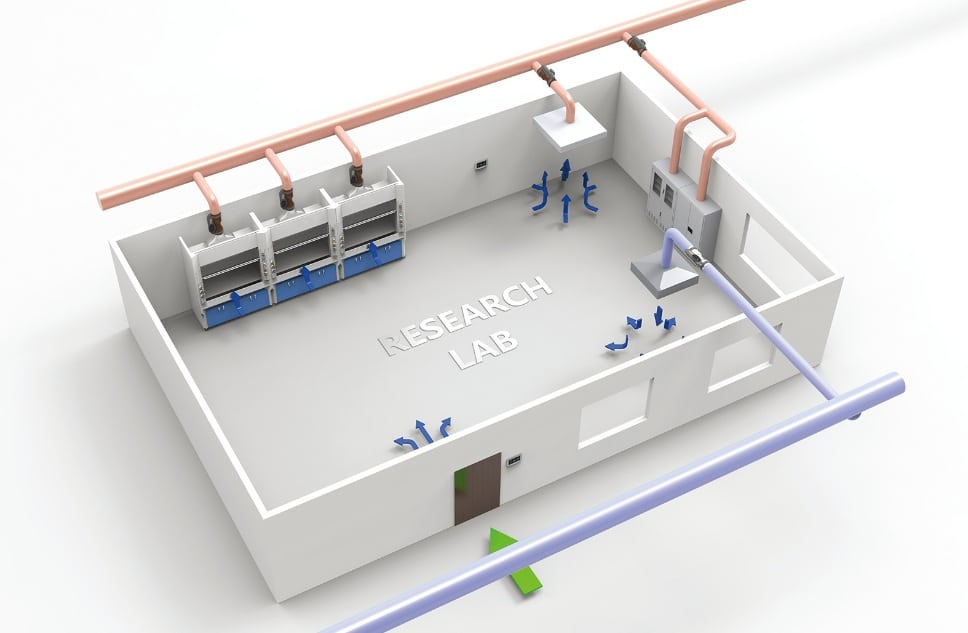

Venturi valves are essential components in modern HVAC systems, providing precise airflow control for critical environments such as laboratories, cleanrooms, and healthcare facilities. These valves maintain consistent air pressure and temperature while ensuring energy efficiency and safety. In this article, we’ll explore the features, benefits, and applications of Venturi valves and explain why they’re the ultimate solution for critical environment controls.

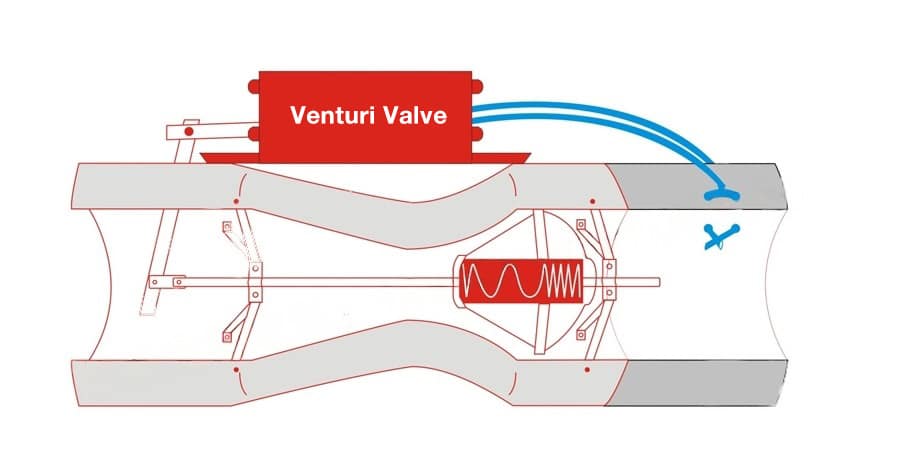

The Science Behind Venturi Valves

Venturi valves operate based on the Venturi effect, a fluid dynamic principle that states that as the velocity of a fluid increases, its pressure decreases. The valve’s unique design creates a pressure drop, resulting in a proportional relationship between the valve’s opening and the airflow rate. This allows for precise control of airflow and pressure in critical environments.

