What is a Bellows Seal Globe Valve

A bellows seal globe valve is an essential component in many industries, such as chemical, oil and gas, and petrochemical industries. It is a type of industrial valve used to regulate and control the flow of fluids, gases, and other media through a pipeline or system. These bellows valves are widely used because of their unique design, which includes a bellows seal that protects the stem from corrosion and prevents fluid from eroding the stem. So it’s very common to see the condition for corrosive or toxic media.

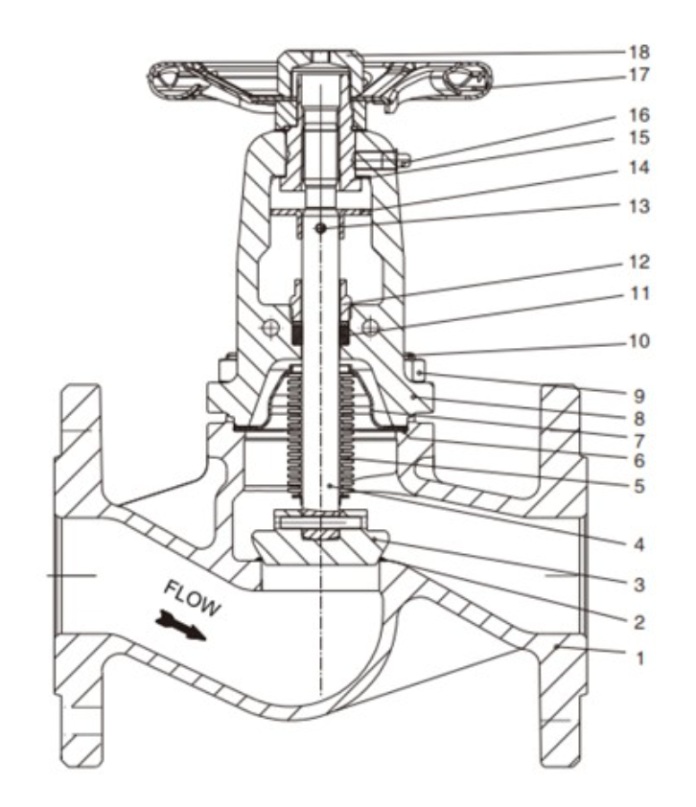

Components of Bellows Seal Globe Valve

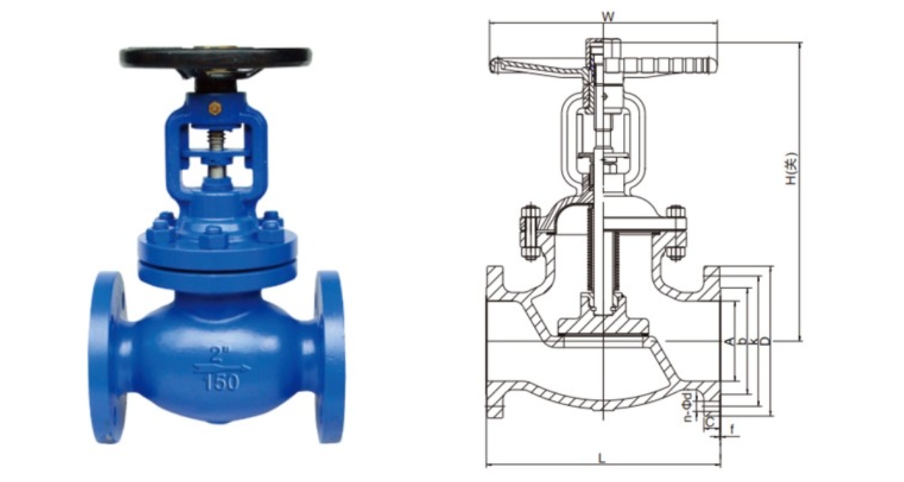

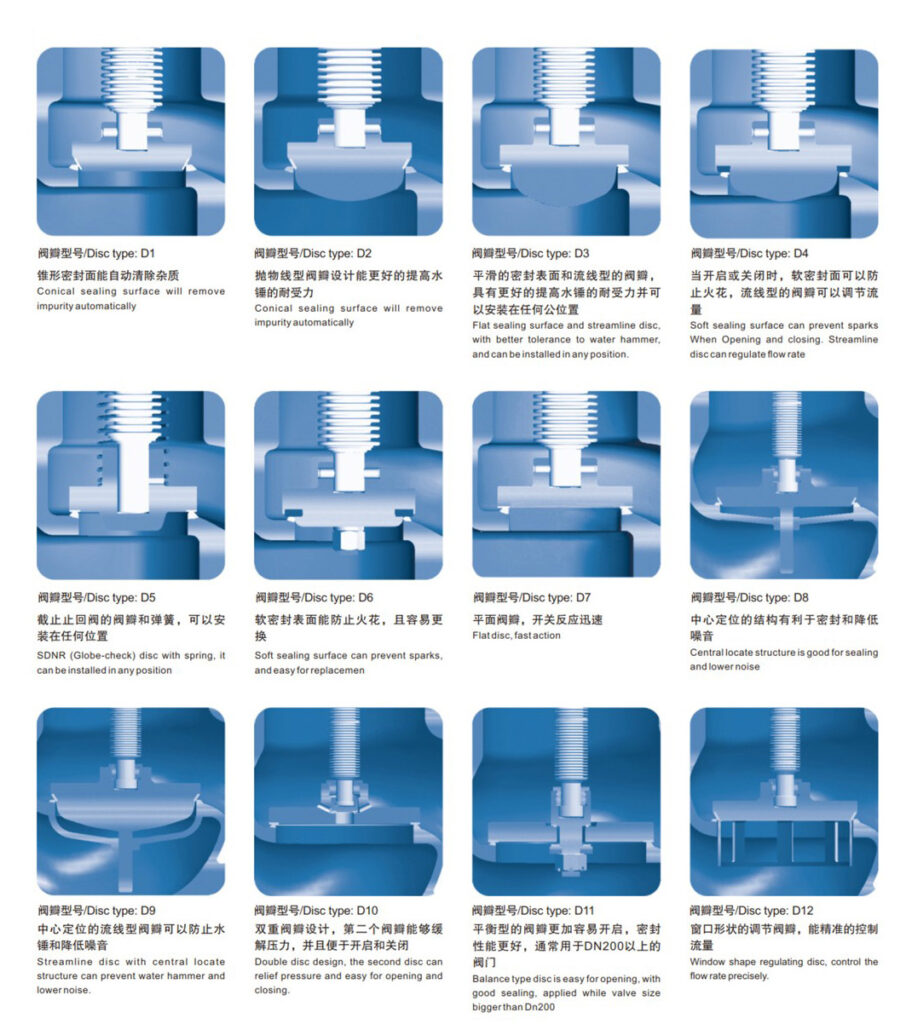

The bellows seal globe valve consists of body, disc, stem, bonnet, bellows seal, and packing. The valve body is the primary component that houses the valve disc, which controls the flow of media. The valve stem connects the valve disc to the actuator or handwheel, which opens or closes the valve. The bonnet covers the stem and packing and the bellows valve provides a seal to prevent leakage. The following is the photo of bellow seal globe valve.

| No. | Parts Name | Materials | ||

| 1 | Body | GS-C25/1.0619 | CF8/1.4301 | CF8M/1.4408 |

| 2 | Seat | Overlay 13Cr | SS304 | SS316 |

