Introduction to Globe Valves

Globe valves are linear motion valves that regulate fluid flow in pipelines. They are named for their spherical body shape, which houses a movable disk or plug mechanism. This mechanism controls the flow of fluid by closing, opening, or partially obstructing the valve’s flow path.

They are widely-used flow control devices in various industrial applications, and designed to regulate the flow of fluids, such as liquids, gases, and steam, in a flow stream a piping system. With their unique construction features and reliable performance, globe valves have gained popularity in industries such as oil and gas, power generation, chemical processing, and water treatment.

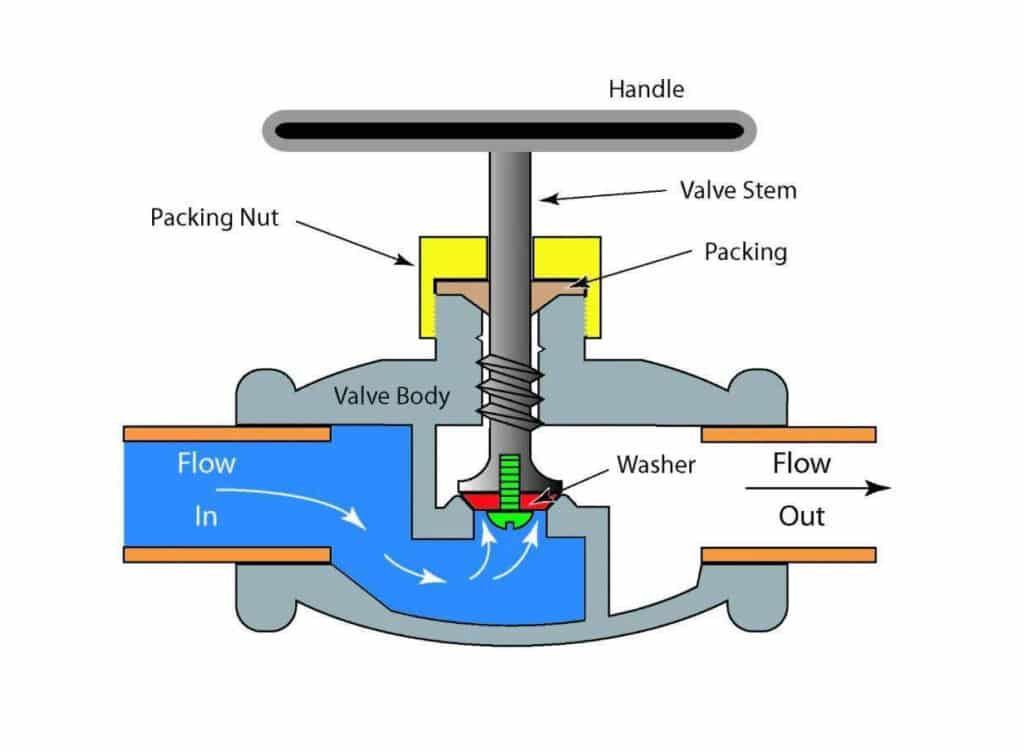

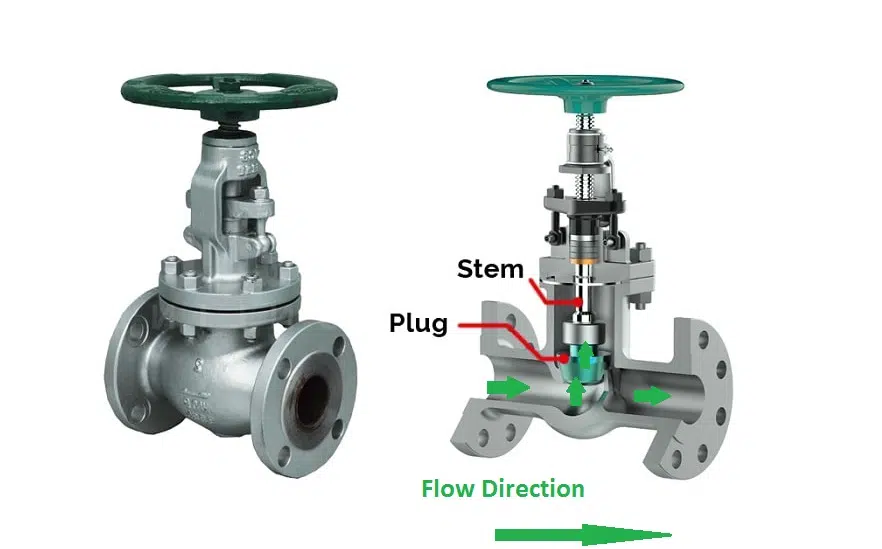

Structure and Functioning

Globe valves are named after their spherical body shape, which houses a movable disc or plug, a stationary seat, and a stem. The stem connects the disc to an external handwheel or actuator. When the handwheel is turned or the actuator is activated, it moves the stem and disc either closer to or farther from the seat, thus controlling the flow rate and pressures.

