The pipe Schedule specifies the tube wall thickness. As the number of pipe schedules rises, so does the thickness of the pipes. The primary role of pipes is to transport process media, such as gas, air, slurry, steam, liquid or mixed medium, etc. under internal pressure, external pressure, or both. Hence, the pipe must be durable enough to execute its intended task without failure. Obviously, for pipes carrying pressured fluids, the wall thickness, and hence the pipe’s strength, is the most significant characteristic. Pipe wall thickness is indicated by “schedules or Schedule numbers,” often known as piping schedules or Pipe Schedules.

What is a Pipe Schedule?

Pipe Wall Thickness and Pipe Schedule, often known as Pipe Schedule number or Pipe Schedule, are related terms. A pipe thickness designator for a certain pipe size is the piping schedule number for that pipe diameter.

What are the Governing Standards For Pipe Schedules?

The most prevalent standards in the oil and gas, and other downstream industries:

- ASME B 36.10 (ASME B 36.10 Welded and Seamless Wrought Steel Pipe)

- ASME B36.19 (ASME B36.19 Stainless Steel Pipe)

| NPS (DN) | SCH No. | O.D inch mm | W.T inch mm | Mass lb/ft kg/m |

|---|---|---|---|---|

| 1/8″ 6 | 5S | 0.405 10.3 | – | – |

| 1/8″ 6 | 10S | 0.405 10.3 | 0.049 1.24 | 0.19 0.28 |

| 1/8″ 6 | 40S | 0.405 10.3 | 0.068 1.73 | 0.24 0.37 |

| 1/8″ 6 | 80S | 0.405 10.3 | 0.095 2.41 | 0.31 0.47 |

| 1/4″ 8 | 5S | 0.540 13.7 | – | – |

| 1/4″ 8 | 10S | 0.540 13.7 | 0.065 1.65 | 0.33 0.49 |

| 1/4″ 8 | 40S | 0.540 13.7 | 0.088 2.24 | 0.43 0.63 |

| 1/4″ 8 | 80S | 0.540 13.7 | 0.119 3.02 | 0.54 0.80 |

| 3/8″ 10 | 5S | 0.675 17.1 | – | – |

| 3/8″ 10 | 10S | 0.675 17.1 | 0.065 1.65 | 0.42 0.63 |

| 3/8″ 10 | 40S | 0.675 17.1 | 0.091 2.31 | 0.57 0.84 |

| 3/8″ 10 | 80S | 0.675 17.1 | 0.126 3.20 | 0.74 1.10 |

| 1/2″ 15 | 5S | 0.840 21.3 | 0.065 1.65 | 0.54 0.80 |

| 1/2″ 15 | 10S | 0.840 21.3 | 0.083 2.11 | 0.67 1.00 |

| 1/2″ 15 | 40S | 0.840 21.3 | 0.109 2.77 | 0.85 1.27 |

| NPS (DN) | Sch. No. | O.D inch mm | W.T inch mm | Mass lb/ft kg/m |

|---|---|---|---|---|

| 8″ 200 | 5S | 8.625 219.1 | 0.109 2.77 | 9.92 14.78 |

| 8″ 200 | 10S | 8.625 219.1 | 0.148 3.76 | 13.41 19.97 |

| 8″ 200 | 40S | 8.625 219.1 | 0.322 8.18 | 28.58 42.55 |

| 8″ 200 | 80S | 8.625 219.1 | 0.500 12.70 | 43.43 64.64 |

| 10″ 250 | 5S | 10.750 273.0 | 0.134 3.40 | 15.21 22.61 |

| 10″ 250 | 10S | 10.750 273.0 | 0.165 4.19 | 18.67 27.78 |

| 10″ 250 | 40S | 10.750 273.0 | 0.365 9.27 | 40.52 60.29 |

| 10″ 250 | 80S | 10.750 273.0 | 0.500 12.70 | 54.79 81.53 |

| 12″ 300 | 5S | 12.750 323.8 | 0.156 3.96 | 21.00 31.24 |

| 12″ 300 | 10S | 12.750 323.8 | 0.180 4.57 | 24.19 35.98 |

| 12″ 300 | 40S | 12.750 323.8 | 0.375 9.53 | 49.61 73.86 |

| 12″ 300 | 80S | 12.750 323.8 | 0.500 12.70 | 65.48 97.44 |

| 14″ 350 | 5S | 14.000 355.6 | 0.156 3.96 | 23.09 34.34 |

| 14″ 350 | 10S | 14.000 355.6 | 0.188 4.78 | 27.76 41.36 |

| 14″ 350 | 40S | 14.000 355.6 | 0.375 9.53 | 54.62 81.33 |

What’s the Difference Between Nominal Pipe Size (NPS) and Nominal Diameter (DN)?

The NPS Nominal Pipe Size is a North American standard dimension for steel pipes that are utilized for different pressures and temperatures. Pipe size is defined by two factors: a nominal pipe size (NPS) in inches and a schedule size (Sched. or Sch.).

The nominal diameter(DN) generally means the outside diameter, due to the wall thickness of steel pipe dimension is small, the outside diameter(OD) is almost the same as the inside diameter(ID), so we use this value DN to describe the general diameter for various steel pipe and tubings. DN is not the diameter of the pipe in the actual size, just a symbol to represent a steel pipe that can be interconnected and interchangeable in the site. They are indicated by DN with a number. For example, DN100 means a steel pipe with a nominal diameter of 100mm.

Nominal Pipe Size (NPS) Convert to Nominal Diameter (DN)

DN = 25.4 x NPS

NPS = DN/25.4

1inch = 25.4mm, NPS: inch, DN: mm

| DN (mm) | 6 | 8 | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 |

| NPS(inch) | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 |

What does SCH Indicate in Terms of the Size of a Steel Pipe?

It is common practice to utilize a pipe schedule, a numerical representation of the pipe wall thickness when describing the many aspects of a steel pipe. Schedule (Sch.) refers to a range of wall thicknesses for pipes. The wall thickness of a steel pipe of the same diameter might vary depending on the pipe schedule. Schedule indicators of SCH 5, SCH 5S, 10, SCH 10S, 20, SCH 20S, 30, SCH 40S, SCH 80S, SCH 100, SCH 120, SCH 140, and SCH 160 are the most common. The surface pipe wall thickness and pressure resistance increase as the table number increases.

What Are Steel Pipe Size Schedule 40 & 80 Means?

The “Sch” symbol denotes the steel pipe schedule used in ASME B 36.10 and several other specifications. Schedule, or Sch for short, is a common prefix for series numbers in the American steel pipe standard. Sch 80, 80, for instance, is a designation for a certain kind of pipe in ASME B 36.10.

