Introduction

At THINKTANK, we work with atmospheric storage tanks across many coastal and high-humidity regions. From our experience, the long-term reliability of these tanks is often determined not by the stored medium itself, but by how well the tank is protected from its surrounding environment.

High ambient humidity, salt-laden marine air, and continuous exposure to moisture are common in coastal installations. These environmental conditions become critical once they are repeatedly drawn into the tank through normal breathing cycles.

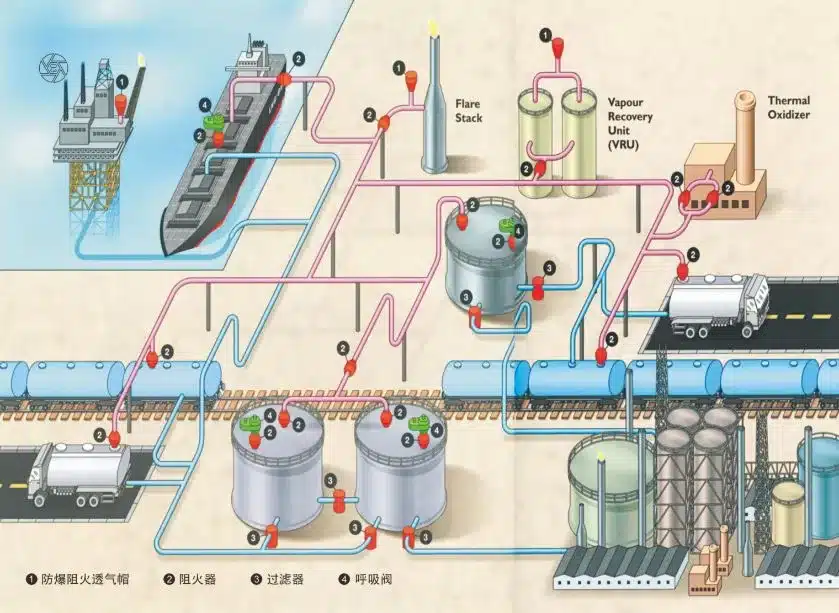

According to API 2000, tank breathing is driven primarily by liquid movement during normal operation—when product is pumped into or out of the tank—and secondarily by ambient temperature fluctuations. Every in-breathing event introduces outside air into the tank. In coastal environments, that air almost always contains moisture.

If this humid air is allowed to enter the tank unchecked, moisture accumulates internally over time. The consequences are not always immediate, but they are predictable and costly.

We first encountered this problem clearly in diesel storage tank systems installed near ports and coastal industrial zones. The diesel itself was stable, but internal corrosion, sludge formation, and shortened maintenance intervals became recurring issues. Re-coating and repairs addressed the symptoms, not the cause. The real issue was uncontrolled humid air entering the tank during normal breathing.

The same engineering logic applies to sulfuric acid storage tanks used in reverse osmosis (RO) plants. Although the stored medium is completely different, the breathing mechanism is the same. Moist air entering the tank can dilute acid concentration, disturb process stability, and increase corrosion risks for the tank shell, nozzles, and downstream piping. From an engineering standpoint, this is not a chemical problem—it is an air ingress problem.

This is where dry breather valves play a critical role.

Why is Moist Air a Big Problem for Storage Tanks?

You know that feeling of damp air in a coastal area? Your tanks feel it too, and it causes big problems. This humidity leads to corrosion and can ruin the product inside.

The core issue is “tank breathing.” As temperatures change or when you fill or empty the tank, the pressure inside changes, and the tank breathes air in or out. In humid places, that inhaled air is full of water vapor, which is the start of your problems.

I once inspected a tank near the coast that didn’t have proper moisture protection. The bottom was so corroded from condensed water that it was almost beyond repair. The client was shocked at how quickly it happened. This experience taught me that preventing moisture entry is not optional; it’s essential. The two main enemies we fight here are corrosion and product contamination. Moisture inside a tank directly causes both of these expensive and dangerous problems.

