Description

Brief of DIN Gate Valve with Bellows

THINKTANK DIN Gate Valve is engineered to comply with the stringent DIN specifications, ensuring consistent quality and reliability. The innovative bellows design provides superior leak protection, extending the valve’s service life and reducing maintenance requirements.

Key Features of Our DIN Gate Valve with Bellows

- Bellows Seal: The valve’s bellows seal is a flexible, metallic component that ensures a tight, leak-free connection between the valve’s moving parts. This unique design prevents fluid leakage and reduces maintenance requirements.

- DIN Standard: Designed and manufactured according to the German Industrial Standards (DIN), this gate valve provides reliable performance and high-quality construction for various industries and applications.

- Durable Construction: Made from high-quality materials, such as cast iron, cast steel, stainless steel, or alloy steel, the DIN Gate Valve with Bellows is built to withstand harsh industrial environments and provide a long service life.

- Bi-directional Flow: This gate valve is designed for bi-directional flow control, allowing for fluid flow regulation in both directions with minimal pressure drop.

- Stem Design: The valve features a rising or non-rising stem design, depending on the application requirements. The rising stem offers a better visual indication of the valve position, while the non-rising stem is ideal for applications with limited space.

- Actuation Options: The DIN Gate Valve with Bellows can be operated manually, using a handwheel, or automatically, such as electric, pneumatic, or hydraulic actuators, depending on the application and system requirements.

- Versatile Applications: This gate valve is suitable for various applications, including water, steam, gas, oil, and other non-corrosive fluid handling systems, in industries such as power generation, chemical processing, oil and gas, and more.

Advantage THINKTANK DIN Gate Valve

- Enhanced Leak Protection: The bellows seal design provides a hermetic seal, minimizing fluid leakage and reducing the risk of fugitive emissions.

- Low Maintenance: The bellows seal design reduces the need for frequent maintenance and replacement of sealing components, lowering operational costs.

- Reliable Performance: The DIN standard ensures that the valve meets strict quality and performance requirements, providing reliable operation in demanding applications.

- Extended Service Life: The durable construction and materials used in the valve ensure a long service life, even in harsh industrial environments.

- Easy Operation: The various actuation options available allow for easy operation and integration into existing control systems.