Steel pipes’ primary use is in pressurized fluid transfer, making the inner diameter a crucial dimension. To determine the nominal diameter, we use this crucial size DN(ND). So, it’s crucial that steel pipes have sufficient strength and wall thickness if they’re going to be transporting fluids under pressure. Schedules, short for pipe schedules, are used to define wall thickness. Specifically, ASME is being used as the normative specification for the pipe schedule.

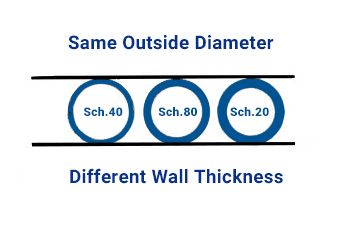

Reading the above content and table, we now know that Pipe Schedule 40 or Pipe Schedule 80 is a different standard with the same OD but a different wall thickness of a pipe.

Pipe Schedule 40 and Pipe Schedule 80 Steel pipes are the most frequent diameters used in many sectors, they are constantly in high demand due to enough pressure rating bared.

How do I Calculate Pipe Schedule? and What is Schedule Number Formula?

In order to get a consistent relationship equivalent to 1000 times the P/[ó]t expression found in the modified Barlow formula for pipe wall thickness, schedule numbers for pipe size/wall thickness combinations are computed (approximatively).

The pipe Schedule Number Formula is

SCH=1000 x (P/[ó]t)

Where:

P: Design Pressure, Unit is MPa.

[ó]t: Allowable Stress of Materials Under Design Temperature. Unit is MPa.

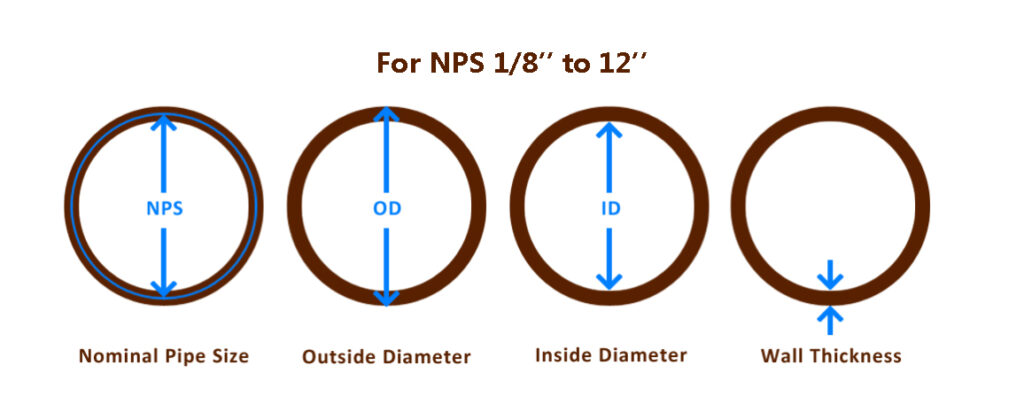

What are the ID and OD of the Pipe?

Speaking of steel pipe, I believe we are familiar with the industrial pipeline transmission or factory process we can see everywhere. The size of the steel pipe is also divided into a variety of types, we should refer to different standards to figure out the right size.

The mean of OD is the outside diameter of the pipeline, and the mean of ID is the inside diameter of the pipeline. The difference between OD and ID is the wall thickness of the pipe.

DN means nominal diameter, for steel pipe, the DN is not outside diameter nor inside diameter of the pipe, but a nominal size approximating the inside diameter of ordinary steel pipe.

For example, for a dn100 (4inches) steel pipe, the outside diameter OD is 114.3mm, according to ASME/ANSI B36.10M, STD wall thickness is 6.02mm, so the ID should be around 108.28mm.

For OD in the pipe size, you can refer to below table 1.