| 3 | Disc surface | Overlay 13Cr | SS304 | SS316 |

| 4 | Stem | X20Cr13 | SS304 | SS316 |

| 5 | Bellows | SS304/SS316/SS321/SS316T1 | SS304/SS316/SS321/SS316H | SS316/SS321/SS3167I |

| 6 | Gasket | Graphite+SS | Graphrte+SS | Graphite+SS |

| 7 | Bellows cover | SS304ZSS316 | SS304/SS316 | SS316 |

| 8 | Bonnet | GS-C25/1.0619 | CF8/1.4301 | CF8M/1.4408 |

| 9 | Nut | A194 2H | A194 8 | A194 8M |

| 10 | Bolt | A193 B7 | A193 B8 | A193 B8M |

| 11 | Packing | Graphite | Graphite | Graphite |

| 12 | Gland | c.s | CF8 | CF8M |

| 13 | Pin | Steel | Steel | Steel |

| 14 | Guide piece | Steel | Steel | Steel |

| 15 | Stem nut | Ductile iron | Copper alloy | Copper alloy |

| 16 | Grease Nipple | H2 | H2 | H2 |

| 17 | Hand wheel | Steel | Steel | Steel |

| 18 | Lock nut | A105 | A105 | A105 |

Types of Bellows Seal Globe Valve

There are several types of bellows seal valves and globe valves available in the market, each with unique design features and applications. Here are some of the most common types of bellows seal globe valves:

Welded Ends bellow seal globe valve

This type of valve has welded metal bellows that provides a flexible, leak-proof seal and protects the stem from corrosion. Welded ends bellows seal globe valves are ideal for high-temperature and high-pressure applications.

