If you are the ethylene plant engineers&contractor, this is the most comprehensive guide available to the process of choosing the right industrial valves for an ethylene plant.

Running a reliable and cost-effective ethylene plant in a growing market for ethylene production comes with more challenges. So, selecting and sizing the best valve solutions that make the manufacturing process of the ethylene plant safe, reliable, and highly efficient.

Ethylene is increasingly used in today’s market for a variety of plastics and chemical applications, and in the near future, it will be in demand for more than 180 million tons. After more than 30 years of technological revolution, ethylene production from natural gas instead of petroleum is not only resourceful but also cost-effective. This also provides a huge opportunity for THINKTANK’s valves, we participate in a dozen of valve packages for ethylene plant projects in the Middle-East market.

In an increasingly competitive global market, uptime is a key factor in determining the profitability of ethylene plants. As the demand for ethylene increases, it means the demand for reliable valve solutions is also increased, which can provide optimum trustworthiness, safety, and service time.

The investment value of a typical ethylene plant project reaches billions of dollars. As a very important part of automation, the valve package a considerable amount goes for control valves, isolation valves, and control systems.

The Main Type Valves For Ethylene Plants

Pneumatic Globe Type Control Valves

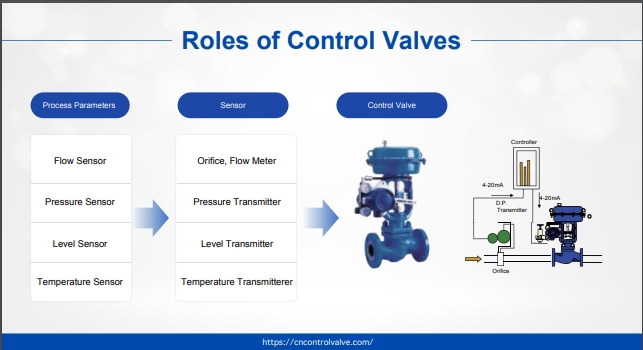

General, pneumatic globe type control valve assembly with multi-spring or single-sping diaphragm actuator to increase the performance stability, and complete with a digital positioner to transfer the variable to controllers, in case the end-user can monitor the data in real-time.

The globe type control valves are designed with a sliding stem, which provides highly precise control for the ethylene plant processing.

And for high pressure condition, Thinktank use multi-hole trim, multi-stage pressure reduction, and Whisper or labyrinth trim design to minimize aerodynamic noise. Meantime, the trim material will be hardened to supply wear resistance and long service time.

We are available acceptable customizable trim for the customers, in case the control valve can meet a wide range of applications.

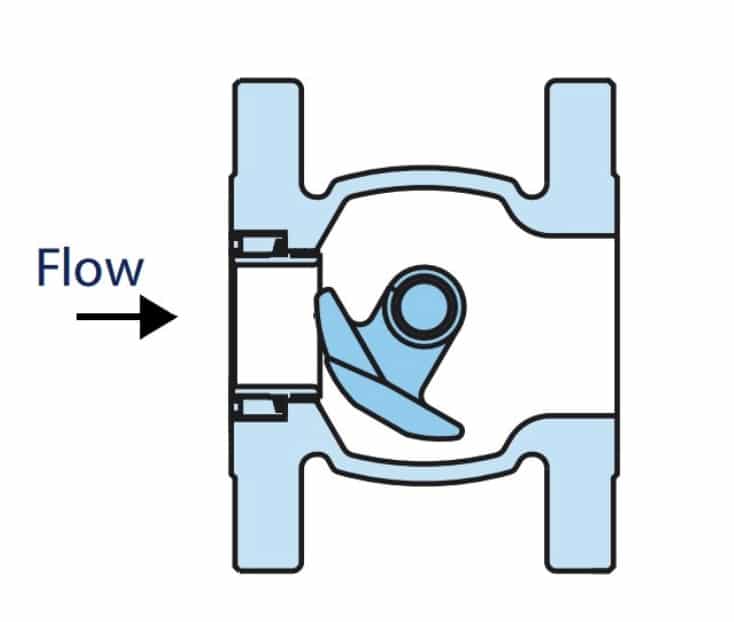

Rotary Control Valves

The rotary control valve assembly with spring return diaphragm actuator and digital positioner, this type of control valve has stable performance, large flow capacity, and easy maintenance.

