As a seasoned engineering professional, you understand the importance of selecting the right gate valves for your industrial applications. At Shanghai Thinktank Process Management Co., Ltd, we share your commitment to excellence and recognize the need for high-quality, cost-effective solutions that meet local market demands. Our THINKTANK brand is dedicated to providing top-tier gate valves, backed by our extensive industry experience and expertise.

Introduction to Gate Valves

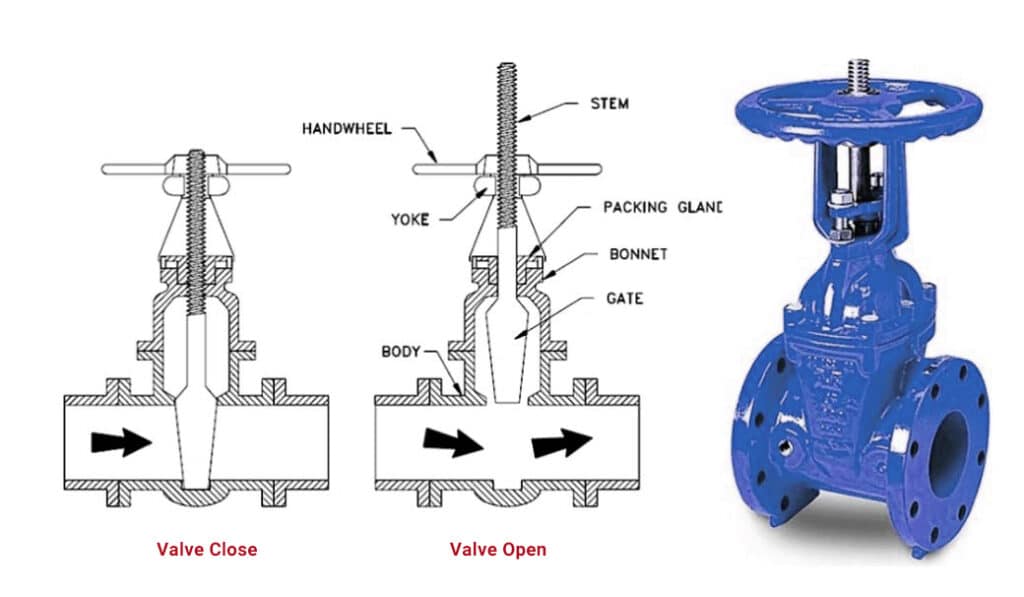

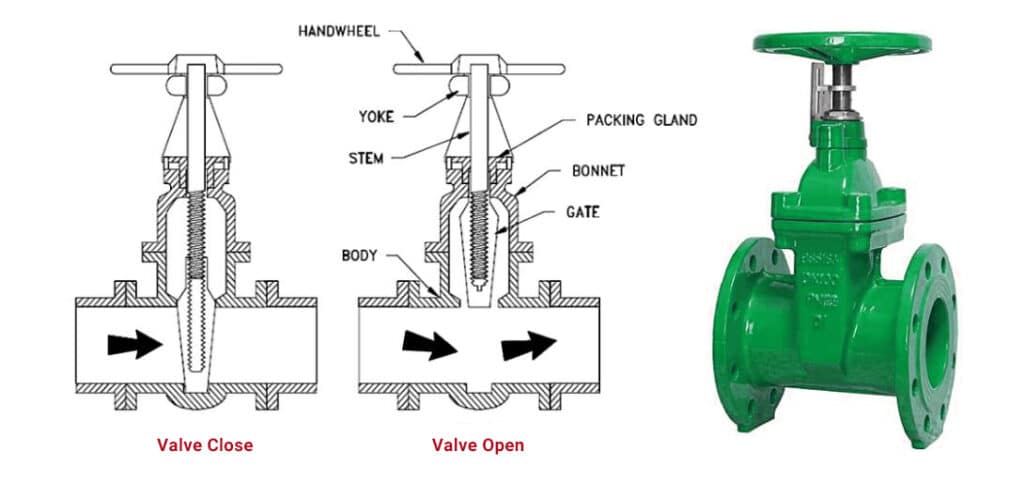

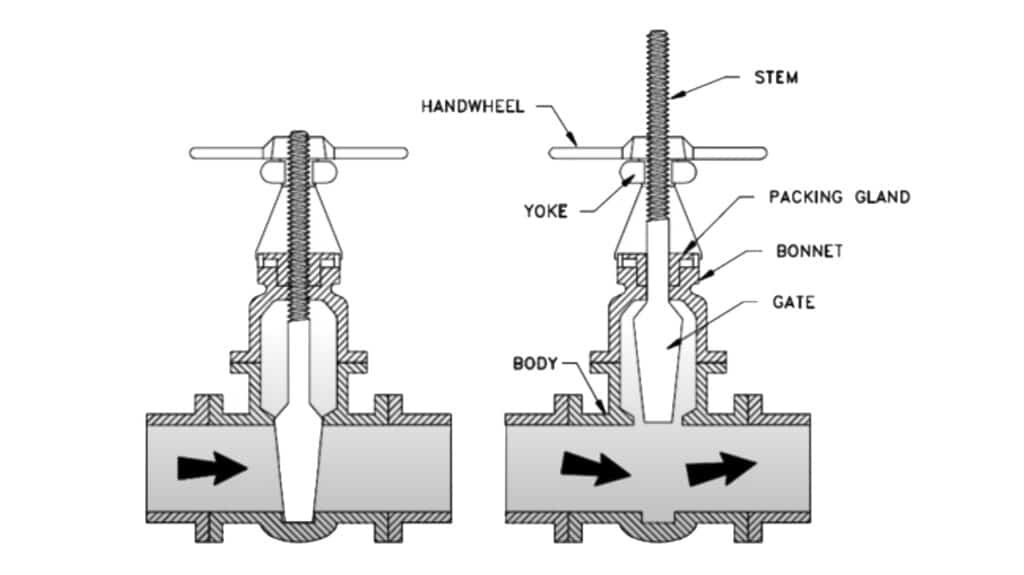

Gate valves are widely used in various industries due to their excellent shutoff capabilities and low-pressure drop. They control the flow of liquid or gas by raising or lowering a gate, which moves perpendicular to the flow direction. There are two main types of gate valves: rising stem gate valves and non-rising stem gate valves.

