What is a Pressure/Vacuum Relief Valve with Flame Arrester

Pressure vacuum relief valves with flame arresters are essential safety equipment used in multiple industries to protect vessels, tanks, and personnel from the risks of overpressure, vacuum, and flame spread. These pressure vacuum vent valves are designed to prevent hazardous pressure or vacuum buildup inside tanks, vessels, or pipelines due to temperature, liquid level fluctuations, or external events such as fires or explosions.

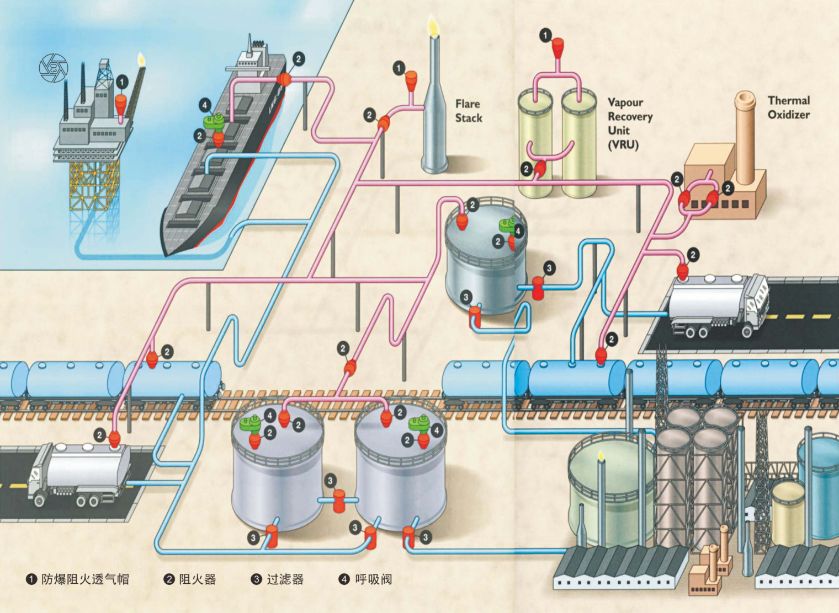

They are commonly used in a wide range of industries including oil and gas, chemical processing, pharmaceuticals, food and beverage, and many other industries. These valves help ensure the safe operation of the equipment while protecting against potential hazards that could otherwise cause extensive damage or harm to employees and our environment.

What is The Purpose of The Breather Valve?

The purpose of a breather valve is to allow safe venting of pressure while preventing any flame or spark from entering the tank or container. In industrial applications that involve the storage and transportation of flammable liquids, gases, or vapors, the pressure inside the tank can fluctuate due to changes in temperature or the liquid level. Breather valves prevent excessive vapor pressure from buildup by allowing the tank to breathe in and out as the pressure changes, thus preventing the tank from rupturing.

In addition to preventing excessive back pressure and vacuum buildup, breather valves also prevent potential explosions or fires by preventing any flame or spark from entering the tank or container. This is achieved through the use of a flame arrestor component, which contains a mesh or other barrier that prevents flames from propagating. When a flame or spark reaches the arrestor, it is cooled down, and the energy is dissipated, preventing it from igniting any flammable gases or liquids inside the tank.

Test and Inspection of Pressure Vacuum Relief Valve with Flame Arrester

End-of-Line Pressure Vacuum Relief Valve with Flame Arrester

Flanged to ASME 150#RF, Stainless Steel 304 A351 CF8 Material

Flame Arrestor With Vent

Model: 7110+FA-S-080

Size: 3″(DN80), Pressure: 150LB

Body Material: CF8(SS304), Trim Material: SS316

Connection: RF Flanged Ends, Diaphragm: NBR+FEP

Inlet&Outlet Flow Rate: 330/ 300L/M

Positive Pressurel:+1.35Kpa

Negative Pressure: -0.3 Kpa

How does a breather work?

As pressure builds up inside the tank, the breather valve opens and allows air to escape, releasing excess pressure and preventing the tank from rupturing due to excessive pressure buildup. Once the pressure inside the tank drops to a safe level, the breather valve closes, and the vapor space pressure and the flame arrestor component prevent any flame or spark from entering the tank or container by containing and extinguishing any flames.

What are The Types of Breather Valves?

