Industry Fields

- Petrochemical

- Fine Chemical

- Basic Chemical

- Gasification Plant

- PP or PE, MTO, DMTO

- Coal Transportation Pipeline

Related Products

- Mid/High-Pressure Control Valve Angle Valve

- Orbital Ball Valve

- Rotary Valve

- Hard Seat Ball Valve

- Slurry Valve

- Disc Valve

- Bottom valve

Case Studies

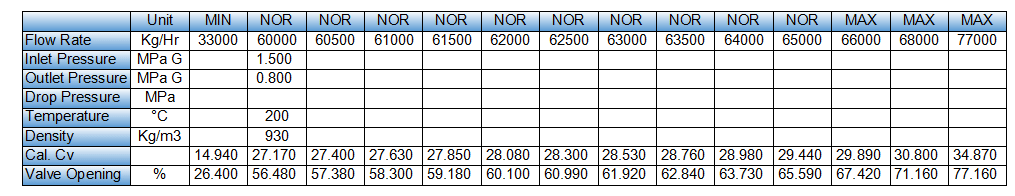

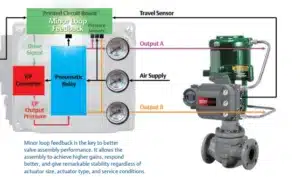

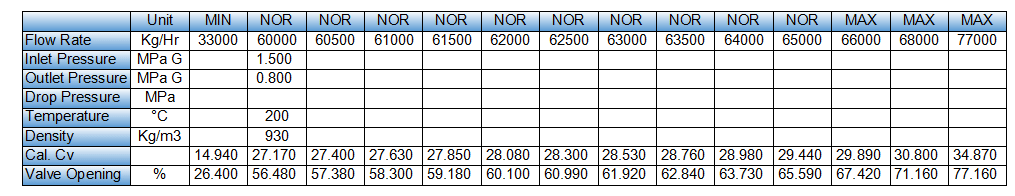

Modification project of flow characteristics of control valves at the feedstock inlet of Wuhan Petrochemical No. 2 catalytic unit.

Problem:

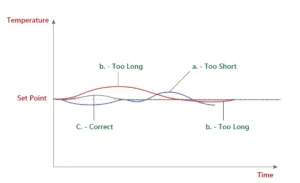

Tag No. FV105 and FV106 control valves are installed at the inlet port of the raw material. The raw material flow rate control needs to be very precise, especially when the flow rate is adjusted between 60~70 Ton. It needs to be adjusted according to the flow rate of 0.5 Ton each time. Due to the high adjustment accuracy requirements, After the valve is put into automatic operation, there will be 5%~10% fluctuations, affecting the end user’s normal production. The user can only change to manual operation, but it can only be set at 0.5% each time the valve position is given. Even then, Due to the positioner’s dead zone and the deviation of the valve itself, precise adjustment cannot be achieved.

Special Design: Cage-guided globe type control valve, with a special design of the flow window:

When the flow rate is below 33 Ton, the flow characteristic is an equal percentage; when the flow rate is 60~70Ton, the flow characteristic is linear; when the flow rate is above 70Ton, the flow characteristic is an equal percentage. In this way, it can meet the adjustment of small flow and large flow rate and meet the precise adjustment of valve opening between 56% and 75% when the flow is 60 ~ 70Ton. To realize the problem of the design flow characteristics of the partition.

FV105 And FV106 Control Valves

FV105 And FV106 Control Valves

Industry Fields

- Pipelines

- Oil and gas stations

- Natural gas station

- LNG transmission pipeline

- LNG station

- Oil refinery

- Underground oil storage

Related Products

- Medium & High-Pressure Valve

- Multi-Stage Pressure Control Valve

- Trunion Ball Valve

- Gate Valve

- Cryogenic Valve

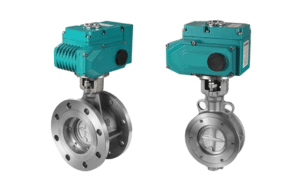

- High-Performance Butterfly Valve

Case Studies

Shannxi Coalbed methane 60000Nm³h Natural Gas Liquefaction LNG Device

- The raw gas purification equipment purifies the raw gas so that the acid gas content in the raw gas meets the process requirements. The purification process is simple to operate, low energy consumption, and has a wide range of applications. It can be used for various common natural gas sources. The main application is a multi-stage speed control valve, which is convenient to control the natural gas source with impurities.

- Natural gas liquefaction uses a high-pressure refrigerant to achieve the liquefaction of natural gas through the adiabatic expansion of the Claude cycle refrigeration of the turbo expander. When the gas expands and cools in the expander, it outputs work to drive the compressor in the process. The nitrogen expansion cycle process is simple and compact, and the cost is relatively low. Quick start, full load products can be obtained within 2 to 4 hours of the hot start, flexible operation, strong adaptability, easy operation and control, good safety, and emptying will not cause fire or explosion hazard.

Main features of the device

- The device is highly intelligent and integrated;

- Innovative purification technology, lower energy consumption, and smaller equipment;

- Modularization of public works and container control;

- Each module is controlled by PLC, and PLC communicates with the host computer through TCP/IP protocol, reducing instrument wiring;

- The complete control scheme, simple operation, and stable performance.

Applicable scope of the device

- Unconventional natural gas (shale gas, coal bed methane, biogas);

- Remote gas wells (isolated well, single well, test well);

- Oilfield associated gas, salt well-associated gas;

- Industrial exhaust gas and fuel gas converted from biomass.

Industry Fields

- Air separation System

- Molecular Sieve Purification System

- Cryogenic Liquefaction Device

- Storage Tank

- Air Compressor

- Turbine

- Pressure Regulating Station

- Natural gas

- Hydrogen device

Related Products

- Medium and High Pressure Control Valve

- On/off Ball Valve

- High Performance Butterfly Valve

- Oxygen Valve

- Multi-Stage Pressure Reducing Valve

- Cryogenic Control Valve

- Cryogenic Aluminum Angle Valve

84000nm³h Air Separation Unit & Air separation molecular sieve oxygen generator

84000nm³h Air Separation Unit & Air separation molecular sieve oxygen generator

Industry Fields

- Water Plant

- Sewage Treatment System

- Pressure Management

Related Products

- Piston Valve

- Knife Gate Valve

- Butterfly Valve

- Automatic Air Valve

- Plug Valve

- Check Valve

- Gate Valve

Hydraulic Control Heavy Hammer Slow Closing Device

Hydraulic Control Heavy Hammer Slow Closing Device

FV105 And FV106 Control Valves

FV105 And FV106 Control Valves

Boiler Feedwater System

Boiler Feedwater System

84000nm³h Air Separation Unit & Air separation molecular sieve oxygen generator

84000nm³h Air Separation Unit & Air separation molecular sieve oxygen generator

Hydraulic Control Heavy Hammer Slow Closing Device

Hydraulic Control Heavy Hammer Slow Closing Device

Nitrogen Equipment

Nitrogen Equipment