In the detailed design of industrial engineering, safety valve and pressure relief valve emerge as silent protectors, standing guard against the unpredictable surges and fluctuations of pressure. Like caring caretakers, these valves are the unnoticed champions ensuring the well-being of machinery and, by extension, the entire operation. In this blog, we shine a spotlight on the dynamic duo – safety valve and pressure relief valve – and the mastery that goes into each unit, proudly crafted by THINKTANK. Let’s start an adventure to uncover the mysteries behind these essential components that keep our industrial landscapes safe and secure. In the delicate coordination of excess pressure and maximum allowable working pressure, these valves play a pivotal role in maintaining balance, creating a seamless symphony of functionality where system pressure doesn’t rise above the set pressure.

What are safety and relief valves

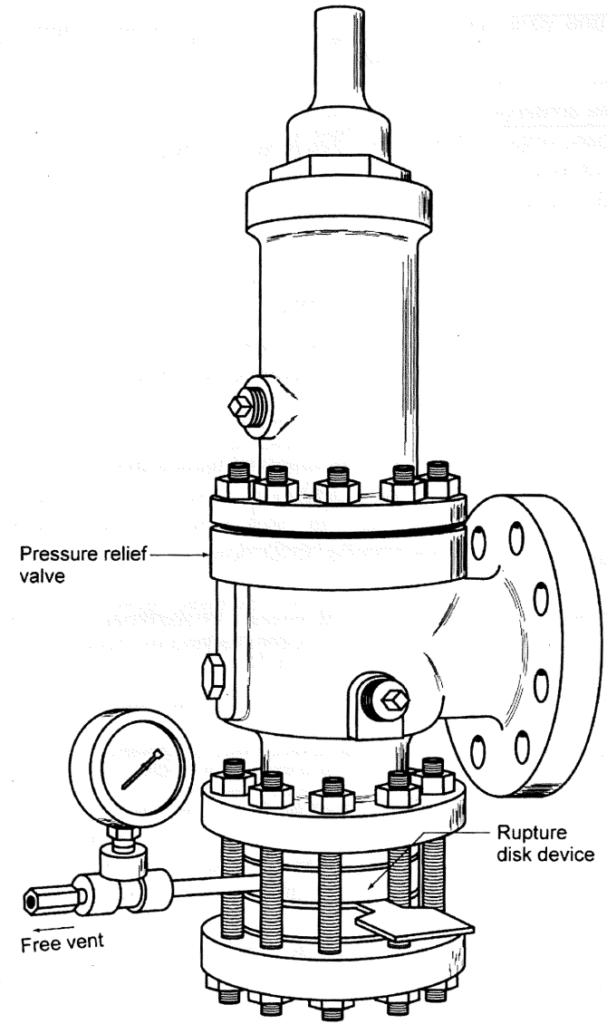

In the active world of industrial and mechanical systems, safety valves and relief valves stand as crucial safety device, these valves are designed to maintain the pressure increases in the pressurized system and preventing potential damage caused by excessive pressure. Let’s dive deeper into the details of these critical components, exploring their roles in ensuring system safety and preventing failures.

