapping a globe valve you can following the below method.

- Disassembling the valve and removing the disc.

- Applying a lapping compound to the seating surface.

- Using a lapping tool, rotate the disc against the seat to create a smooth, leak-tight surface.

- Clean off the compound and inspect the seat and disc for a uniform, polished appearance before reassembly.

How to make a system curve for the globe valve

To create a system curve for a globe valve:

- Plot the flow rate (x-axis) against the head loss or pressure drop (y-axis) at various open positions.

- Measure the pressure drop at different flow rates with the valve in multiple positions.

- Draw a curve through these points to represent the system curve.

How to open a stuck globe valve

To open a stuck globe valve, please check the following tips.

- First, ensure that there is no pressure in the line.

- Apply a penetrating lubricant to the valve stem.

- Gently tap the valve body and stem with a rubber mallet to loosen any corrosion or debris.

- Slowly turn the handwheel back and forth until it moves freely.

How to refill a leaky globe valve

Refilling typically refers to replenishing the packing:

- Isolate the valve from system pressure.

- Remove the packing gland.

- Take out the old packing and clean the stuffing box.

- Replace with new packing, making sure to stagger the joints of the packing rings.

- Reassemble the packing gland and adjust to the proper compression.

How to repair globe valve

To repair a globe valve, here are some tips for your reference.

- Disassemble the valve, inspect all parts for damage or wear.

- Clean all components.

- Replace any damaged parts such as the seat, disc, stem, or packing.

- Reassemble the valve carefully and test to ensure it operates smoothly.

How to replace a globe valve

Here is a way to replace a globe valve

Step 1: Shut off the system and relieve pressure.

Step 2: Disconnect the valve from the pipeline.

Step 3: Remove the old valve.

Step 4: Install the new valve, ensuring the flow direction is correct.

Step 5: Test the valve for proper operation.

How to use globe valve

The following is the method to use globe valve.

First, Turn the handwheel clockwise to close and counter-clockwise to open.

Second, Make incremental adjustments to the handwheel to throttle the flow as needed.

Finally, Do not force the valve to open or close, as this can damage the seating surfaces.

