Welcome to our all-encompassing guide on P&IDs (Piping & Instrumentation Diagrams) and P&ID Valves! In the field of process control, these diagrammatic representations and vital valves are crucial for smooth operations and upholding safety standards. We invite you to embark on this journey with us as we explore the basics, different types, and practical uses of P&IDs and P&ID Valves across various industries. Let’s dive right in!

Understanding P&IDs (Piping & Instrumentation Diagrams) and P&ID Valves

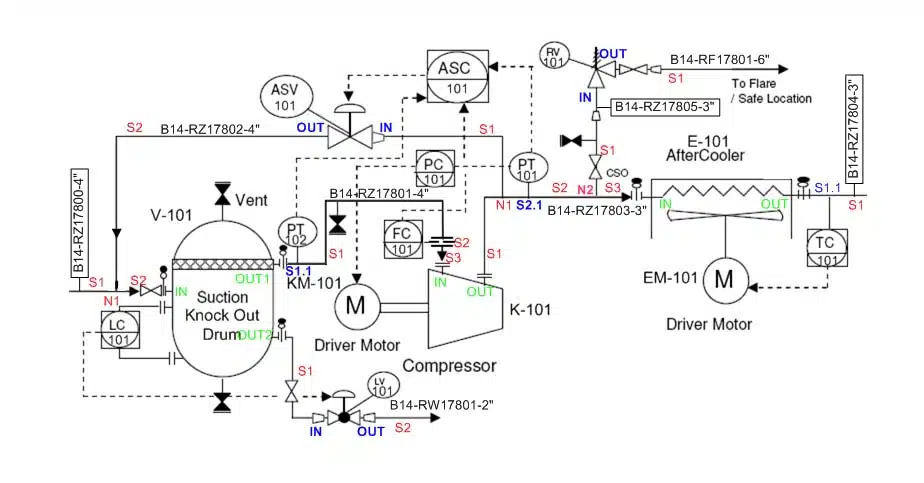

P&IDs, also known as Piping & Instrumentation Diagrams, are schematics that showcase the interconnections and functional relationships between piping, equipment, and instrumentation within a process system. These diagrams act as essential documentation tools utilized by engineers, operators, and maintenance personnel in multiple industries.

P&ID Valve Symbols

What Makes Up a P&ID?

P&IDs typically comprise the following vital components:

Process Piping

This depicts the interconnected network of pipes transporting fluids or gases within the system.

Equipment

This includes major components such as tanks, vessels, pumps, compressors, heat exchangers, and more.

Instruments

These are the tools responsible for measuring, controlling, and monitoring the process parameters, including pressure, temperature, flow, level, and composition.

Valves

These are the elements that control the flow, pressure, and direction of the process fluids.

Why Are P&IDs Important in Process Control?

P&IDs are invaluable tools in process control for several reasons:

Clarity and Communication

P&IDs offer a clear visual representation of the process system, fostering effective communication among engineering teams, operators, and other stakeholders.

Troubleshooting and Maintenance

P&IDs help in troubleshooting issues, identifying faults, and performing maintenance tasks by providing a detailed overview of the process equipment and instrumentation.

Safety and Compliance

P&IDs play a critical role in ensuring safety and compliance with industry regulations. They aid in hazard analysis, risk assessment, and the implementation of safety measures.

Process Optimization

By understanding the process flow and equipment configuration through P&IDs, engineers can identify areas for improvement, optimize performance, and enhance overall efficiency.

Introducing P&ID Valves: The Control Element

P&ID Valves, critical components in process control systems, enable precise control over fluid flow, pressure, and direction. These valves, also known as process control valves, regulate the flow of process fluids to achieve desired process parameters. Let’s delve deeper into P&ID Valves and explore their various types and applications.

