In the industrial process, we often find that the size of the control valve will be smaller than the pipe size, while other on/off valves are generally the same size as the pipeline. In this article, we’ll discuss several reasons why flow control valves are usually smaller than the pipe size.

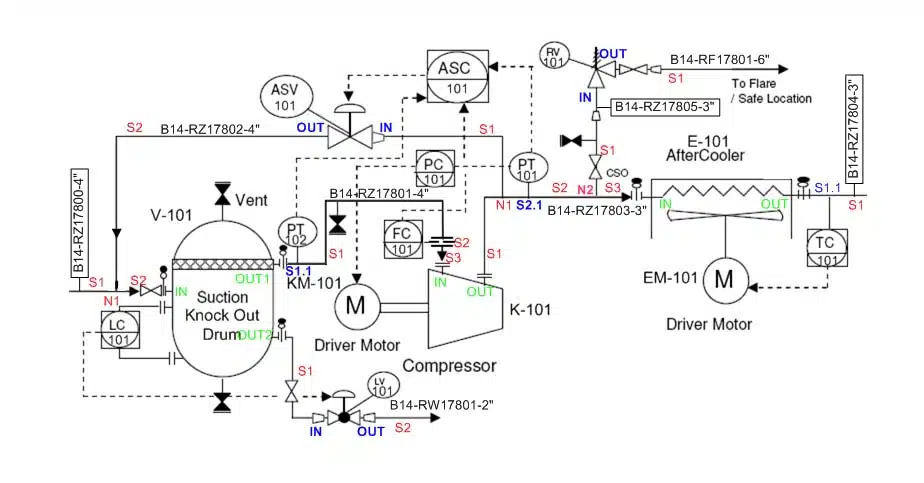

For example, you need to install a flow meter or control valve into the system by calculating had to reduce a 1.5 inches pipe to 0.5 inches in order to install the flow meter or control valve. And by looking at the P&ID, you will find that almost all flow control valves in the area have the same reduced size, i.e., the actual size of the control valve is smaller than the pipe size.

6 Reasons Why Flow Control Valves Smaller Than Line Size

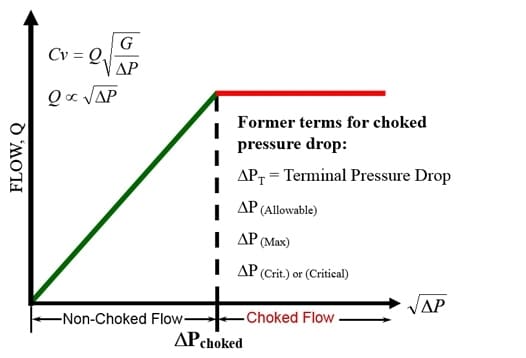

1. Controlling pressure drop

Because control valves make their living generating pressure drop, and their purpose is usually to generate large pressure drops, control valves of smaller size relative to the pipe diameter are used to generate larger pressure drops to meet system requirements.

2. Market Competition – Price First

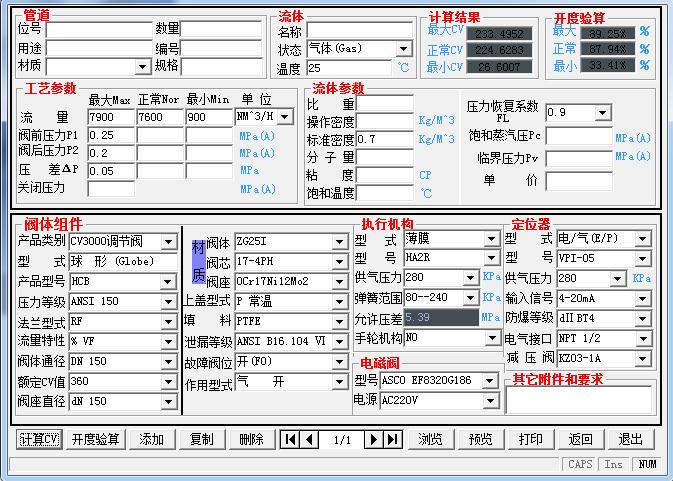

To a certain extent, we cannot deny the impact of the market on the professionalism of the control valve. In the selection and calculation, we will consider a variety of factors to ensure excellent control performance of the control valve, not just pressure drop or control the flow rate, temperature, and other basic parameters.