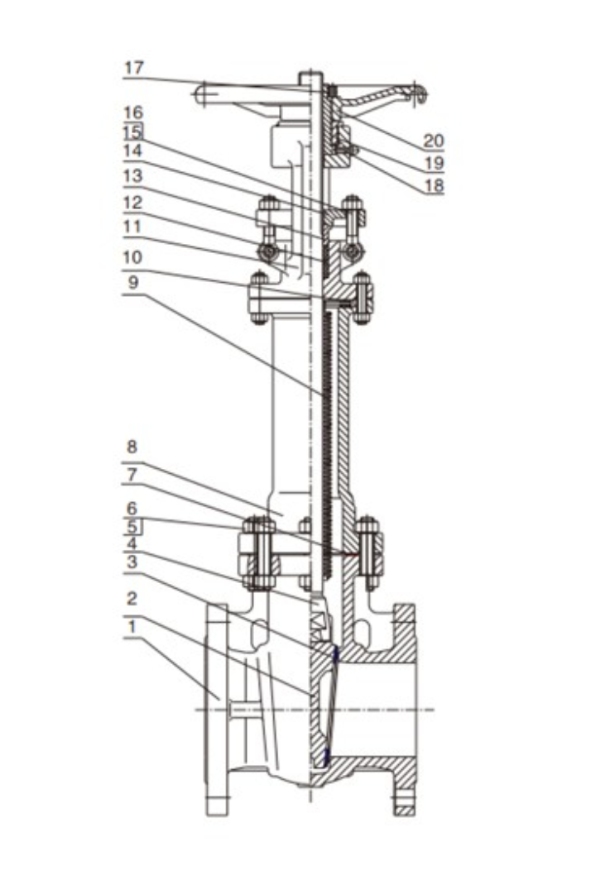

Parts of DIN Gate Valve with Bellows

| No. | Parts Name | Materials | No. | Parts Name | Materials |

| 1 | Body | 1.0619 | 11 | Packing | Graphite |

| 2 | Disc | A351 CF8 | 12 | Pressing sleeve | A105 |

| 3 | Stem | F304 | 13 | Pressing sleeve | A105 |

| 4 | Bolt | A193 B7 | 14 | Pin | A276 410 |

| 5 | Nut | A194 2H | 15 | Gland eyebolt | A193B7 |

| 6 | Gasket | 304+Graphite | 16 | Nut | A914 2H |

| 7 | Bonnet | 1.0619 | 17 | Handwheel | WCB |

| 8 | Bellows | SS304 | 18 | Bearing | 1035 |

| 9 | Bellows cover | SS304 | 19 | Oil nipple | H62 |

| 10 | Gasket | 304+Graphite | 20 | Stem nut | QT400-15 |

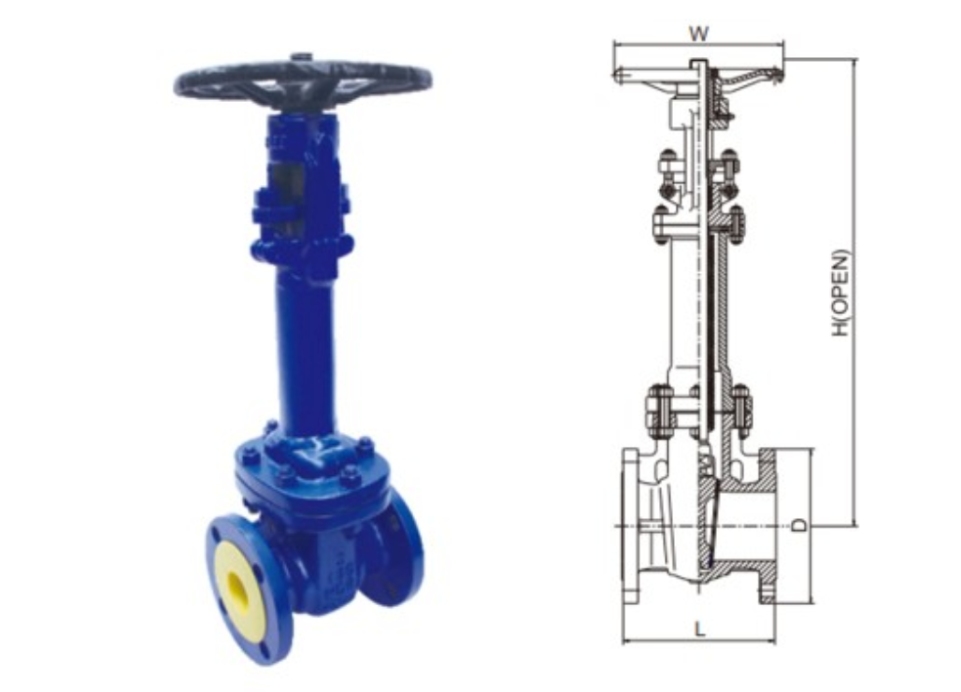

DIN Gate Valve with Bellows Dimensions

| Pressure rating | PN16 | ||||||||||||||

| Size | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| L | 108 | 117 | 127 | 140 | 165 | 175 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 |

| H | 200 | 210 | 250 | 260 | 290 | 370 | 398 | 440 | 490 | 530 | 580 | 670 | 760 | 850 | 950 |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 |

| Weight(kg) | 8 | 9 | 10 | 15 | 22 | 30 | 43 | 57 | 73 | 105 | 150 | 190 | 270 | 380 | 480 |

| Pressure rating | PN25 | ||||||||||||||

| Size | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| L | 140 | 152 | 165 | 178 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 457 | 457 | 502 | 762 |

| H | 200 | 210 | 250 | 260 | 290 | 370 | 398 | 440 | 490 | 530 | 580 | 760 | 760 | 850 | 980 |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 |

| Weight(kg) | 9 | 10 | 12 | 17 | 23 | 34 | 50 | 65 | 82 | 115 | 165 | 210 | 300 | 420 | 560 |

| Pressure rating | PN40 | ||||||||||||||

| Size | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| L | 165 | 190 | 216 | 229 | 241 | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 |

| H | 200 | 210 | 250 | 260 | 290 | 370 | 398 | 440 | 490 | 530 | 580 | 670 | 760 | 850 | 980 |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 |

| Weight(kg) | 9 | 10 | 12 | 18 | 25 | 38 | 53 | 70 | 88 | 125 | 175 | 225 | 310 | 440 | 560 |