Safety Valve

Function

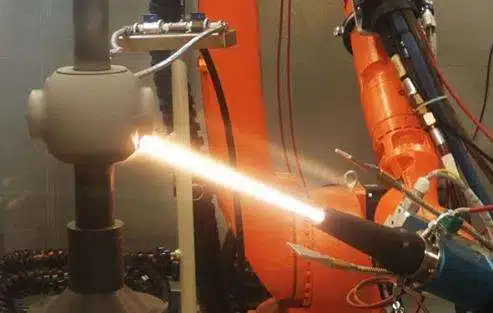

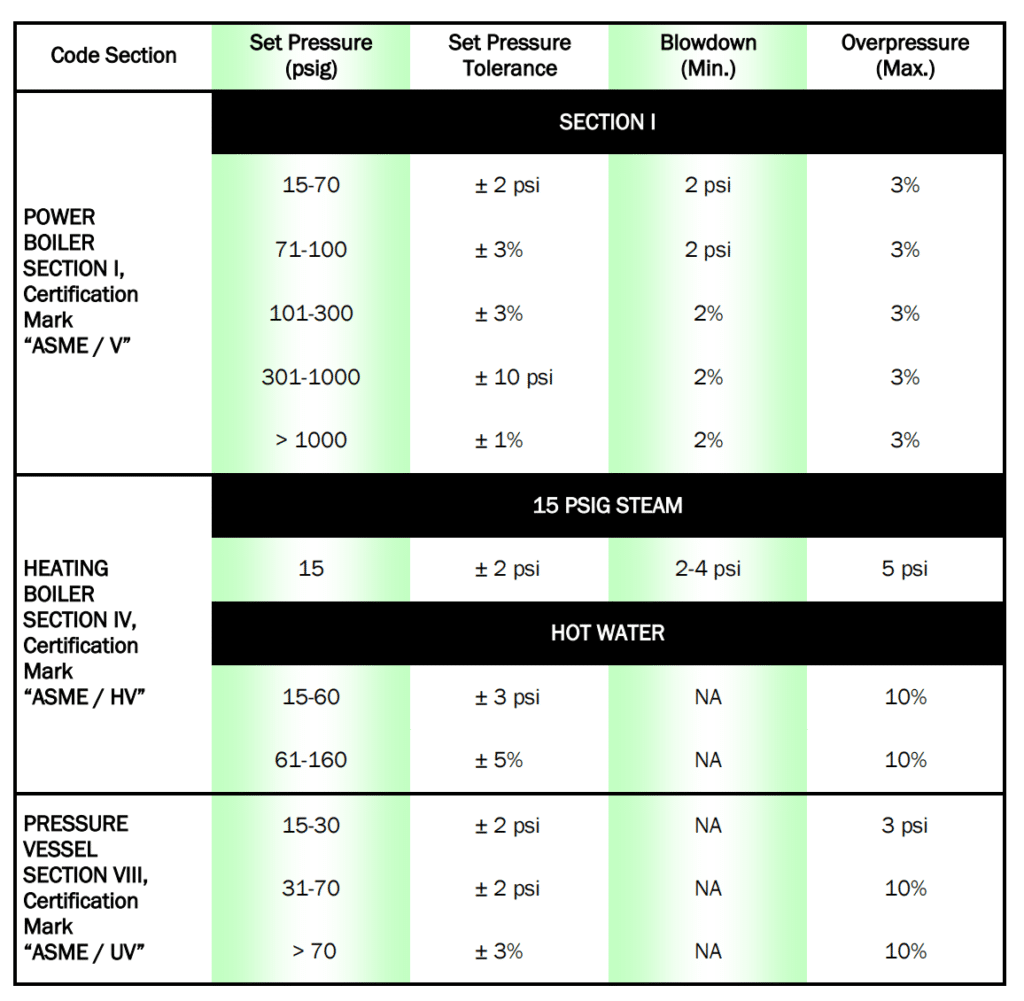

Safety valves serve as the careful keepers of industrial and mechanical systems, engineered to automatically release substances—whether steam, gas, or liquid—from a diverse array of applications such as boilers, pressure vessels, or other critical systems. These valves are skillfully crafted to respond decisively when the pressure or temperature surpasses preset limits, preventing potential damage and ensuring the overall safety and reliability of the system.

Moreover, their protective influence extends beyond release pressure; safety valve protects pressure sensitive equipment, becoming indispensable safeguards in critical environments environments where precision and reliability are crucial.