Types of Globe Valves

There are three main types of globe valves, each with distinct characteristics:

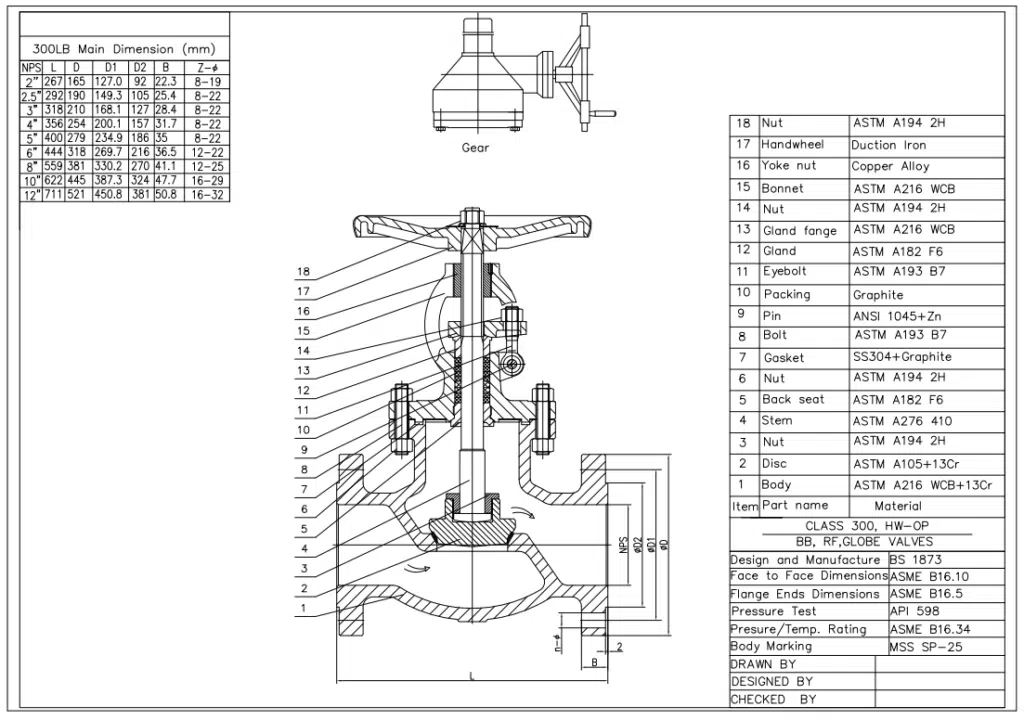

Straight Pattern Globe Valves(Z Type Globe Valves)

Straight pattern globe valves have a linear flow path, with the inlet and outlet ports aligned vertically. The main components include a spherical body, a movable disc or plug, a stationary seat, and a stem connecting the disc to an external handwheel or actuator. The fluid enters from the port at the bottom and exits from the top of the valve, with the disc moving up and down to regulate the flow.

Angle Pattern Globe Valves

In angle pattern globe valves, the inlet and outlet ports are oriented at a 90-degree angle to each other. This design allows the fluid to change direction within the valve, making them ideal for situations where a change in flow direction is required or when space is limited. The main components are similar to those of a straight pattern globe valve: a body, a disc, a seat, and a stem. However, the flow path is bent within the angle pattern globe valve body, creating a 90-degree angle between the inlet and outlet ports.