The Science of Tank Corrosion

Corrosion is basically a chemical reaction, and it loves water. When humid air enters a tank, the water vapor can turn into liquid water, or condensation, as temperatures drop overnight. This water then settles at the bottom of the tank or clings to the walls. For a steel tank, this is the perfect recipe for rust. Exposure to moisture and oxygen is what causes steel to oxidize and rust away. This process slowly eats away at the tank’s structure, weakening it over time and leading to potential leaks or even catastrophic failure. In coastal areas, the salty air makes this even worse, as salt accelerates the corrosion process significantly.

| Factor | Condition | Impact on Tank |

|---|---|---|

| Moisture | High humidity leads to condensation | Creates an electrolyte for corrosion to occur |

| Oxygen | Always present in the air | A key ingredient for the rusting process |

| Salt | Present in coastal air | Accelerates the electrochemical corrosion reaction |

| Temperature Fluctuations | Day/Night Cycles | Increases the amount of condensation inside the tank |

The Real Risk Of Tank Breathing in Coastal Environments

Atmospheric storage tanks must breathe to remain structurally safe. During liquid filling, the tank exhales; during liquid withdrawal, it inhales. This breathing is unavoidable and necessary.

What is often underestimated is the quality of the air being inhaled.

In coastal regions, incoming air typically contains:

- High absolute humidity

- Salt particles and marine aerosols

- Moisture that readily condenses on cooler internal tank surfaces

Over time, repeated in-breathing cycles introduce water vapor into the tank headspace. Condensation forms on internal walls and roof plates, even when the stored medium itself is non-aqueous.

This internal moisture leads to:

- Accelerated corrosion from the inside out

- Product contamination or dilution

- Increased sludge or byproduct formation

- Higher maintenance frequency and reduced tank service life

Once moisture is inside the tank, it is difficult to remove. Preventing its entry is far more effective than managing its consequences.

How Does a Dry Breather Valve Actually Work?

You might think it’s complicated, but the idea is simple. A dry breather valve acts like a filter for the air your tank breathes, stopping moisture before it can get inside and cause damage.

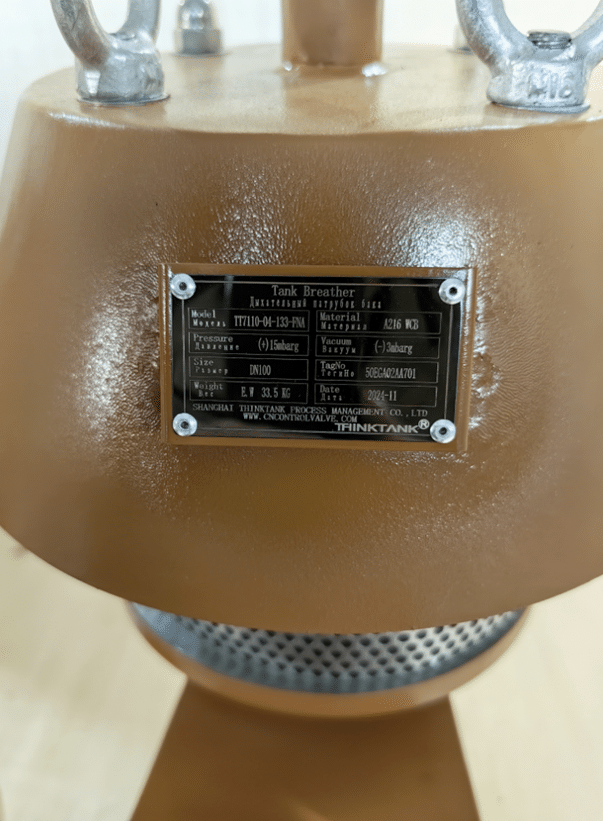

It works in two simple steps. First, it filters out dust and dirt. Second, it uses a special material called a desiccant, often silica gel, to absorb water vapor from the air. This means only clean, dry air enters your tank, stopping rust and contamination.