Part 4: Differentiation of Globe Valve with Other Valves

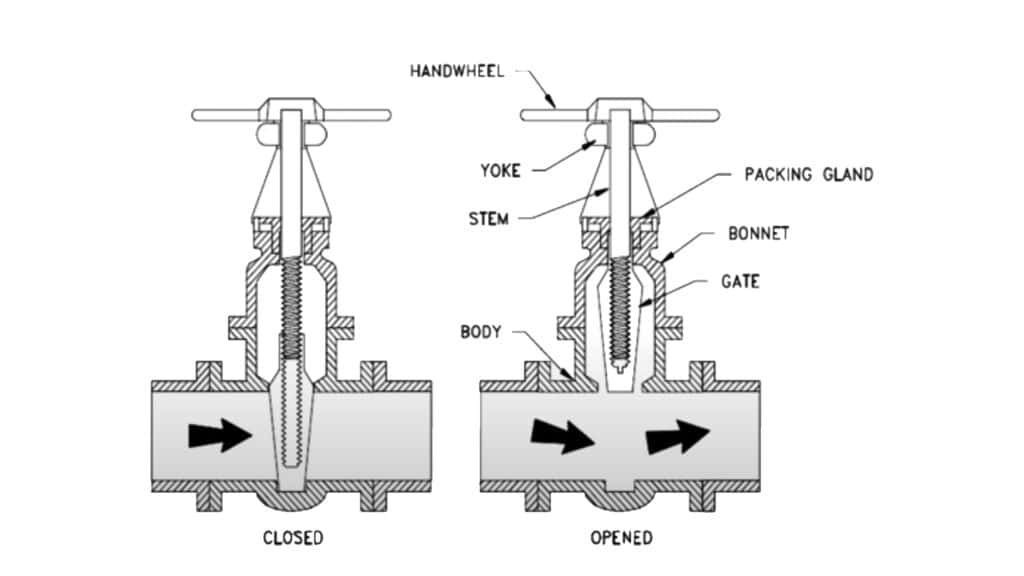

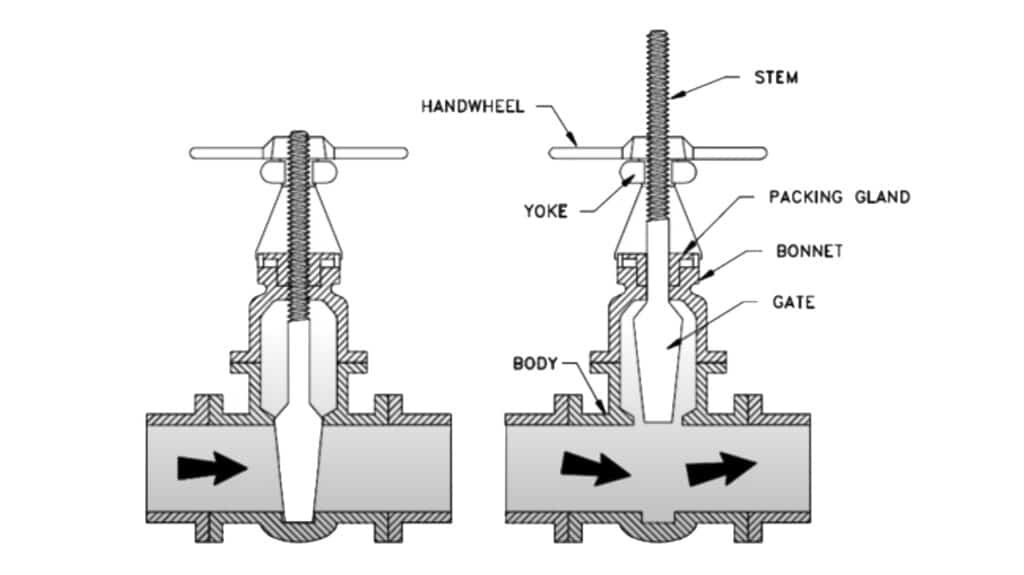

How to identify gate and globe valve

Gate valves have a flat gate that slides vertically in and out of the flow, while globe valves have a movable disk that moves perpendicular to the flow. Globe valves typically have a round body, and their stem movement is usually guided by a bonnet outside the valve body. Gate valves have a rising or non-rising stem that moves up or down as the valve is operated.

What is the difference between a gate valve and a globe valve

The main difference lies in their design and functionality: gate valves are optimized for on/off control, with a gate that moves up or down to block flow, while globe valves are used for throttling, with a disk that moves in or out of the seat to regulate flow.

How to tell a globe valve from a gate valve

A globe valve typically has a spherical body with the valve stem at the top operating perpendicular to the flow, while a gate valve has a more elongated body with a gate that moves up and down parallel to the flow.

What’s the difference between shutoff valves: ball, gate, and globe

- Ball valves provide tight shut-off and are used for on-off service with low pressure drop.

- Gate valves are designed for on-off service, featuring a gate that moves up and down in the flow path and are used where straight-line flow with minimum restriction is required.

- Globe valves are used for throttling service, offering precise flow control.

Gate Valve VS. Globe Valve

Both the globe valve and gate valve can be used in the pipeline to shut off the flow of the medium, and due to gate valve and globe valve also have similar structures. Therefore, for some new guys whom just enter to industrial valves market, it will be really confused about the difference between globe valve and gate valve.There are four aspects to compare the difference between globe valve and gate valve.

1. difference in structure

The structure of the gate valve is more complicated than that of the globe valve.

First of all, according to the structure of the gate valve, there are two types of gate valves:

Rising Stem Gate Valves and Non-Rising Stem Gates. But globe valves don’t have this different design.

Secondly, in terms of appearance and structure, the face to face(length) of the gate valve is shorter than that of the globe valve, but the height is higher than that of the globe valve.

Therefore, the gate valve requires more installation space, especially the rising stem gate valve.

The rising stem gate valve is also called OS&Y design, which means Outside Stem and Yoke.

2. difference in principle

The operation method of the gate valve and globe valve is the same, all can use a pneumatic actuator, electric actuator, or handwheel to drives the valve stem open and close the valve.

The difference between them is that the gate valve can only be fully opened and fully closed. And its travel/stroke is larger than the globe valve. It means that the opening and closing time of the gate valve is longer than the globe valve.

Due to the distance of plug to seat is short of globe valve, globe valve can be stopped at any travel during the movement for flow throttling. This is not available in gate valves.

In addition, when the gate valve is installed in the pipeline, there is no requirement for the direction of the inlet and outlet, and the medium can circulate in both directions. But the globe valve definitely has a direction of inlet and outlet. The flow direction of the globe valve can be down to up or up to down. Most flow type is from down to up for globe valve.

3. difference in flow resistance

Because the gate valve can only be fully open and fully closed, when it is in a fully open state, the flow path in the entire pipeline is straight. When the medium flows through the valve body, there is nearly no obstruction, and the flow resistance is almost zero. In the globe valve, when the medium flows through the valve body, the flow direction is from top to bottom, and the resistance of the valve plug is relatively large.

4. difference between maintenance costs

When the gate valve is maintained and repaired, the gate valve needs to be disassembled completely from the pipeline, so the labor costs are relatively high. But for the globe valve, In most cases, the valve seat and plug can be directly replaced on the site without disassembling the complete valve. Therefore, the globe valve is suitable for welding connection applications.

Globe Valve VS. Ball Valve

The ball valve and globe valve both can be shut off the fluid of the pipeline.

The ball valve is evolved from the plug valve. Its opening and closing part is a sphere, which uses the sphere to rotate 90° around the axis of the valve stem to achieve the purpose of opening and closing.

Advantages of ball valves

- Ball valve has the lowest flow resistance.

- It can action fast opening and closing.

- With compact structure and lightweight, the ball valve can be considered as the most reasonable valve structure for cryogenic media systems.

- The ball valve body uses an asymmetrical design, especially the welded valve body structure, which can withstand the stress from the pipeline well.

Disadvantages of ball valves

- The throttling performance is worse than that of the globe valve, especially the pneumatic globe type control valve (or electric globe type control valve).