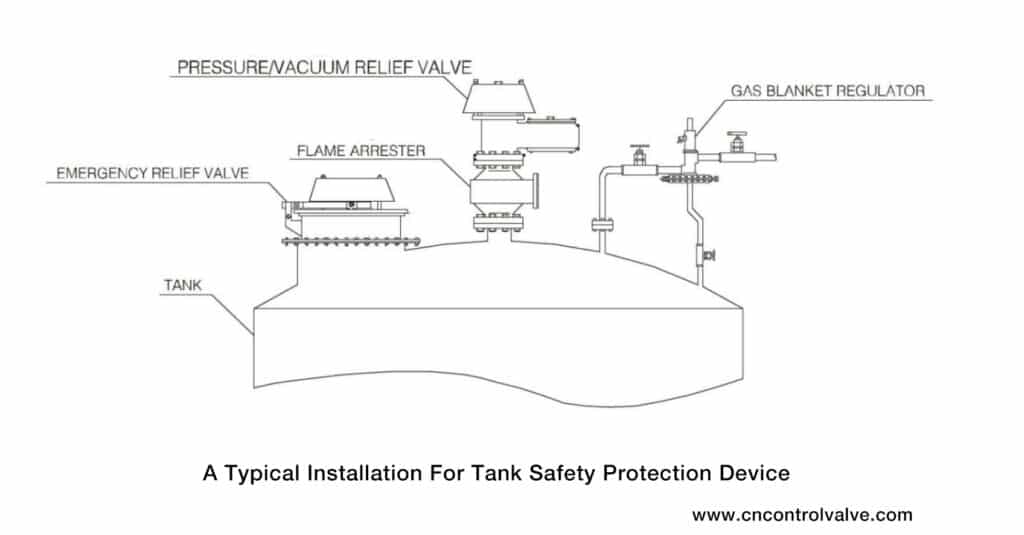

- Pressure/Vacuum Relief Valve – This valve is designed to protect tanks and vessels that contain liquids that can produce vapors. The pressure/vacuum relief valve protects the tank from both excessive pressure buildup and vacuum conditions that can cause the tank to collapse.

- Emergency Relief Valve – This valve is designed to operate in emergency situations, such as a fire, by providing full-bore flow to prevent the tank from rupturing. Emergency relief valves typically have a higher flow capacity than other types of breather valves and may be set to open at lower pressures.

- Inline Breather Valve – This type of valve is designed to prevent the ingress of airborne contaminants into a tank or vessel. The inline breather valve is installed in the tank or vessel’s vent line and is typically fitted with a filter element to trap airborne particles.

- Flame Arresting Breather Valve – This valve is designed to prevent the spread of flames inside a tank or vessel. The flame arresting breather valve consists of a flame arrestor component that extinguishes any flames or sparks that might enter the tank or vessel.

- Tank Blanketing Valve – This valve is designed to maintain constant pressure inside a tank or vessel by introducing an inert gas, such as nitrogen or argon, into the tank or vessel. The tank blanketing valve is used to prevent the oxidation of the tank’s contents and reduce the risk of explosions or fires.

How do breather valves with flame arrestors work?

Breather valves with flame arrestors are crucial safety devices used in many industrial applications to keep pressure settings and prevent explosions and fires. They function by allowing safe venting of pressure while preventing any flame or spark from entering the tank or container.

THINKTANK offers a range of breather valves with flame arrestors, which consist of two primary components: the breather valve and the flame arrestor. The breather valve component allows pumping liquid in the tank to breathe in and out as the liquid level changes or as the pressure inside the tank fluctuates. The flame arrestor component prevents any flame or spark from entering the tank or container.

The breather valve functions by releasing excess pressure from the tank. When the pressure inside the tank rises beyond a certain level set pressure, the breather valve opens and allows the air to escape. This prevents the tank from rupturing due to excessive pressure buildup. As the pressure inside the tank drops to a safe level, the breather valve closes again.

The flame arrestor component of the breather valve works by extinguishing any flame or spark that tries to enter the tank or container. The flame arrestor contains a mesh or other barrier that prevents flames from propagating the storage tank. When a flame or spark reaches the arrestor, it is cooled down, and the energy is dissipated, preventing it from igniting any flammable gases or liquids inside the tank.

THINKTANK’s breather valves with flame arrestors may also include additional features to ensure safe operation. For instance, some valves are equipped with pressure gauges or indicators that allow operators to monitor the pressure inside the tank. Others may have backpressure valves or vacuum breakers that prevent the tank from collapsing or imploding due to extreme atmospheric pressure or changes.

Different Types of Breather Valves with Flame Arrestors

Breather valves with flame arrestors come in different types and designs, each suitable for specific applications and industries. Understanding the different types of breather valves with flame arrestors can help engineers and operators select the right valve for their specific needs.

One type of breather valve with flame arrestor is the pressure/vacuum relief valve. This valve is typically used in tanks and vessels that contain liquids that can produce vapors. The pressure/vacuum relief valve protects the tank from both excessive pressure buildup pressure and vacuum relief conditions that can cause the tank to collapse.

Another type of breather valve with flame arrestor is the emergency relief pressure valve only. This valve is designed to operate in emergency situations, such as a fire, by providing full-bore flow to prevent the tank from rupturing. Emergency relief valves typically have a higher flow capacity than other types of breather valves and may be set to open at lower pressures.