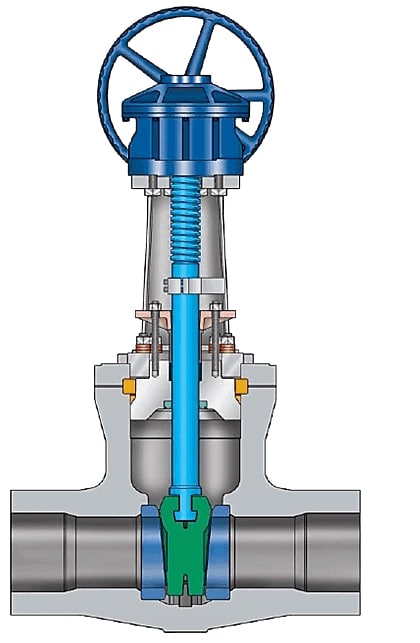

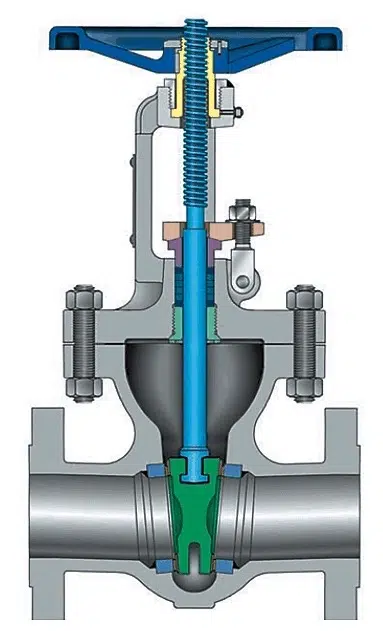

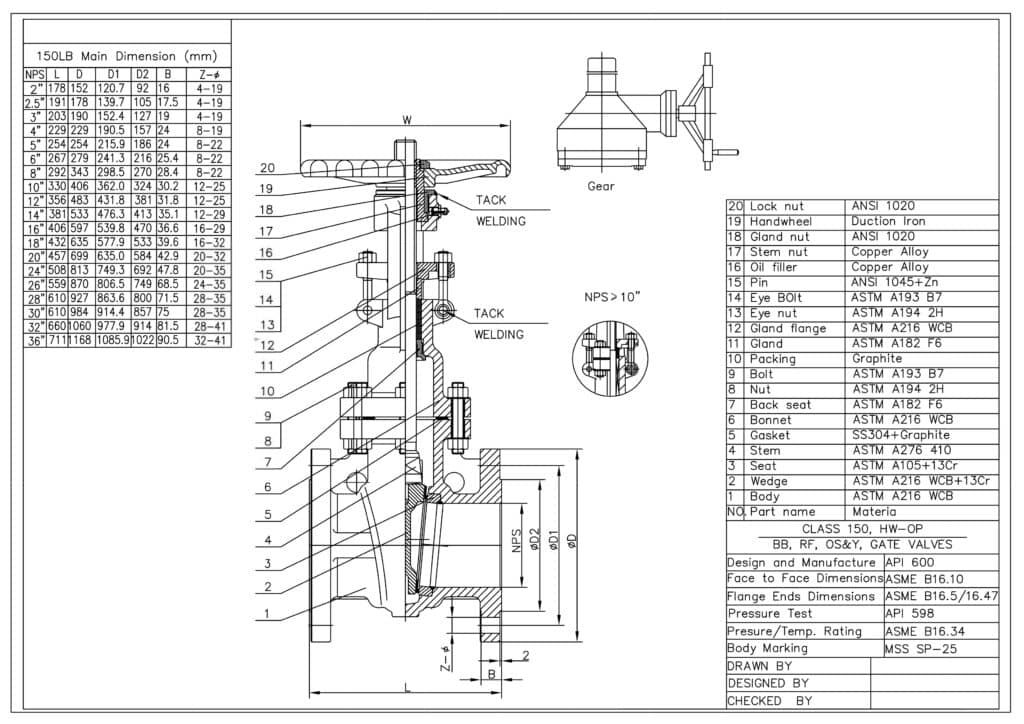

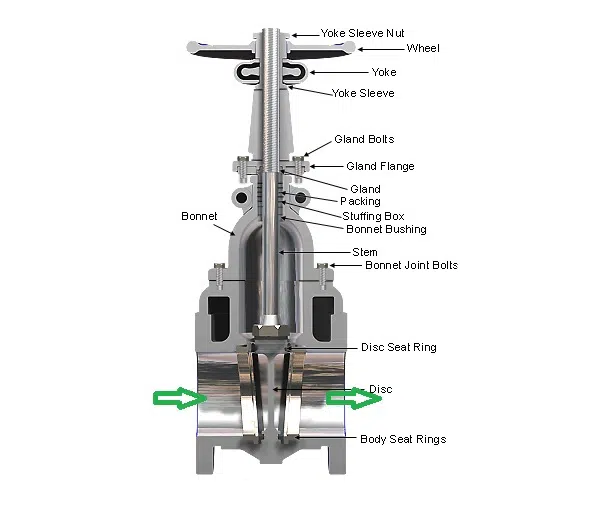

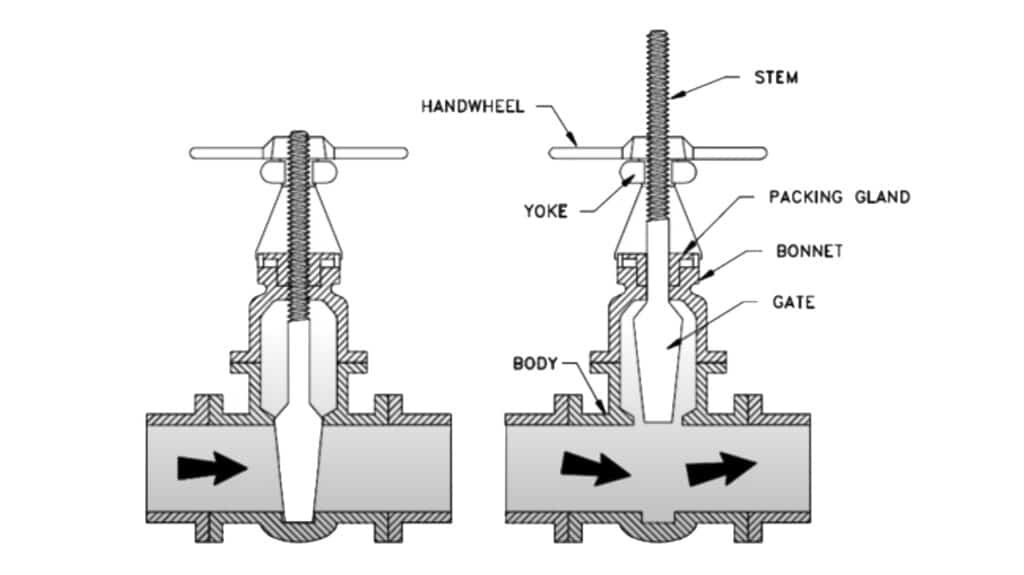

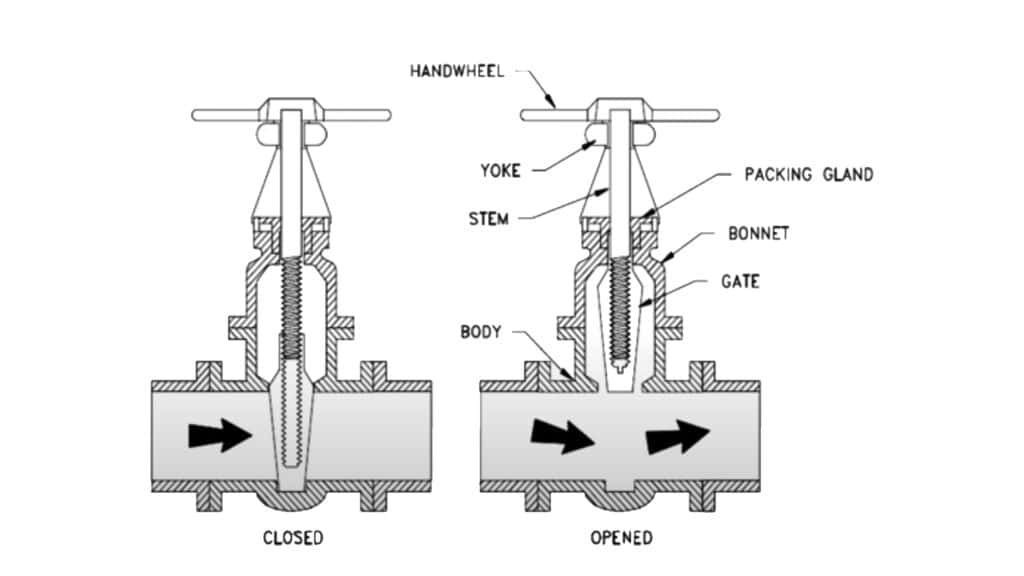

Images For Rising Stem Gate Valve and Non-Rising Stem Gate Valve

Rising Stem Gate Valve: Overview and Benefits

Rising stem gate valves feature a stem that rises vertically as the gate is lifted. The rising stem allows operators to visually determine the valve’s open or closed position, ensuring proper flow control.

What is a Rising Stem Gate Valve

A rising stem gate valve is a type of gate valve that features a stem that rises vertically as the gate is lifted to open or close the flow. This movement provides a clear visual indicator of the valve’s position, which is crucial for ensuring proper flow control and safety in various industrial applications.

THINKTANK: Your Reliable Supplier for Rising Stem Gate Valves

