Water purification technology has seen significant advances over the years, and at the heart of many modern systems lies the Reverse Osmosis (RO) process. An integral component in ensuring the efficiency and longevity of an RO system is the Barstock Control Valve. This article offers an in-depth exploration of the Barstock Control Valve, its functions, design considerations, and its crucial role in RO systems.

The BarStock Control Valve offers precise control over fluids in various pressure and industrial control applications, combining enhanced durability and corrosion resistance. The reverse osmosis system is one of the most popular techniques used for water purification. One of the most important components of a reverse osmosis system is the control valve. If you are looking to purchase new control valves for your reverse osmosis system, then barstock control valves are worth considering. In this article, we will cover everything you need to know about barstock control valve for reverse osmosis systems.

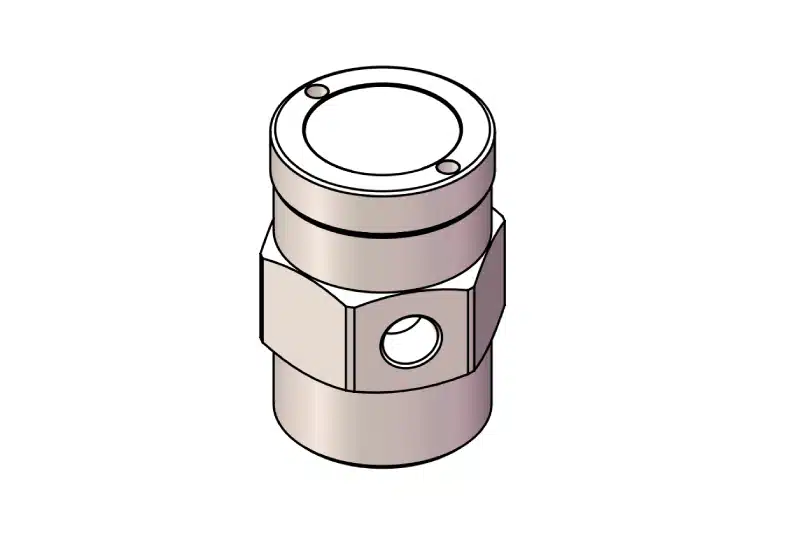

What is a Barstock Control Valve?

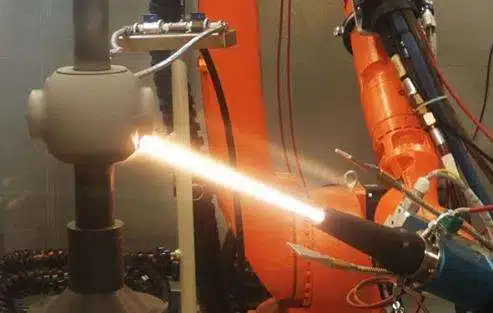

Barstock Control Valves are precision instruments designed to regulate the flow of fluid in industrial applications, particularly in reverse osmosis systems. The barsrock control valve is made of a single piece of barstock material, which makes it strong and less prone to leaks, and also boast enhanced strength and durability compared to cast valves. Their unique design ensures optimal flow control, safeguarding the membrane and ensuring consistent water quality.