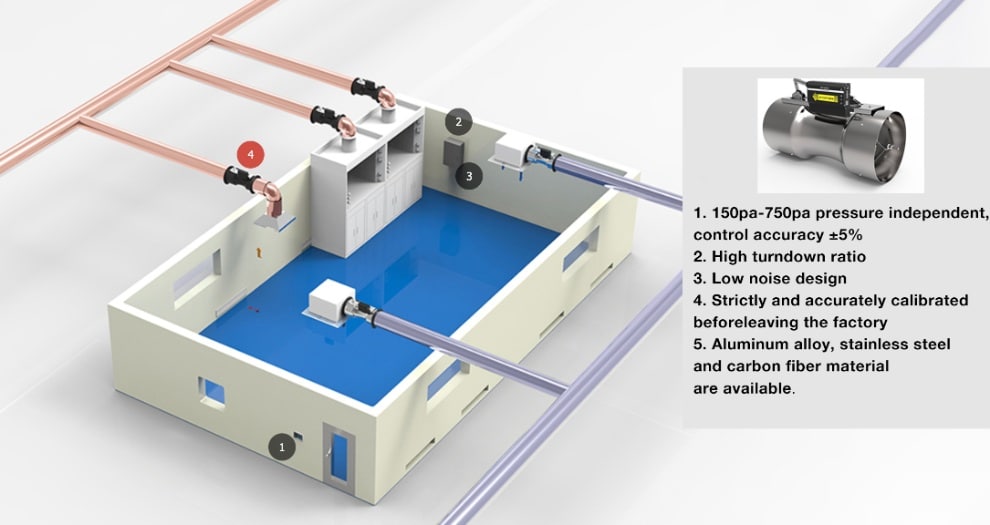

Key Features of Venturi Valves

Accurate Airflow Control

Venturi valves provide unparalleled accuracy in airflow control, ensuring that critical environments maintain the required pressure and temperature levels. They are able to compensate for fluctuations in supply pressure, delivering consistent and stable airflow.

Energy Efficiency

By offering precise control over airflow, Venturi valves help reduce energy consumption in HVAC systems. With their ability to modulate airflow based on demand, these valves contribute to significant energy savings in critical environments.

Easy Installation and Maintenance

Venturi valves are designed for simple installation and minimal maintenance. Their compact design allows for easy integration into existing HVAC systems, and their durable construction ensures long-lasting performance with minimal upkeep.

Various Materials for Venturi Valves

THINKTANK’s VA series venturi valves are available in aluminum alloy, stainless steel, carbon fiber, and other valve body materials to meet all the needs of different environments and severity levels.

Aluminum Alloy Venturi Valve

Aluminum alloy venturi valves are becoming a popular choice in many industries due to their lightweight, yet strong and corrosion-resistant properties. They are widely used in the air conditioning and refrigeration industry as well as other applications where precise control of airflow is needed. Aluminum alloy offers excellent heat transfer capabilities, making it ideal for temperature control purposes. The valves are highly customizable and relatively easy to install, making them a great choice for anyone looking for reliable performance with minimal maintenance requirements.

Stainless Steel Venturi Valve

Stainless steel venturi valves are an ideal choice for many industries due to their ability to withstand rust, corrosion, and staining. They are widely used in the food and beverage processing industry, as well as HVAC systems. Stainless steel venturi valves offer a variety of benefits including cost-effectiveness, durability, high-pressure ratings, and low maintenance requirements. These valves are also easy to install and maintain, making them a great choice for any application.

Carbon Fiber Venturi Valve

Carbon fiber is a new type of fiber material with high strength and high modulus fibers with a carbon content of more than 95%. Carbon fiber is “soft on the outside and rigid on the inside”. It is lighter than metal aluminum, but its strength is higher than that of steel, and it has the characteristics of corrosion resistance and high modulus. It is an important material in national defense and civilian applications.

