Description

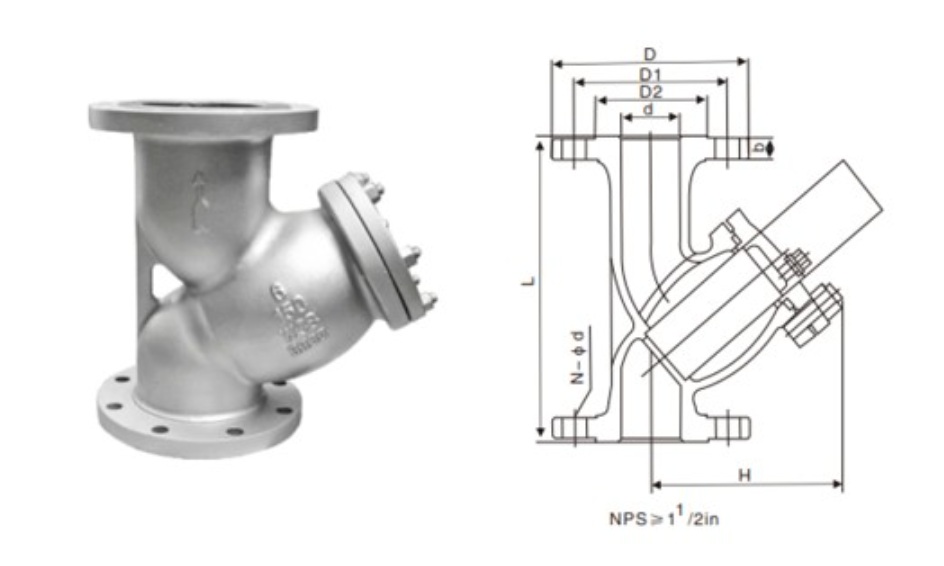

What is API Y Type Filter Valve

API Y-type filter valve, also known as a Y-strainer or Y-type strainer, is a filtering device designed to remove solid particles from liquids or gases within a pipeline system.

The Y-type filter valve features a Y-shaped body, which allows fluid to flow through it while trapping debris in a built-in screen or mesh filter element. The design of the Y-strainer enables easy access and removal of the filter element for cleaning or replacement. The Y-shape also helps minimize pressure drops, as it provides a relatively large filtering area while maintaining a compact size.

Application of API Y Type Filter Valve

- Oil and gas production: Filtering contaminants from crude oil or natural gas to protect pumps, valves, compressors, turbines, and other downstream equipment from damage.

- Refining and petrochemical processing: Removing solid impurities from feedstocks and intermediate products to maintain product quality, prevent fouling, and protect processing equipment.

- Pipeline transportation: Protecting pipeline components, such as pumps and meters, from damage caused by debris and solid particles in the transported fluids.

- Offshore drilling and production: Filtering drilling mud, process fluids, and seawater to protect equipment and maintain system integrity.