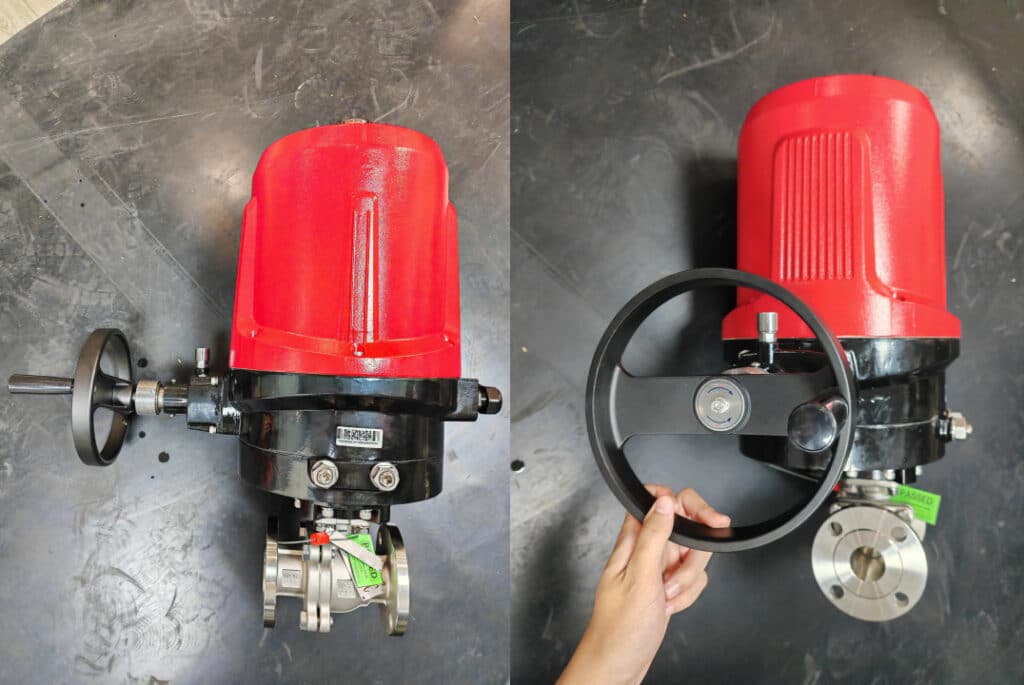

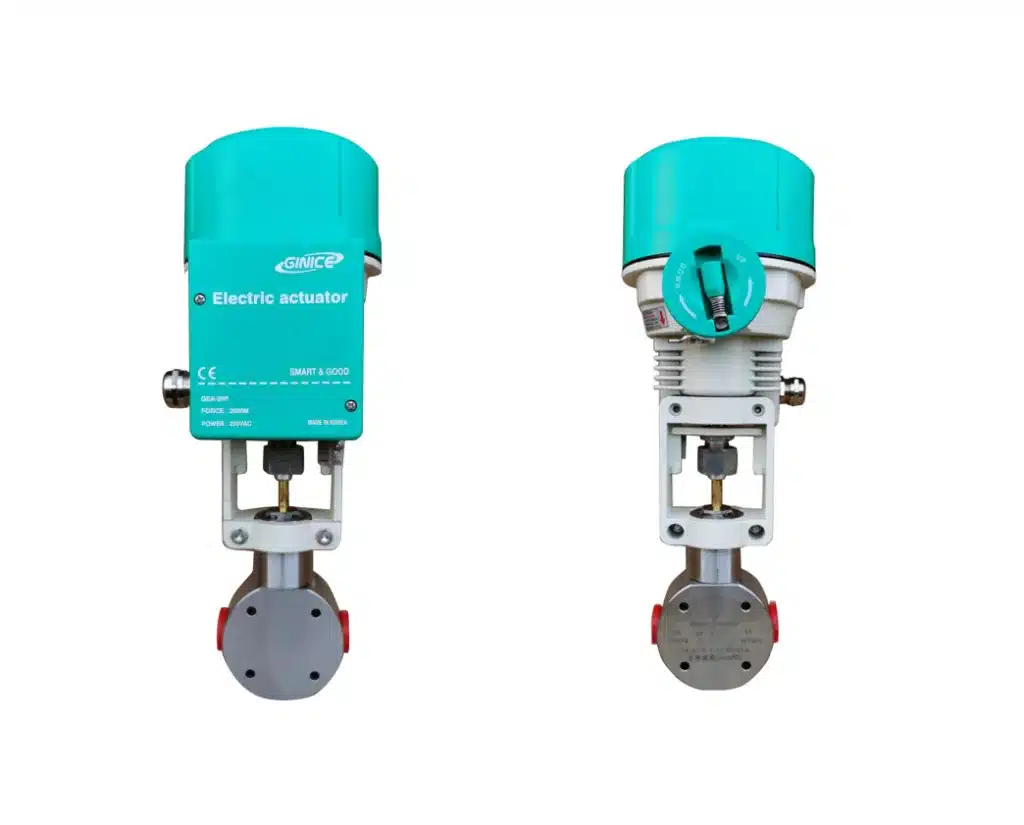

THINKTANK’s barstock control valve is designed to handle high-pressure, low flow to control the flow of water in the RO reverse osmosis system. With its threaded (standard type) and butt weld or flanged end connections (constructed from a special alloy for various operating temperatures even in cryogenic conditions) it offers outstanding performance in many different industries. Our barstock control valve also delivers accurate pressure regulation and reliable operation under demanding process conditions making it an indispensable part of these systems.

Key Features and Advantages of Barstock Control Valves

- Durability and Strength: Being carved from a single piece of material, Barstock Control Valves offer superior structural integrity.

- Precision Control: Designed for accurate flow regulation, they maintain system balance and prevent damage to the membrane.

- Corrosion Resistance: Many Barstock Control Valves are made from materials resistant to corrosion, making them ideal for RO systems where salt and mineral content can be high.