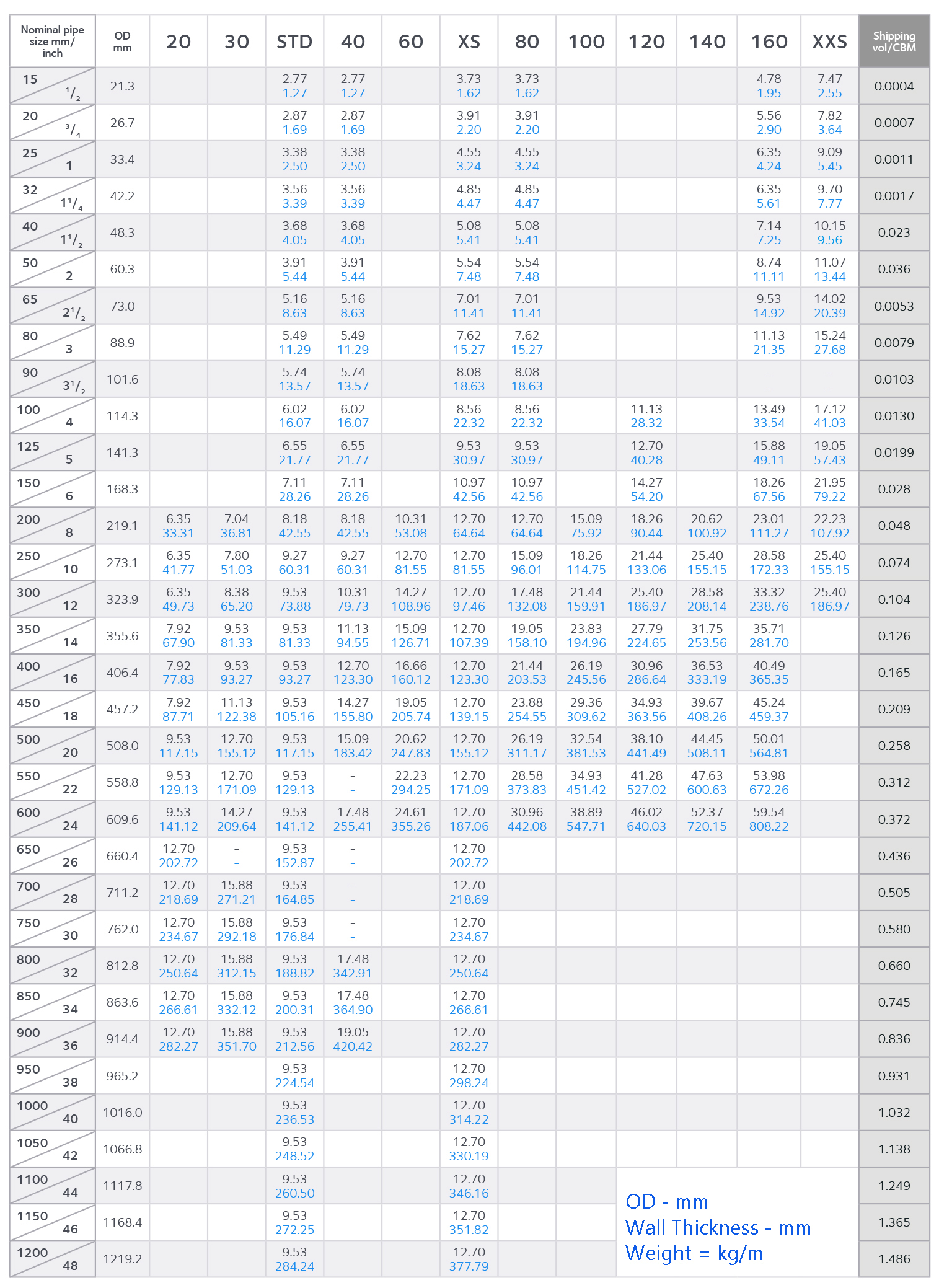

The Pipe schedule is identified as Standard (STD), Ex-Standard (XS), or Double Extra Strong(XSS), or with Pipe Schedule 20, 30, 40, 60, 80, 100, 120, 140, and 160.

So if you are looking for SCH 40 pipe data, you can find it in the sixth column in the table above, and for standard pipe size, the fifth column is the data you want.

3 Parameters For Steel Pipe Sizing

If you need to purchase steel for your project, 3 parameters are needed to completely describe your requirements, including outside diameter (OD), wall thickness (WT), and pipe length (usually 20 feet by 6 meters, or 40 feet by 12 meters).

You can describe your pipe requirements in 4 different methods as the following.

Pipe wall thickness is expressed by Steel Pipe Schedule.

Pipe Diameter is expressed by Nominal Pipe Size (NPS) and DN (Nominal Diameter)

Pipe Weight Class (WGT), kg/m (Kg per meter), lb/ft(pounds per feet)

- Use “OD x lb/ft” to describe steel pipe size. (i.e: OD 3 1/2”, 16.8 lb/ft.)

- Use “NPS x WGT Class” (i.e: NPS 6 inch x SCH STD.)

- Use “OD × WT”. (i.e: Φ 88.9mm x 5.49mm (3 1/2” x 0.216” ). 114.3mm x 6.02mm (4 1/2” x 0.237”), length 6m (20ft) or 12m (40ft), Single Random Length (SRL 18-25ft), or Double Random Length (DRL 38-40ft).)

- Use “NPS x Schedule” (i.e: NPS 3 inch x Sch 40, NPS 4 inch x Sch 40.)

With these 3 parameters, we can calculate the weight of the pipe, the ultimate pressure the pipe can withstand, and the cost per meter or feet.

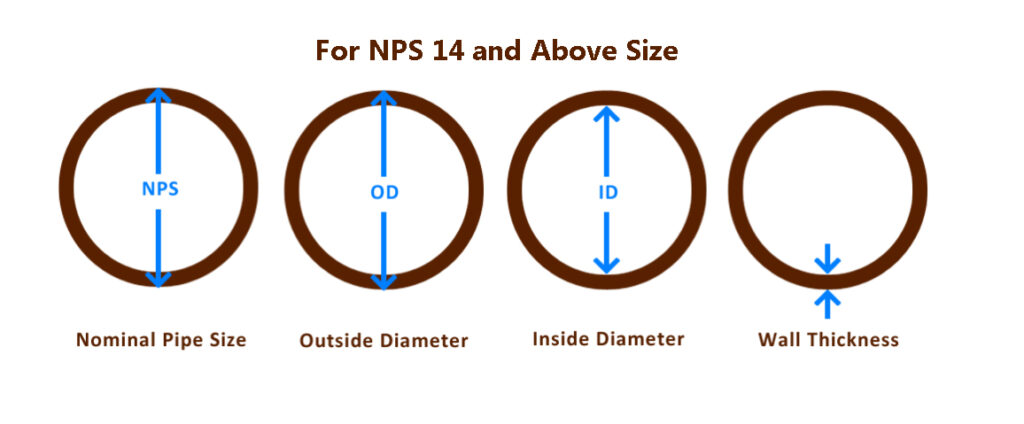

What is Nominal Pipe Size in Pipe Design?

The nominal size is used to identify all pipe sizes. Pipes with outside diameters ranging from NPS 1/8 (DN 6) to NPS 12 (DN 300) are made using a standardized outside diameter (OD). Originally, this OD was set so that the interior diameter (ID) of a pipe with a standard OD and normal wall thickness at the time would nearly match the nominal size. While there is no such relationship between current standard thicknesses, OD outside diameters, and nominal sizes, but still in use as “standards” with OD as nominal diameter.

Pipes with a nominal size of NPS14 (DN350) and larger are made with an outside diameter equal to the nominal size. Hence, the outer diameter (mm) of pipe sizes NPS14 and larger can be calculated by multiplying the NPS (in this example, 14) by 25.4. However, at smaller sizes, calculating the outside diameter is not as simple.

Dimensional Differences in Pipe Schedule and Pipe Size

Pipe Schedule vs Pipe Size

The outside diameter of all pipe diameters is the same. Consequently, any change in pipe size, i.e. wall thickness, has no effect on the outside diameter. As the pipe size number grows, the wall thickness increases and the actual interior diameter lowers.

Standard (STD) is equivalent to SCH 40 through NPS 10. Standard (STD Schedule) larger sizes have a wall thickness of 9.53 mm.

Extra Strong (XS) corresponds to SCH 80 and NPS 8. All larger Extra Strong sizes have a wall thickness of 12.70 millimeters.

From NPS 1/8 to NPS 6, Double Extra Strength (XXS) has a thicker wall than SCH 160, but SCH 160 has a thicker wall in diameters NPS 8 and above.

It can be clearly observed from the graph below that as the pipe thickness increases, the inner diameter of the pipe decreases while the outer diameter of the pipe remains the same.

Features of Pipe Schedule

Pipe thickness is specified and determined by the suitable ASME B 36.10M/B 36.19M standard for certain pipe sizes and schedules. Pipe thickness can alternatively be defined in millimeters or inches according to the ASME standard, although the Schedule Sizes are used exclusively as a handy designation scheme for buying pipe products.