I remember talking to a procurement manager who was worried about adding another maintenance task for his team. I showed him how the desiccant crystals in our breathers change color. They start as one color (like blue or orange) and gradually change as they absorb moisture. This visual check makes maintenance incredibly simple. A quick glance tells your field engineer if it is time to replace the desiccant. He realized it would actually make his maintenance plan easier, not harder.

The Step-by-Step Process of Drying the Air

The function of a dry breather valve is straightforward and effective. It integrates directly with the tank’s existing vent or breather valve, which is designed to manage pressure changes. Here is how the process unfolds when the tank needs to “breathe in”:

- Pressure Drop: As the liquid level in the tank drops or the outside temperature cools, a negative pressure, or vacuum, is created inside the tank.

- Valve Opens: The breather valve automatically opens to equalize the pressure by drawing in outside air.

- Filtration: The incoming air first passes through a particle filter, which removes solid contaminants like dust and dirt. This protects both the desiccant and the tank’s contents.

- Moisture Adsorption: Next, the air flows through the chamber filled with desiccant beads. The desiccant material, typically silica gel, has a high capacity to attract and hold water molecules on its surface. A single grain can adsorb up to 40% of its weight in water.

- Dry Air Enters: The resulting clean, dry air then passes into the tank, protecting it from the harmful effects of moisture.

This process ensures that the tank can breathe as needed to maintain structural integrity without introducing the risk of internal corrosion or product contamination.

THINKTANK’s Proven Projects: From Diesel Tanks to Sulfuric Acid Storage in RO Plants

Our initial applications focused on diesel storage tanks, where the benefits of moisture control are well understood. Once dry breather valves were installed, corrosion rates dropped significantly, sludge formation slowed, and maintenance became more predictable.

When we evaluated sulfuric acid storage tanks in RO plants, the same principles applied.

Although sulfuric acid systems are designed for corrosion resistance, uncontrolled moisture ingress can still:

- Alter acid concentration

- Increase corrosion risk at interfaces and nozzles

- Create instability in dosing and downstream processes

The stored medium changed, but the breathing mechanism did not. In both cases, dry air entering the tank was the decisive factor.

From an engineering standpoint, this transfer of experience was straightforward. Dry breather valves do not care what is stored inside the tank—they address the environmental conditions outside it.

Maintenance Steps for Dry breather valve

One of the most practical features of modern dry breather valves is the use of color-indicating silica gel. This provides a clear, visual signal for maintenance crews.

| Desiccant Condition | Color Appearance | Required Action |

|---|---|---|

| New / Dry | Typically Blue or Orange | No action needed. The valve is fully effective. |

| Partially Saturated | Color begins to change (e.g., to Pink or Green) | Monitor closely. Prepare for replacement. |

| Fully Saturated | Fully changed color (e.g., Pink or Green) | Replace the desiccant canister immediately. |

This simple system removes all the guesswork from maintenance. Instead of sticking to a rigid schedule that might be too frequent or not frequent enough, engineers can perform a quick visual inspection to see the exact condition of the desiccant. This prevents them from replacing cartridges that are still good, saving money, and ensures they never leave a saturated, ineffective breather on the tank. It is a smart, simple feature that makes protecting a major asset like a storage tank incredibly efficient.

Extending Tank Lifespan and Reducing Capital Costs

The primary and most obvious benefit is the extension of your storage tank’s service life. Corrosion is a relentless force that can thin the walls of a steel tank and attack critical areas like welds and the tank bottom. By preventing the moisture that fuels corrosion from ever entering the tank, you drastically slow down this degradation process. A tank that might have needed major repairs or complete replacement in 10-15 years could last 20 years or more with this simple protection. This delays a massive capital expenditure, freeing up funds for other critical projects. It also reduces the risk of leaks, which can lead to environmental fines and cleanup costs. Protecting the physical asset is a direct and measurable return on investment.