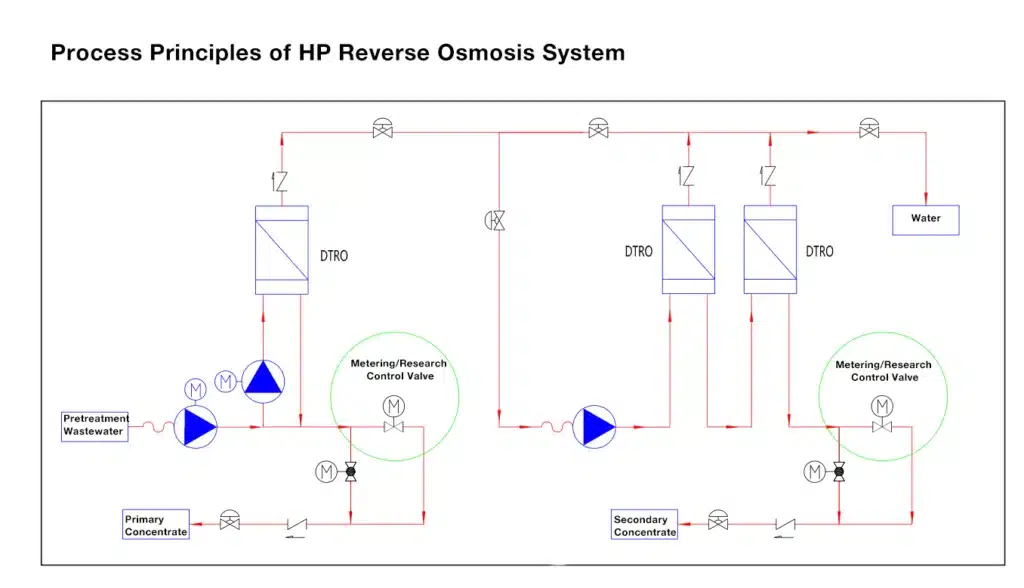

Application of Barstock Control Valve in Reverse Osmosis Systems

Barstock control valves are commonly used in the following applications:

- Water treatment plants

- Reverse osmosis systems

- Food and beverage production

- Pharmaceutical production

- Chemical processing plants

Why Use a Barstock Control Valve in an RO System?

Reverse osmosis is a delicate process. Maintaining the right pressure and flow is crucial to prevent damage to the system and ensure water purification efficiency. The following points make barstock control valves so important in RO system.

- Protect the Membrane: By ensuring consistent flow, these valves help in prolonging the life of the RO membrane.

- Enhance Water Quality: With precise flow control, the system can effectively filter out impurities, ensuring top-notch water quality.

- Boost Efficiency: Proper flow regulation reduces system wear and tear, leading to reduced maintenance needs and longer system lifespan.

Advantages of Barstock Control Valve

Barstock control valves offer several benefits compared to other types of control valves, including:

Durability

Barstock control valves are designed to last for many years. They are made of high-quality materials, which makes them less prone to wear and tear.

Precision

Barstock control valves are known for their precise control of the system. They can maintain the pressure and temperature of the system accurately.

Easy to maintain

Barstock control valves are designed to be easy to maintain. They can be disassembled and serviced without the need for special tools.

Cost-effective

Barstock control valves are affordable and provide a cost-effective solution for reverse osmosis systems.

Versatile

Barstock control valves can be used in a wide range of applications, making them a versatile choice for engineers and manufacturers.

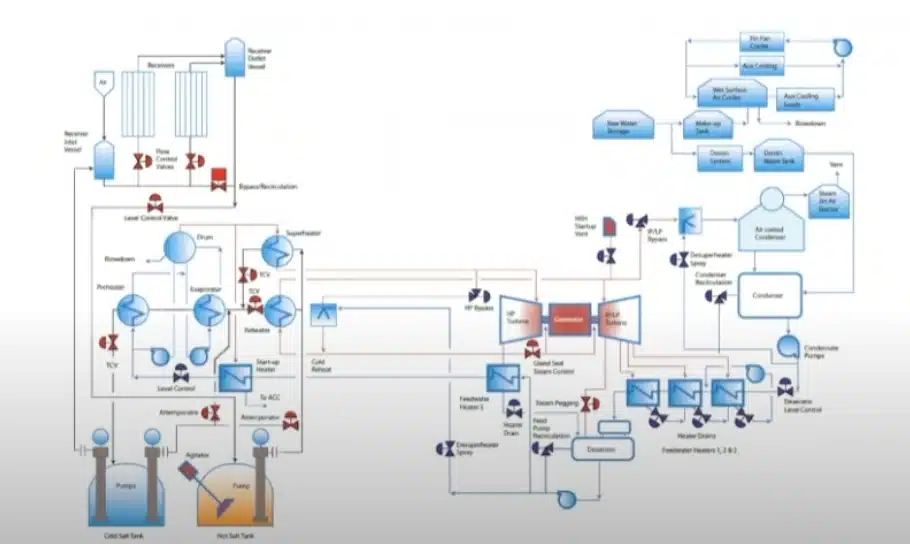

Industrial Applications of Reverse Osmosis Systems

Certain industries require water purity that meets or exceeds the standards of potable drinking water. These industries often operate continuous systems that treat large volumes of water under pressures ranging from 100 psig to 1,000 psig. To achieve the necessary water quality, multiple membranes and passes can be utilized to enhance effectiveness and reduce the volume of rejected water. Here are some common applications:

Boiler Systems

Plants that utilize steam to power turbines often purify their water before transforming it into steam. Contaminated water can cause damage to turbine blades, resulting in shutdowns and maintenance issues. Purifying the water is a cost-effective measure to prolong the lifespan of turbines.