Carbon fiber has many excellent properties, such as high axial strength and modulus, low density, high specific performance, no creep, ultra-high temperature resistance in the non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and Between metals, thermal expansion coefficient is small and anisotropic, and the corrosion resistance is good.

Carbon fiber can be divided into general-purpose, high-strength, medium-mode high-strength, high-model and ultra-high-model carbon fibers according to performance. With the development of aerospace and aviation industries, high-strength and high-strength carbon fibers have also appeared, and their elongation is greater than 2%. The largest amount is polyacrylonitrile PAN-based carbon fiber, and the main raw material of THINKTANK Venturi valve is this kind of PAN-based carbon fiber. The valve body made of carbon fiber is light in weight, easy to install, high in strength, and the anti-corrosion property can reach 10 grades, which meets the harsh environmental requirements of the laboratory and fully guarantees the safety of the laboratory.

THINKTANK carbon fiber venturi valve has unique pressure independence, and the air volume has been strictly debugged and calibrated before leaving the factory. Therefore, when installing the valve, it is not necessary to set straight pipe sections before and after the valve, even after the air pipe elbow, and variable diameter, Immediate installation of the variable air volume Venturi valve can also guarantee its good performance. It is mainly used in all places that require high air volume precision, such as air supply and return air in clean rooms, animal rooms, biosafety laboratories, air supply and exhaust systems in hospitals and GMP pharmaceutical factories, and rooms and ventilation in physical and chemical laboratories. Cabinets, reagent cabinets, and exhaust hood air supply and exhaust systems.

In extreme laboratory environments such as high temperature and high pressure, the industry’s first THINKTANK carbon fiber venturi valve still has many excellent characteristics other than ordinary venturi valves, such as high strength, high modulus, low density, no creep, and non-oxidizing Ultra-high temperature resistance in the environment, good fatigue resistance, small thermal expansion coefficient and excellent corrosion resistance. In recent years, it has gradually become the first choice for middle and high-end laboratories.

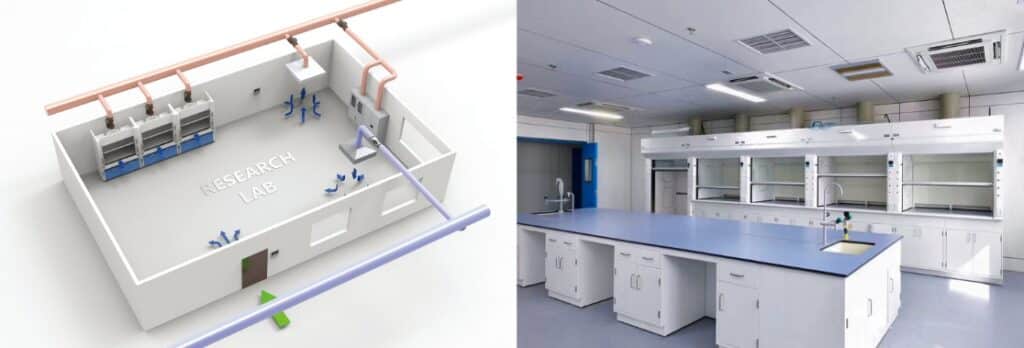

Wide Range of Applications of Venturi Valves

Venturi valves can be used in a variety of critical environments, including laboratories, cleanrooms, hospitals, and pharmaceutical manufacturing facilities. Their versatility and reliability make them a popular choice for professionals in various industries.

1. HVAC control systems

Venturi valves are devices used in HVAC control systems to regulate airflow and pressure levels. They consist of a tube or pipe with a small opening in the center, known as a throat. When fluid passes through the throat, it creates a vacuum that pulls air from the surrounding areas into the system, creating precise air pressure control. The flow rate can also be adjusted by inserting an adjustable valve into the valve body to achieve desired results.

2. Chemistry lab

Chemical labs carry out important scientific activities like research, development, testing, and teaching. However, conducting chemical experiments can produce hazardous pollutants that pose significant challenges to the safety and health of experimenters and the laboratory’s facilities and equipment.