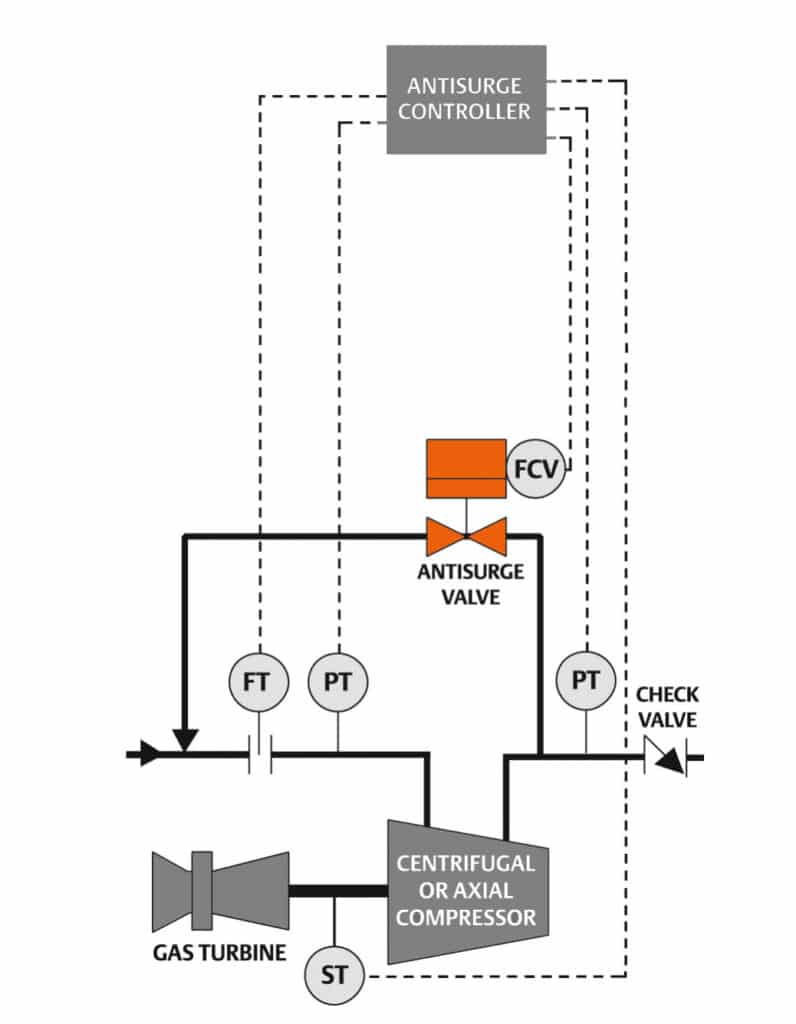

Anti-Surge Valves

Anti-surge valves recycle gas from the outlet to the inlet of the compressor to ensure a sufficiently high flow rate. These valves must respond quickly and accurately to prevent serious damage to the compressor.