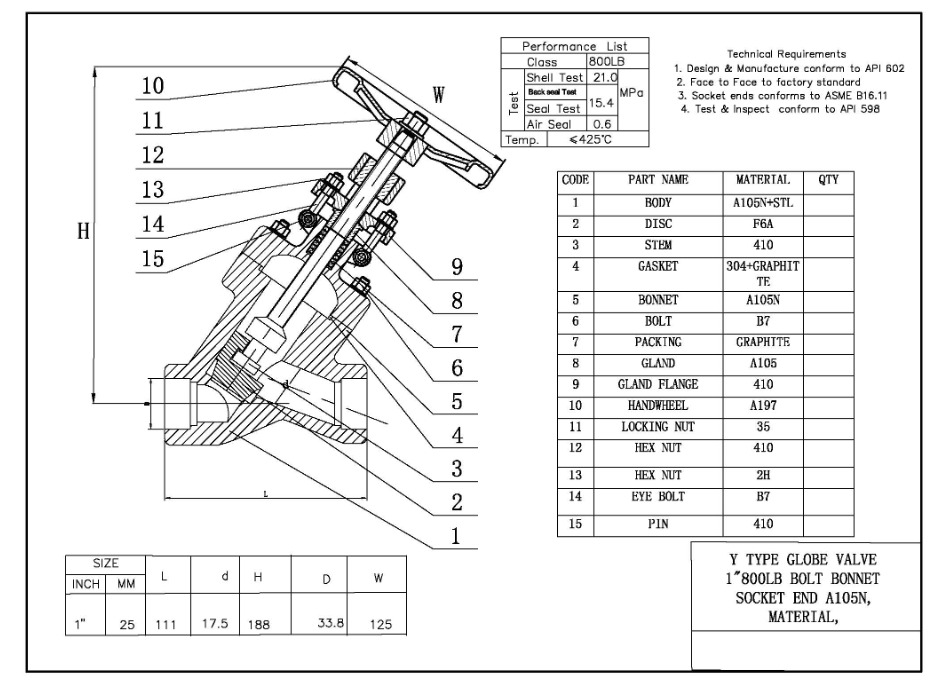

Y-Pattern Globe Valves

Y-pattern stainless steel globe valves feature a 45-degree angle between the inlet and outlet ports. This design reduces pressure drop and turbulence within the valve, making them suitable for high-pressure and high-temperature applications or when minimizing erosion is critical. The main components of a Y-pattern, steel globe valve include a Y-shaped body, a disc, a seat, and a stem. The flow path is inclined at a 45-degree angle, which helps reduce flow resistance and minimize wear on the valve components.

Globe Valve Components and Materials

Globe valves consist of several key components:

- Body: The valve’s main structure is typically made from cast iron, carbon steel, stainless steel, or alloy materials.

- Bonnet: The top part of the valve that houses the stem and packing.

- Stem: A threaded rod connected to the disk or plug that controls valve movement.

- Disk or Plug: The movable element that regulates flow by obstructing the flow path.

- Seat: The stationary component that the disk or plug seals against to prevent fluid flow.

- Handwheel or Actuator: The manual or automatic mechanism used to operate the valve.

Advantages and Disadvantages of Globe Valves

| Advantages | Disadvantages |

| Precise flow control | Higher pressure drop |

| Excellent sealing capabilities | Limited flow capacity |

| Ease of maintenance | Heavier and bulkier than other valves |

| Bi-directional flow | Not suitable for high-slurry systems |

| Suitable for a wide range of fluids | Higher cost compared to other valves |

| Good throttling ability | Slower to operate |

Advantages:

- Precise flow control: Globe valves allow for accurate and incremental adjustments to the fluid flow, making them ideal for throttling and flow regulation tasks.

- Excellent sealing capabilities: The disc and seat design provides a tight seal when closed, preventing fluid leakage.

- Easy maintenance: Globe valves are generally simple to disassemble, clean, and replace parts, making them a cost-effective choice for many applications.

- Bi-directional flow: Globe valves can be used for flow in either direction, making them versatile and suitable for a wide range of applications.

- Suitable for a wide range of fluids: Globe valves can handle various types of fluids, including liquids, gases, and steam.

- Good throttling ability: Globe valves are effective at controlling the flow rate by adjusting the position of the disc.