To maintain a safe airflow environment in the lab, the ventilation system requires a significant amount of energy and incurs high costs. It also becomes challenging to control the temperature and humidity, making it difficult to ensure a comfortable indoor environment.

THINKTANK will provide the overall HVAC system control solution for chemical laboratories, including fume hood variable air volume control, automatic control of the fume hood window, the overall negative pressure control of the laboratory, frequency conversion control of ventilation and exhaust system, air-conditioning unit control, and man-machine interface and monitoring system interface.

- Fume hood variable air volume control

Through real-time monitoring and control of the surface wind speed of the fume hood to keep it within the safe surface wind speed range (0.3~0.5m/s), it not only prevents the escape of experimental pollutants but also achieves significant energy saving.

- Automatic control of the fume hood window

When the experimental operator leaves the fume hood, the window will automatically drop and reduce the exhaust air volume, which can save a lot of exhaust energy consumption, and easily control windows opening.

- The overall negative pressure control of the laboratory

Through monitoring and control of the pressure difference between indoors and outdoors, ensure a stable negative pressure in the room and prevent the leakage of indoor pollutants.

- Frequency conversion control of ventilation and exhaust system

When the indoor exhaust air volume is adjusted and changed, by controlling the frequency conversion fan, the indoor air supply and exhaust air can not only meet the necessary ventilation but also ensure moderate energy saving.

- Air-conditioning unit control

While ensuring the ventilation and exhaust requirements of the system, the air-conditioning comfort in the room can be ensured by precisely controlling the temperature and humidity of the air supply in the room or the unit.

Man-machine interface and monitoring system interface: The laboratory area is equipped with an operable display screen, and the user can directly monitor the area-level air supply and exhaust air volume, temperature and humidity, pressure and other parameters; the standard communication protocol supports higher-level monitoring system integration Require.

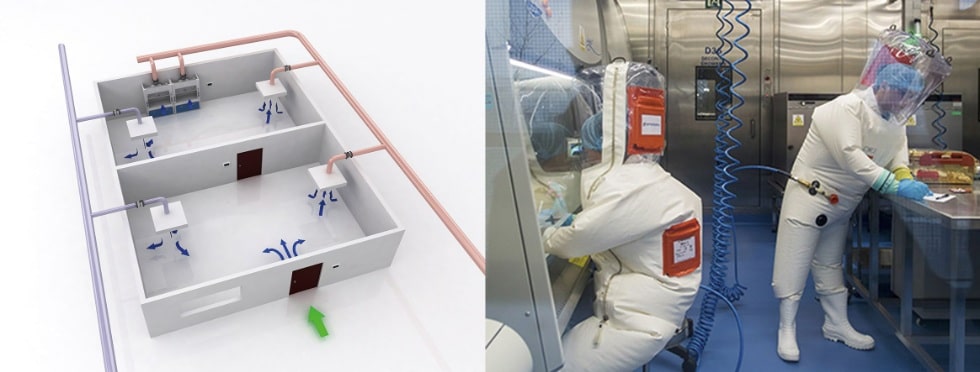

3. Biology laboratory

There are potential hazards of various microorganisms, germs, and viruses in the biological laboratory. In order to ensure the safety and health of the entire area, the air conditioning and ventilation system needs precise, fast and reliable control; the pressure matching and balanced control of each experimental room requires careful and precise air volume configuration; under this condition, it is also necessary to ensure comfortable temperature and humidity.

- High-performance Venturi valve control

The high-performance Venturi valve can ensure accurate and fast air volume control in each room of the biological laboratory, including constant air volume control and variable air volume control. The unique performance of the Venturi valve can ensure the stable adjustment and switching of the air volume in a very short time, and ensure that the air volume remains constant under the fluctuation of the system pressure.

- Air volume distribution control for each room

Through the overall fast controller, according to the air volume demand of each room, responds immediately, quickly control the air supply and exhaust air volume of each room, and keep the air volume and pressure of the overall system stable.

- Frequency conversion control of the ventilation and exhaust air system

When the air supply and exhaust air in the room is adjusted and changed, adjust the frequency conversion fan to meet the required air volume, keep the system pressure relatively stable, and achieve the purpose of energy saving.

