What is the HART Communication Protocol

HART is an acronym that stands for Highway Addressable Remote Transducer. HART communication protocol enables two-way digital communication between intelligent devices and a host system, allowing users to monitor, control and configure process parameters such as temperature, pressure, and flow in real-time. HART provides a standard approach to transmitting data, making it possible to connect HART-enabled devices from multiple vendors.

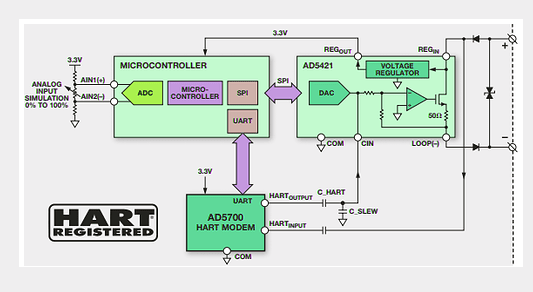

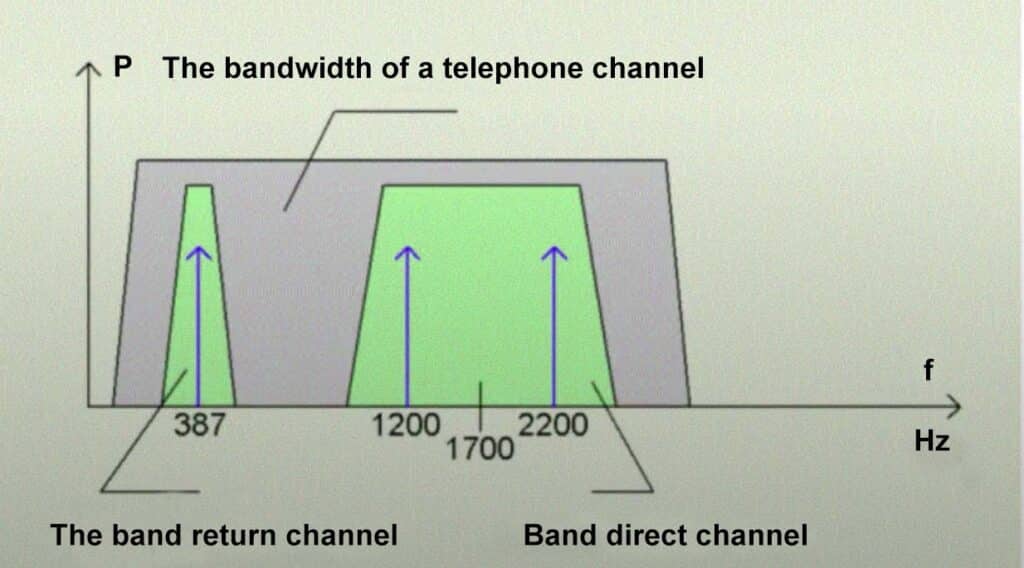

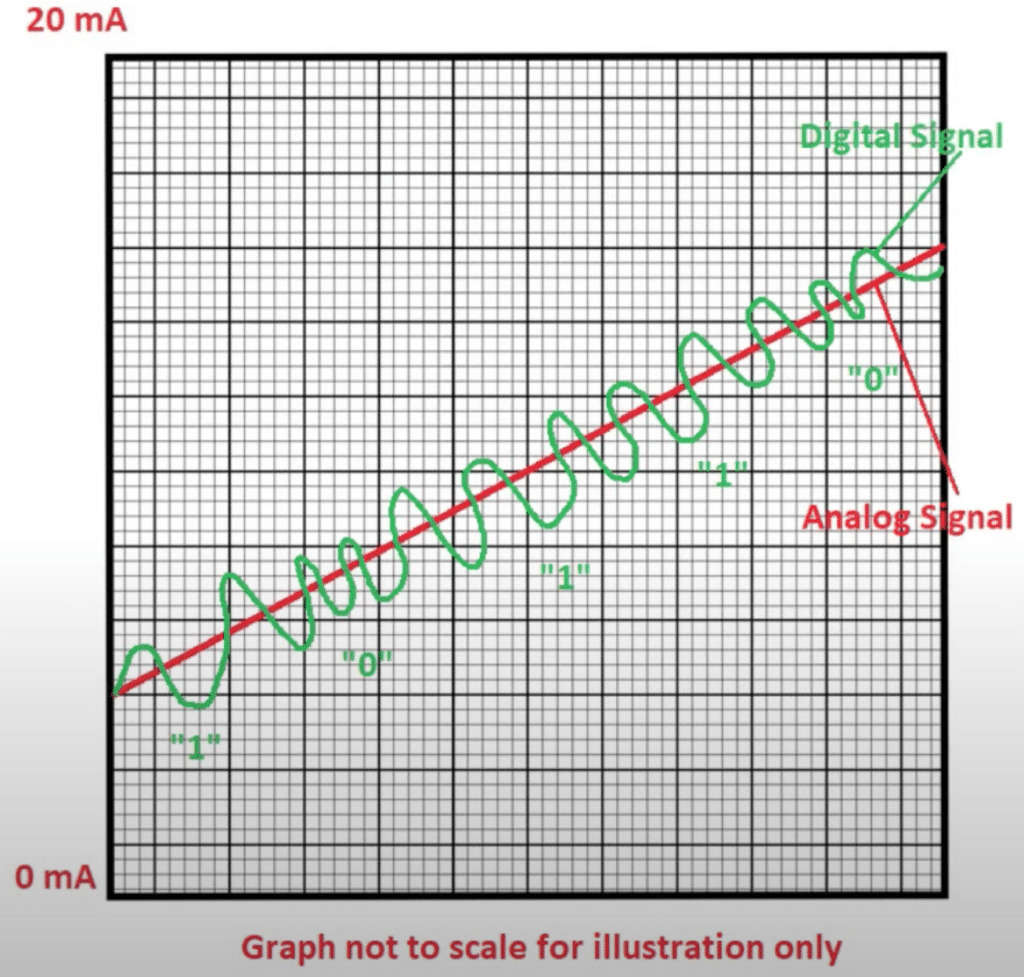

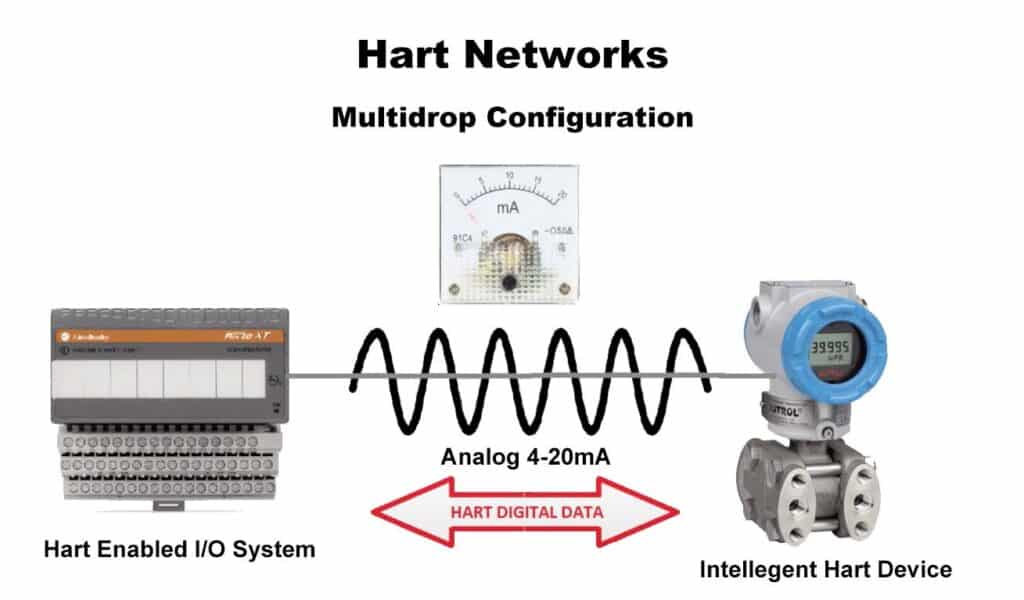

The HART Protocol uses Bell 202 Frequency Shift Keying (FSK) to overlay low-level digital communication signals onto the 4-20mA signal, allowing for the transmission of more data than the analog signal alone.