- The globe valve is used to cut off the flow of the medium and is suitable for occasions that need to be opened very frequently. The most commonly used is in a chemical plant.

Advantages of globe valve

- Simple structure, convenient manufacturing, and maintenance.

- The working stroke is small, and the opening and closing time is short.

- Good sealing performance, small friction between the sealing surfaces and plug, and long service life.

Disadvantages of globe valve

- The fluid resistance is large, and the force required for opening and closing is large.

- It is not suitable for media with particles, high viscosity, and coking medium.

- The fluid resistance is large, and the reliability of the seal is not suitable during long-term operation.

Globe Valve VS. Butterfly Valve

Globe valve and butterfly valve both are common valves in industrial processes. What is the difference between the globe valve and the butterfly valve? The globe valve and the butterfly valve have similar functions, both of globe valve and butterfly valve can be used for flow regulating or cut off. The difference is that the globe valve has a better flow adjusting function when it is used to controlling the flow rate. The advantage of the butterfly valve is that it is more widely used, has a large flow capacity, shorter structure length, and a simpler structure.

The globe valve only allows the medium to flow in one direction when installed. The opening or closing stroke of the valve stem of the globe valve is relatively short, and it has a reliable shut-off function. Due to the response of the valve seat is proportional to the stroke of the valve plug, it is very suitable for flow adjustment. Therefore, this type of shut-off valve is very suitable for cutting off or regulating and throttling. The structural length of the globe valve is larger than butterfly valve.

A Butterfly valve is a rotary motion valve, which consists of four main parts: valve body, stem, disk and seat. A butterfly valve has a disc which is mounted on a rotating shaft. When the butterfly valve is fully closed, the disk back to seat and completely blocks the line. When the butterfly valve is fully opened, the disc is at a right angle to control the flow of gas or liquid.

Butterfly valve is a simple regulating valve, and it can also be used for on-off control of low-pressure pipeline media. There are many types of butterfly valves and used for wide range application. Butterfly valves are suitable for pipelines that transport various corrosive and non-corrosive fluid media in engineering systems such as generators, natural gas, petroleum, air, chemical and power plant, and are used for controlling and on/off medium. Butterfly valves have two-way sealing and one-way sealing.

Globe Valve VS. Plug Valve

The plug valve is suitable for cutting off or connecting pipeline media in various working conditions such as petroleum, chemical, pharmaceutical, fertilizer, and electric power industries with a nominal pressure of CLASS150-1500LBS and a working temperature of -29~550℃.

In total plug valve has a compact structure and a small volume, compared with a gate valve, the height of the valve is greatly reduced, also fluid resistance is greatly reduced.

A plug valve is a rotary type valve, the plug shaped like a cone or cylinder. It can be rotated inside the valve body to control the flow of fluids.

The opening process of the plug valve: When opening the valve, you need to rotate the handwheel to raise the plug and disengage it from the sealing surface. Rotate the handle 90° to make the passage of the plug communicate with the passage of the valve body, then to achieve the purpose of opening. The process of closing the valve is to rotate the handle 90° to make the passage of the plug perpendicular to the passage of the valve body, and then rotate the handwheel to lower the plug to achieve the seal.

Part 5: Globe Valves in the Field

Applications and Real-World Usage

Why is a globe valve used in a steam line

Globe valves are used in steam lines because they can precisely control the flow and pressure of the steam, which is critical for the efficiency and safety of steam systems.

Where are globe valves used

Globe valves are used in a variety of applications, including water, steam, and gas systems, where flow needs to be regulated or stopped completely.

A globe valve is best suited for

A globe valve is best suited for applications that require flow regulation, throttling, and frequent operation. It’s also used where pressure drop through the valve is not a critical concern.

Can you control steam pressure with globe valves

Yes, steam pressure can be controlled with globe valves by adjusting the valve opening, which regulates the flow and, consequently, the pressure.

Can you use hunter pgv globe valves on golf course

Hunter PGV globe valves are typically used in irrigation systems and may be suitable for use on golf courses, depending on the specific requirements of the irrigation system.

Do gas cylinders have gate or globe valves

Gas cylinders can have different types of valves, including gate or globe valves, depending on their intended use and the requirements of the system in which they are installed.

Do globe valves restrict flow hot water

When fully open, globe valves do not significantly restrict flow, but they do have a higher pressure drop compared to other valves like ball or gate valves. When partially open, they effectively restrict and regulate the flow of hot water.

Do you use globe valves on a steam system

Yes, globe valves are commonly used on steam systems for their ability to throttle and precisely control the flow of steam.

When to use a globe valve

A globe valve should be used when you need to regulate or throttle the flow, or when you require frequent operation of the valve.

When to use a globe valve in steam

Use a globe valve in a steam system when you need to control the steam flow rate or maintain and reduce steam pressure.

Where to place globe valve on an irrigation system

Place a globe valve at strategic points where flow control is needed, such as at the start of a zone, to regulate or stop flow for maintenance, or to control the flow to different sections of the system.

Where we use globe valve

Globe valves are used in applications that require flow regulation, such as cooling systems, fuel oil systems, feedwater, chemical feed, and steam services.