- Air-conditioning unit control

In the biological laboratory, a large number of filters are used, and its status needs to be monitored in time, and the required temperature, humidity, pressure, air volume, etc. need to be finely adjusted to achieve environmental comfort in the air-conditioned area.

- Man-machine interface and monitoring system interface

The biological laboratory needs to monitor the status of the ventilation and exhaust system in real-time, and realize the traceability of sensor status values and user operation records. The preservation of electronic data is realized through the local cache record of the controller, as well as higher-level monitoring systems and safety data systems.

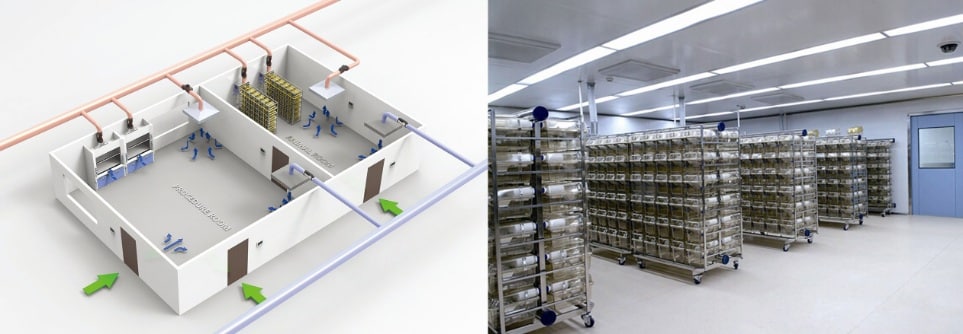

4. Animal room

The animal room has special environmental requirements to ensure the quality of animals and the accuracy and reliability of experimental research. There are a variety of rooms and laboratories with special functions in the animal room, including general-purpose functional rooms, corridors, and research facilities throughout. The area has a clean area and a polluted area. Each functional room and area has different room airflow organization requirements, and it is highly challenging to ensure its complex and changeable air supply and exhaust air control requirements.

THINKTANK VA series products can provide solutions and highly applicable products for the overall application of animal rooms, including:

- High-performance Venturi valve control

The high-performance and precise Venturi valve can meet the complex and strict air supply and exhaust requirements of various functional rooms and areas in the animal room. The constant air volume Venturi valve with small diameter can be used for reliable air flow and volume control of animal cages to ensure the safety of animals. Variable air volume and constant air volume Venturi valves of various calibers can guarantee to respond to changes in air volume demand and system pressure in a very short time.

- Regional ventilation and exhaust air control

Through the high-performance dedicated controller, the air supply and exhaust interlock control of each area and room is realized, including the direct connection control between Venturi valves, and it also supports real-time monitoring and control of the pressure difference in the area. Closed-loop control to achieve continuous and stable operation of the overall system.

- Frequency conversion control of ventilation and exhaust system

Various functional rooms and areas in the animal room may change due to the switching of working conditions and other conditions, and the overall demand for air supply and exhaust air volume is also changing. Through fine system pressure adjustment, the frequency conversion fan is realized. Adjustment, so as to not only ensure the stability of the working pressure of the system, but also achieve the purpose of optimizing energy saving.

- Air-conditioning unit control

Animal rooms have relatively high requirements for environmental cleanliness, temperature and humidity, outside air regulation, especially for animal breeding rooms. Air-conditioning unit controls must be precise, reliable, and trouble-free to operate, otherwise the safety of the animals will be jeopardized. Ensure a safe environment by using high-performance, high-reliability controllers, as well as high-reliability, proven control software and programs.

- Human-machine interface and monitoring system interface

The animal room has strict requirements on the environment, and there are also strict regulations on the relevant operating data and parameters of dynamic environment of the control system. The local real-time monitoring area environmental operating parameters can be set, and the traceable electronic data preservation of the entire system can be realized through a higher-level monitoring system interface.

