| Size | 3/4″ – 16″ |

| Type | Straight Though, Globe Type Valve |

| Rating | ANSI Class 150, Class 300, Class 600 JIS10K, 16K, 20K, 30K, 40K |

| Materials | A216Gr WCB, WC6, A352 LCB, CF8, CF8M, CF3M, CF3, Other Alloys. |

| Connection | Flanged, Butt Welded, Socket Welded, RTJ |

| Seat Leakage | ANSI / FCI 70-2, Class IV.Class V. Class VI(Soft Seat) |

| Actuator | Multi-Spring Diaphragm/Single Spring Diaphragm Pneumatic Actuator, Cylinder Actuator, Electric Actuator |

Should you be interested in further information on cage type control valves, Please do not hesitate to contact us.

THINKTANK is a specialist control valve manufacturer of cage-guided globe control valves designed to meet the critical service process control requirements of a variety of applications in the oil and gas, petrochemical, and power industries.

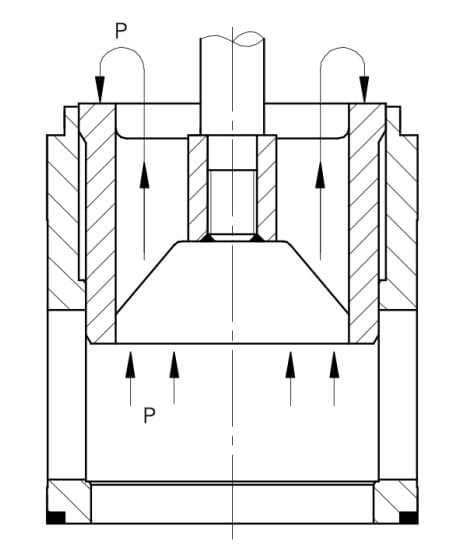

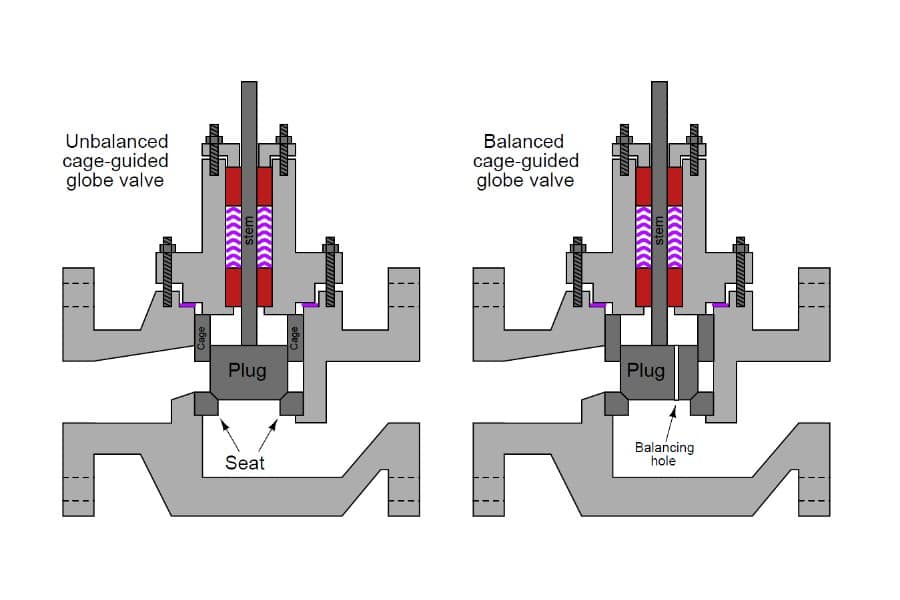

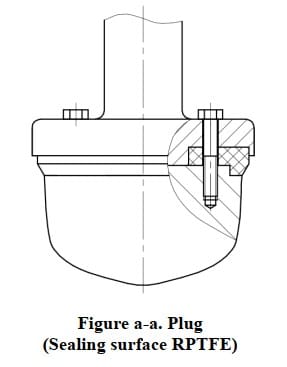

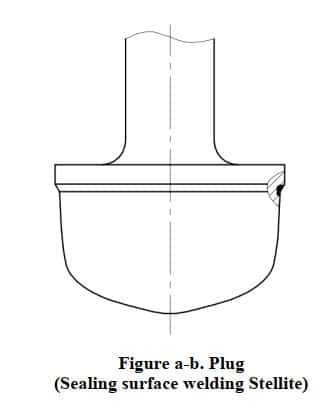

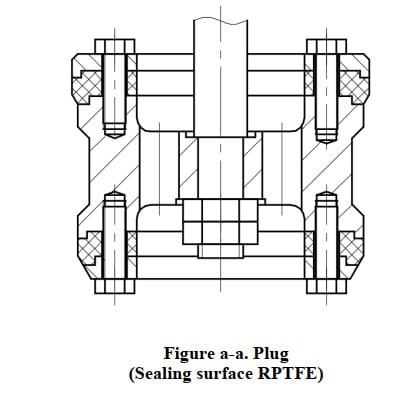