Pharmaceuticals Industry

Pharmaceutical companies require pure water, free from dissolved particles, bacteria, and organics, to ensure consistent and pure products. The required levels of dissolved particles in pharmaceutical manufacturing can be up to 10,000 times lower than those deemed safe for drinking water. Reverse osmosis systems, in conjunction with other water treatment processes, are employed to achieve this level of purity.

Food and Beverage Industries

The production of food and beverages necessitates purified water to maintain product quality and prevent health issues. Reverse osmosis systems, coupled with additional treatment processes, are used to ensure the water is safe, maintaining a consistent taste and odor.

Agriculture

While irrigation water does not require the same level of purity as drinking water, finding suitable water sources can still be challenging. By utilizing simple reverse osmosis systems, non-potable water can be treated to meet agricultural standards.

Choosing the Right Barstock Control Valve for Your RO System

Selecting the appropriate valve is essential for optimal system performance. When choosing a Barstock Control Valve for your RO system, consider the following:

Material

Ensure the valve material is suitable for the type of fluid and is resistant to corrosion.

Size and Dimension

The valve should fit seamlessly into your RO system without causing obstructions.

Flow Rate

Ensure the valve can handle the flow rate of your system.

Commonly industrial valves in RO systems

Different valves are used at various stages of the reverse osmosis system to accurately and safely control the flow. Each valve has its own pros and cons, making them optimal for specific steps within the process.

Feedwater valve

This initial valve controls the flow of contaminated water into the system. It can isolate the system from pretreatment procedures or facilitate maintenance. Depending on the system’s sophistication, it may be a solenoid, ball, or butterfly valve.

Automatic shutoff valve

Positioned after the pump, this valve is either pressure-controlled or a solenoid valve. It monitors the output pressure and closes if pressure increases (indicating a closed valve downstream or flow obstruction), preventing water from entering the RO membrane. It reopens when pressure returns to normal.

Reject drain valve

Even with reject water recirculation, some water will still be directed to the drain. To control this flow precisely, a ball, butterfly, or needle valve may be used.

Recirculated reject valve

If reject water is recirculated, it is monitored and controlled by a ball, butterfly, or needle valve. In multi-stage or pass systems, this water is directed to additional RO membranes.

Check valve

Located directly after the RO membrane, this valve prevents backflow through the membrane. If downstream flow is obstructed, the osmotic pressure can cause purified water to flow back through the membrane, potentially damaging the system. A check valve ensures this does not occur and is necessary if an automatic shutoff valve is employed.

Diverting valve

When the flow through the RO system exceeds or falls short of industrial application requirements, purified water is often stored in tanks. A three-way ball valve is commonly used to distribute water to these tanks.

Float valve

To prevent overfilling of purified water tanks, float valves are employed. They work alongside automatic shutoff valves, as water overflow can be costly.

Sample valve

A sampling valve is installed to monitor the quality of purified water immediately after the RO membrane.

Installation and Maintenance

Proper installation and regular maintenance are vital to ensure the Barstock Control Valve functions optimally:

- Installation: Always follow the manufacturer’s guidelines. Ensure the valve is installed in the correct orientation and in the right section of the RO system.

- Regular Inspection: Check for signs of wear and tear or any blockages.

- Cleaning: Depending on water quality, mineral deposits can accumulate. Regular cleaning can prevent buildup and maintain valve performance.

The Future of Barstock Control Valves in RO Systems

As RO technology continues to evolve, the demand for high-quality, reliable components like the Barstock Control Valve is set to grow. Innovations in materials and design promise even more efficient, durable, and precise valves in the future, further solidifying their place in advanced water purification systems. As a reliable supplier of barstock control valves, THINKTANK has been updating its technology to meet the high requirements of new systems.

Conclusion

The Barstock Control Valve plays an invaluable role in Reverse Osmosis Systems. By ensuring optimal flow and protecting the system’s membrane, it guarantees both the longevity of the system and the quality of the water produced.

THINKTANK‘s Barstock control valves are a popular choice for manufacturers and engineers who need a reliable and cost-effective control valve for their reverse osmosis system. Our valves offer precise control, durability, and ease of maintenance.

Whether your business field of water store systems, brackish water purification systems, seawater desalination systems, or mobile & solar-powered water treatment systems, we always provide a excellent performance barstock control valves, meter control valve, and research control valves for you.

If you are looking for a new control valve supplier for your reverse osmosis system, then THINKTANK definitely worth considering.