5. Pharmaceutical plant

In pharmaceutical workshops, there are high technological requirements for the overall air-conditioning and ventilation environment, especially for air purification. At the same time, in order to prevent various types of pollution, the characteristics of the drug itself, the production process and the special requirements of the production line, etc., the environmental pressure, temperature and humidity need to be carefully planned and controlled. At the same time, due to the normative requirements of the industry, such as GMP certification and traceable electronic data records, higher requirements are put forward for the data preservation of the control system.

THINKTANK products can provide highly applicable products for pharmaceutical plants, including:

- High-performance air volume control valve

In the air conditioning and ventilation system of pharmaceutical factories, various air volume control air valves are used in various pipes and links, including both constant flow air volume and variable air volume control air valves of various calibers.

- Highly weather-resistant air volume sensor

The traditional duct air volume sensor uses a heat-sensitive or through-type differential pressure sensor to measure the duct air volume. However, due to impurities in the duct air, especially the exhaust system, it is easy to cause blockage and probe failure. The non-through-type weather-resistant differential pressure sensor greatly prolongs the service life and reduces maintenance.

- Frequency conversion control of ventilation and exhaust system

There may be changes in air volume demand in various areas and systems in the pharmaceutical factory building or pressure fluctuations caused by various reasons. Using frequency conversion to control fans can ensure real-time and stable air volume and pressure of air regulation in the system. Can achieve the purpose of energy saving.

- Air-conditioning unit control

Pharmaceutical production has strict air-conditioning process requirements, and a large number of filters will be used to control the temperature and humidity of the air-conditioning unit accurately and stably, so as to ensure the safety of pharmaceutical production. High-performance, high-reliability dedicated controllers and proven high-reliability control programs are used to meet the environmental requirements of pharmaceutical workshops.

- Human-machine interface and monitoring system interface

Due to the particularity of the industry, the operating parameters and data and operation records of the relevant air-conditioning control system in the pharmaceutical production process must be traceable, and high-reliability data preservation cannot be artificially changed. The compliance of the overall management system is achieved through interfaces that meet the specification requirements.

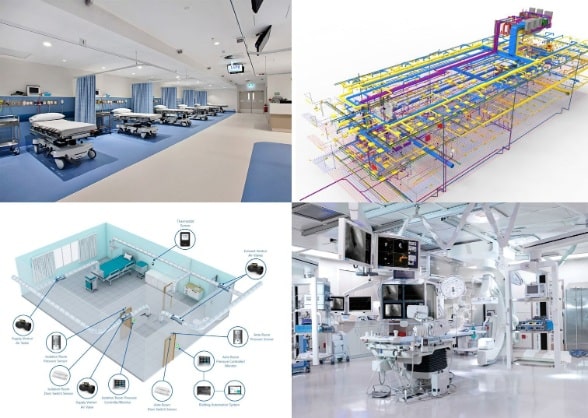

6. Hospital

In a hospital environment, different areas and functional centers have different requirements for air conditioning and ventilation systems. For example, forwards and outpatient clinics, it is mainly to ensure the desired airflow organization in each area, to prevent cross-infection, and to ensure a certain temperature and humidity comfort requirements in the room; for places with high cleanliness requirements such as operating rooms, the air cleanliness requirements must first be met, followed by temperature and humidity environmental requirements. At the same time, in some hospital environments, there are also biochemical laboratories and testing laboratories, and the requirements are similar to those of chemical and biological laboratories.

In such an intricate system, THINKTANK products can provide overall highly applicable products and systems, including:

- High-performance air volume control valve

In the entire air-conditioning and ventilation system, the air volume control valve can be applied to various occasions that require air volume, pressure, and airflow organization to achieve precise air volume control for each system and terminal.

- Frequency conversion control of the ventilation and exhaust system

The operation of the hospital may have obvious time and load characteristics. Under different ventilation and exhaust requirements, the frequency conversion fan control is adopted to realize the ventilation and exhaust requirements of the system and achieve energy saving at the same time.

- Control of air-conditioning units

In the hospital environment system, for various types of fresh air and return air air-conditioning units, the control requirements are complex and changeable, and involve different climate characteristics in different regions, resulting in different control requirements. In order to ensure the safe operation of the entire air-conditioned ventilation environment, the control of the air-conditioning unit must be carefully planned and controlled.