The outside Diameter (OD) of pipe size remains constant while Internal Diameter (ID) fluctuates for any given pipe size with changing schedule numbers or wall thicknesses. With a rise in the thickness makes pipe strength increase, but the inside diameter decreases. Outside diameter is maintained constant to enable the design of support hardware in order that the same support hardware can be utilized for pipes of the same diameter. (different thickness)

Different pipe diameters may have the same Pipe Schedule number, but this does not imply that the tube thickness is the same. It may be the same or differ based on pipe sizes. For instance, 3 inches of schedule 40 pipes have a thickness of 5.49 millimeters, whereas 4 inches of schedule 40 pipes have a thickness of 6.02 millimeters. This indicates that the thickness is growing despite schedule 40. Similarly, the thickness of 8 inches Schedule standard pipes is 8.18 millimeters.

Pipe Schedule Chart

| NPS(in.) | OD (in.) | ID (in.) | Schedules | Wall Thickness (in.) | Weight (lb/ft) | OD (mm) | ID (mm) | Wall Thickness (mm) | Weight (kg/m) |

| 1/8″ | 0.405 | 0.307 | 10, 10S | 0.049 | 0.1863 | 10.287 | 7.7978 | 1.2446 | 0.277244942 |

| 1/8″ | 0.405 | 0.269 | 40, STD, 40S | 0.068 | 0.2447 | 10.287 | 6.8326 | 1.7272 | 0.364153716 |

| 1/8″ | 0.405 | 0.215 | 80, XS, 80S | 0.095 | 0.3145 | 10.287 | 5.461 | 2.413 | 0.468027559 |

| 1/4″ | 0.54 | 0.41 | 10, 10S | 0.065 | 0.3297 | 13.716 | 10.414 | 1.651 | 0.490647651 |

| 1/4″ | 0.54 | 0.364 | 40, STD, 40S | 0.088 | 0.4248 | 13.716 | 9.2456 | 2.2352 | 0.632172042 |

| 1/4″ | 0.54 | 0.302 | 80, XS, 80S | 0.119 | 0.5351 | 13.716 | 7.6708 | 3.0226 | 0.796316524 |

| 3/8″ | 0.675 | 0.545 | 10, 10S | 0.065 | 0.4235 | 17.145 | 13.843 | 1.651 | 0.630237429 |

| 3/8″ | 0.675 | 0.493 | 40, STD, 40S | 0.091 | 0.5676 | 17.145 | 12.522 | 2.3114 | 0.844681852 |

| 3/8″ | 0.675 | 0.423 | 80, XS, 80S | 0.126 | 0.7388 | 17.145 | 10.744 | 3.2004 | 1.099455519 |

| 1/2″ | 0.84 | 0.674 | 10, 10S | 0.083 | 0.671 | 21.336 | 17.12 | 2.1082 | 0.998558004 |

| 1/2″ | 0.84 | 0.622 | 40, STD, 40S | 0.109 | 0.851 | 21.336 | 15.799 | 2.7686 | 1.266427513 |

| 1/2″ | 0.84 | 0.546 | 80, XS, 80S | 0.147 | 1.088 | 21.336 | 13.868 | 3.7338 | 1.619122367 |

| 1/2″ | 0.84 | 0.466 | 160 | 0.187 | 1.304 | 21.336 | 11.836 | 4.7498 | 1.940565778 |

| 1/2″ | 0.84 | 0.252 | XXS | 0.294 | 1.714 | 21.336 | 6.4008 | 7.4676 | 2.550712993 |

| 3/4″ | 1.05 | 0.884 | 10, 10S | 0.083 | 0.8572 | 26.67 | 22.454 | 2.1082 | 1.275654129 |

| 3/4″ | 1.05 | 0.824 | 40, STD, 40S | 0.113 | 1.131 | 26.67 | 20.93 | 2.8702 | 1.683113416 |

| 3/4″ | 1.05 | 0.742 | 80, XS, 80S | 0.154 | 1.474 | 26.67 | 18.847 | 3.9116 | 2.193553648 |

| 3/4″ | 1.05 | 0.614 | 160 | 0.218 | 1.937 | 26.67 | 15.596 | 5.5372 | 2.882573552 |

| 3/4″ | 1.05 | 0.434 | XXS | 0.308 | 2.441 | 26.67 | 11.024 | 7.8232 | 3.632608178 |

| 1″ | 1.315 | 1.097 | 10, 10S | 0.109 | 1.404 | 33.401 | 27.864 | 2.7686 | 2.089382172 |

| 1″ | 1.315 | 1.049 | 40, STD, 40S | 0.133 | 1.679 | 33.401 | 26.645 | 3.3782 | 2.498627255 |

| 1″ | 1.315 | 0.957 | 80, XS, 80S | 0.179 | 2.172 | 33.401 | 24.308 | 4.5466 | 3.232292078 |

| 1″ | 1.315 | 0.815 | 160 | 0.25 | 2.844 | 33.401 | 20.701 | 6.35 | 4.232338245 |

| 1″ | 1.315 | 0.599 | XXS | 0.358 | 3.659 | 33.401 | 15.215 | 9.0932 | 5.445191856 |

| 1 1/4″ | 1.66 | 1.442 | 10, 10S | 0.109 | 1.806 | 42.164 | 36.627 | 2.7686 | 2.687624076 |

| 1 1/4″ | 1.66 | 1.38 | 40, STD, 40S | 0.14 | 2.273 | 42.164 | 35.052 | 3.556 | 3.382596636 |

| 1 1/4″ | 1.66 | 1.278 | 80, XS, 80S | 0.191 | 2.997 | 42.164 | 32.461 | 4.8514 | 4.460027328 |

| 1 1/4″ | 1.66 | 1.16 | 160 | 0.25 | 3.765 | 42.164 | 29.464 | 6.35 | 5.602937234 |

| 1 1/4″ | 1.66 | 0.896 | XXS | 0.382 | 5.214 | 42.164 | 22.758 | 9.7028 | 7.759286783 |

| 1 1/2″ | 1.9 | 1.682 | 10, 10S | 0.109 | 2.085 | 48.26 | 42.723 | 2.7686 | 3.102821815 |

| 1 1/2″ | 1.9 | 1.61 | 40, STD, 40S | 0.145 | 2.718 | 48.26 | 40.894 | 3.683 | 4.044829589 |

| 1 1/2″ | 1.9 | 1.5 | 80, XS, 80S | 0.2 | 3.631 | 48.26 | 38.1 | 5.08 | 5.403523266 |

| 1 1/2″ | 1.9 | 1.337 | 160 | 0.281 | 4.859 | 48.26 | 33.96 | 7.1374 | 7.230988584 |