Technical Specifications

- Design standard: ASME B16.34

- Face to Face standard: ASME B16.10

- Connection standard: ANSI B16.5

- Test and inspection standards: API598

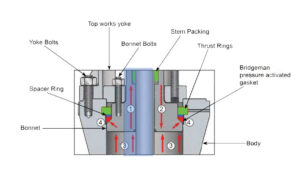

Parts and Material of DIN Y Type Filter Valve

| No. | Name | Material |

| 1 | Valve body | WCB/LCB/WC6/CF8M |

| 2 | Filter | SS304/SS3116 |

| 3 | Bonnet | WCBfl-CB/WC6/CF8M |

| 4 | Bolt | B7/B8/45/35 |

| 5 | Nut | 2H/8/45/35 |

| 6 | Gasket | Flexible graphite+304 |

| 7 | Screw plug | 45/304/316 |

| Size Inch | mm | d | D | D1 | D2 | b | n-φd | L | H |

| 150Lb | |||||||||

| 1/2” | 15 | 13 | 89 | 60.3 | 35 | 11.5 | 4-16 | 108 | – |

| 3/4″ | 20 | 19 | 98 | 69.9 | 43 | 12 | 4-16 | 117 | – |

| 1″ | 25 | 25 | 108 | 79.4 | 51 | 12 | 4-16 | 127 | – |

| 1l/4″ | 32 | 32 | 117 | 88.9 | 64 | 13 | 4-16 | 140 | – |

| 1l/2″ | 40 | 38 | 127 | 98.4 | 73 | 15 | 4-16 | 165 | – |

| 2″ | 50 | 51 | 152 | 120-7 | 92 | 16 | 4-19 | 203 | 205 |

| 21/2″ | 65 | 64 | 178 | 139.7 | 105 | 18 | 4-19 | 216 | 230 |

| 3″ | 80 | 76 | 190 | 152.4 | 127 | 19 | 4-19 | 241 | 255 |

| 4″ | 100 | 102 | 229 | 190.5 | 157 | 24 | 8-19 | 292 | 300 |

| 5″ | 125 | 127 | 254 | 215.9 | 186 | 24 | 8-22 | 356 | 350 |

| 6″ | 150 | 152 | 279 | 241.3 | 216 | 26 | 8-22 | 406 | 390 |

| 8″ | 200 | 203 | 343 | 298.5 | 270 | 29 | 8-22 | 495 | 450 |

| 10″ | 250 | 254 | 406 | 362 | 324 | 31 | 12-26 | 622 | 580 |

| 12n | 300 | 305 | 483 | 431.8 | 381 | 32 | 12-26 | 698 | 640 |

| 14″ | 350 | 337 | 533 | 476.3 | 413 | 35 | 12-29 | 787 | 720 |

| 16″ | 400 | 387 | 597 | 539.8 | 470 | 37 | 12-29 | 914 | 900 |

| 18″ | 450 | 438 | 635 | 577.9 | 533 | 40 | 16-32 | 978 | 1100 |

| 20″ | 500 | 489 | 699 | 635 | 584 | 43 | 20-32 | 978 | 1225 |

| 24″ | 600 | 591 | 813 | 749.3 | 692 | 48 | 20-35 | 1295 | 1335 |

| 300Lb | |||||||||

| 2″ | 50 | 51 | 165 | 120.7 | 92 | 23 | 8-19 | 267 | 235 |

| 21/2″ | 65 | 64 | 190 | 149.2 | 105 | 26 | 8-22 | 292 | 250 |

| 3″ | 80 | 76 | 210 | 168.3 | 127 | 29 | 8-22 | 318 | 289 |

| 4″ | 100 | 102 | 254 | 200 | 157 | 32 | 8-22 | 356 | 320 |

| 5″ | 125 | 127 | 279 | 235 | 186 | 35 | 8-22 | 400 | 365 |

| 6″ | 150 | 152 | 318 | 269.9 | 216 | 37 | 12-22 | 444 | 420 |

| 8″ | 200 | 203 | 381 | 330.2 | 270 | 42 | 12-26 | 559 | 480 |

| 10″ | 250 | 254 | 445 | 387.4 | 324 | 48 | 16-29 | 622 | 600 |

| 12″ | 300 | 305 | 521 | 450.8 | 381 | 51 | 16-32 | 711 | 700 |

| 14″ | 350 | 337 | 584 | 514.4 | 413 | 54 | 20-32 | 838 | 770 |

| 16″ | 400 | 387 | 648 | 571.5 | 470 | 58 | 20-35 | 864 | 915 |

| 18” | 450 | 432 | 711 | 628.6 | 533 | 61 | 24-35 | 978 | 1150 |

| 20″ | 500 | 483 | 775 | 685.8 | 584 | 64 | 24-35 | 1016 | 1250 |

| 24” | 600 | 584 | 914 | 812.8 | 692 | 70 | 24-41 | 1346 | 1330 |