What is FSK Frequency shift key

The technology for the HART Communication Protocol is based on the Bell 202 modem. The Bell 202 modem was a standard introduced by the Bell System in 1976. It defines an audio frequency shift key (AFSK) to encode and send data at 1200 bits per second, half-duplex, at a rate of 1200 bits per second, just transmitting in one direction at a time.

Highway Addressable Remote Transducer

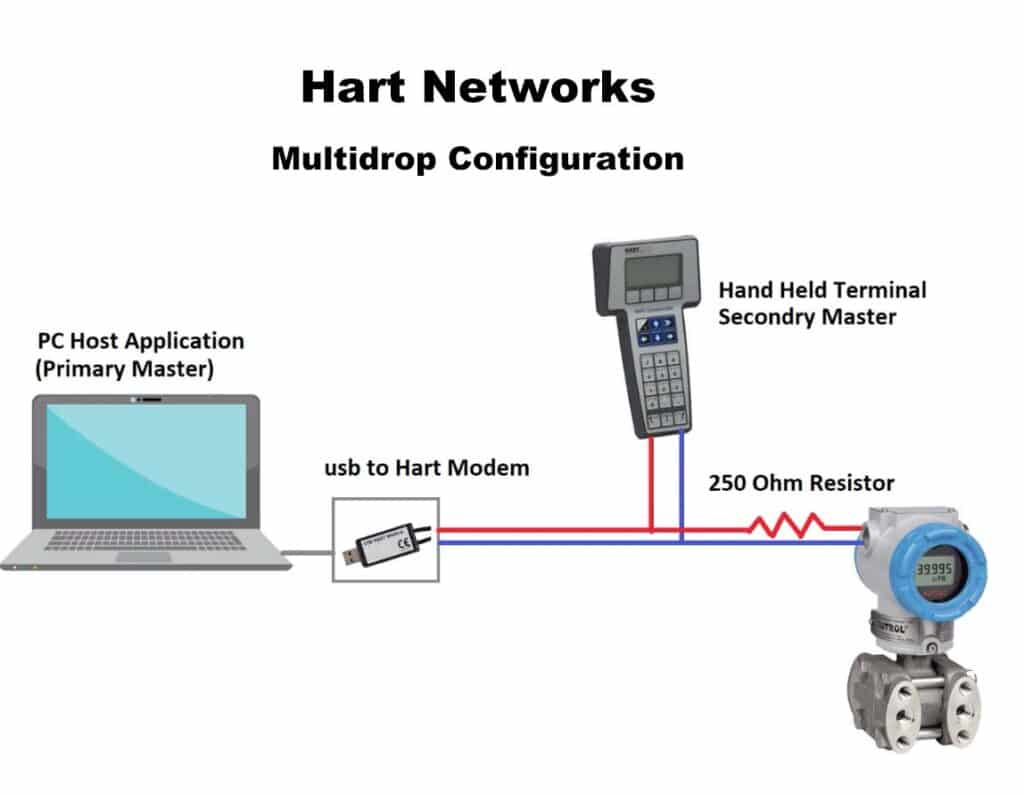

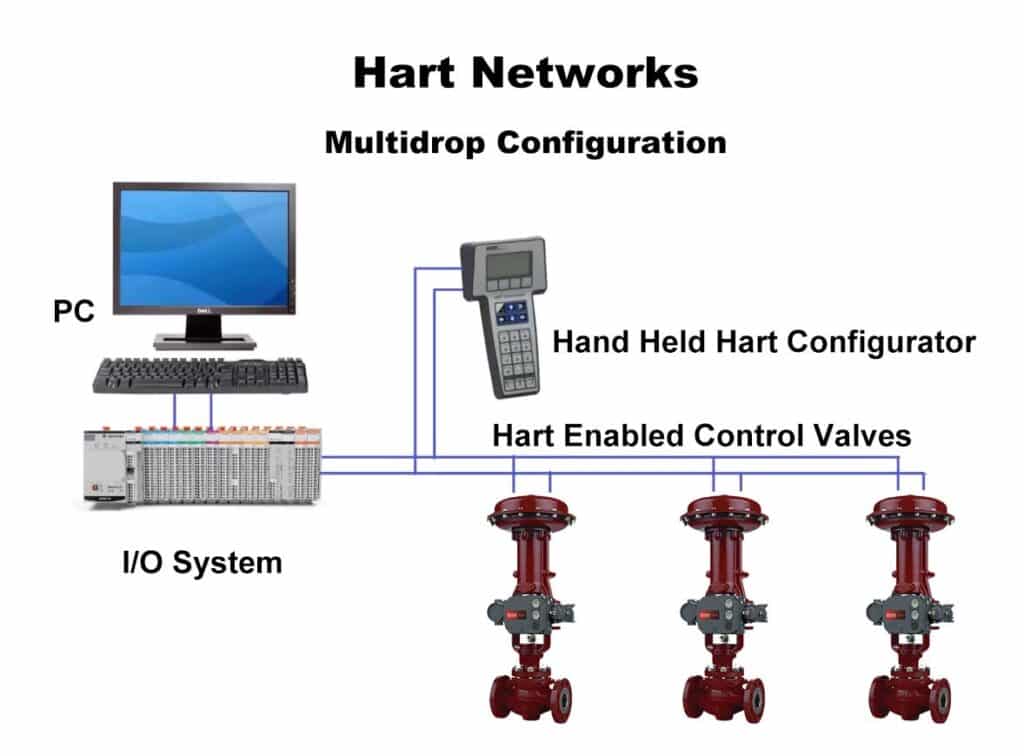

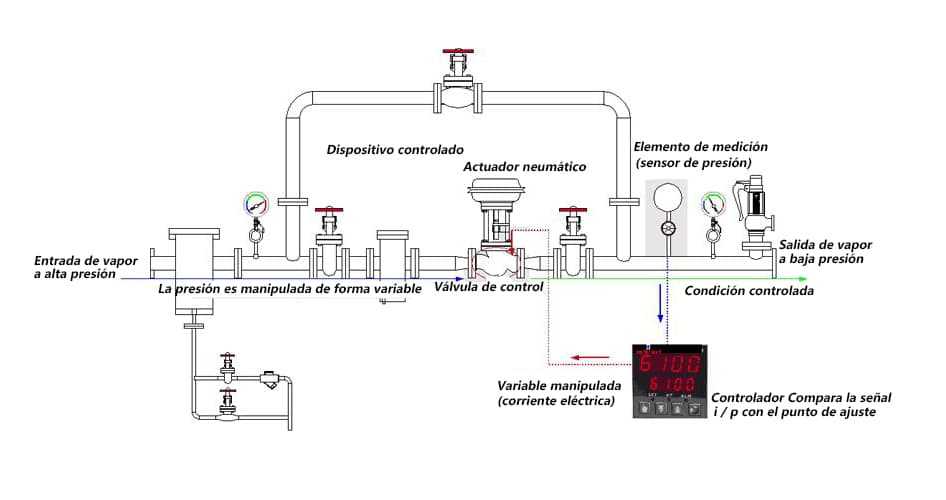

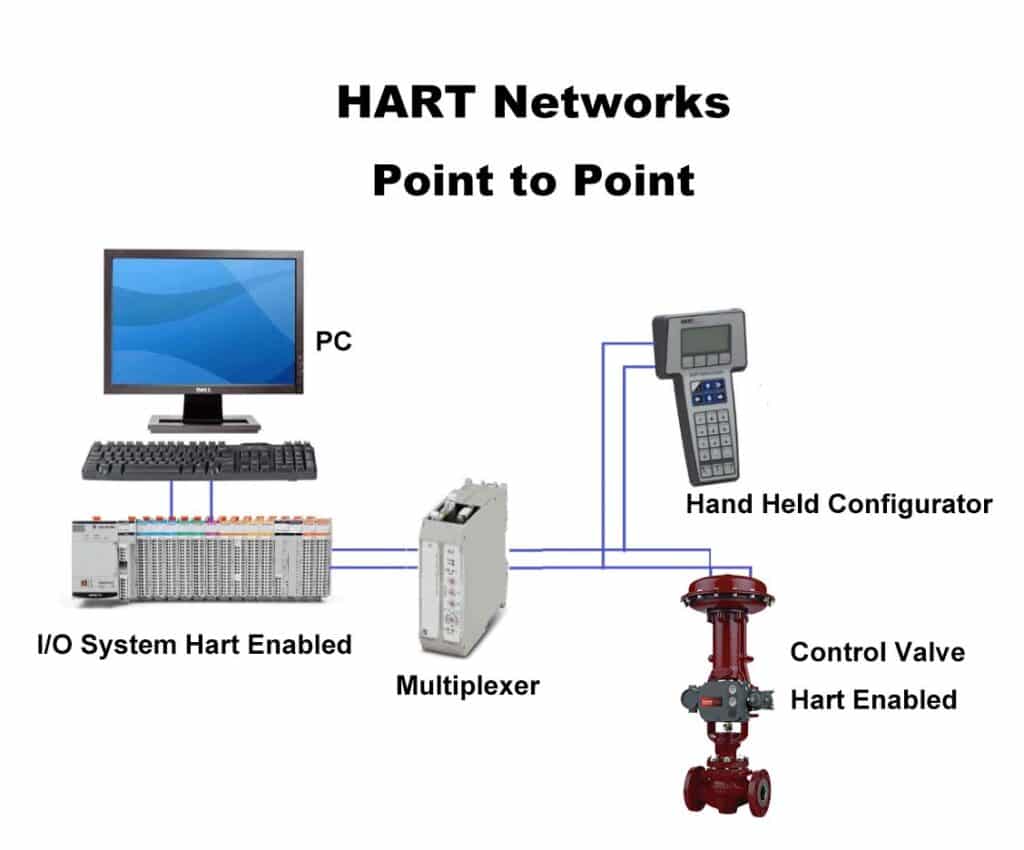

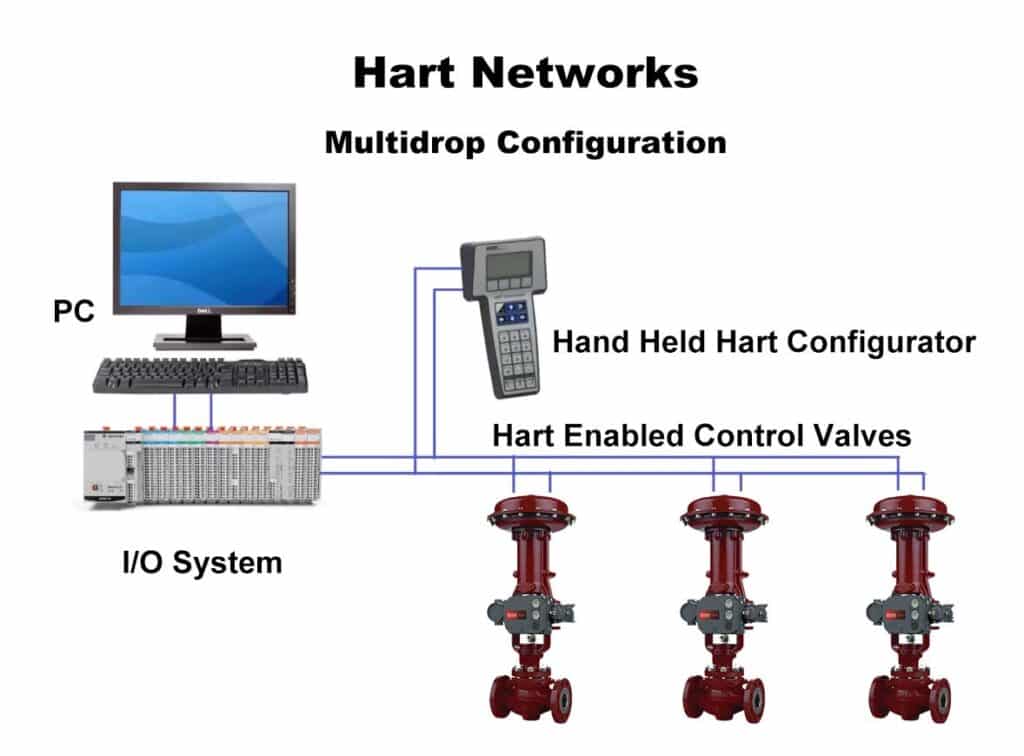

The HART – Highway Addressable Remote Transducer Communication Protocol enables two-way communication between intelligent field devices and a higher-level control system using digital data packets sent over the 4-20mA signal. HART is a master-slave