| 1 1/2″ | 1.9 | 1.1 | XXS | 0.4 | 6.408 | 48.26 | 27.94 | 10.16 | 9.536154528 |

| 2″ | 2.375 | 2.157 | 10, 10S | 0.109 | 2.638 | 60.325 | 54.788 | 2.7686 | 3.925776474 |

| 2″ | 2.375 | 2.067 | 40, STD, 40S | 0.154 | 3.853 | 60.325 | 52.502 | 3.9116 | 5.733895661 |

| 2″ | 2.375 | 1.939 | 80, XS, 80S | 0.218 | 5.022 | 60.325 | 49.251 | 5.5372 | 7.473559307 |

| 2″ | 2.375 | 1.689 | 160 | 0.344 | 7.462 | 60.325 | 42.901 | 8.7376 | 11.10467932 |

| 2″ | 2.375 | 1.503 | XXS | 0.436 | 9.029 | 60.325 | 38.176 | 11.0744 | 13.43663221 |

| 2 1/2″ | 2.875 | 2.635 | 10, 10S | 0.12 | 3.531 | 73.025 | 66.929 | 3.048 | 5.254706872 |

| 2 1/2″ | 2.875 | 2.469 | 40, STD, 40S | 0.203 | 5.793 | 73.025 | 62.713 | 5.1562 | 8.620933704 |

| 2 1/2″ | 2.875 | 2.323 | 80, XS, 80S | 0.276 | 7.651 | 73.025 | 59.004 | 7.0104 | 11.3859423 |

| 2 1/2″ | 2.875 | 2.125 | 160 | 0.375 | 10.01 | 73.025 | 53.975 | 9.525 | 14.89652104 |

| 2 1/2″ | 2.875 | 1.771 | XXS | 0.552 | 13.7 | 73.025 | 44.983 | 14.0208 | 20.38784598 |

| 3″ | 3.5 | 3.26 | 10, 10S | 0.12 | 4.332 | 88.9 | 82.804 | 3.048 | 6.446726188 |

| 3″ | 3.5 | 3.068 | 40, STD, 40S | 0.216 | 7.576 | 88.9 | 77.927 | 5.4864 | 11.27433001 |

| 3″ | 3.5 | 2.9 | 80, XS, 80S | 0.3 | 10.25 | 88.9 | 73.66 | 7.62 | 15.25368039 |

| 3″ | 3.5 | 2.624 | 160 | 0.438 | 14.32 | 88.9 | 66.65 | 11.1252 | 21.31050762 |

| 3″ | 3.5 | 2.3 | XXS | 0.6 | 18.58 | 88.9 | 58.42 | 15.24 | 27.65008601 |

| 3 1/2″ | 4 | 3.76 | 10, 10S | 0.12 | 4.937 | 101.6 | 95.504 | 3.048 | 7.347065372 |

| 3 1/2″ | 4 | 3.548 | 40, STD, 40S | 0.226 | 9.109 | 101.6 | 90.119 | 5.7404 | 13.55568533 |

| 3 1/2″ | 4 | 3.364 | 80, XS, 80S | 0.318 | 12.51 | 101.6 | 85.446 | 8.0772 | 18.61693089 |

| 3 1/2″ | 4 | 2.728 | XXS | 0.636 | 22.85 | 101.6 | 69.291 | 16.1544 | 34.00454603 |

| 4″ | 4.5 | 4.26 | 10, 10S | 0.12 | 5.613 | 114.3 | 108.2 | 3.048 | 8.353064195 |

| 4″ | 4.5 | 4.026 | 40, STD, 40S | 0.237 | 10.79 | 114.3 | 102.26 | 6.0198 | 16.05728891 |

| 4″ | 4.5 | 3.826 | 80, XS, 80S | 0.337 | 14.98 | 114.3 | 97.18 | 8.5598 | 22.29269582 |

| 4″ | 4.5 | 3.624 | 120 | 0.438 | 19 | 114.3 | 92.05 | 11.1252 | 28.27511486 |

| 4″ | 4.5 | 3.438 | 160 | 0.531 | 22.51 | 114.3 | 87.325 | 13.4874 | 33.49857029 |

| 4″ | 4.5 | 3.152 | XXS | 0.674 | 27.54 | 114.3 | 80.061 | 17.1196 | 40.98403491 |

| 4 1/2″ | 5 | 4.506 | STD, 40S | 0.247 | 12.54 | 127 | 114.45 | 6.2738 | 18.66157581 |

| 4 1/2″ | 5 | 4.29 | XS, 80S | 0.355 | 17.61 | 127 | 108.97 | 9.017 | 26.20656698 |

| 5″ | 5.563 | 5.295 | 10, 10S | 0.134 | 7.77 | 141.3 | 134.49 | 3.4036 | 11.56303381 |

| 5″ | 5.563 | 5.047 | 40, STD, 40S | 0.258 | 14.62 | 141.3 | 128.19 | 6.5532 | 21.7569568 |

| 5″ | 5.563 | 4.813 | 80, XS, 80S | 0.375 | 20.78 | 141.3 | 122.25 | 9.525 | 30.92404667 |

| 5″ | 5.563 | 4.563 | 120 | 0.5 | 27.04 | 141.3 | 115.9 | 12.7 | 40.23995294 |

| 5″ | 5.563 | 4.313 | 160 | 0.625 | 32.96 | 141.3 | 109.55 | 15.875 | 49.04988346 |

| 5″ | 5.563 | 4.063 | XXS | 0.75 | 38.55 | 141.3 | 103.2 | 19.05 | 57.36871989 |

| 6″ | 6.625 | 6.357 | 10, 10S | 0.134 | 9.29 | 168.275 | 161.47 | 3.4036 | 13.825043 |

| 6″ | 6.625 | 6.065 | 40, STD, 40S | 0.28 | 18.97 | 168.275 | 154.05 | 7.112 | 28.23046994 |

| 6″ | 6.625 | 5.761 | 80, XS, 80S | 0.432 | 28.57 | 168.275 | 146.33 | 10.9728 | 42.51684377 |

| 6″ | 6.625 | 5.501 | 120 | 0.562 | 35.39 | 168.275 | 139.73 | 14.2748 | 52.66612184 |

| 6″ | 6.625 | 5.189 | 160 | 0.719 | 43.35 | 168.275 | 131.8 | 18.2626 | 64.5119068 |

| 6″ | 6.625 | 4.897 | XXS | 0.864 | 53.16 | 168.275 | 124.38 | 21.9456 | 79.11079505 |

| 8″ | 8.625 | 8.329 | 10, 10S | 0.148 | 13.4 | 219.075 | 211.56 | 3.7592 | 19.9413968 |

| 8″ | 8.625 | 8.125 | 20 | 0.25 | 22.36 | 219.075 | 206.38 | 6.35 | 33.2753457 |