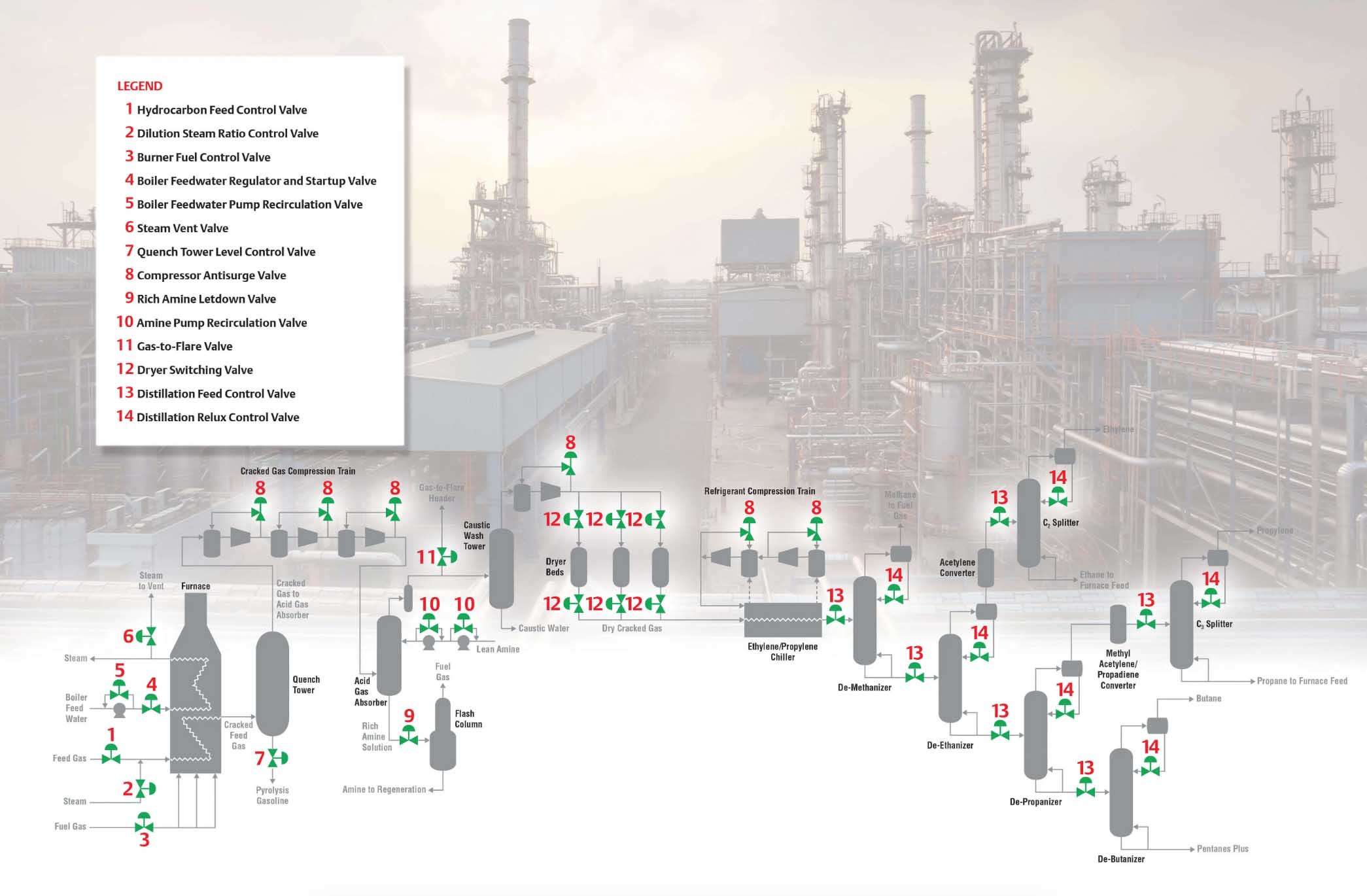

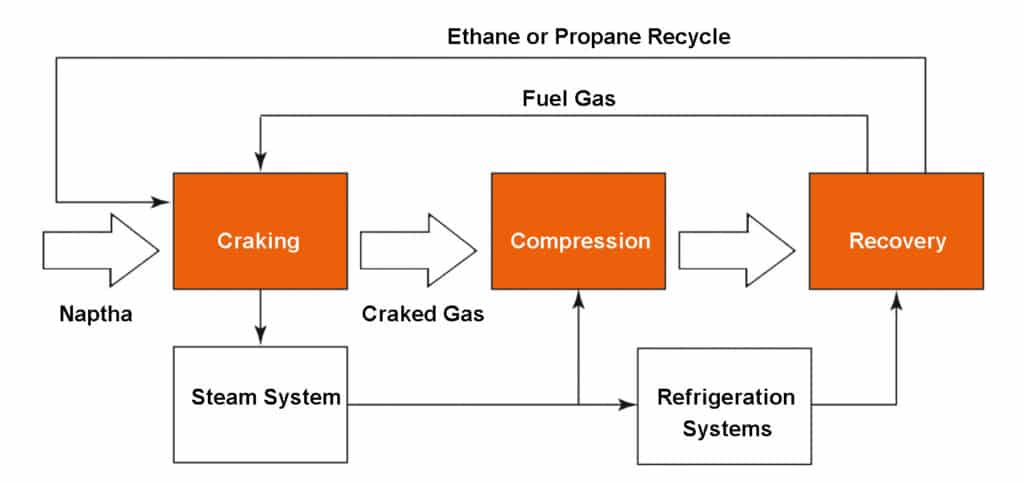

Ethylene Plant Processing

There are three main areas in the Ethylene plant processing, hot section, compressor section, and recovery section.

If you are interested in further information, you can refer to Fisher’s article to learn more.