Flanged bellow seal globe valve

This type of valve has a flanged connection that makes it easy to install and remove. Flanged bellows seal globe valves are suitable for applications that require frequent maintenance and inspection.

Socket-welded bellows seal globe valve

This type of valve has socket-welded connection ends which are suitable for high-pressure applications.

Threaded bellows seal globe valve

This type of valve has a threaded connection that makes it easy to install and remove. Threaded bellows seal globe valves are commonly used for small pipeline.

Extended bellows seal globe valve

This type of valve has extended bellows that provide additional protection against corrosion and allows the valve to operate at extreme temperatures and pressures.

Y Pattern Bellows seal globe valve

The Y-Type Bellows Seal Globe Valve is an exceptionally secure and reliable component, featuring a double sealing structure of bellows and packing. This ensures complete protection from any potential leakage at the stem, making it ideal for use in pipelines carrying dangerous, flammable, explosive, toxic or valuable substances. Additionally, its construction ensures tight seals are maintained under high temperatures and pressures, while also minimizing any risk of leaks.

THINKTANK is a reliable globe valve manufacturer that has been producing high-quality industrial valves for over three decades. Our valves are made from high-quality materials and are designed to meet the specific needs of each application, just feel free to contact us for a free consultation.

Difference between a Globe Valve and a Bellows Seal Globe Valve

A globe valve and a bellows seal globe valve both belong to the family of globe valves, which are used to control the flow of fluids through a pipeline or system. However, the primary difference between them is the presence of a bellows seal in a bellows seal globe valve. A bellows seal is a flexible metal component that provides a leak-proof seal and protects the stem from corrosion, which makes the bellows seal globe valve more suitable for applications that require high performance and reliability.

Purpose of Bellows in Valves

The primary purpose of bellows in valves is to provide a flexible, leak-proof seal that protects the stem from corrosion and prevents fluid from eroding the stem. Bellows are also used to compensate for changes in temperature and pressure in the system, which allows the valve to operate smoothly and efficiently.

Difference between Bellows Seal Valve and Common Valve

The primary difference between a bellows seal valve and a common valve is the presence of a bellows seal. A bellows seal valve has flexible metal bellows that provide a leak-proof seal and protect the stem from corrosion, while a normal valve does not have this feature.

Meaning of Bellows Seal

A bellows seal is a flexible metal component that is used in valves to provide a leak-proof seal and protect the stem from corrosion. The bellows seal consists of metal bellows that is welded to the stem and a packing gland that secures the bellows in place.

Reason for Bellows

The primary reason for using bellows in a valve is to provide a flexible, leak-proof seal that protects the stem from corrosion and prevents fluid from eroding the stem. Bellows are also used to compensate for changes in temperature and pressure in the system, which allows the valve to operate smoothly and efficiently.

How Bellows Work

Bellows work by expanding and contracting to compensate for changes in temperature and pressure in the system. When the temperature or pressure in the system changes, the bellows expand or contracts to allow the valve stem to move freely, which prevents damage to the valve and ensures smooth operation.

Types of Valve Seals

There are three types of valve seals: packing, mechanical, and bellows.

Packing seals use a flexible material, such as graphite, to provide a seal around the stem. Mechanical seals use a rotating component to provide a seal, while bellows seals use a flexible metal component to provide a leak-proof seal and protect the stem from corrosion.

Two Types of Valve Seals

The two basic types of valve seals are static and dynamic. Static seals provide a seal between two stationary components, while dynamic seals provide a seal between two moving components.

Disadvantages of Bellows

One of the primary disadvantages of bellows is that they can fail over time, which can lead to leakage and other issues. Bellows can also be more expensive than other types of valve seals, which can make them less suitable for certain applications.

Bellows Failure

Bellows failure can occur due to a variety of factors, such as fatigue, corrosion, or mechanical damage. When a bellows fails, it can lead to leakage, reduced valve performance, and other issues. Regular inspection and maintenance can help prevent bellows failure and ensure the continued performance of the valve.

How Does Bellows Seal Globe Valve Work?

The operational principle of a bellows seal globe valve is based on its unique design, which includes a bellows seal that protects the stem from corrosion and prevents fluid from eroding the stem. The valve consists of a valve body, a valve disc, a valve stem, a bonnet, a bellows seal, and packing.