Understanding P&ID Valve Types

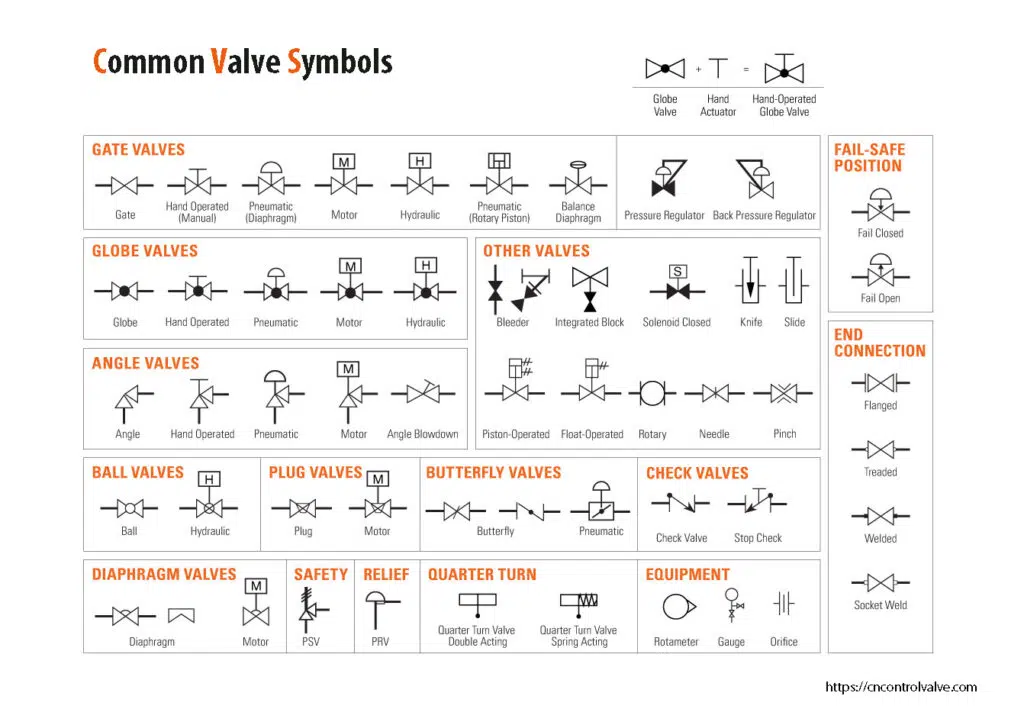

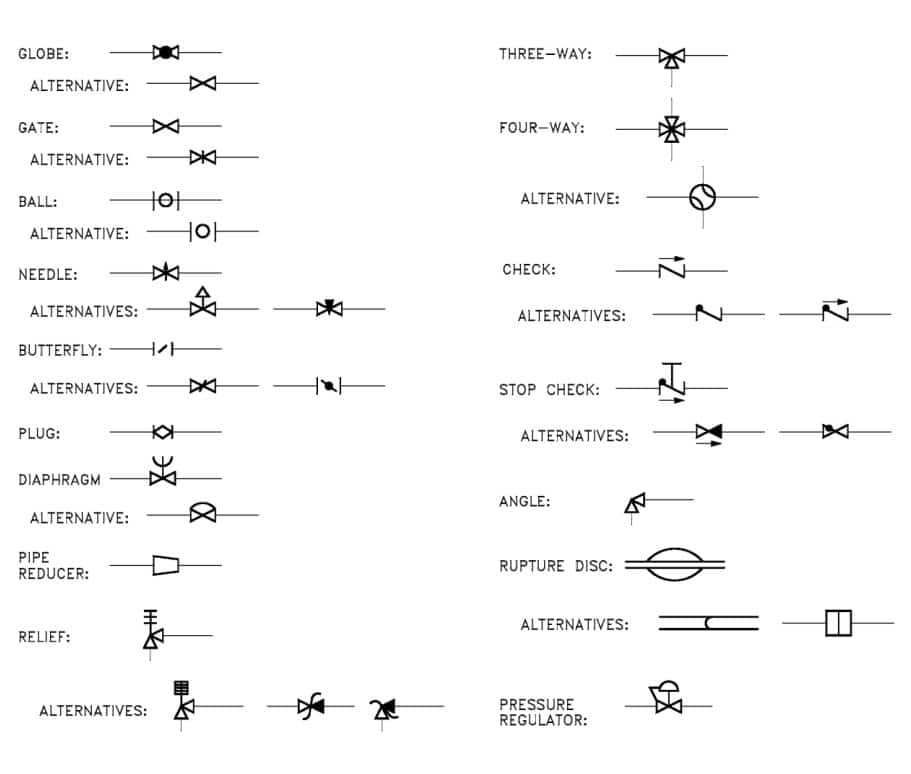

P&ID Valves come in various types, each with unique characteristics and applications. Some common types include:

Gate Valves

These valves control fluid flow using a sliding gate mechanism, either allowing or completely restricting the flow.

Ball Valves

Featuring a spherical closure element, ball valves offer excellent shut-off capabilities and low flow resistance.

Globe Valves

Globe valves regulate flow through a movable plug, making them suitable for precise control in various industries.

Butterfly Valves

These valves use a disk-shaped closure element that rotates to control the flow. They’re commonly used for large-diameter pipelines and applications requiring quick shut-off.

Check Valves

These valves allow fluid flow in one direction while preventing backflow, protecting equipment from damage.

