Description

What is API Check Valve

An API check valve is a type of check valve that complies with the standards set by the American Petroleum Institute (API), a trade association responsible for establishing guidelines and standards for the oil and gas industry. Check valves are used to allow fluid to flow in one direction while preventing backflow, and safeguarding pumps, compressors, and other equipment from potential damage.

API check valves are designed specifically for applications in the oil and gas sector and are subjected to rigorous testing and quality assurance processes to ensure they can withstand the harsh environments and demanding operating conditions typically found in this industry.

There are several types of check valves that can fall under the API classification, such as swing check valves, lift check valves, piston check valves, and ball check valves. Each type has a unique mechanism for controlling fluid flow and preventing backflow.

The API standards for check valves cover various aspects, including design, materials, manufacturing, testing, and documentation. These standards help ensure the valves’ compatibility, interchangeability, and reliable performance in their intended applications. API check valves are often specified by their API standards, such as API 6D or API 594, which dictate the specific requirements for different types of check valves.

Technical specifications

| Type | Design and manufacturing | Face-to-face dimension | Flange size | Pressure- temperature | Test and inspection |

| Swing check valve | ANSI B16.34 | ANSI B16.10 | ANSIB16.15 | ANSI B16.34 | API598 |

| Lift check valve | BS 1 868 |

| Pressure rating PN(MPa) | Strength test | Water seal test | Air seal test | |||

| MPa | Lbf/in4 | MPa | Lbf/ins | MPa | Lbf/in4 | |

| 150 | 3 | 430 | 2.2 | 315 | 0.4~0.7 | 60-100 |

| 300 | 7.7 | 1110 | 5.7 | 815 | ||

| 600 | 15.3 | 2220 | 11.3 | 1630 | ||

| 900 | 23 | 3330 | 17 | 2445 | ||

| 1500 | 38.4 | 5560 | 28.2 | 4080 | ||

| 2500 | 64 | 9255 | 47 | 6790 | ||

Parts Material of the API Check Valve

| Parts name | Material science | Working temperature |

| Valve nut | Carbon steel/stainless steel | -196℃~565℃ |

| Gasket | Carbon steel/stainless steel | |

| Rocker pin | Carbon steel/stainless steel | |

| Seat | CS+SS/SS/SS+STL | |

| Discs | CS+SS/SS/SS+STL |

| Parts name | WCB | LCB | WC6 | WC9 | Applicable medium |

| Inner bolt | A193GrB7/A194Gr2H | A320GrL7/A194Gr4 | A193 GrB16/A194Gr4/7 | A193GrB16/A194Gr4/7 | Water, oil, gas Nitric acid, acetic acid |

| Middle flange bolt nut | A193 GrB7/A194Gr2H | A320 GrL7/A194Gr4 | A193 GrB16/A194Gr4/7 | A193GrB16/A194Gr4/7 | |

| Gasket | Spiral wound/soft iron | Spiral wound/soft iron | Spiral wound/SS304 | Spiral wound/SS304 | |

