Description

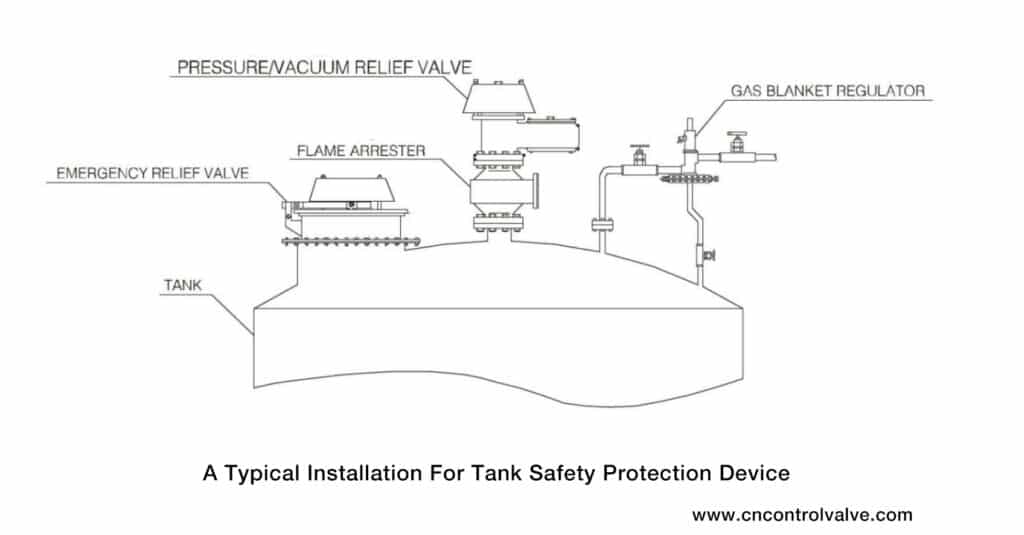

Introducing our state-of-the-art Breather Valves with Flame Arrestors

a crucial component for maintaining the safety and efficiency of your industrial storage tank facilities. Designed with precision and durability in mind, these advanced valves offer a comprehensive solution for pressure regulation, vacuum prevention, and fire protection in a variety of applications.

Key Features of Breather Valves with Flame Arrestors

Pressure Regulation

Our Breather Valves are meticulously engineered to maintain optimal pressure levels within storage tanks, preventing over-pressurization and ensuring the structural integrity of your tanks is preserved.

Vacuum Prevention

The Breather Valves also prevent vacuum formation inside the tanks, safeguarding your storage facilities from potential damage and reducing the risk of tank collapse or implosion.

Integrated Flame Arrestors

The built-in Flame Arrestors provide an added layer of safety by preventing the propagation of flames into the storage tanks, effectively guarding against fire hazards and explosions. This feature is essential for industries dealing with flammable liquids, gases, or combustible materials.

Durable Construction

Manufactured using high-quality materials, our Breather Valves with Flame Arrestors are designed to withstand harsh industrial environments and provide long-lasting, reliable performance.

Versatility

Suitable for various industries and applications, our Breather Valves with Flame Arrestors are compatible with a wide range of storage tank types and capacities.

Easy Installation & Maintenance

The user-friendly design of our Breather Valves ensures effortless installation and minimal maintenance, allowing for seamless integration into your existing storage tank systems.

Design Features For Pressure/Vacuum Relief Valve

- Size: 2″ ~12″ (DN50-DN300)

- API7100 series breathing valve discharge port is the same as the inlet, which is convenient for the end-users to choose.

- API8100 series breathing valve discharge port is larger than the inlet to increase the exhaust volume.

- Breathing mode: discharge, inhalation atmosphere.

- A Rainproof cap is easy to disassemble and install, so as to facilitate inspection and maintenance of equipment, protective net can stop external debris from entering the breathing port.

- According to the user’s needs, can add an explosion-proof flame arrester, inhalation bend, jacket, blowing hole, lining, dehumidification, and other functions (need to confirm before ordering);

- Flange standard according to ANSI B16.5, according to user requirements can choose HG series, GB series, SH series, JIS series, EN series.