communication protocol, meaning that each slave (field device) communication is started by a master communication device during normal operation. Each HART loop can link to two masters.

Typically, a distributed control system (DCS), programmable logic controller (PLC), or personal computer serves as the primary master (PC). This secondary master may be a portable terminal or a second computer. Transmitters, actuators, and controllers that respond to orders from the primary or secondary master constitute slave devices.

In fact, it is a worldwide standard for the transmission and reception of digital information via analog lines between smart devices and host computers.

Control or monitoring system

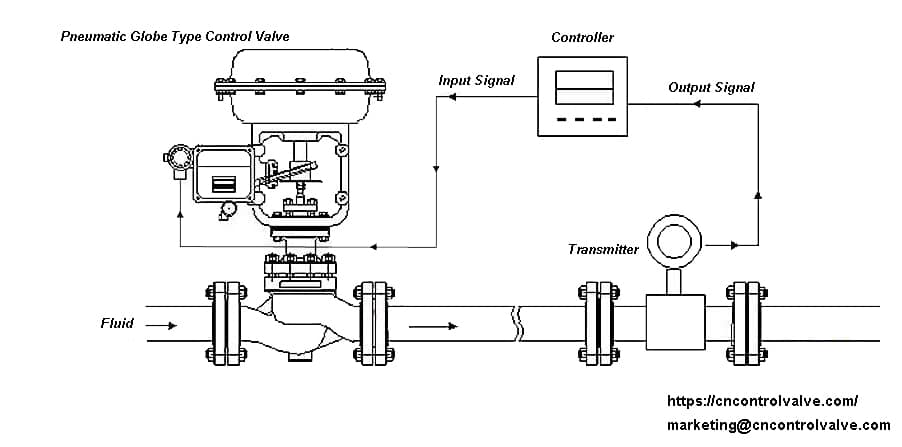

Communication between two HART-enabled devices is made possible through the use of a smart field device, such as a control or monitoring system, and the digital data packets sent over the 4-20mA signal. Standard termination procedures and instrumentation-grade wiring provide dependable connection. The HART protocol has become the international standard for the transmission and reception of digital data via analog lines between smart devices and control or monitoring systems.

Why Use the technology of Hart communication protocol

Hart communication protocol technology has shown to be user-friendly and dependable. The HART protocol is a reliable communication method used to maximize the performance of digital field devices. The HART protocol improves system capabilities for two-way digital communication with intelligent field instruments while preserving the standard 4–20 mA signal. The HART protocol provides the finest option for smart field device communications and has the largest global support base of any field device protocol. The HART protocol is supported by more instruments than any other digital communications system. Almost every process application may be addressed by one of HART instrument providers’ products.

The HART protocol offers a special communication solution that is backwards compatible with the installed base of current equipment, in contrast to other digital communication systems. Due to this backward compatibility, investments made in present control systems and cabling will be safe for the foreseeable future.

The HART protocol is different from other digital communication technologies because it offers a unique way to communicate that works with the instruments that are already in use. This makes sure that investments made in existing cabling and control strategies will be safe for a long time to come.

