What is The Pneumatic Control Valve?

The control valve, is generally composed of actuators and valves. It is the final control element to change the process parameters such as medium flow, pressure, temperature, liquid level, and so on by receiving the control signal output from the control unit and using the actuator operation. The regulating valve can directly control the pressure and flow rate.

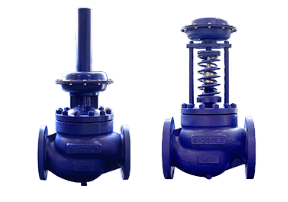

What is The Self-Operated Control Valve?

The self-operated control valve (self-operated control valve) changes the opening of the valve by using the pressure and temperature of the medium itself flowing through the valve as the energy drive plug and achieves the automatic operation of regulating pressure, flow rate, and temperature without the need of external power supply and secondary instrument. The self-operated control valve is often used to control the upstream or downstream pressure.

The Difference Between The Pneumatic Control Valve and the Self-Operated Control Valve:

The self-operated regulating valve can not only control the downstream pressure but also control the upstream pressure. The self-operated regulating valve is actually a pure proportional regulating system with residual error. The main function of the self-operated regulating valve is to meet the upstream or set pressure value, and there is no great requirement for the flow rate. But for the regulating valve, the direct control is the flow rate. The biggest difference between these two kinds of valves is that the control valve needs external energy (such as a power supply or gas source) as the driving force, and the relative position of the interceptor in the valve is changed by controlling the instrument signal, so as to change the flow rate. The self-operated regulating valve does not need foreign energy or external control instrument signal. The pressure adjustment can be realized only by the pressure or temperature signal of the medium itself.

So we can distinguish a pneumatic control valve from a self-operated control valve in three aspects.

a. Adjustment accuracy:

The adjustment accuracy of the self-operated regulating valve basically depends on the spring and diaphragm accuracy of the self-operated valve. The final adjustment accuracy will not be better than 5% and the general control accuracy is only 10%.

Pneumatic control valve, the final adjustment accuracy depends on the transmitter accuracy and regulator accuracy, and the regulator accuracy is very high, its influence is generally ignored. THINKTANK control valves can generally achieve 3/1000 to 5/1000 static accuracy.

Therefore, the adjustment accuracy of the self-operated valve is much lower than that of the pneumatic control valve. When the adjustment accuracy is high, it is not recommended to adopt the self-operated control valve.

b. Application conditions:

Control valve DCS remote control can quickly change the input signal, thus changing the opening of the valve, can also change the set value, and record the test value.

The setting value of the self-regulating valve can not be adjusted basically, and can only be operated on the spot. The degree of intelligence is much weaker. The self-operated regulating valve is more troublesome to adjust the setting value, so it is used in situations where there is no need to change the setting frequently, such as equipment lubricating oil supply and so on. The self-operated regulating valve should be pressed from the process medium, so it is not suitable if the medium has corrosion, particles, and so on.

c. Installation and Design:

The self-operated regulating valve has pressure control before the valve and pressure control after the valve. The design should be for the installation of pressure points to leave good spacing. During installation, the self-operated regulating valve actuator on the steam pipeline shall be installed downward, and the pressure point shall be connected to the condenser from the bottom of the pipe. The condenser shall be higher than the actuator and lower than the steam pipe to avoid steam overheating damage to the valve body. In addition, in other gases or liquids, the actuator is installed upward. Since the self-operated regulating valve is often used in gas pipes, the pressure point should be opened from the top of the pipe.

The regulating valve does not need to reserve the installation position, as long as according to the design requirements, the distance between the valves is designed.

Final Thought

In this post, we have learned the main difference between pneumatic control valves and self-operated control valves, if you want to learn more information about self-operated pressure regulators, you can read the below post, or the following is the post on control valves 101.