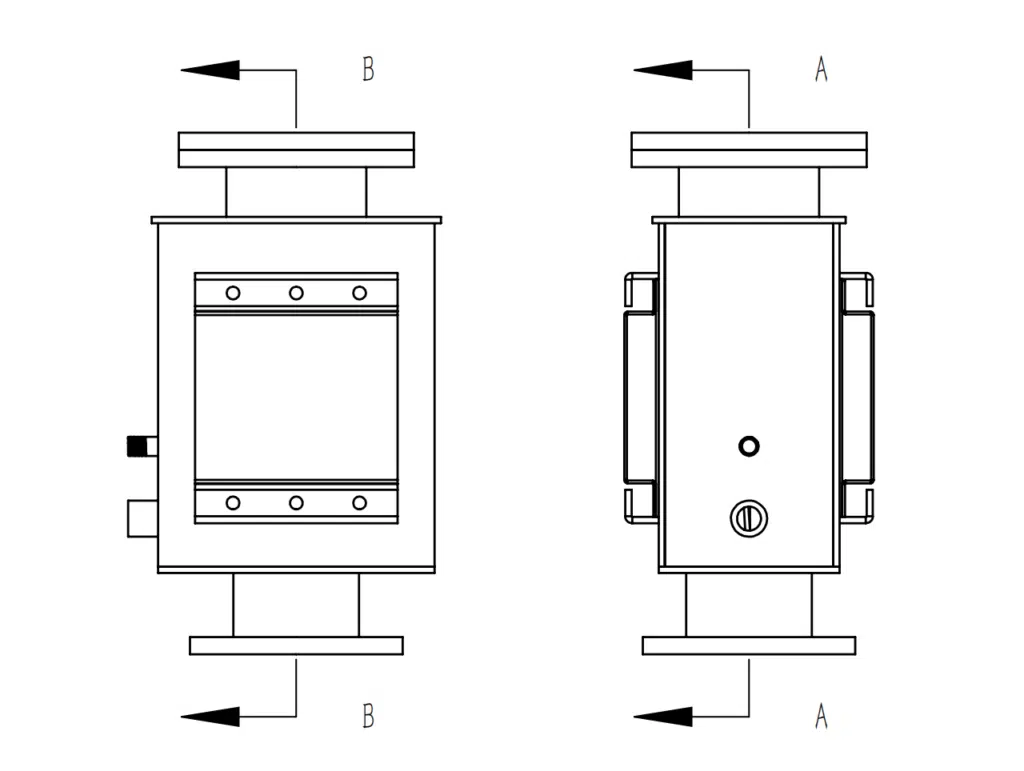

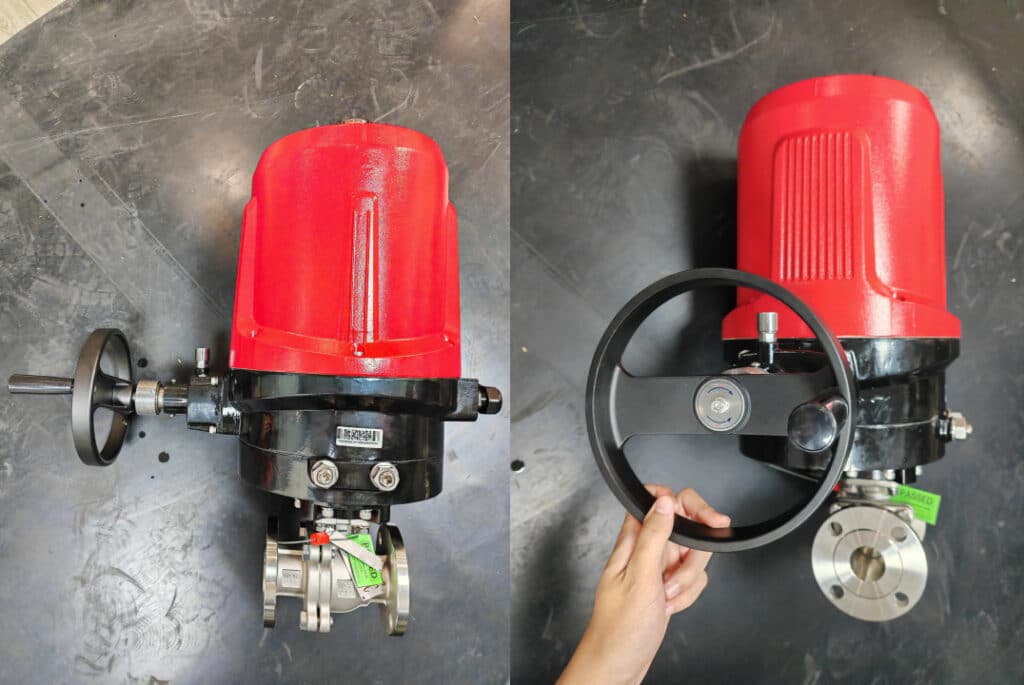

Operation

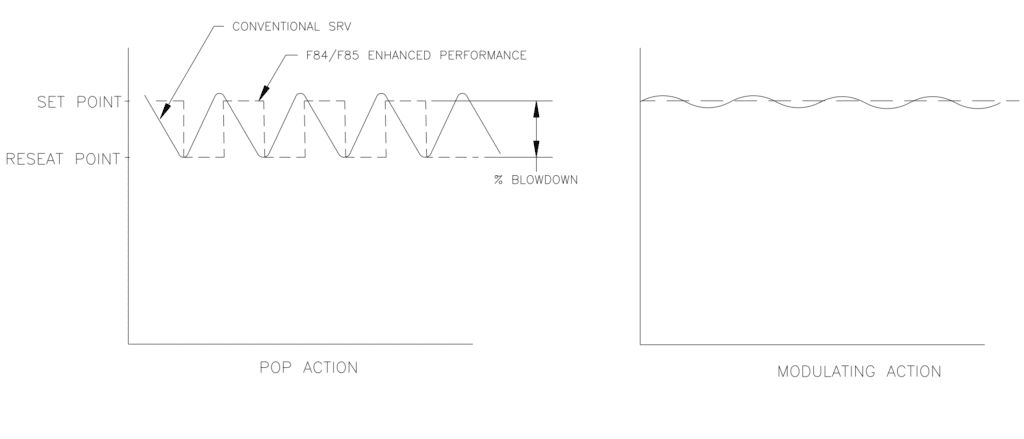

Safety valves, engineered with precision by companies like THINKTANK, feature a rapid “pop action” that rapidly responds when system pressure reaches set pressure limits, efficiently relieving excess pressure. In crucial scenarios, these loaded safety valves discharge fluid with speed and precision, safeguarding pressure vessel, liquid systems, and prevent system failures. Beyond their role in fluid flow dynamics, safety valves play a crucial part in protecting pressure-sensitive equipment, showcasing their direct action in the complex dance of safety valves and relief. THINKTANK’s mastery in this craft ensures that each valve exceeds the demands of modern industrial landscapes, where the delicate balance of safety and reliability is upheld with unwavering precision.

Applications

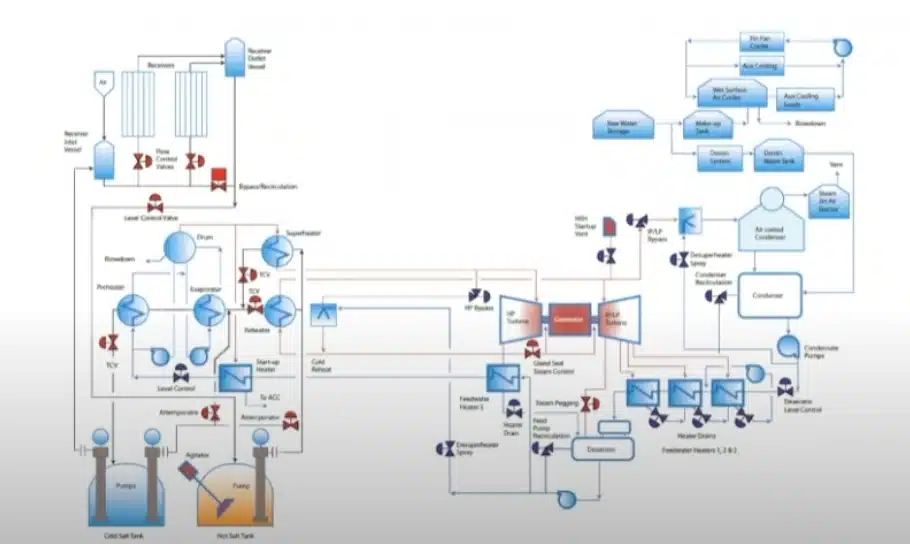

Safety valves find diverse applications across industrial landscapes, ensuring the protection of equipment and preventing system failures. Functioning interchangeably with relief valves, they relieve pressure in pressurized systems when the set pressure, often a predetermined limit, is reached. From power plants to steam systems, these valves play a critical role in controlling pressure build-up. Designed to open at specific set pressure, safety valves, often equipped with a manual lever, discharge fluids efficiently, preventing accidents and safeguarding against further release. Whether in carbon steel construction or dealing with corrosive fluids, these valves are key components in maintaining control over system pressures, a testament to their pivotal role in various processes and industries.

Key Feature

Their primary role is to protect life, property, and the environment by venting excess pressure and keep the system pressure under control. They also act as pivotal safety devices, relieving pressure in diverse applications such as pressure vessels and liquid system. Their key function, often interchangeably used with relief valves, is to prevent system failure by efficiently venting excess pressure, ensuring that set pressures, predetermined limits, are maintained.