However, in the process of participating in the bidding process, if an aspect can surface to complete the pressure reduction needs, without regard to cavitation, noise, or cavitation phenomenon, the control valve size can be selected as one or two smaller than the pipe size so that it will be cheaper. Then the probability of getting this order is greatly increased.

In fact, we found this out during the quotation process, choosing different trim designs and sizes have a big impact on the final order. We still insist on doing what we think is right, a good control valve can help customers to increase production, and more durable normal operation in the production, reducing the cost of downtime waste.

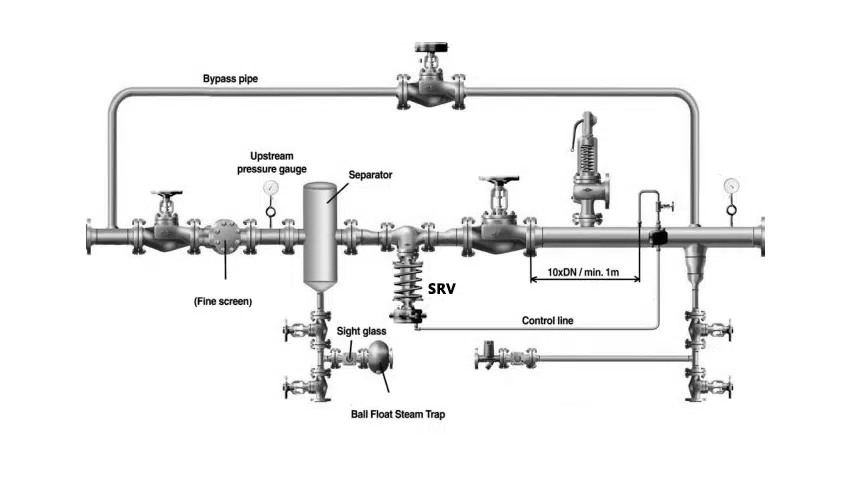

3. Steam or gas service

Many control valves for steam or gas service are specifically sized to avoid excessive release of gas into low pressure downstream systems in the event of control valve failure, resulting in unnecessary increases in relief valve, tank vent, and flare system sizes, etc.

Most control valve sizes are usually found on drawings and in systems or connection systems that are often located some distance from the valve.

For example, pipe size for compressible flows with M=0.1, or 100 fps for compressed air. pipe size for incompressible flows at V=5 fps. Consider that the valves and flow meters will be half the pipe size. Plan for valves and flow meters to be half the size of the pipe. After that, go to more particular part specifications.

4. Control valve sizing – Sensitivity and Accuracy

In the past, engineering designs were simply and crudely implemented by reducing the size of control valves in order to reduce the budget for plant manufacturing costs. This is dangerous, and the higher the pressure drop across the control valve, the more sensitive its control action will be in perpetuating a low-cost design.

This is achieved by making the control valve one or two sizes smaller than the pipe to allocate about 30% of the system pressure drop to the control valve, and the accuracy of the control flow is improved due to the small diameter and narrow control range.

Simply to say, a smaller flow area allows for more precise control, especially for micro-flow proportional regulation conditions.

Oversized control valves, on the other hand, can be very sensitive, i.e., a small valve position movement can produce large flow changes, so control becomes more difficult.

5. Smaller valves take up less space

A control valve with a smaller pipe will obviously take up less installation space than a valve with the same pipe size. This difference is especially noticeable for large pipelines with diameters over DN100. Because the larger the bore, the larger the actuator is equipped, and the size of the actuator directly affects the space reserved for installation in the piping system.

6. Lifespan

The service life of control valves is critical to process control loops, and control valves that operate between 30-80% of their travel primarily will have a longer life than valves that are almost fully open or fully closed. If you choose an oversized control valve, the valve will have not only poor control performance but also a short service life if it is always operating below 30% at a small opening.

In Conclusion

An unsuitable control valve can have a significant impact on your capital expenditure and operating cost budget, especially if it forces you to perform unscheduled shutdowns. As a professional control valve manufacturer – THINKTANK, we can provide free control valve calculation and sizing services to provide unique and customized services for your project.