| 8″ | 8.625 | 8.071 | 30 | 0.277 | 24.7 | 219.075 | 205 | 7.0358 | 36.75764932 |

| 8″ | 8.625 | 7.981 | 40, STD, 40S | 0.322 | 28.55 | 219.075 | 202.72 | 8.1788 | 42.48708049 |

| 8″ | 8.625 | 7.813 | 60 | 0.406 | 35.64 | 219.075 | 198.45 | 10.3124 | 53.03816282 |

| 8″ | 8.625 | 7.625 | 80, XS, 80S | 0.5 | 43.39 | 219.075 | 193.68 | 12.7 | 64.57143336 |

| 8″ | 8.625 | 7.439 | 100 | 0.594 | 50.95 | 219.075 | 188.95 | 15.0876 | 75.82195274 |

| 8″ | 8.625 | 7.189 | 120 | 0.719 | 61.71 | 219.075 | 182.6 | 18.2626 | 91.83459674 |

| 8″ | 8.625 | 7.001 | 140 | 0.812 | 67.76 | 219.075 | 177.83 | 20.6248 | 100.8379886 |

| 8″ | 8.625 | 6.813 | 160 | 0.906 | 74.79 | 219.075 | 173.05 | 23.0124 | 111.2997811 |

| 8″ | 8.625 | 6.875 | XXS | 0.875 | 72.42 | 219.075 | 174.63 | 22.225 | 107.7728325 |

| 10″ | 10.75 | 10.42 | 10, 10S | 0.165 | 18.65 | 273.05 | 264.67 | 4.191 | 27.75425748 |

| 10″ | 10.75 | 10.25 | 20 | 0.25 | 28.04 | 273.05 | 260.35 | 6.35 | 41.72811688 |

| 10″ | 10.75 | 10.136 | 30 | 0.307 | 34.24 | 273.05 | 257.45 | 7.7978 | 50.95473331 |

| 10″ | 10.75 | 10.02 | 40, STD, 40S | 0.365 | 40.48 | 273.05 | 254.51 | 9.271 | 60.24087629 |

| 10″ | 10.75 | 9.75 | 60, XS, 80S | 0.5 | 54.74 | 273.05 | 247.65 | 12.7 | 81.46209408 |

| 10″ | 10.75 | 9.564 | 80 | 0.594 | 64.43 | 273.05 | 242.93 | 15.0876 | 95.88240265 |

| 10″ | 10.75 | 9.314 | 100 | 0.719 | 77.03 | 273.05 | 236.58 | 18.2626 | 114.6332683 |

| 10″ | 10.75 | 9.064 | 120 | 0.844 | 82.29 | 273.05 | 230.23 | 21.4376 | 122.4610106 |

| 10″ | 10.75 | 8.75 | 140, XXS | 1 | 104.1 | 273.05 | 222.25 | 25.4 | 154.9178662 |

| 10″ | 10.75 | 8.5 | 160 | 1.125 | 115.6 | 273.05 | 215.9 | 28.575 | 172.0317515 |

| 12″ | 12.75 | 12.39 | 10, 10S | 0.18 | 24.16 | 323.85 | 314.71 | 4.572 | 35.95404079 |

| 12″ | 12.75 | 12.25 | 20 | 0.25 | 33.38 | 323.85 | 311.15 | 6.35 | 49.67491232 |

| 12″ | 12.75 | 12.09 | 30 | 0.33 | 43.77 | 323.85 | 307.09 | 8.382 | 65.13693565 |

| 12″ | 12.75 | 12 | STD, 40S | 0.375 | 49.56 | 323.85 | 304.8 | 9.525 | 73.75340487 |

| 12″ | 12.75 | 11.938 | 40 | 0.406 | 53.52 | 323.85 | 303.23 | 10.3124 | 79.64653407 |

| 12″ | 12.75 | 11.75 | XS, 80S | 0.5 | 65.42 | 323.85 | 298.45 | 12.7 | 97.35568495 |

| 12″ | 12.75 | 11.626 | 60 | 0.562 | 73.15 | 323.85 | 295.3 | 14.2748 | 108.8591922 |

| 12″ | 12.75 | 11.376 | 80 | 0.688 | 88.63 | 323.85 | 288.95 | 17.4752 | 131.89597 |

| 12″ | 12.75 | 11.064 | 100 | 0.844 | 107.9 | 323.85 | 281.03 | 21.4376 | 160.5728891 |

| 12″ | 12.75 | 10.75 | 120, XXS | 1 | 125.5 | 323.85 | 273.05 | 25.4 | 186.7645745 |

| 12″ | 12.75 | 10.5 | 140 | 1.125 | 136.7 | 323.85 | 266.7 | 28.575 | 203.4320106 |

| 12″ | 12.75 | 10.126 | 160 | 1.312 | 150.3 | 323.85 | 257.2 | 33.3248 | 223.6710402 |

| 14″ | 14 | 13.624 | 10S | 0.188 | 27.73 | 355.6 | 346.05 | 4.7752 | 41.26678606 |

| 14″ | 14 | 13.5 | 10 | 0.25 | 36.71 | 355.6 | 342.9 | 6.35 | 54.63049824 |

| 14″ | 14 | 13.375 | 20 | 0.312 | 45.61 | 355.6 | 339.73 | 7.9248 | 67.8751573 |

| 14″ | 14 | 13.25 | 30, STD, 40S | 0.375 | 54.57 | 355.6 | 336.55 | 9.525 | 81.20910621 |

| 14″ | 14 | 13.124 | 40 | 0.438 | 63.44 | 355.6 | 333.35 | 11.1252 | 94.40912035 |

| 14″ | 14 | 13 | XS, 80S | 0.5 | 72.09 | 355.6 | 330.2 | 12.7 | 107.2817384 |

| 14″ | 14 | 12.814 | 60 | 0.594 | 85.05 | 355.6 | 325.48 | 15.0876 | 126.5683431 |

| 14″ | 14 | 12.5 | 80 | 0.75 | 106.1 | 355.6 | 317.5 | 19.05 | 157.894194 |

| 14″ | 14 | 12.124 | 100 | 0.938 | 130.9 | 355.6 | 307.95 | 23.8252 | 194.8006597 |

| 14″ | 14 | 11.814 | 120 | 1.09 | 150.8 | 355.6 | 300.08 | 27.686 | 224.4151222 |