In addition to these types of breather valves, there are also specialized valves for specific applications. For example, THINKTANK offers breather valves with flame arrestors designed for use in offshore platforms, which are made from materials that can withstand harsh marine environments. There are also breather valves with flame arrestors specifically designed for use in explosive atmospheres, such as in the chemical and petrochemical industries.

Installation and maintenance of breather valves with flame arrestors for tank applications

Breather valves with flame arrestors are crucial safety devices for tanks that store flammable liquids, gases, or vapors. Correct installation and maintenance of these valves are essential to ensure they function effectively and prevent potential safety hazards.

During vacuum valve installation, it is crucial to follow the manufacturer’s instructions carefully to ensure the valve is installed correctly. The valve should be placed in a location where it can operate effectively, and it should be installed in a way that ensures there are no obstructions to the airflow.

Regular maintenance and inspection are also critical to ensure breather valves with flame arrestors are functioning correctly. THINKTANK provides customers with detailed instructions and a video demonstration of the test and inspection process for their valves.

Regular inspection and maintenance can prevent potential issues, such as valve blockage, corrosion, or damage, and ensure that the valve remains effective in preventing explosions or fires. It is recommended to perform regular inspections and maintenance at least once a year or as required by industry regulations.

Industry standards and regulations for breather valves with flame arrestors in tank applications

Breather valves with flame arrestors are essential safety devices for tanks that store flammable liquids, gases, or vapors. As such, there are specific industry standards and regulations that must be followed to ensure their safe and effective operation.

In the United States, breather valves with flame arrestors are regulated by the National Fire Protection Association (NFPA) and the American Petroleum Institute (API). These organizations provide guidelines and standards for the design, installation, and maintenance of breather valves with flame arrestors in tank applications.

In Europe, breather valves with flame arrestors are regulated by the European Committee for Standardization (CEN). They provide guidelines for the design, installation, and maintenance of breather valves with flame arrestors in tank applications.

API 2000:

The American Petroleum Institute (API) 2000 standard provides guidance on the selection, installation, and maintenance of pressure relief devices for storage tanks in the petroleum industry. Our Pressure Vacuum Relief Valve with Flame Arrester meets the API 2000 standard for pressure relief devices.

ISO 28300:

The International Organization for Standardization (ISO) 28300 standard specifies requirements and gives guidelines for the design, selection, installation, testing, and maintenance of pressure relief devices for use in the oil and gas, petrochemical, and chemical industries. Our Pressure Vacuum Relief Valve with Flame Arrester meets the ISO 28300 standard for pressure relief devices.

ATEX:

The ATEX directive is a European Union regulation that applies to equipment and protective systems intended for use in potentially explosive atmospheres. Our Pressure Vacuum Relief Valve with Flame Arrester meets the ATEX directive for use in potentially explosive atmospheres.

ASME:

The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code sets safety standards for the design, fabrication, installation, inspection, testing, and repair of boilers and pressure vessels. Our Pressure Vacuum Relief Valve with Flame Arrester meets the ASME Boiler and Pressure Vessel Code for safety devices.

THINKTANK ensures that all of the breather valves with flame arrestors comply with industry standards and regulations for safe and effective operation. This includes the necessary certifications and testing to ensure the valves meet or exceed industry standards.

In industrial applications that involve the storage and transportation of flammable liquids, gases, or vapors, safety is of utmost importance. Breather valves with flame arrestors are crucial safety devices in bulk storage tanks that prevent potential explosions or fires by allowing safe venting of pressure while preventing any flame or spark from entering the tank or container.

THINKTANK offers a range of breather valves with flame arrestors designed for different applications and industries. These valves consist of two primary components: the breather valve and the flame arrestor. The breather valve allows the tank to breathe in and out as the liquid level vapor pressure changes, or as the pressure inside the tank fluctuates, while the flame arrestor prevents any flame or spark from entering the tank or container.

Proper installation and maintenance of breather valves with flame arrestors are essential to ensure they function effectively and prevent potential safety hazards. Regular inspection and maintenance can prevent potential issues and ensure that the valve remains effective in preventing explosions or fires. THINKTANK provides customers with detailed instructions and video demonstrations specific to tank applications for their valves to ensure safe and effective operation.

Industry standards and regulations must be followed to ensure the safe and effective operation of breather valves with flame arrestors in industrial applications. In the United States, breather valves with flame arrestors are regulated by the National Fire Protection Association (NFPA) and the American Petroleum Institute (API), while in Europe, they are regulated by the European Committee for Standardization (CEN).

In conclusion

Breather valves with flame arrestors are essential safety devices in industrial applications that involve the storage and transportation of flammable liquids, gases, or vapors. By choosing a reliable manufacturer such as THINKTANK and adhering to industry standards and regulations, customers can ensure the safe and effective operation of their valves and prevent potential safety hazards.