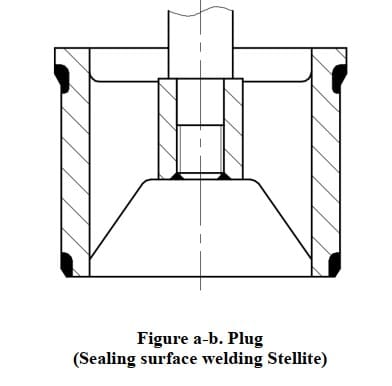

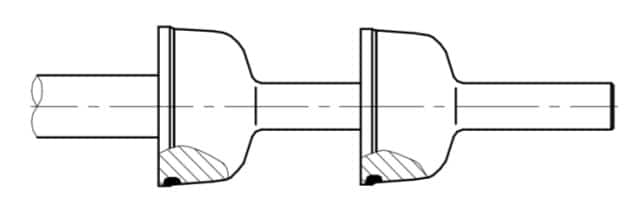

Cage-type control valves are designed for balanced plugs or unbalanced plugs. The difference point is the plug of the balanced cage-guided globe valve has a balancing hole located at the top of the plug. This trim is suited for both high and low-pressure drop conditions.

The unbalanced plugs will generate an inner force, which equals differential pressure across the plug plus the plug area. F= P x A

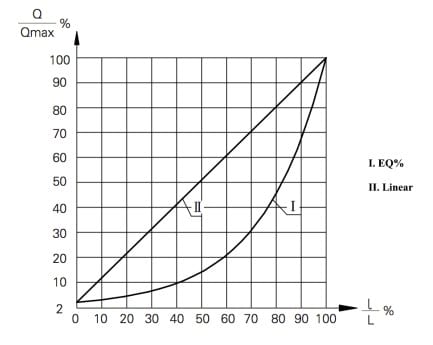

The standard cage trim is designed with special window shapes which depend on the flow characteristic(linear, equal percentage, quick opening, and others)of the control valve.

Picture from instrumentationtools

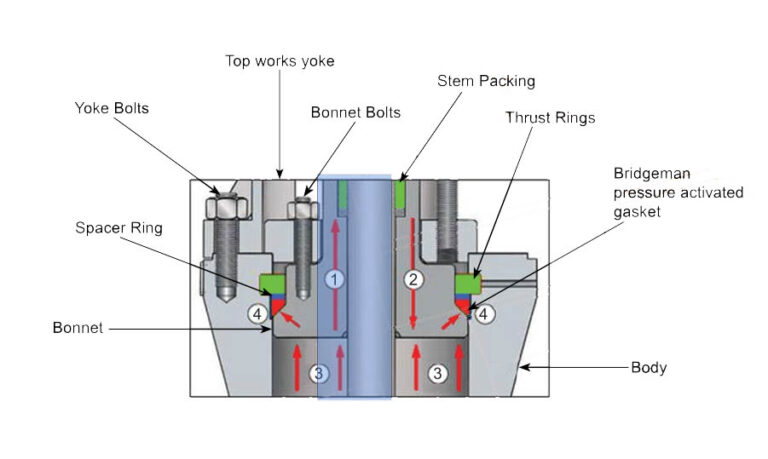

1. The third generation of S-type smooth casting body cavity gets greater circulation ability to reduce the initial investment, as it is now with more efficient average flow velocity by improving the second generation through CFD (Computational Fluid Dynamics)