- Suitable for high-pressure and high-temperature applications

- Tight shutoff capabilities

Disadvantages

- Higher pressure drop: Globe valves create more resistance to fluid flow than other types of valves, resulting in a higher pressure drop across the valve.

- Limited flow capacity: Due to their design, globe valves have a smaller flow capacity compared to other valve types, such as gate valves or ball valves.

- Heavier and bulkier than other valves: Globe valves are generally larger and heavier than other valves, making them less suitable for applications where space and weight constraints are critical.

- Not suitable for high slurry systems: The internal design of globe valves makes them prone to clogging or damage when used with high slurry or highly viscous fluids.

- Higher cost compared to other valves: Globe valves can be more expensive than other types of valves, such as gate valves or ball valves, due to their more complex design and materials.

- Slower to operate: Globe valves require more turns of the handwheel or more actuation force to open or close compared to other valves, making them slower to operate.

- Potential for cavitation and noise

Applications and Industries

Globe valves are used across various industries, including:

- Oil and gas

- Chemical processing

- Power generation

- Water and wastewater treatment

- Pharmaceutical and biotechnology

Common applications include:

- Flow regulation and control

- Steam distribution

- Pump and compressor discharge

- Cooling water systems

Installation, Maintenance, and Troubleshooting

Proper installation, maintenance, and troubleshooting of globe valve control systems are essential for ensuring their optimal performance and longevity. By following best practices and addressing issues as they arise, you can maintain the reliability and efficiency of your globe valve system.

Installation

Globe valves should be installed with the disk facing upwards to ensure proper seating and minimize wear. This orientation also facilitates easier maintenance and inspection.

- Location: Choose an accessible location for the globe valve, ensuring enough clearance for operation and maintenance. For straight pattern globe valves, install them with the stem in a vertical position to prevent sediment accumulation in the valve.

- Flow direction: Install the valve in the correct flow direction, as indicated by the flow arrow on the valve body. Incorrect installation can result in poor valve performance and reduced lifespan.

- Support: Ensure proper support for the piping system to minimize stress on the valve body and prevent misalignment or leakage.

- Gaskets: Use appropriate gaskets or seals that are compatible with the fluid and operating conditions to ensure a leak-free connection between the valve and flanges.

- Actuator alignment: When using an actuator, make sure it is properly aligned with the valve stem to prevent undue stress on the valve components.

Maintenance

Regular maintenance is essential to extend the globe valve lifespan and ensure optimal performance. Maintenance tasks include:

- Inspection: Conduct regular visual inspections of the valve for signs of wear, corrosion, or leakage. Check the valve’s packing gland for any leaks and adjust or replace the packing material as needed.

- Lubrication: Regularly lubricate the valve stem, threads, and moving parts according to the manufacturer’s recommendations. Use a lubricant compatible with the valve’s material and operating conditions.

- Cleaning: Keep the valve and surrounding area clean and free of debris to prevent contamination and ensure smooth operation.

- Replacement parts: Use only manufacturer-recommended replacement parts for repairs to maintain the valve’s performance and safety standards.

- Scheduled maintenance: Follow a regular maintenance schedule based on the manufacturer’s recommendations and the valve’s operating conditions.

Troubleshooting

Proper troubleshooting is essential for identifying and resolving issues with globe valves. By addressing problems promptly and accurately, you can ensure the reliable and efficient operation of your valve system. Below are some common issues encountered with globe valves and their potential solutions:

Leakage at the Stem:

Issue: Fluid leakage is observed around the valve stem.

Solution: First, attempt to tighten the packing gland to compress the packing material and create a better seal. If the leakage persists, replace the packing material or consider repacking the entire valve.

Leakage at the Flange Connections:

Issue: Fluid leakage is detected at the flange connections.

Solution: Inspect the flange bolts for proper tightness and ensure they are evenly tightened following a crisscross pattern. If the leakage continues, replace the flanged gasket with a new one compatible with the fluid and operating conditions.

Difficulty in Operation:

Issue: The valve becomes difficult to operate or the handwheel is hard to turn.

Solution: Check for misalignment, bent stems, or damaged actuators. Lubricate the stem and moving parts according to the valve manufacturer’s recommendations. If the problem persists, disassemble the valve to inspect for internal damage or obstructions and repair or replace the affected components as needed.