Relief Valves

Function

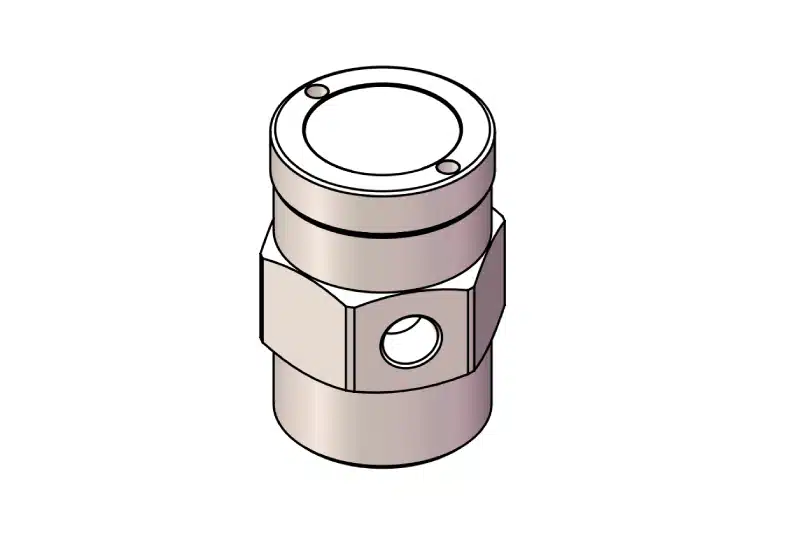

Relief valves or pressure relief valves are crucial safeguards, proactively preventing system failure by managing pressure in diverse applications. Similar to safety valves, they protect equipment and uphold system integrity. Precision-designed pressure relief valves control pressure build-up, ensuring safe release pressure in pressurized systems. Operating in varied environments, from petrochemical systems to those with compressible fluids, these valves are key control devices, preventing pressure surpassing maximum allowable pressure. Their dynamic operation, often facilitated by manual mechanisms, safeguards equipment, prevents accidents, and maintains industrial process reliability. In this intricate dance of fluid dynamics and pressure management, relief valves, including other pressure relief valves, exemplify excellence in design and manufacturing by companies like THINKTANK.

Operation

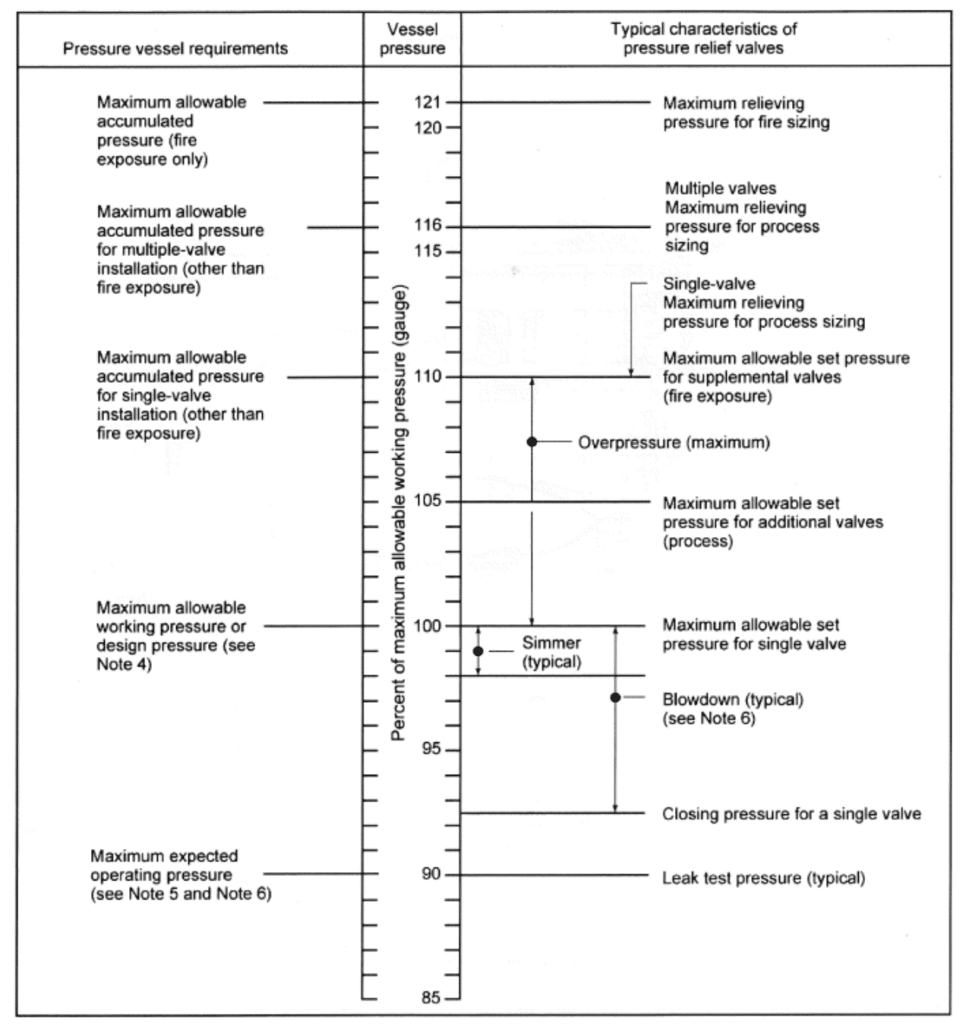

In operation, pressure relief valves exhibit precision in responding to pressure increase, ensuring that pressure does not exceed set limits. When the system pressure reaches a critical point, these valves open to release excess pressure, averting potential damage and catastrophic failures. This rapid and controlled operation is an evidence to the engineering excellence embedded in pressure relief valves, creating a dynamic balance in pressurized systems.