| 14″ | 14 | 11.5 | 140 | 1.25 | 170.2 | 355.6 | 292.1 | 31.75 | 253.2855026 |

| 14″ | 14 | 11.188 | 160 | 1.406 | 189.1 | 355.6 | 284.18 | 35.7124 | 281.4118011 |

| 16″ | 16 | 15.624 | 10S | 0.188 | 31.75 | 406.4 | 396.85 | 4.7752 | 47.2492051 |

| 16″ | 16 | 15.5 | 10 | 0.25 | 42.05 | 406.4 | 393.7 | 6.35 | 62.57729368 |

| 16″ | 16 | 15.375 | 20 | 0.312 | 52.27 | 406.4 | 390.53 | 7.9248 | 77.78632914 |

| 16″ | 16 | 15.25 | 30, STD, 40S | 0.375 | 62.58 | 406.4 | 387.35 | 9.525 | 93.12929937 |

| 16″ | 16 | 15 | 40, XS, 80S | 0.5 | 82.77 | 406.4 | 381 | 12.7 | 123.1753293 |

| 16″ | 16 | 14.688 | 60 | 0.656 | 107.5 | 406.4 | 373.08 | 16.6624 | 159.9776236 |

| 16″ | 16 | 14.314 | 80 | 0.844 | 136.6 | 406.4 | 363.58 | 21.4376 | 203.2831942 |

| 16″ | 16 | 13.938 | 100 | 1.031 | 164.8 | 406.4 | 354.03 | 26.1874 | 245.2494173 |

| 16″ | 16 | 13.564 | 120 | 1.22 | 192.4 | 406.4 | 344.53 | 30.988 | 286.3227421 |

| 16″ | 16 | 13.124 | 140 | 1.438 | 223.6 | 406.4 | 333.35 | 36.5252 | 332.753457 |

| 16″ | 16 | 12.814 | 160 | 1.594 | 245.3 | 406.4 | 325.48 | 40.4876 | 365.0466145 |

| 18″ | 18 | 17.624 | 10S | 0.188 | 35.76 | 457.2 | 447.65 | 4.7752 | 53.21674249 |

| 18″ | 18 | 17.5 | 10 | 0.25 | 47.99 | 457.2 | 444.5 | 6.35 | 71.41698748 |

| 18″ | 18 | 17.375 | 20 | 0.312 | 58.94 | 457.2 | 441.33 | 7.9248 | 87.71238262 |

| 18″ | 18 | 17.25 | STD, 40S | 0.375 | 70.59 | 457.2 | 438.15 | 9.525 | 105.0494925 |

| 18″ | 18 | 17.124 | 30 | 0.438 | 82.15 | 457.2 | 434.95 | 11.1252 | 122.2526677 |

| 18″ | 18 | 17 | XS, 80S | 0.5 | 93.45 | 457.2 | 431.8 | 12.7 | 139.0689202 |

| 18″ | 18 | 16.876 | 40 | 0.562 | 104.7 | 457.2 | 428.65 | 14.2748 | 155.8107645 |

| 18″ | 18 | 16.5 | 60 | 0.75 | 138.2 | 457.2 | 419.1 | 19.05 | 205.6642565 |

| 18″ | 18 | 16.126 | 80 | 0.938 | 170.9 | 457.2 | 409.6 | 23.8252 | 254.3272173 |

| 18″ | 18 | 15.688 | 100 | 1.156 | 208 | 457.2 | 398.48 | 29.3624 | 309.5380995 |

| 18″ | 18 | 15.25 | 120 | 1.38 | 244.1 | 457.2 | 387.35 | 35.052 | 363.2608178 |

| 18″ | 18 | 14.876 | 140 | 1.562 | 274.2 | 457.2 | 377.85 | 39.6748 | 408.0545523 |

| 18″ | 18 | 14.438 | 160 | 1.781 | 308.5 | 457.2 | 366.73 | 45.2374 | 459.0985755 |

| 20″ | 20 | 19.564 | 10S | 0.218 | 48.05 | 508 | 496.93 | 5.5372 | 71.50627732 |

| 20″ | 20 | 19.5 | 10 | 0.25 | 52.73 | 508 | 495.3 | 6.35 | 78.47088456 |

| 20″ | 20 | 19.25 | 20, STD, 40S | 0.375 | 78.6 | 508 | 488.95 | 9.525 | 116.9696857 |

| 20″ | 20 | 19 | 30, XS, 80S | 0.5 | 104.1 | 508 | 482.6 | 12.7 | 154.9178662 |

| 20″ | 20 | 18.812 | 40 | 0.594 | 123.1 | 508 | 477.82 | 15.0876 | 183.192981 |

| 20″ | 20 | 18.376 | 60 | 0.812 | 155.4 | 508 | 466.75 | 20.6248 | 231.2606763 |

| 20″ | 20 | 17.938 | 80 | 1.031 | 208.9 | 508 | 455.63 | 26.1874 | 310.8774471 |

| 20″ | 20 | 17.438 | 100 | 1.281 | 256.1 | 508 | 442.93 | 32.5374 | 381.118785 |

| 20″ | 20 | 17 | 120 | 1.5 | 296.4 | 508 | 431.8 | 38.1 | 441.0917918 |

| 20″ | 20 | 16.5 | 140 | 1.75 | 341.1 | 508 | 419.1 | 44.45 | 507.6127199 |

| 20″ | 20 | 16.064 | 160 | 1.969 | 379.2 | 508 | 408.03 | 50.0126 | 564.311766 |

| 24″ | 24 | 23.5 | 10, 10S | 0.25 | 63.41 | 609.6 | 596.9 | 6.35 | 94.36447544 |

| 24″ | 24 | 23.25 | 20, STD, 40S | 0.375 | 96.42 | 609.6 | 590.55 | 9.525 | 143.4887671 |

| 24″ | 24 | 23 | XS, 80S | 0.5 | 125.5 | 609.6 | 584.2 | 12.7 | 186.7645745 |

| 24″ | 24 | 22.876 | 30 | 0.562 | 140.7 | 609.6 | 581.05 | 14.2748 | 209.3846664 |

| 24″ | 24 | 22.626 | 40 | 0.688 | 171.3 | 609.6 | 574.7 | 17.4752 | 254.9224829 |

| 24″ | 24 | 22.064 | 60 | 0.969 | 238.4 | 609.6 | 560.43 | 24.6126 | 354.7782833 |

| 24″ | 24 | 21.564 | 80 | 1.219 | 296.8 | 609.6 | 547.73 | 30.9626 | 441.6870574 |

| 24″ | 24 | 20.938 | 100 | 1.531 | 357.4 | 609.6 | 531.83 | 38.8874 | 531.8697922 |