Poor Flow Control:

Issue: The valve fails to provide accurate flow control or the flow rate does not correspond to the handwheel position.

Solution: Inspect the disc and seat for wear, damage, or contamination. Replace or recondition the disc and seat if necessary. Also, check the stem and actuator for proper operation and alignment.

Excessive Noise or Vibration:

Issue: The valve produces excessive noise or vibration during operation.

Solution: Excessive noise or vibration may indicate cavitation, water hammer, or turbulent flow. Address the root cause by adjusting the flow rate, installing a valve with a different design, or adding additional flow control valves, accessories, or devices like a pressure-reducing valve or a flow control valve.

Failure to Close Fully:

Issue: The valve does not close completely, leading to fluid leakage through the valve.

Solution: Inspect the disc and seat for damage, wear, or debris that may be preventing a tight seal. Clean, repair, or replace the disc and seat as necessary. Also, ensure that the valve stem is not bent or obstructed, preventing full closure.

By following a systematic approach to troubleshooting industrial valves and addressing issues as they arise, you can maintain the reliability and efficiency of your globe valve system. Regular inspection, timely repairs, and adherence to manufacturer guidelines will help prevent costly downtime and prolong the service life of your valves.

Sizing and Selection Considerations

Selecting the right size and type of globe valve for your application is crucial for optimal performance, efficiency, and longevity. Several factors must be considered when choosing a globe valve, including the fluid type, flow rate, pressure, temperature, and installation requirements. Here are some key aspects to consider when sizing and selecting a globe valve:

2. Flow Rate:

Determine the required flow rate for your application to ensure the globe valve can adequately handle the flow. Valve sizing is based on the flow coefficient (Cv), which is a measure of the valve’s capacity to pass fluid. The larger the Cv value, the greater the flow rate the valve can handle. Select a valve with an appropriate Cv value to meet your flow requirements while minimizing pressure drop.

2. Fluid Type:

Consider the type of fluid the valve will handle (liquid, gas, or steam) and its properties, and features such as viscosity and corrosiveness. Select materials and sealing components compatible with the fluid to ensure reliable operation and prevent damage to the valve.

3. Pressure and Temperature:

Evaluate the operating pressure and temperature of the system to select a valve that can withstand these conditions. Ensure the selected valve’s pressure class and temperature rating meet or exceed the system’s requirements.

4. Valve Type:

Choose the appropriate type of globe valve (straight pattern, angle pattern, or Y-pattern) based on your application’s specific needs. Consider factors such as space constraints, flow direction changes, and pressure drop when selecting the valve type.

5. Material Selection:

Select the appropriate materials for the valve body, disc, seat, stem, and gaskets based on factors such as fluid compatibility, corrosion resistance, and temperature requirements. Common materials include cast iron, carbon steel, stainless steel, and brass.

6. Actuation:

Determine the appropriate method of actuation for your application (manual, electric, pneumatic, or hydraulic). Consider factors such as the required speed of operation, available utilities, and fail-safe requirements.

7. End Connections:

Select the appropriate end connections (flanged, threaded, or welded) based on your piping system requirements and ease of installation and maintenance.

8. Standards and Certifications:

Ensure the chosen globe valve meets the necessary industry standards and certifications for your application, such as ASME, API, or ISO.

9. Maintenance and Accessibility:

Consider the ease of maintenance and accessibility when selecting a globe valve. Options for valves that are easy to disassemble, clean, and replace parts, make them cost-effective and reducing downtime.

By taking these factors into account, you can select a globe valve that meets your application’s specific requirements and ensures efficient, reliable and long-lasting performance. Consult with valve manufacturers or engineers for expert advice on sizing and selecting the most suitable stainless steel globe valve for your needs.

Globe Valve Standards and Certifications

Various standards and certifications govern the design, manufacturing, testing, and performance of globe valves to ensure their safety, reliability, and efficiency. Adherence to these standards is essential for maintaining quality and performance in the industry. Some of the most widely recognized standards and certifications for globe valves include:

1. ASME (American Society of Mechanical Engineers):

ASME develops codes and standards for pressure-containing components, including valves. Key ASME standards related to globe valves include:

- ASME B16.34: Valves – Flanged, Threaded, and Welding End

- ASME B16.10: Face-to-Face and End-to-End Dimensions of Valves

These standards cover aspects such as pressure-temperature ratings, materials, dimensions, and testing requirements for various valve types, including globe valves.