Benefits of using Hart technology

- Quick and easy access to equipment in the field

- Full-time connectivity to real-time asset management and/or control systems

- Leverage the power of a full suite of smart device data to improve operations.

- Get early warning of equipment, product, or process performance variances.

- Accelerate troubleshooting time between identification and resolution.

- Continuously validate loop integrity and strategies for controlling automated systems.

- Improve asset productivity and system availability.

How Does Hart communication protocol work

In order to set up a system using the HART protocol, two compatible components must be used: an intelligent field device capable of sending and receiving digital signals, and a control system with a matching protocol attached. The field device sends out its signal through the 4-20mA current loop which carries either analog or digital information back to the controller for further processing. When it receives confirmation that the data was received successfully, it sends back any necessary updates or changes based on conditions found in the field.

As technology continues to evolve and new protocols develop alongside it, utilizing reliable communication networks like the HART solution will become increasingly important. It has already made significant advancements towards increased safety standards while simultaneously lower costs through efficient monitoring practices and predictive maintenance abilities that are largely unseen in industries today — making it an incredibly powerful tool for industrial operations everywhere going forward!

What Does Hart communication protocol do

The HART communication protocol enables simultaneous digital and analog data transmission for the process variable, parameters, device configuration, calibration, and device diagnostics. The process variable is still transmitted through a 4-20 mA analog signal. So, through HART connectivity, central control or monitoring systems may access a variety of new information about plant functioning.

HART & Device Description

Device descriptions (DD) are used by some HART host programs to learn more about the variables and features of a HART field device. The DD contains all the data a host application requires to interface with the field device fully.

The DD, which compiles all the data required by the host application into a single structured file, is written using the HART device description language (DDL). The DD specifies all device-specific commands’ formats and structures as well as which common practice commands are compatible.

DD for a HART field device is comparable to a computer’s printer driver. Host providers no longer need to create and maintain unique interfaces and controllers thanks to DDs. A DD offers a standardized linguistic representation of all the characteristics and capabilities of a device.

For their HART field product, HART suppliers can give a DD. If you want to supply one, the DD will offer details so that a host application with DD support may read and write data in accordance with each device’s instructions. The DD source files for HART devices resemble C programming language files. The HCF receives the DD files to register them in the HCF DD Library.

Each DD supplied is put through quality checks to make sure it complies with the standards, to make sure it doesn’t conflict with any DD that has previously been registered, and to make sure it works with typical HART hosts.

To make use of HART DDs in host programs like PCs and handhelds, the HCF DD Library serves as the primary hub for the management and dissemination of all HART DDs. Some host apps might need more details for the screen format and other purposes that aren’t covered by the DD.

How Does A Hart Help With Configuration And Commissioning

The time needed to launch a network has greatly decreased because of HART technology (loop). For instance, since the device and application information is fed into instruments that can be immediately confirmed by the host management system, the devices can be validated more quickly. Connecting a PC configuration to each HART communication loop online—either through the control system or a multiplexing I/O system—simplifies commissioning even further.

As a result, it is no longer necessary to switch the configuration device between termination points while the devices are still connected to the network. The primary PC configuration programs also have a loop test feature that ensures the installation of record-keeping tools and suitable connections for long-term paperwork and service.

Conclusion

Now we know that HART communication protocol is a great tool for configuration and commissioning, enabling faster setup of networks. HART devices are equipped with Device Descriptions (DDs) which provide the host application with all the necessary information to fully interface with it.

The HCF DD Library serves as the main hub for managing and distributing HART DDs so that they can be used in different host applications. With HART technology, you will have an easier time setting up your network while ensuring proper connections and record-keeping tools are installed.

THINKTANK is a professional manufacturer of control valves. In the selection process, many positioners of control valves need to be equipped with HART communication protocol. The general selection brands include Siemens, FISHER, Rotork (YTC), Flowserve, Yamatake, and others brands. If the customer has a specified brand or model, the customer’s selection shall prevail.