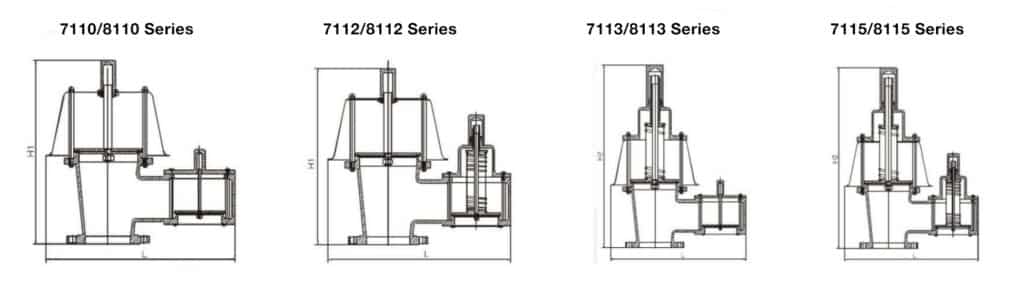

Setting Pressure of 7100/8100 Pressure/Vacuum Relief Valve

| Model | 7110.8110 | 7112, 8112 | 7113.8113 | 7115.8115 |

| Positive Pressure Setting(KPa) | 0.2-6.9 | 0.2-6.9 | 6.9-103.4 | 6.9-103.4 |

| Negative Pressure Setting(KPa) | -0.2–4.3 | -4.3~-82 | -0.2—4.3 | -4.3—82 |

Dimension Sheet For 7110, 7112, 7113, 7115 Series

| Size | 2″[50] | 3″(80] | 4″1100] | 6″[150] | 8″[200] | 10″[250| | 12″ [300] |

| L | 301 | 368 | 416 | 525 | 675 | 824 | 967 |

| Hl | 290 | 352 | 393 | 490 | 622 | 746 | 876 |

| H2 | 394 | 422 | 505 | 636 | 870 | 1030 | 1230 |

Dimension Sheet For 8110, 8112, 8113, 8115 Series

| Size | 2″[50] | 3″[80] | 4″[100] | 6″[150] | 8″ [200] | 10″[250] | 12″[300] |

| L | 322 | 405 | 473 | 620 | 770 | 912 | 1075 |

| H1 | 335 | 378 | 466 | 613 | 701 | 830 | 956 |

| H2 | 403 | 490 | 615 | 860 | 985 | 1182 | 1225 |

Pressure Vacuum Relief Valve Applications

Pressure Vacuum Relief Valves (PVRVs) are commonly used in various industries to protect storage tanks and process vessels from excessive pressure and vacuum conditions. They are essential safety devices that maintain the internal pressure of a tank or vessel within a safe operating range, preventing potential damage, leaks, and environmental hazards. Here are some typical applications and detailed conditions for PVRVs.

Petrochemical Industry

PVRVs are extensively used in the petrochemical industry to protect storage tanks containing volatile organic compounds (VOCs), such as benzene, toluene, and xylene. The valves release excess pressure or admit air to maintain the internal pressure within a predetermined range, preventing tank rupture or implosion.

Project Example: A petrochemical plant required PVRVs to manage pressure and vacuum fluctuations in several storage tanks containing different VOCs. THINKTANK provided customized PVRVs to meet the specific pressure and vacuum settings for each tank, ensuring safe operation while minimizing VOC vapor emissions.

Oil and Gas Industry

In the oil and gas industry, PVRVs are the equipment used to protect storage tanks containing crude oil, gasoline, diesel, and other petroleum products. These valves help maintain safe pressure levels during filling, emptying, or temperature changes.

Project Example: An oil refinery needed PVRVs for its crude oil storage tanks. The refinery experienced significant pressure fluctuations due to temperature changes and tank filling and emptying operations. THINKTANK supplied PVRVs with appropriate pressure and vacuum settings to maintain the tanks’ integrity and minimize the risk of environmental hazards.

Pharmaceutical Industry

PVRVs are used in the pharmaceutical industry to protect process vessels and reactors during manufacturing operations. They maintain the required pressure levels in the vessels, ensuring the stability and safety of the chemical reactions.

Project Example: A pharmaceutical company required PVRVs for its chemical reactors involved in producing active pharmaceutical ingredients (APIs). THINKTANK provided PVRVs with the necessary pressure and vacuum settings and materials compatible with the chemicals used in the reactors, ensuring safe and efficient production processes.

Food and Beverage Industry

PVRVs are employed in the food and beverage industry to protect storage tanks containing liquid products, such as juices, wines, and edible oils. The valves prevent tank damage and product spoilage by maintaining stable internal pressure.

Project Example: A winery needed PVRVs to protect its wine storage tanks during fermentation and aging processes. THINKTANK supplied PVRVs with the appropriate pressure and vacuum settings, ensuring the tanks’ safety while preserving the quality of the wine.

Chemical Industry

In the chemical industry, PVRVs are used to protect storage tanks containing hazardous chemicals, such as acids, bases, and solvents. These valves help maintain the proper pressure levels in the tanks, preventing the risk of tank rupture, leaks, or chemical spills.

Project Example: A chemical plant required PVRVs for its sulfuric acid storage tanks. Due to the corrosive nature of sulfuric acid, THINKTANK provided PVRVs made of corrosion-resistant materials, such as Hastelloy, with proper pressure and vacuum settings to ensure the safety and integrity of the storage tanks.

Invest in the safety and efficiency of your industrial storage facilities with our cutting-edge Breather Valves with Flame Arrestors. Combining superior pressure management and flame protection, these innovative valves offer an unparalleled level of protection for your storage tanks, personnel, and assets.

Top 8 Industrial Valve Manufacturers Around The World In 2023 Year