- Man-machine interface and monitoring system interface

Standard communication interface, which can support local information panel display, and also support higher-level hospital comprehensive information management system integration, so as to realize the overall automation and information management requirements of the hospital.

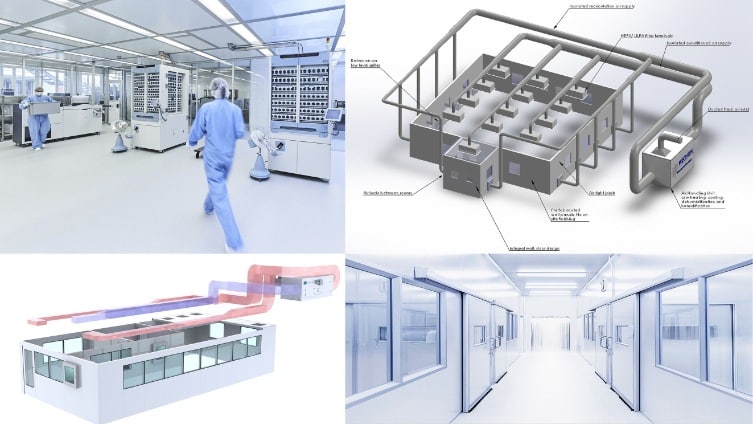

7. Clean workshop

In the electronics, semiconductor, food and other industrial industries, for production plants, workshops, or certain functional areas, due to the characteristics of the products produced, or the requirements of the production process, the cleanliness of the environment is required to be high, so that the quality of the products can be guaranteed, or The production of products is carried out. For the cleanliness requirements of the air conditioning ventilation system, the key is to ensure the precise control of the air supply and exhaust volume.

THINKTANK products provide highly applicable products and systems that meet these cleanliness requirements, including:

- High-performance air volume control valve

In order to ensure the precise control of the air supply and exhaust air volume, a high-performance air volume control valve is used to maintain the stability of the air volume under the condition of air volume demand and pipeline pressure changes, including constant air volume valves of various calibers, Variable air volume valve.

- Highly weather-resistant air volume sensor

The traditional duct air volume sensor uses a heat-sensitive or through-type differential pressure sensor to measure the duct air volume. However, due to impurities in the duct air, especially the exhaust system, it is easy to cause blockage and probe failure. The non-through-type weather-resistant differential pressure sensor greatly prolongs the service life and reduces maintenance.

- Frequency conversion control of the ventilation and exhaust system

In the system, the air volume demand or pressure changes, and the frequency conversion fan control is used to ensure the stability of the system pressure and air volume and realize energy saving at the same time.

- Man-machine interface and monitoring system interface

Various air volume control valves and controllers are equipped with standard communication interfaces, which support local user panel display and also support the integration of the monitoring and management system of the entire plant.

Benefits of Venturi Valves in Critical Environments

Improved Indoor Air Quality

By providing precise airflow control, Venturi valves help maintain the optimal indoor air quality in critical environments. They prevent contaminants and pollutants from entering sensitive spaces, ensuring the safety of both occupants and processes.

Enhanced Safety and Compliance

Venturi valves contribute to a safer environment by maintaining consistent air pressure and preventing hazardous pressure fluctuations. Their accurate airflow control ensures compliance with industry regulations and standards, such as ASHRAE, ANSI, and ISO.

Cost Savings

The energy efficiency of Venturi valves leads to reduced operational costs for facilities. By minimizing energy consumption and maintenance requirements, these valves offer significant cost savings over the long term.

Venturi Valves: The Preferred Choice for Critical Environment Controls

In conclusion, Venturi valves are the ultimate solution for critical environment controls. Their precise airflow control, energy efficiency, and easy installation make them a popular choice for professionals in various industries. By ensuring improved indoor air quality, enhanced safety, and compliance, Venturi valves contribute to the overall performance and cost-effectiveness of HVAC systems in critical environments.