Protecting Product Quality and Preventing Spoilage

For many businesses, the product inside the tank is more valuable than the tank itself. Maintaining product purity is critical. Dry breather valves protect against contamination that can lead to product spoilage, degradation, or failure to meet quality specifications.

- Fuels: Prevents microbial growth and sludge formation.

- Chemicals: Avoids unwanted reactions and maintains purity.

- Lubricants: Preserves lubricating properties and prevents additive precipitation.

- Food-Grade Liquids: Ensures hygienic standards are met by preventing water-borne contamination.

By ensuring only dry air enters the tank, you safeguard your inventory, reduce waste, and uphold your reputation for delivering a quality product.

Simplifying Maintenance and Improving Safety

Predictable maintenance is far more efficient and less costly than emergency repairs. Dry breather valves shift tank maintenance from a reactive to a proactive model.

| Reactive Maintenance (No Dry Breather) | Proactive Maintenance (With Dry Breather) |

|---|---|

| Responding to leaks after they occur | Preventing leaks by stopping corrosion |

| Frequent testing for water contamination | Visual checks of desiccant color |

| Costly product filtering or replacement | Simple, scheduled desiccant replacement |

| Unplanned downtime for repairs | Planned, quick maintenance with no downtime |

The color-indicating desiccant makes visual inspections fast and foolproof. Maintenance staff can quickly assess the status of the breather without any special tools. This reduces labor costs and minimizes the time personnel need to spend on top of tanks, improving overall site safety. Regular maintenance is simplified to just replacing the desiccant cartridge, a quick and clean job.

Engineering Perspective: Prevention Over Correction

In many projects, we see dry breather valves added only after corrosion or contamination has already appeared. By that stage, the tank has already paid the price.

Based on our experience, moisture damage inside atmospheric tanks is rarely minor. It leads to unplanned shutdowns, higher lifecycle costs, and avoidable operational risk. Controlling humid air ingress from the beginning is a far more effective strategy.

For tanks operating in coastal, high-humidity environments—whether storing diesel, sulfuric acid, or other sensitive media—dry breather valves are not an upgrade. They are a preventive engineering measure that protects the tank, the process, and the asset lifecycle.

FAQs

Why are dry breather valves necessary for coastal storage tanks?

In coastal environments, atmospheric air contains high humidity and salt aerosols. During normal tank breathing caused by liquid transfer, this moist air enters the tank and leads to internal corrosion, condensation, and product contamination. Dry breather valves prevent moisture ingress by drying incoming air before it enters the tank.

Is tank breathing mainly caused by temperature change or liquid movement?

According to API 2000, tank breathing is primarily driven by liquid movement during filling and emptying operations. Temperature changes are a secondary factor. This means moisture ingress occurs regularly during normal operation, not only during day–night temperature cycles.

Can dry breather valves be used for sulfuric acid storage tanks?

Yes. Although sulfuric acid systems differ from fuel tanks in terms of materials and corrosion resistance, the tank breathing mechanism is the same. Moist air ingress can dilute acid concentration, increase corrosion risk at nozzles and interfaces, and affect downstream process stability. Dry breather valves address the environmental cause, not the stored medium.

How do I know when maintenance is required for a dry breather valve?

Modern dry breather valves use color-indicating silica gel desiccant. Maintenance personnel can visually inspect the desiccant color. Once the color fully changes, the desiccant cartridge should be replaced. This eliminates guesswork and allows condition-based maintenance instead of fixed schedules.

Is a dry breather valve the same as a pressure/vacuum relief valve?

Yes. In engineering practice, the terms breather valve and pressure/vacuum relief valve (PVRV) refer to the same functional device used on atmospheric storage tanks, as defined in API 2000.

A dry breather valve is not a different type of valve. It is a pressure/vacuum relief valve equipped with an integrated air-drying system, typically using desiccant, to control the quality of incoming air during in-breathing.

The pressure and vacuum relief function remains unchanged. The added dry-breather system ensures that the air entering the tank is free from moisture and contaminants, which is especially critical in coastal and high-humidity environments.