When the valve is in the open position, the valve disc is lifted away from the valve seat, allowing media to flow through the valve. The stem and the disc move together as the stem is rotated by the actuator. When the valve is in the closed position, the valve disc is pressed against the valve seat, preventing media from flowing through the valve.

Comparison of Bellows Seal Globe Valve with Other Valve Types

| Parameter | Globe Valve | Ball Valve | Butterfly Valve | Gate Valve | Diaphragm Valve | Bellows Seal Globe Valve |

|---|---|---|---|---|---|---|

| Flow control | Excellent | Good | Good | Not Suitable | Good | Excellent |

| Leakage | Low | Low | Low | Low | Very Low | Very low(Zero Leakage) |

| Corrosion resistance | Good | Good | Good | High | High | Very high |

| Maintenance | Moderate | Moderate | Moderate | Low | Low | Low |

| Temperature range | -20°C to 500°C | -40°C to 200°C | -20°C to 120°C | -29°C to 425°C | -29°C to 150°C | -196°C to 600°C |

| Pressure range | Up to 2500 psi | Up to 1000 psi | Up to 150 psi | Up to 5000 psi | Up to 200 psi | Up to 2500 psi |

| Applications | Water, steam, gases, oils | Water, gases, oils | Water, air, gases | Steam, water, gases, oils | Slurries, viscous fluids, corrosive chemicals | Corrosive fluids, high temperature, and high pressure applications |

Applications of Bellows Seal Globe Valve

The bellows seal globe valve is widely used in industries where leak-proof and corrosion-resistant valves are required. Some common applications of the bellows seal globe valve are:

- Chemical industry: The valve is used to control the flow of chemicals, acids, and other corrosive media.

- Petrochemical industry: The valve is used in refineries and petrochemical plants to control the flow of various media.

- Pharmaceutical industry: The valve is used in pharmaceutical plants to control the flow of sterile media.

- Food and beverage industry: The valve is used to control the flow of food-grade media, such as milk, juice, and beer.

Advantages of Bellows Seal Globe Valve

- Zero Leakage: The bellows seal provides a leak-proof seal that prevents fluid from leaking out of the valve.

- Corrosion-resistant: The bellows seal protects the stem from corrosion, which extends the valve’s lifespan.

- Maintenance-free: The bellows seal design eliminates the need for maintenance, which reduces downtime and lowers operating costs.

- High temperature and pressure resistance: The bellows seal globe valve can withstand high temperatures and pressures, making it suitable for use in a wide range of applications.

FAQs For Bellow seal globe valve

Who manufactures bellow seal Globe valves in China?

Here are some reliable bellow seal globe valves manufacturer in China for your reference.

- Shanghai Thinktank Process Management

- Zhejiang Youfumi Valve Co., Ltd.

- Beijing Valve General Factory Group Co.,Ltd

- Suzhou Neway Valve

- Zhejiang Boteli Valve

- Zhejiang Sedelon Valve Co., Ltd.

- Shanghai Valve Factory Co.,Ltd.

- Wuzhou Valve Co., Ltd.

- Lanzhou High Pressure Valve Co., Ltd.

- Shanghai Kaiweixi Valve Limited Company

What is the difference between Bellows Seal Globe Valve and Traditional Globe Valve?

The primary difference between a bellows seal valve and a traditional valve is the presence of a bellows seal. A bellows seal valve has flexible metal bellows that provide a leak-proof seal and protect the stem from corrosion, while a traditional valve does not have this feature.

How do you select the right Bellows Seal Globe Valve for your application?

Selecting the right bellows seal globe valve for your application is crucial to ensure optimal performance, reliability, and safety. Here are some factors to consider when selecting the right bellows seal globe valve for your application:

- Fluid compatibility: It is important to select a valve that is compatible with the fluid being transported through the pipeline. This includes considering the chemical composition, temperature, and pressure of the fluid.

- Operating conditions: The operating conditions, including the temperature and pressure range, must be considered when selecting a bellows seal globe valve. This includes ensuring that the valve can handle the temperature and pressure range of the system.

- Flow rate: The flow rate of the fluid is an important consideration when selecting a bellows seal globe valve. The valve must be able to handle the required flow rate without causing excessive turbulence or pressure drop.

- End connections: The end connections of the valve must be compatible with the piping system to ensure proper installation and operation.

- Maintenance requirements: The maintenance requirements of the valve must be considered when selecting a bellows seal globe valve. This includes considering factors such as ease of maintenance, frequency of maintenance, and cost of maintenance.