2. In accordance with ASME, the valve body and the upper bonnet are pressed together by the double-head stud bolt

3. The stability of plug movement is improved due to the strong cage guide and the unique balanced sealing ring (GF TFE structure for room temperature, graphite 1398 & Graph-lock structure for high temperature) so that the vibration and mechanical noise are reduced

4. With the solid cage, the valve body is protected from steam and cavitation damage. There was an S streamlined channel and this makes the small loss of pressure drop, high flow, a wide range of control.

Top guided and cage guided control valves are the most popular control element in the process loop.

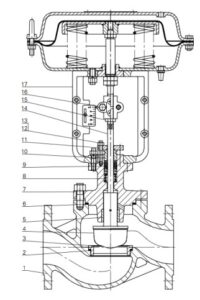

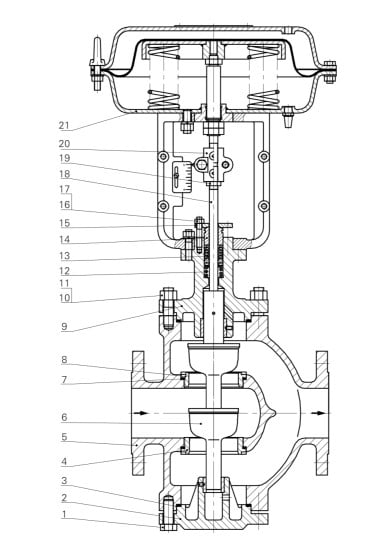

Model HTS Pneumatic Top-guided Single-Seated Control Valves are designed for heavy-duty service.

The compact valve body, having an S-shape flow passage with low-pressure loss, allows a large flow capacity, rangeability, and high accuracy flow characteristics.

The valve plug is highly vibration-resistant as it is held by a top guide section with a large sliding area. The flow shut-off performance complies with the IEC or JIS Standards. The actuator integrated with the simplest mechanisms utilizes a compact yet powerful diaphragm actuator loaded with multiple springs.

The model HTS Valves are widely applicable for reliable control, with high shut-off performance, in high or low temperature, high-pressure process lines.