2. API (American Petroleum Institute):

API is a leading organization that develops standards for the oil and gas industry, including valves. The following API standards are relevant to globe valves:

- API 600: Steel Gate Valves – Flanged and Butt-welding Ends, Bolted Bonnets

- API 602: Compact Steel Gate Valves – Flanged, Threaded, Welding, and Extended Body Ends

Although these standards primarily focus on gate valves, they may also apply to globe valves in certain situations, particularly for high-pressure and high-temperature applications.

3. ISO (International Organization for Standardization):

ISO develops international standards for various industries, including valves. Some of the key ISO standards related to globe valves are:

- ISO 5208: Industrial Valves – Pressure Testing of Valves

- ISO 5752: Metal Valves for Use in Flanged Pipe Systems – Face-to-Face and Centre-to-Face Dimensions

These standards address aspects such as pressure testing and dimensional requirements for globe valves and other industrial valves.

4. MSS (Manufacturers Standardization Society):

MSS is an organization that develops standards for the valve and fittings industry. Some MSS standards that apply to globe valves include:

- MSS SP-42: Corrosion Resistant Gate, Globe, Angle, and Check Valves with Flanged and Butt Weld Ends

- MSS SP-61: Pressure Testing of Valves

These standards cover requirements for corrosion-resistant valves and pressure testing procedures for globe valves and other valve types.

5. NACE (National Association of Corrosion Engineers):

NACE develops standards related to the prevention and control of corrosion in various industries. The following NACE standard is relevant for globe valves used in corrosive environments:

- NACE MR0175/ISO 15156: Petroleum and Natural Gas Industries – Materials for Use in H2S-Containing Environments in Oil and Gas Production

This standard outlines material requirements and guidelines for valve control systems, including globe valves, used in sour service applications where hydrogen sulfide (H2S) is present.

Conclusion

This article provides an in-depth understanding of the various aspects of globe valves, including their design, types, functions, and key considerations for sizing, selection, and troubleshooting. This comprehensive guide aims to support professionals in making informed decisions when choosing the right valve for their application, ensuring optimal performance, reliability, and longevity.

As a reliable globe valve manufacturer in China, THINKTANK is committed to delivering high-quality products and unparalleled customer support. With our professional engineers ready to assist in sizing, selection, drawing, and other project requirements, we can provide customized solutions tailored to your specific needs. THINKTANK is known for offering affordable pricing without compromising on quality, making our cast steel globe valves a cost-effective choice for a wide range of applications.

Having exported to over 42 countries and provided OEM services for 25 international valve brands, THINKTANK has established a strong reputation for excellence in the global market. Our extensive experience and commitment to customer satisfaction make THINKTANK a trusted partner for your globe valve requirements.

By utilizing the information provided in this ultimate guide and partnering with a reputable manufacturer like THINKTANK, you can ensure the successful integration of globe valves in your applications, contributing to the efficiency, safety features, and reliability of your power systems.

Authoritative Sources

1.ASME B16.34 – Valves – Flanged, Threaded, and Welding End: https://www.asme.org/codes-standards/find-codes-standards/b16-34-valves-flanged-threaded-welding-end

2. API 600 – Steel Gate Valves – Flanged and Butt-welding Ends, Bolted Bonnets: https://www.api.org/~/media/files/publications/whats%20new/600_e13%20pa.pdf

3.ISO 5208 – Industrial Valves – Pressure Testing of Valves: https://www.iso.org/standard/71597.html

4.ISO 5752 – Metal Valves for Use in Flanged Pipe Systems – Face-to-Face and Centre-to-Face Dimensions: https://www.iso.org/standard/31775.html

5.MSS SP-42 – Corrosion Resistant Gate, Globe, Angle, and Check Valves with Flanged and Butt Weld Ends: https://webstore.ansi.org/standards/mss/msssp422004

6.NACE MR0175/ISO 15156 – Petroleum and Natural Gas Industries – Materials for Use in H2S-Containing Environments in Oil and Gas Production: https://www.iso.org/standard/68564.html