As a leading manufacturer and supplier of industrial valves, THINKTANK understands the importance of quality, reliability, and precision in gate valve design. Our rising stem gate valves are engineered with the highest standards, ensuring exceptional performance and durability even in the most demanding conditions.

Key Features of THINKTANK Rising Stem Gate Valves

- Robust Construction: Our rising stem gate valves are made from high-quality materials, such as cast iron, cast steel, stainless steel, and other corrosion-resistant alloys, providing superior strength and longevity.

- Precision Engineering: THINKTANK’s rising stem gate valves are designed with exacting tolerances and advanced manufacturing techniques, ensuring optimal sealing and smooth operation.

- Versatile Applications: Suitable for a wide range of industries, including oil and gas, petrochemical, power generation, and water treatment, our rising stem gate valves can handle high-pressure and high-temperature systems.

- Customization Options: At THINKTANK, we understand that each application is unique, and we offer customized solutions to meet your specific requirements, including various end connections, pressure ratings, and body materials.

By choosing THINKTANK as your reliable supplier for rising stem gate valves, you can be confident in the quality and performance of our products. Our expert team is dedicated to providing exceptional customer service, technical support, and timely delivery to ensure your projects run smoothly and efficiently.

Advantages of Rising Stem Gate Valve

- Visual Indicator: The rising stem provides a clear visual indication of the valve’s position, which is essential for safety and operational efficiency.

- Easier Maintenance: Rising stem gate valves enable easier access to the stem and packing, allowing for quicker maintenance and reduced downtime.

- Less Friction: As the stem rises, it experiences less friction against the gate, leading to less wear and tear on the valve components.

Non-Rising Stem Gate Valves: Overview and Benefits

Non-rising stem gate valves have a stem that remains stationary while the gate moves up and down. The stem is threaded and connects directly to the gate, making these valves more compact than their rising stem counterparts.