- Quality and reliability: It is important to select a high-quality and reliable bellows seal globe valve to ensure optimal performance and safety.

What are the advantages of using Bellows Seal Globe Valve in high-pressure and high-temperature applications?

Bellows seal globe valves offer several advantages in high-pressure and high-temperature applications, making them a popular choice for such applications. Here are some of the advantages of using bellows seal globe valves in high-pressure and high-temperature applications:

- Leak-proof seal: Bellows seal globe valves provide a flexible, leak-proof seal that protects the stem from corrosion and prevents fluid from eroding the stem. This makes them ideal for applications where leakage could cause significant damage or safety hazards.

- Corrosion resistance: Bellows seal globe valves are made of high-quality materials that are resistant to corrosion, making them suitable for use in harsh environments and corrosive fluids.

- Temperature range: Bellows seal globe valves can operate in a wide range of temperatures, from cryogenic temperatures to high-temperature applications up to 600°C. This makes them suitable for use in applications with extreme temperature ranges.

- Pressure range: Bellows seal globe valves can operate in high-pressure applications up to 2500 psi, making them ideal for use in applications where high pressures are required.

- Smooth operation: Bellows seal globe valves are designed to operate smoothly and efficiently, providing accurate flow control and reducing the risk of valve failure.

- Low maintenance: Bellows seal globe valves require low maintenance due to their durable construction and reliable operation. This makes them ideal for applications where maintenance is difficult or costly.

How often should you replace the Bellows Seal in Bellows Seal Globe Valve?

The frequency of bellows seal replacement in bellows seal globe valves depends on several factors, such as the type of fluid being transported, operating conditions, and the quality of the bellows seal.

In general, bellows seal replacement is typically required when there is evidence of seal failures, such as leakage or reduced performance. Regular inspection and maintenance can help detect signs of bellows seal failure and prevent unexpected downtime or safety hazards.

The recommended replacement interval for bellows seals can vary depending on the application and the manufacturer’s guidelines. However, a general rule of thumb is to replace the bellows seal every 2-3 years or when there is evidence of seal failure, such as leakage or reduced performance.

It is important to note that regular inspection and maintenance are crucial to ensuring the proper functioning of the bellows seal globe valve. This includes checking the bellows seal for signs of wear and damage, inspecting the stem and disc for proper alignment, and ensuring that the valve is properly lubricated.

By following the manufacturer’s guidelines and performing regular inspection and maintenance, you can ensure that the bellows seal globe valve operates safely and efficiently and that the bellows seal is replaced as needed to prevent leakage and other issues.

How do you troubleshoot issues with Bellows Seal Globe Valve?

Here is a table outlining some common issues that can arise with bellows seal globe valves and possible troubleshooting steps:

| Issue | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Leakage | Damaged or worn bellows seal, improperly installed valve, damaged valve body or disc, excessive fluid pressure or temperature | Inspect bellows seal for signs of wear or damage, check valve installation for proper alignment and torque, inspect valve body and disc for signs of damage, check fluid pressure and temperature to ensure they are within valve limits |

| Valve does not close completely | Improperly adjusted actuator, damaged valve disc or seat, obstruction in valve body | Check actuator settings and adjust if necessary, inspect valve disc and seat for signs of damage or wear, inspect valve body for obstructions and remove if necessary |

| Excessive noise or vibration | Misaligned valve components, excessive fluid pressure or flow rate, worn valve components | Inspect valve components for proper alignment, check fluid pressure and flow rate to ensure they are within valve limits, inspect valve components for signs of wear and replace as needed |

| Difficult to operate | Damaged or worn stem or packing, improper lubrication, misaligned valve components | Inspect stem and packing for signs of damage or wear, lubricate valve components according to manufacturer’s recommendations, inspect valve components for proper alignment |

| Corrosion | Exposure to corrosive fluids or environments, low-quality materials | Select valve materials that are resistant to corrosion, ensure proper maintenance and cleaning to prevent corrosion buildup |

Conclusion

In conclusion, the bellows seal globe valve is an essential component in many industries due to its unique design and functionality. Its ability to provide a leak-proof and corrosion-resistant seal makes it an excellent choice for applications that require high performance and reliability. We hope that this article provides you with valuable insights into the design, functionality, and applications of the bellows seal globe valve. Please do not hesitate to contact us if you have any questions or comments. THINKTANK is your reliable industrial valve partner here.