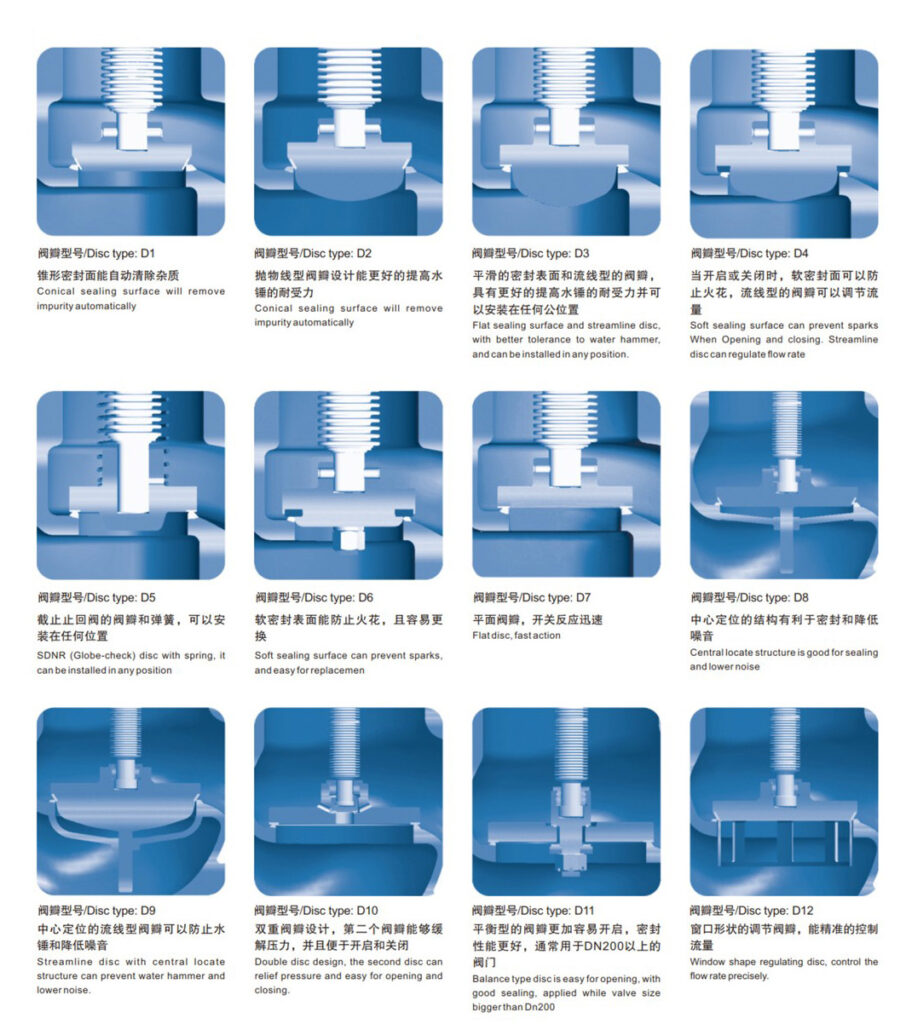

Available Disc Types

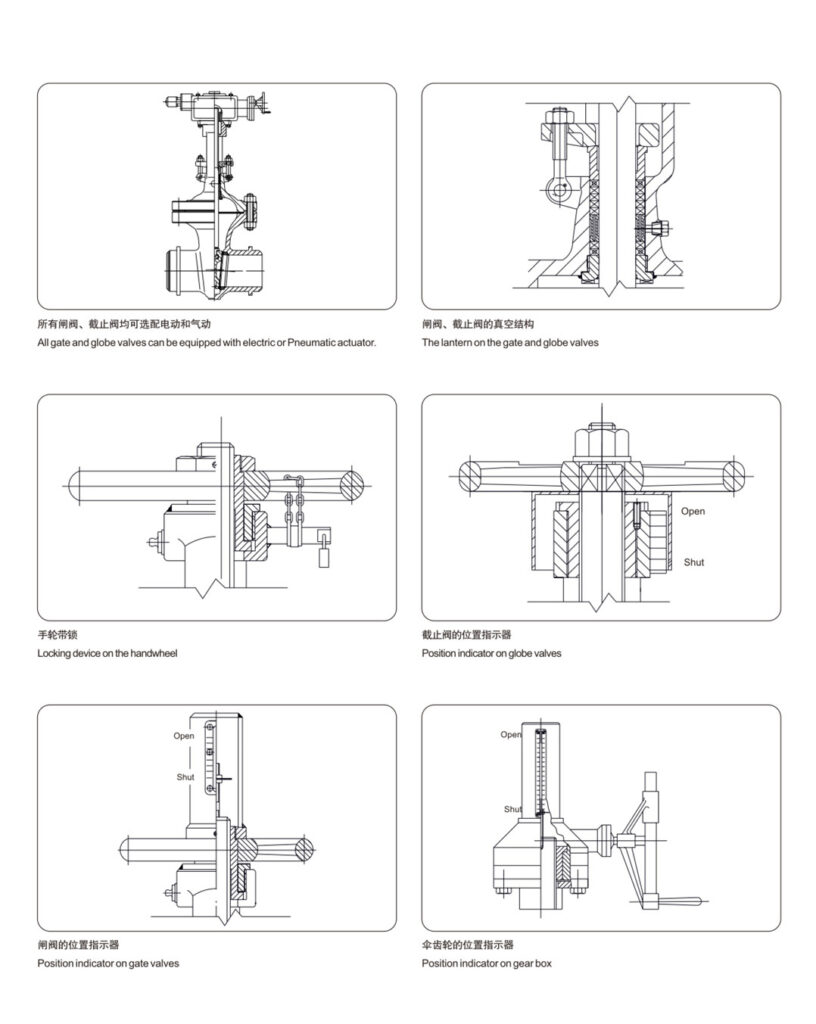

Special Design On Handwheel