| Bracket | A216GrWCB | A352 GrLCB | A217GrWC6 | A217GrWC9 | |

| Rocker arm | A216GrWCB | A352 GrLCB | A217GrWC6 | A217GrWC9 | |

| Valve cover | A216GrWCB | A352 GrLCB | A217GrWC6 | A217GrWC9 | |

| Body | A216GrWCB | A352 GrLCB | A217GrWC6 | A217GrWC9 |

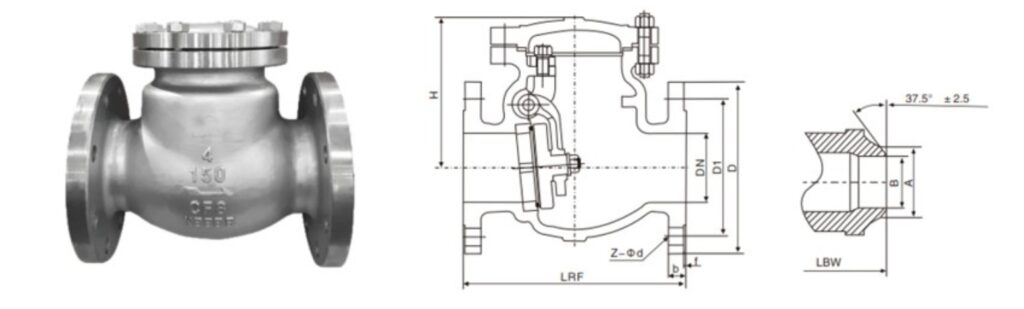

| Size Inch | DN | LRF | LBW | D | D1 | b | Z-φd | A | B | H |

| 150Lb | ||||||||||

| 2 | 50 | 203 | 203 | 150 | 120.5 | 14 | 4-19 | 60 | 52 | 160 |

| 2l/2 | 65 | 216 | 216 | 180 | 139.5 | 16 | 4-19 | 75 | 63 | 180 |

| 3 | 80 | 241 | 241 | 190 | 152.5 | 17.5 | 4-19 | 91 | 78 | 190 |

| 4 | 100 | 292 | 292 | 230 | 190.5 | 22 | 8-19 | 117 | 102 | 205 |

| 5 | 125 | 330 | 330 | 255 | 216 | 22 | 8-22 | 144 | 128 | 230 |

| 6 | 150 | 356 | 356 | 280 | 241.5 | 24 | 8-22 | 172 | 154 | 258 |

| 8 | 200 | 495 | 495 | 345 | 298.5 | 27 | 8-22 | 223 | 203 | 295 |

| 10 | 250 | 622 | 622 | 405 | 362 | 28.6 | 12-25 | 278 | 255 | 355 |

| 12 | 300 | 699 | 699 | 485 | 432 | 30 | 12-25 | 329 | 305 | 395 |

| 14 | 350 | 787 | 787 | 535 | 476 | 33.4 | 12-29 | 362 | 337 | 445 |

| 16 | 400 | 864 | 864 | 595 | 540 | 35 | 16-29 | 413 | 387 | 490 |

| 18 | 450 | 978 | 978 | 635 | 578 | 38 | 16-32 | 464 | 438 | 520 |

| 20 | 500 | 978 | 978 | 700 | 635 | 41 | 20-32 | 516 | 489 | 545 |

| 24 | 600 | 1295 | 1295 | 815 | 749.5 | 46 | 20-35 | 619 | 591 | 880 |

| 300Lb | ||||||||||

| 2 | 50 | 267 | 267 | 165 | 127 | 21 | 8-19 | 60 | 52 | 180 |

| 2l/2 | 65 | 292 | 292 | 190 | 149.4 | 24 | 8-22 | 75 | 63 | 190 |

| 3 | 80 | 318 | 318 | 210 | 168.1 | 27 | 8-22 | 91 | 78 | 215 |

| 4 | 100 | 356 | 356 | 255 | 200.2 | 30 | 8-22 | 117 | 102 | 242 |

| 5 | 125 | 400 | 400 | 280 | 235 | 33 | 8-22 | 144 | 128 | 268 |

| 6 | 150 | 444 | 444 | 320 | 269.7 | 35 | 12-22 | 172 | 154 | 305 |

| 8 | 200 | 533 | 533 | 380 | 330.2 | 40 | 12-25 | 223 | 203 | 368 |

| 10 | 250 | 622 | 622 | 445 | 387.4 | 46 | 16-29 | 278 | 255 | 395 |

| 12 | 300 | 711 | 711 | 520 | 450.9 | 49 | 16-32 | 329 | 305 | 445 |

| 14 | 350 | 38 | 838 | 585 | 514.5 | 52 | 20-32 | 362 | 337 | 470 |

| 16 | 400 | 846 | 846 | 650 | 571.5 | 56 | 20-35 | 413 | 387 | 530 |

| 18 | 450 | 978 | 978 | 710 | 628.5 | 59 | 24-35 | 464 | 438 | 585 |

| 20 | 500 | 1016 | 1016 | 775 | 686 | 62 | 24-35 | 516 | 489 | 610 |

| 24 | 600 | 1346 | 1346 | 915 | 813 | 68 | 24-41 | 619 | 591 | 750 |

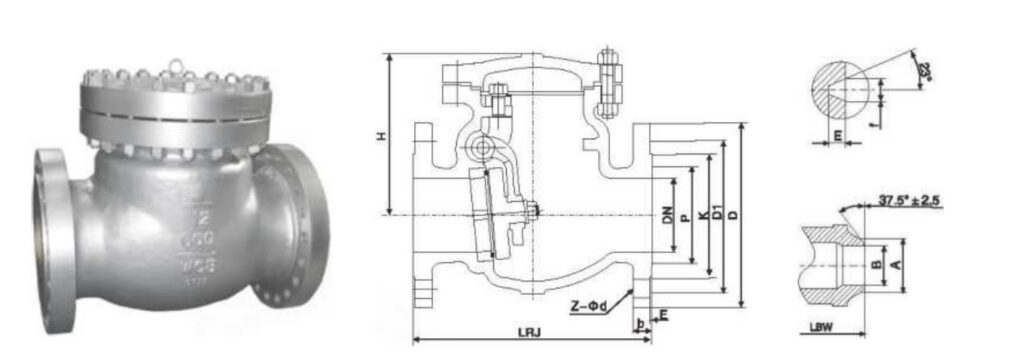

| Size Inch | DN | LBW | LRJ | D | D1 | b | Z-φd | K | P | E | F | A | B | H |

| 600Lb | ||||||||||||||

| 2 | 50 | 292 | 295 | 165 | 127 | 26 | 8-1 9 | 108 | 82.55 | 7.92 | 11.91 | 60 | 49 | 205 |