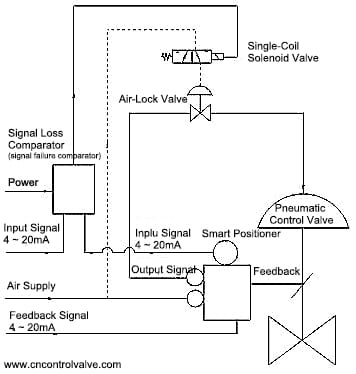

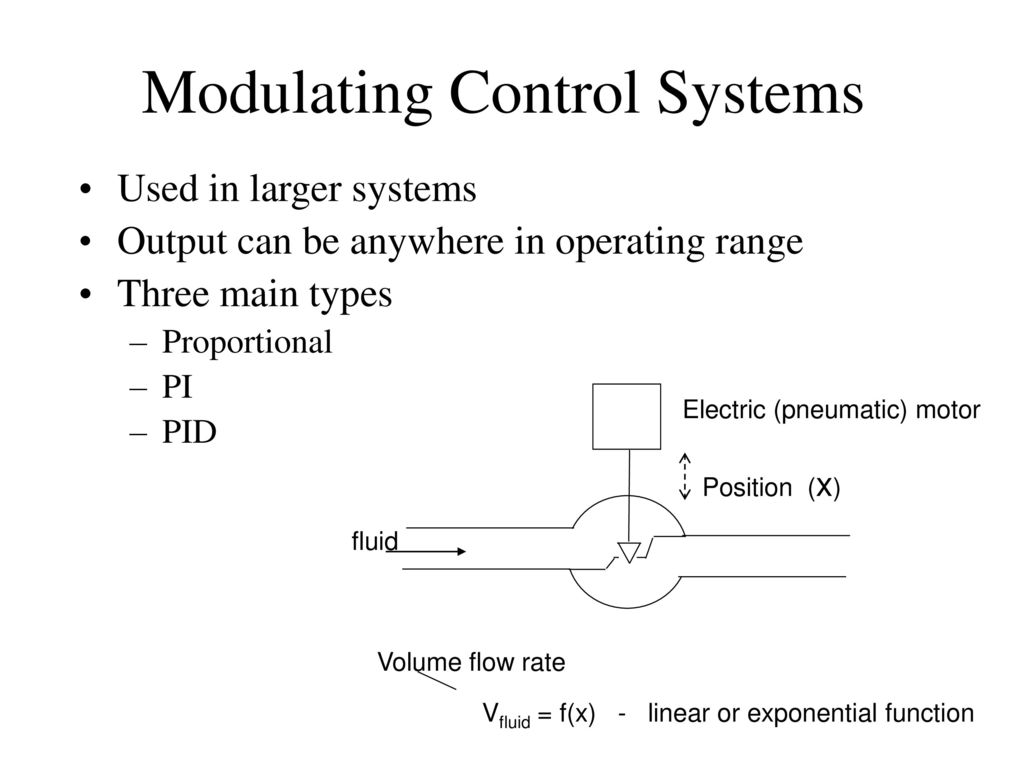

Control Valves

Control valves modulate the flow rate based on signals from the control system, crucial for maintaining process parameters within desired ranges.

Safety Relief Valves

These valves automatically release excess pressure to protect equipment and prevent system failures, ensuring safe operations by avoiding overpressure situations.

Applications of P&ID Valves

P&ID Valves are employed across a wide range of industries, such as:

Oil and Gas

P&ID Valves are utilized in oil and gas production, refining, and transportation processes to control the flow of crude oil, natural gas, and various petroleum products.

Chemical Industry

Chemical processes often involve handling hazardous substances, and P&ID Valves play a crucial role in controlling the flow and preventing leaks or spills.

Pharmaceuticals

In pharmaceutical manufacturing, P&ID Valves regulate the flow of liquids, gases, and solvents to ensure accurate dosing and maintain quality standards.

Water and Wastewater Treatment

P&ID Valves are used in water treatment plants to control the flow of water, chemicals, and wastewater, ensuring efficient treatment processes.

Power Generation

P&ID Valves are integral to power plants, controlling the flow of steam, water, and gases to optimize energy production and maintain safety.

Frequently Asked Questions (FAQs)

Q1: What is the primary purpose of P&IDs (Piping & Instrumentation Diagrams)?

P&IDs serve as visual representations that depict the interconnections and functional relationships between the piping system, equipment, and instrumentation within a process system. They are used for communication, troubleshooting, safety, and process optimization purposes.

Q2: How are P&IDs beneficial for process control?

P&IDs provide a clear overview of the process system, aiding in effective communication, troubleshooting issues, ensuring safety compliance, and identifying areas for process optimization.

Q3: What is the role of P&ID Valves in process control?

P&ID Valves regulate the flow, pressure, and direction of process fluids. They ensure precise control over process parameters, allowing for safe and efficient operations.

Q4: What are the common types of P&ID Valves?

Some common types of P&ID Valves include gate valves, ball valves, globe valves, butterfly valves, check valves, control valves, and safety relief valves.

Q5: In which industries are P&ID Valves widely used?

P&ID Valves find applications in industries such as oil and gas, chemical manufacturing, pharmaceuticals, water and wastewater treatment, and power generation.

Q6: What are the key considerations when selecting P&ID Valves?

When selecting P&ID Valves, factors such as the required flow rate, pressure rating, temperature range, fluid characteristics, and compatibility with the process need to be considered.

Conclusion

In summary, P&IDs (Piping & Instrumentation Diagrams) and P&ID Valves are indispensable components in process control systems. P&IDs provide a visual representation of the process system, facilitating effective communication, troubleshooting, safety compliance, and process optimization. P&ID Valves play a critical role in the process lines by regulating the flow, pressure, and direction of process fluids, ensuring precise control and maintaining safe operations. Understanding the fundamentals of P&IDs and the different types and applications of P&ID Valves is crucial for professionals in various industries. By leveraging the power of P&IDs and using the appropriate P&ID Valves, industries can achieve efficient and safe process control.