Applications

Pressure relief valves find wide-ranging applications across industries, functioning interchangeably with safety valves. From power plants to chemical processing units, these valves play a pivotal role in controlling pressure build-up and maintaining specific pressure levels. Their versatility extends to various scenarios, including those involving pressure increases environments, low-pressure environments, and situations where system’s pressure must be carefully managed.

Key Feature

A key feature that distinguishes pressure relief valves is their ability to provide a controlled release of pressure, preventing excessive pressure from causing damage to equipment or compromising system integrity. In essence, pressure relief valves act as critical control devices, allowing for the safe release of pressure to protect both machinery and the surrounding environment. This key feature underscores the vital role played by relief valves in ensuring the reliability and safety of industrial processes, a commitment exemplified by companies like THINKTANK in their precise design and manufacturing.

Comparison

Action

Safety valves are characterized by a rapid, pop action, rapidly responding to predetermined pressure limits, providing an immediate and decisive release of excess pressure. In contrast, pressure relief valves exhibit a more gradual opening mechanism, allowing for a controlled and progressive release of pressure over time.

Use Case

Safety valve play a critical role in systems where the consequences of overpressure can be catastrophic, such as in steam boilers or gas storage tanks. Their swift action is paramount in preventing potential damage and ensuring system safety. On the other hand, pressure relief valves find their niche in scenarios requiring precise and controlled pressure management. They are commonly employed in situations where a gradual release of pressure is necessary to maintain optimal system conditions and prevent instability that could impact performance.

System Compatibility

Safety valves are commonly associated with gas and steam systems, where their rapid pop action is well-suited to respond to the dynamic nature of these materials. In contrast, relief valves are often integrated into liquid systems, providing a more gradual release of pressure suitable for the complex requirements of fluid dynamics. This variation in system compatibility highlights the personalized nature of these valves, ensuring their optimal performance in specific industrial contexts.

In both cases, the correct selection, maintenance, and regular testing of these valves are essential to ensure they function correctly when required, thereby ensuring the safety and reliability of the systems they protect.

Where Safety valve and Relief Valve Shine

Safety valve and pressure relief valve find their excellence in diverse applications and industries. From steam boilers to chemical processing units, these valves play a pivotal role in controlling pressure build-up and preventing system failures. This exploration shines a spotlight on the varied scenarios where safety and relief valves become indispensable components for maintaining operational integrity.

Safety vs. Relief – Which is Right for Your System?

After exploring the specific features and functions of safety valve and relief valve and gaining a comprehensive understanding of their unique roles in managing pressure, a crucial question emerges: which pressure relief valve type is the optimal fit for your system? Both safety and relief valves fall under the umbrella of pressure relief valves, differing slightly in their implementation. We suggest to consider experimenting with both options to decide which one aligns best with the unique requirements of your industrial or mechanical setup. By testing both safety and relief valves, you empower yourself to make a choice based on firsthand observations and the specific demands of your system.

Conclusion

In conclusion, the correct operation of safety and relief valves is not only dependent on their essential design but also relies on consistent maintenance and testing protocols. These valves, whether ensuring rapid response in crisis situations when system reaches specific pressure or facilitating controlled pressure release, are key factors in the safety and reliability of industrial systems.

The main difference lies in safety valves vs. relief valves operation and application: safety valves are ideal for gas and vapor systems with rapid pressure release needs, while relief valves are more suitable for liquid systems requiring gradual pressure release. Safety-relief valves combine aspects of both and offer flexible application in mixed systems.

Ensuring the commitment to precision and excellence in selection, maintenance, and testing ensures that these valves, including the top-notch products from THINKTANK, stand ready to fulfill their critical roles, prevent accidents, and safeguard against potential failures. As a reliable safety and pressure relief valve manufacturer, THINKTANK always provides good quality and competitive prices to support your business. Any questions just feel free to contact us.