| 21/2 | 65 | 330 | 333 | 190 | 149.5 | 29 | 8-22 | 127 | 101.6 | 7.92 | 11.91 | 75 | 59 | 230 |

| 3 | 80 | 356 | 359 | 210 | 168 | 32 | 8-22 | 146 | 123.83 | 7.92 | 11.91 | 91 | 74 | 235 |

| 4 | 100 | 432 | 435 | 275 | 216 | 39 | 8-25 | 175 | 149.23 | 7.92 | 11.91 | 117 | 97 | 286 |

| 5 | 125 | 508 | 511 | 330 | 266.5 | 45 | 8-29 | 210 | 180.98 | 7.92 | 11.91 | 144 | 122 | 295 |

| 6 | 150 | 559 | 562 | 355 | 292 | 48 | 12-29 | 241 | 211.12 | 7.92 | 11.91 | 172 | 146 | 330 |

| 8 | 200 | 660 | 663 | 420 | 349 | 56 | 12-32 | 302 | 269.88 | 7.92 | 11.91 | 223 | 194 | 381 |

| 10 | 250 | 787 | 791 | 510 | 432 | 64 | 16-35 | 356 | 323.85 | 7.92 | 11.91 | 278 | 243 | 458 |

| 12 | 300 | 838 | 841 | 560 | 489 | 67 | 20-35 | 413 | 381 | 7.92 | 11.91 | 329 | 298 | 581 |

| 14 | 350 | 889 | 892 | 605 | 527 | 70 | 20-38 | 457 | 419.1 | 7.92 | 11.91 | 362 | 330 | 635 |

| 16 | 400 | 991 | 994 | 685 | 603 | 76 | 20-41 | 508 | 469.9 | 7.92 | 11.91 | 413 | 373 | 585 |

| 900Lb | ||||||||||||||

| 2 | 50 | 368 | 371 | 215 | 165.1 | 38 | 8-25 | 124 | 95.25 | 7.92 | 11.91 | 60 | 49 | 215 |

| 21/2 | 65 | 419 | 422 | 245 | 190.5 | 41 | 8-25 | 137 | 107.95 | 7.92 | 11.91 | 75 | 59 | 255 |

| 3 | 80 | 381 | 384 | 240 | 190.5 | 38 | 8-29 | 156 | 123.83 | 7.92 | 11.91 | 91 | 74 | 295 |

| 4 | 100 | 457 | 460 | 290 | 235 | 45 | 8-32 | 181 | 149.23 | 7.92 | 11.91 | 117 | 97 | 318 |

| 5 | 125 | 559 | 562 | 350 | 279.4 | 51 | 8-35 | 216 | 180.98 | 7.92 | 11.91 | 144 | 122 | 345 |

| 6 | 150 | 610 | 613 | 380 | 317.5 | 56 | 12-32 | 241 | 211.12 | 7.92 | 11.91 | 172 | 146 | 368 |

| 8 | 200 | 737 | 740 | 470 | 393.7 | 64 | 12-38 | 308 | 269.88 | 7.92 | 11.91 | 223 | 194 | 435 |

| 10 | 250 | 838 | 841 | 545 | 469.9 | 70 | 16-38 | 362 | 323.85 | 7.92 | 11.91 | 278 | 243 | 545 |

| 12 | 300 | 965 | 968 | 610 | 533.5 | 79 | 20-39 | 419 | 381 | 7.92 | 11.91 | 329 | 298 | 660 |

| 1500Lb | ||||||||||||||

| 2 | 50 | 368 | 371 | 215 | 165.1 | 38 | 8-25 | 124 | 95.25 | 7.92 | 11.91 | 60 | 42 | 215 |

| 21/2 | 65 | 419 | 422 | 245 | 190.5 | 41 | 8-29 | 137 | 107.95 | 7.92 | 11.91 | 75 | 54 | 265 |

| 3 | 80 | 470 | 473 | 265 | 203.2 | 48 | 8-32 | 168 | 136.53 | 7.92 | 11.91 | 91 | 67 | 290 |

| 4 | 100 | 546 | 549 | 310 | 241.3 | 54 | 8-35 | 194 | 161.93 | 7.92 | 11.91 | 117 | 87 | 325 |

| 5 | 125 | 673 | 676 | 375 | 292.1 | 73 | 8-42 | 229 | 193.68 | 7.92 | 11.91 | 144 | 110 | 402 |

| 6 | 150 | 705 | 711 | 395 | 317.5 | 83 | 12-38 | 248 | 211.14 | 9.53 | 13.49 | 172 | 132 | 435 |

| 8 | 200 | 832 | 841 | 485 | 393.7 | 92 | 12-45 | 318 | 269.88 | 11.13 | 16.66 | 223 | 178 | 520 |