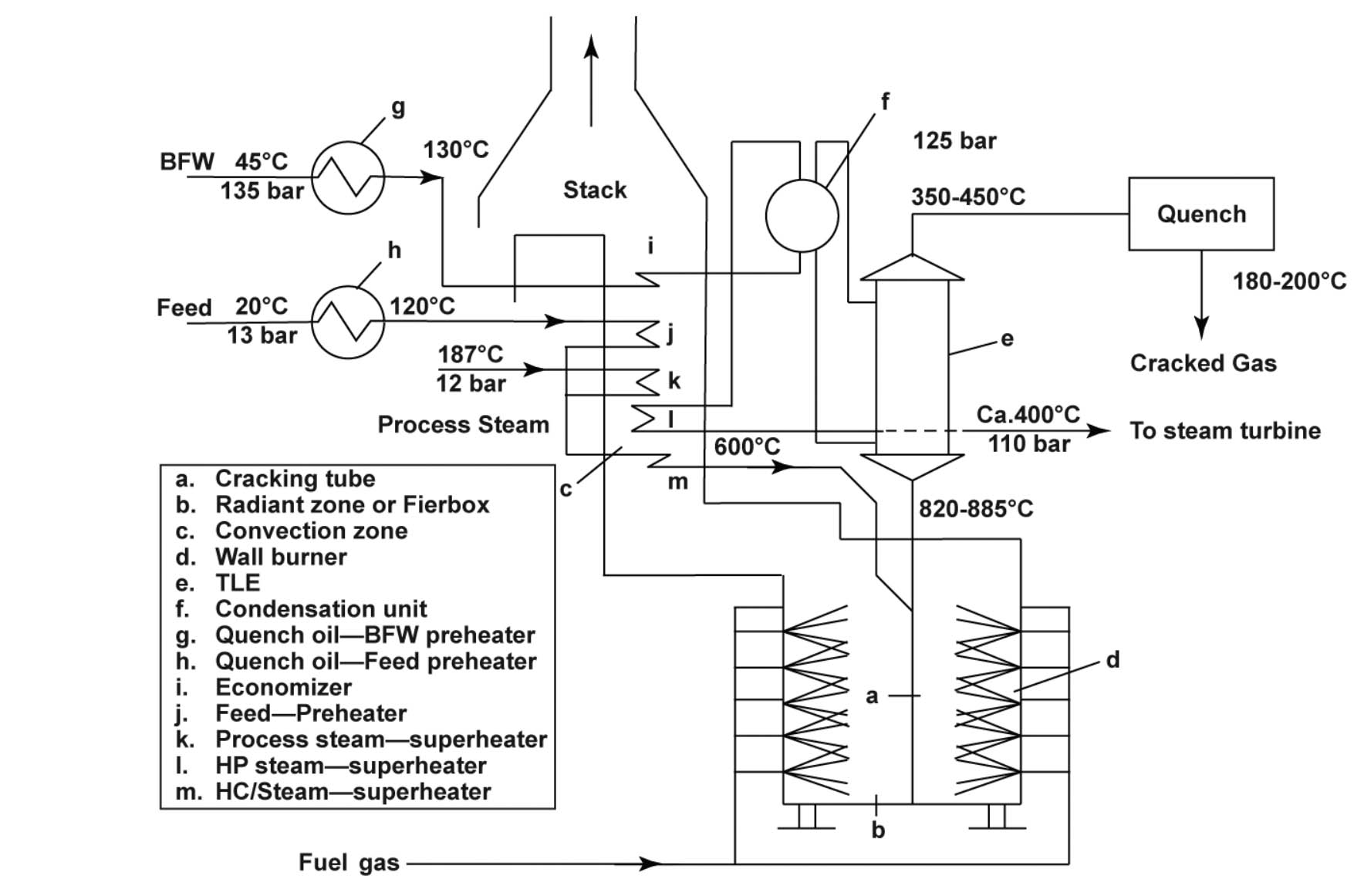

Hot Section

Several control valves are critical in the hot section, where non-optimal control can lead to cracking tubes. Feedstock flow control valves and steam feed valves are important control points for the furnace. Feed rates must be balanced with steam to increase production. Several valves are used to control the flow of gas into the furnace. The reliability of inlet feed valves is their main consideration.

Compressor Section

This area supplies the necessary pressure to move the raw material through the plant and provides cooling. In the compressor section, the new unsaturated hydrocarbons must be cooled quickly to prevent adverse reactions that could reduce the total yield.

