Description

Product Name: Pneumatic Diaphragm Actuator

Type: Spring return diaphragm

Action: Reverse acting or direct acting

Supply air pressure: 260 to 800 kPa

Air connection: 1/4 NPT or 3/8 NPT

Optional accessories: Positioner, Pressure regulator with filter, Limit switch, Solenoid valve, Handwheel, etc,

I. APPLICATION AREA

The multi-spring diaphragm pneumatic actuators are applied for the modulating operation of control valves in industrial automatic systems. There are three following design options for the actuator:

– direct action (air – advances the steam)

– reverse action (air – retracts the steam)

– direct action, handwheel

– reverse action, handwheel

II. FEATURES

· Completely reversible action, option to change spring range w/o extra parts.

· Rigid structure of cast yoke.

· Wide range of the available forces.

· Linear relationship between rod displacement and control pressure as a result of using membranes with constant active area.

· Various ranges of spring pressures due to the changeability of spring number and /or dislocation of distance fencers.

· Capability of the actuator to incorporate side-mounted handwheel, pneumatic or electro-pneumatic positioners, limit switches, air sets, three-way pneumatic solenoid valves, lockup valves, position transducers.

· High strength of diaphragms, springs, and packings.

· Small size and weight.

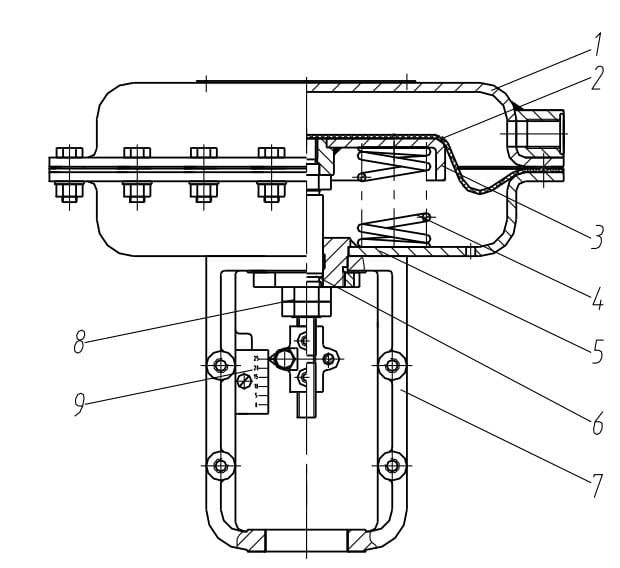

(a)Direct-acting Pneumatic Diaphragm Actuator(PZMA)

1. Up diaphragm castings 2. Diaphragm

3. Diaphragm plate 4. Spring

5. Down diaphragm castings 6. Actuator stem

7. Yoke 8. Adjust nut

9. Travel indicator

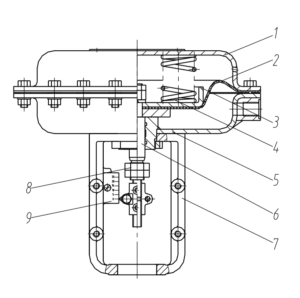

(b)Reverse-acting Pneumatic Diaphragm Actuator(PZMB)

1. Up diaphragm castings 2. Diaphragm

3. Diaphragm plate 4. Spring

5. Down diaphragm castings 6. Actuator stem

7. Yoke 8. Adjust nut

9.Travel indicator