Advantages of Non-Rising Stem Gate Valve

- Space-saving Design: The non-rising stem valve’s compact design makes it suitable for installations with limited space.

- Lower Cost: Non-rising stem gate valves tend to be more affordable due to their simpler design and fewer components.

- Reduced Risk of Leakage: With fewer exposed parts, non-rising stem gate valves have a lower risk of stem leakage.

How does a non-rising stem valve work

A non-rising stem gate valve functions by using a threaded stem that remains stationary while the gate moves up and down to open or close the flow. The stem is threaded on the inside and connects directly to the gate, which moves along the stem’s threads when the handwheel is rotated.

Here’s a step-by-step explanation of how a non-rising stem valve works:

- Closing the valve: When the handwheel is turned clockwise, the gate moves downward along the threaded stem, gradually closing off the flow path. As the gate makes contact with the valve seat, it forms a tight seal, preventing fluid or gas from passing through the valve.

- Opening the valve: To open the valve, the handwheel is turned counterclockwise. This action causes the gate to move upward along the threaded stem, creating a passage for the fluid or gas to flow through the valve.

- Position indication: Unlike rising stem gate valves, non-rising stem valves do not provide a clear visual indication of the valve’s position. However, the position can often be determined by the number of handwheel turns or by using position indicators mounted on the handwheel or stem.

THINKTANK is committed to providing high-quality non-rising stem gate valves that deliver reliable performance across various applications. Our expert team is available to assist you in selecting the most suitable valve for your specific needs, ensuring optimal functionality and efficiency in your projects.

Comparing Rising Stem and Non-Rising Stem Gate Valve

Both rising stem and non-rising stem gate valves have their unique advantages, making them suitable for different applications. Here’s a comparison of their key features:

| Feature | Rising Stem | Non-Rising Stem |

|---|---|---|

| Visual Indicator | Yes, clear position indication | No, position not easily visible |

| Maintenance Ease | Easier, accessible stem and packing | More difficult, limited access |

| Friction | Lower, less wear and tear | Higher, increased wear and tear |

| Space Requirement | More space is needed, larger stem area | Compact design, ideal for tight spaces |

| Cost | Generally higher, due to complex design | Generally lower, simpler design |

| Risk of Leakage | Higher due to exposed stem | Lower, fewer exposed parts |

| Applications | Suitable for high-pressure and high-temperature systems | Ideal for space-constrained, low to moderate-pressure systems |

It’s essential to consider these differences when choosing a gate valve for your specific requirements. For instance, if visual indication and easy maintenance are top priorities, a rising stem gate valve might be the better choice. On the other hand, if space limitations and cost are significant concerns, a non-rising stem gate valve could be the ideal solution. Ultimately, the decision should be based on the specific needs of your application and the factors most important to your project’s success.

Which gate valve is the most widely used

As a professional valve manufacturer, THINKTANK recognizes that gate valves are utilized across a diverse range of industries and applications. However, it is challenging to pinpoint a single gate valve type as the most widely used, as the choice depends on the specific requirements and conditions of each application.

That being said, the two most common types of gate valves are the rising stem gate valve and the non-rising stem gate valve. Each has its own unique advantages and is suitable for different situations:

- Rising Stem Gate Valves are preferred when a clear visual indicator of the valve’s position is crucial for operational safety and efficiency. They are also ideal for high-pressure and high-temperature systems, such as those found in the oil and gas, petrochemical, and power generation industries.

- Non-Rising Stem Gate Valves are the go-to choice for installations with space constraints, as their compact design allows for easy integration into tight spaces. These valves are typically used in low to moderate-pressure systems and are suitable for applications in water treatment, building services, and general industrial processes.

At THINKTANK, we strive to provide high-quality gate valves tailored to the specific needs of our customers. Our expert team is always available to assist you in selecting the most suitable gate valve type for your unique application, ensuring optimal performance and reliability for your projects.

Conclusion

Selecting the right gate valve for your industrial applications is a critical task that demands a thorough understanding of the advantages and disadvantages of each valve type. As a leading brand by Shanghai Thinktank Process Management Co., Ltd, THINKTANK is committed to offering top-quality gate valves that deliver on performance without compromising on cost-efficiency. We trust that the information provided in this guide will help you make an informed decision that aligns with your requirements and contributes to the success of your projects. Should you have any further questions or need assistance in selecting the perfect gate valve, our experienced team of professionals is always here to help.