1. Body 2. Seat Gasket 3. Seat 4. Plug 5. Top-Guided

6. Seal Gasket 7. Bonnet 8. Packing Spring 9. Packing

10. Packing Screw 11. Packing Flange 12. Screw 13. Nuts

14. Stem 15. locknut 16. Stem Connector 17. Actuator

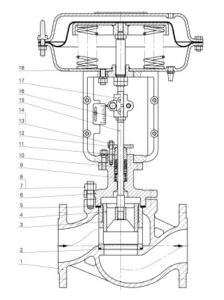

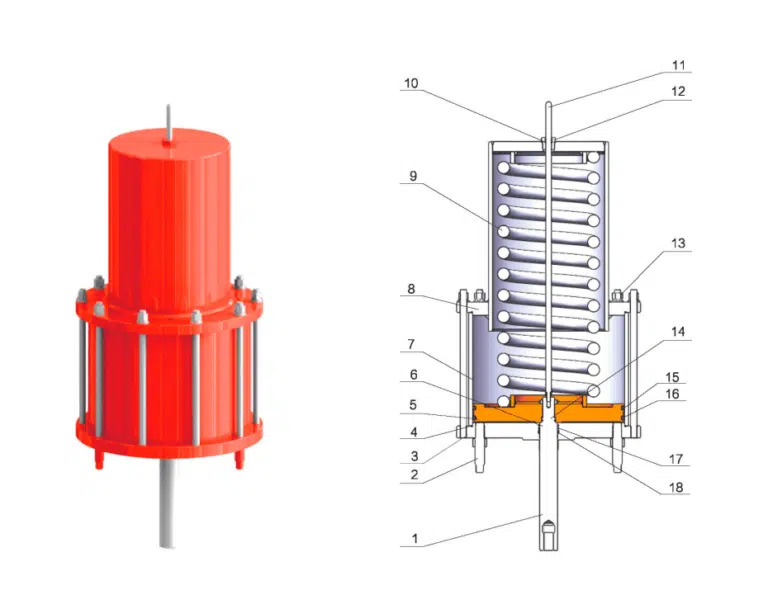

Model HCB Pressure Balanced Cage Type Control Valves are designed for heavy-duty services. The compact valve body, having an S-shape flow passage that features low-pressure loss and a stabilizer that regulates turbulent flow around the cage, allows a large flow capacity, rangeability, and high accuracy flow characteristics.

The valve plug is structured in a pressure-balanced type that permits flow control of high differential pressure with a small actuating force. The actuator integrated with the simplest mechanisms utilizes a compact yet powerful diaphragm actuator loaded with multiple springs. The model HCB valves are widely applicable for reliable control of high or low temperature, high pressure, or high differential pressure process lines where dynamic stability, low noise, and cavitation/flashing resistance are required.

1. Body 2. Seat Gasket 3. Cage 4. Plug 5. Sealing

6. Bonnet 7. Double-screw Bolt 8. Hexagon Nut 9. Packing

Spring 10. Packing 11. Packing Screw 12. Packing Plate

13&14. Nuts&Bolts 15. Stem 16. Locknut

17. Stem Connector 18. Actuator

Optional accessories for Control Valves

• P/P or I/P Positioner

• Air filter regulator

• Top-mounted or Side-mounted Handwheel

• Limit switch

• Solenoid valve

• Motion transmitter

• Booster relay

• Lock-up valve

• Airlock relay

• Others

Top and bottom cage guided control valves are also called double seat globe control valves.

Model HDB Control valve is excellent for applications involving dirty fluids combined with high-pressure drops. Some typical service conditions and operating requirements include:

– Clean and dirty process fluids

– Moderate to high-pressure drops

– Large flow capacities and operating range

– Resistant to process system vibration

– Low emissions and zero leakage options

A double-seated control valve combines excellent high-pressure drop control performance along with the ability to handle dirty fluid applications. The two ports design provides a balanced pressure effect within the valve, which reduces actuator size and thrust requirements.

Dynamic force on the plug tends to be balanced as flow opens one port and closes the other. Reverse-Acting double ported Globe-Style valve bodies typically have higher capacity than single-ported valves of the same line size.

Many double-ported bodies reverse, so the valve plug can be installed as either push down to open or push down to close.

Metal-to-metal seating of double-seated control valve usually provides only Class II shutoff capability, although Class III capability is also possible.

Port-guided valve plugs from THINKTANK® are often used for on-off or low-pressure throttling service. Top and bottom guided valve plugs furnish stable operation for severe service conditions.

1. Hexagon Bolts 2. Cover Cap 3. Winding Sealing Ring

4. Bottom Seat 5. Valve Body 6. Plug 7. Sealing Gasket 8.

Top Seat 9. Valve Bonnet 10. Stud 11. Hexagon Nuts 12.

Packing Spring 13. Packing Set 14. Packing Screw 15.

Packing Gland 16. Screw 17. Nuts 18. Stem 19. Locking

Nut 20. Indicator 21. Actuator

We are looking for valuable brand customers with long-term cooperation. Only with high-quality quality and service can bring our customers more market share and stable business.

Avoid your inquiry is delay response, please enter your WhatsApp/Wechat/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 185 1656 9221, or WeChat: +86 199 2125 0077. or call +86 189 5813 8289 directly.

Just leave your name, email, and simple message or requirements, We will contact you within 1 hour.

WhatsApp: +86 199 2125 0077

Skype ID: sowell85

Wechat ID: +86 199 2125 0077

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 199 2125 0077, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.