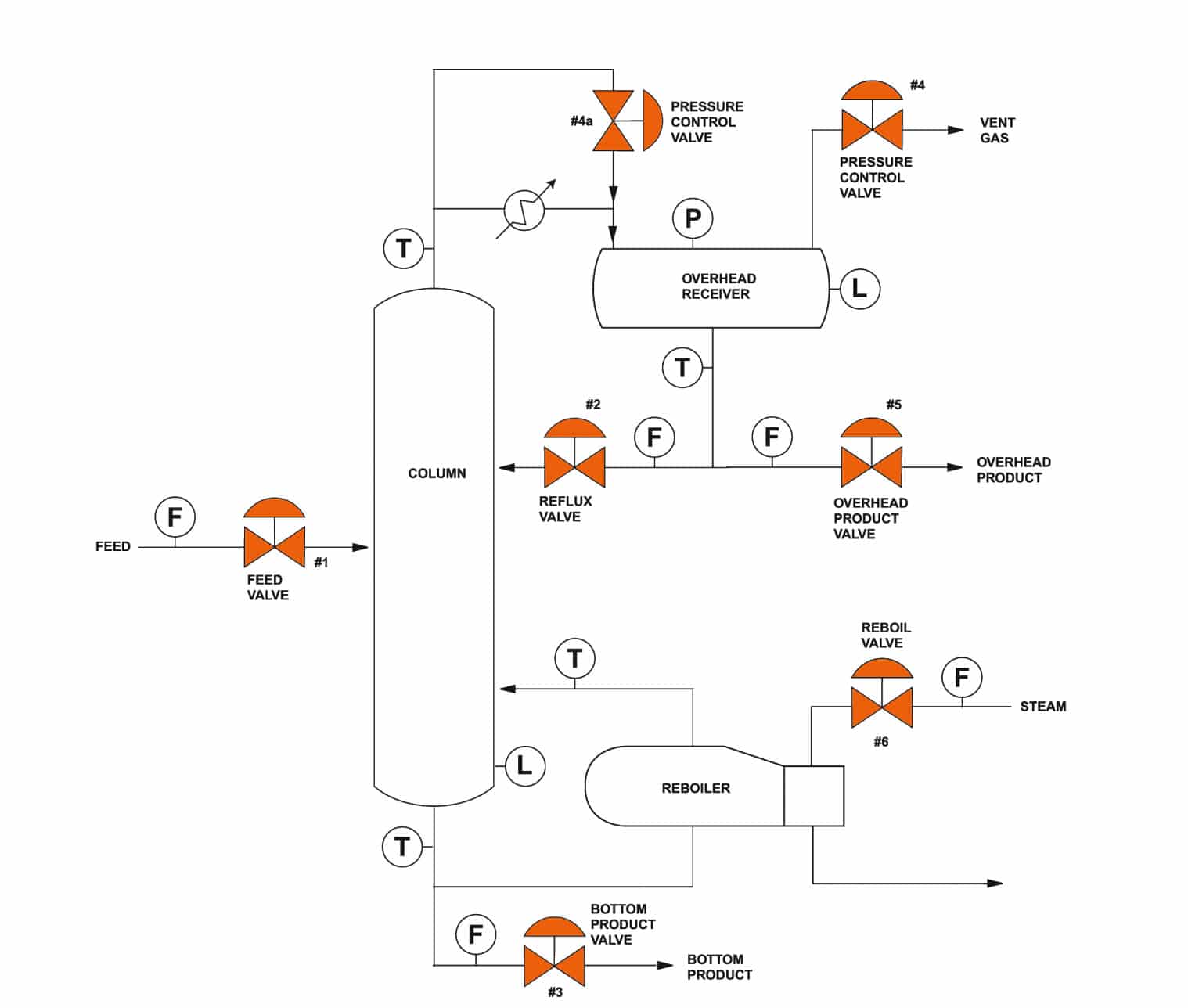

Recovery Section

In this area, you can find the distilled product in low-temperature conditions.

In Conclusion

Ethylene plants use lots of control valves throughout the production process. It is critical to understand the various applications throughout the Ethylene plants processing, in order to provide an engineered solution for the engineering&contractor or the end-users. By selecting a suitable control valve solution, plant performance will be improved due to increased reliability variability, safety, and so on.

As a responsible valve manufacturer, we pay more attention for select and sizing the right valves for ethylene plant projects. Underperforming valves not only waste money for the end-users but also break the engineers&contractors reputation. The worst for selecting the ill-fitting valves may risk the worker’s life.

We believe that you definitely want the valves to be perfect running for your plant with cost-efficient performance. Expensive does not equal the best quality, sometimes most expensive is also not necessary for your manufacturing production, the most important is to choose the right valves for your process.

For every ethylene plant with a different production process, we need to focus on the process-centric approach that is most suitable for valve selection. Please noted that not the most durable material, fast response, or the most expensive valve is the best choice. So in case, you can clearly understand the ethylene plant engineering from the automated valve selection, we highly recommend you to read the related article titled ethylene project engineering. In that article, we will tell you what type of industrial valves need third-party test and inspection, and which valves need to engineering&contractor’s approval, it helps you to avoid quarrels during the installation, start-up, and commissioning process. After you read all the articles about the ethylene projects, you will know what kind of valves are best for your application.

Now you are at the first step to opening the right way to learn to select the suitable valves, with cost-effective and good performance and a target running time.