| 24″ | 24 | 20.376 | 120 | 1.812 | 429.4 | 609.6 | 517.55 | 46.0248 | 639.0175958 |

| 24″ | 24 | 19.876 | 140 | 2.062 | 483.1 | 609.6 | 504.85 | 52.3748 | 718.9319994 |

| 24″ | 24 | 19.314 | 160 | 2.344 | 542.1 | 609.6 | 490.58 | 59.5376 | 806.7336719 |

| 30″ | 30 | 29.376 | 10, 10S | 0.312 | 98.93 | 762 | 746.15 | 7.9248 | 147.2240586 |

| 30″ | 30 | 29.25 | STD, 40S | 0.375 | 118.65 | 762 | 742.95 | 9.525 | 176.5706515 |

| 30″ | 30 | 29 | 20, XS, 80S | 0.5 | 157.53 | 762 | 736.6 | 12.7 | 234.4304655 |

| 30″ | 30 | 28.75 | 30 | 0.625 | 196.06 | 762 | 730.25 | 15.875 | 291.7694221 |

| 36″ | 36 | 35.376 | 10 | 0.312 | 118.92 | 914.4 | 898.55 | 7.9248 | 176.9724557 |

| 36″ | 36 | 35.25 | STD, 40S | 0.375 | 142.68 | 914.4 | 895.35 | 9.525 | 212.331231 |

| 36″ | 36 | 35 | XS, 80S | 0.5 | 189.57 | 914.4 | 889 | 12.7 | 282.1112381 |

| 36″ | 36 | 34.75 | 30 | 0.625 | 235.13 | 914.4 | 882.65 | 15.875 | 349.9119872 |

| 48″ | 48 | 47.25 | STD, 40S | 0.375 | 190.74 | 1219.2 | 1200.2 | 9.525 | 283.8523899 |

| 48″ | 48 | 47 | XS, 80S | 0.5 | 253.65 | 1219.2 | 1193.8 | 12.7 | 377.4727834 |

Where,

STD: Standard

XS: Extra Strong

XXS: Double Extra Strong

The pipe schedule chart is a table showing pipe NPS and wall thicknesses relative to different schedule numbers. Depending on the pipe size, a certain schedule has a specific wall thickness. In the aforementioned ASME standards, the outside diameter OD, inside diameter ID, wall thickness Schedule Number, and weights of cast steel and stainless steel pipes are specified. The tables in categorized into the following dimension range for all sizes and wall thicknesses within their scope, although some of the larger, thicker wall segments cannot be produced in a seamless mill and must be supplied from forged and bored billets or other sources.

More frequently, stainless steel pipe is offered in standard weight sizes, for example, NPS SCH10S, the stainless steel denoted by S. Yet, there are more pipe schedules available for stainless steel pipe.

What is a Schedule 40 Pipe? and Does STD and Sch40 the Same?

From table 1, we can see below that NPS10 inches, the OD(outside diameter), and WT(wall thickness) are the same for STD and Sch40, but above size NPS 12”, the pipe diameter is totally different. We list the Schedule 40 Pipe Dimensions refer to standard ASME B 36.10M for your reference.

| NPS(in.) | Schedule Code | OD(in.) | Wall Thickness(in.) | Weight (lb/ft) | OD(mm) | Wall Thickness(mm) | Weight (Kg/m) |

| 1/8 | 40/STD | 0.405 | 0.068 | 0.24 | 10.3 | 1.73 | 0.37 |

| 1⁄4 | 40/STD | 0.540 | 0.088 | 0.43 | 13.7 | 2.24 | 0.63 |

| 3⁄8 | 40/STD | 0.675 | 0.091 | 0.57 | 17.1 | 2.31 | 0.84 |

| 1⁄2 | 40/STD | 0.840 | 0.109 | 0.85 | 21.3 | 2.77 | 1.27 |

| 3⁄4 | 40/STD | 1.050 | 0.113 | 1.13 | 26.7 | 2.87 | 1.69 |

| 1 | 40/STD | 1.315 | 0.133 | 1.68 | 33.4 | 3.38 | 2.50 |

| 1-1⁄4 | 40/STD | 1.660 | 0.140 | 2.27 | 42.2 | 3.56 | 3.39 |

| 1-1⁄2 | 40/STD | 1.900 | 0.145 | 2.72 | 48.3 | 3.68 | 4.05 |

| 2 | 40/STD | 2.375 | 0.154 | 3.66 | 60.3 | 3.91 | 5.44 |

| 2-1⁄2 | 40/STD | 2.875 | 0.203 | 5.80 | 73.0 | 5.16 | 8.63 |

| 3 | 40/STD | 3.500 | 0.216 | 7.58 | 88.9 | 5.49 | 11.29 |

| 4 | 40/STD | 4.500 | 0.237 | 10.80 | 114.3 | 6.02 | 16.08 |

| 5 | 40/STD | 5.563 | 0.258 | 14.63 | 141.3 | 6.55 | 21.77 |

| 6 | 40/STD | 6.625 | 0.280 | 18.99 | 168.3 | 7.11 | 28.26 |

| 8 | 40/STD | 8.625 | 0.322 | 28.58 | 219.1 | 8.18 | 42.55 |

| 10 | 40/STD | 10.750 | 0.365 | 40.52 | 273.0 | 9.27 | 60.29 |

| 12 | 40 | 12.750 | 0.406 | 53.57 | 323.8 | 10.31 | 79.71 |

| 14 | 40 | 14.000 | 0.438 | 63.50 | 355.6 | 11.13 | 94.55 |

| 16 | 40 | 16.000 | 0.500 | 82.85 | 406.4 | 12.70 | 123.31 |

| 18 | 40 | 18.000 | 0.562 | 104.76 | 457 | 14.27 | 155.81 |

| 20 | 40 | 20.000 | 0.594 | 123.23 | 508 | 15.09 | 183.43 |

| 24 | 40 | 24.000 | 0.688 | 171.45 | 610 | 17.48 | 255.43 |

| 32 | 40 | 32.000 | 0.688 | 230.29 | 813 | 17.48 | 342.94 |

| 34 | 40 | 34.000 | 0.688 | 245.00 | 864 | 17.48 | 364.92 |

| 36 | 40 | 36.000 | 0.750 | 282.62 | 914 | 19.05 | 420.45 |

Final Thoughts:

In this post, we have explained the basic information about the Pipe Schedule. Hope it can help you to understand the specifications of the pipe before you purchase an order. Of course, if you have inquiries or projects on industrial valves, we can help you to sizing and selecting the right control valve or GGC valve for your application.

Also if you are interested in reading further information on control valves, please kindly click the following posts.