Description

Research Control Valve Specification

- Size: 3/4″~1-1/4″

- Design Pressure: PN160

- Connection: NPT, GB

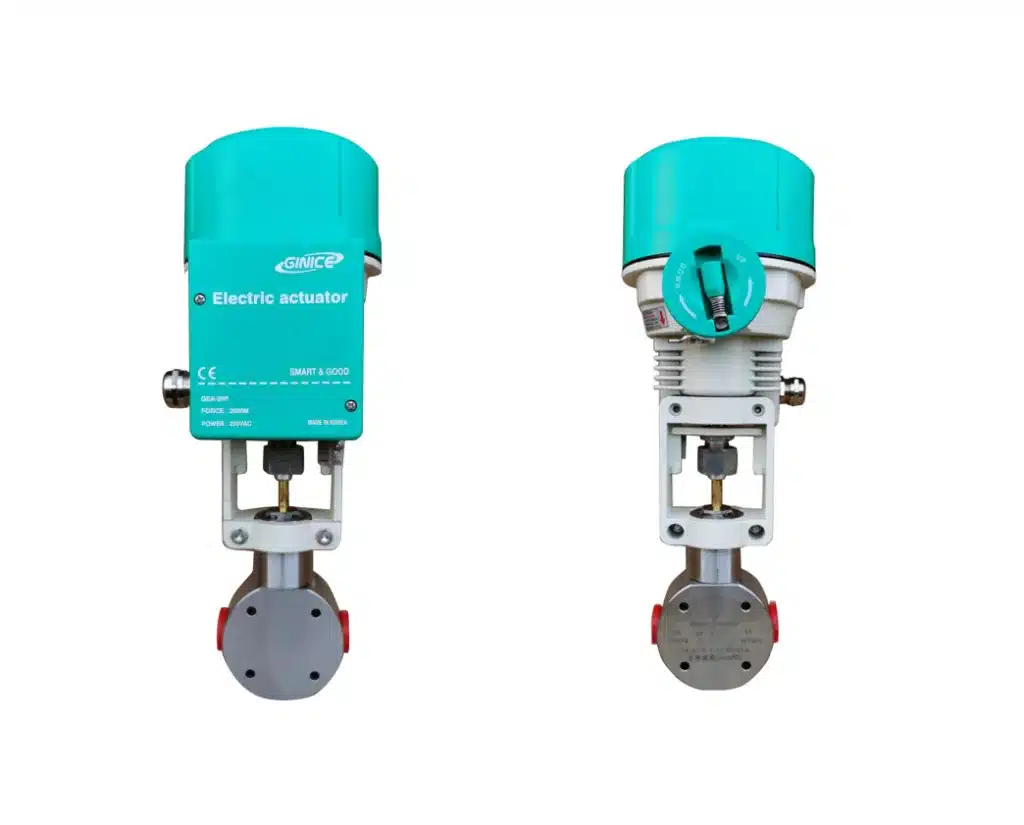

- Control Mode: Electric Regulating Type, Electric Switching Type

- Structure: Needle Valve Seat

Advantages of Research Control Valve

1. Small size and light weight.

2. The valve body is made of raw material forging, high pressure resistance is outstanding, the valve internal parts can be disassembled, reducing the maintenance cost, to ensure that the equipment can be a long-term stable operation, to eliminate leakage.

3. High regulation precision, through the electric actuator slowly adjust to control the spool of the valve tiny outlet, to realize the flow of tiny precise control, to maintain the pressure required for the separation of water molecules inside the membrane, to control the discharge of concentrated water.

4. Eliminate cavitation, high noise, piping vibration and other problems caused by high-speed fluid flow.

5. Fluid passes through labyrinth type valve cage to realize multi-stage pressure reduction. A full range of valve sizes is available with reduced internals and inherently adjustable ratios up to 100:1 to provide a wide range of flow capacities. Packing seal plus O-ring double sealing ensures that the valve has no external leakage.

6. Different model of electric actuators are available to meet the needs of low pressure drop to high pressure drop.

Unique Features

1. High Precision

All imported precision electric actuator slowly open and close to control the valve core tiny outlet holes, to realize the flow of tiny precise control.

2. Long Service Time

All contact media materials are used 316L/2507/904L and other materials, the structure of the control valve can be disassembled, low maintenance costs, to ensure the long-term stable operation of the equipment. Different needs using different special treatment of the valve needle to ensure that the service life.

3. Compact Structure Design

Simple structure, small volume, easy to install, meet the needs of various sizes of flow.

4. Special Tools

Equipped with special tools and wearing parts to facilitate late maintenance.

Served Industries

• Water & Wastewater

• Chemical

• Gas

• Oil

• General Manufacturing

• Pharmaceuticals

• Aerospace

Specialized Conditions

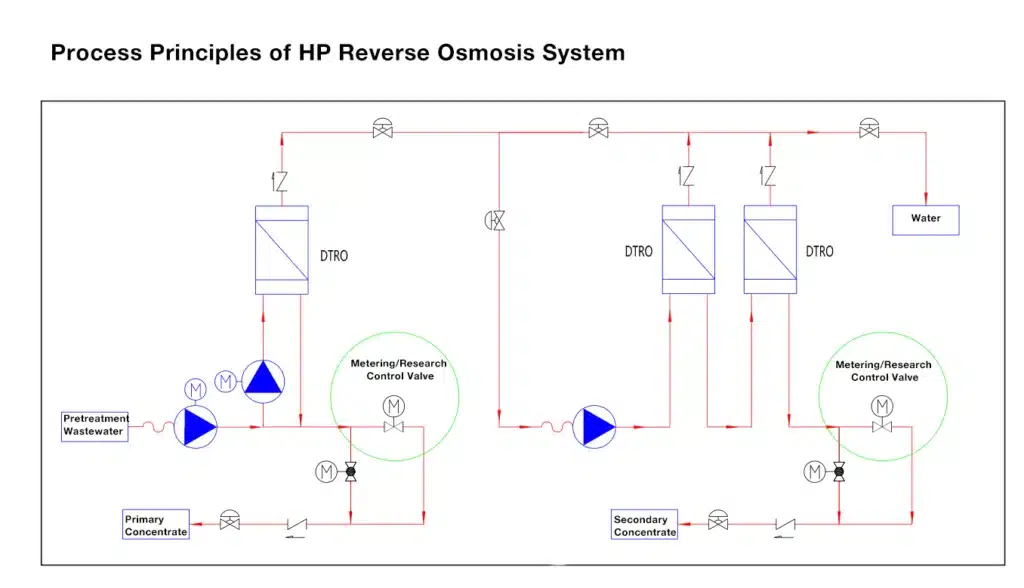

Concentrated water Metering control valve is a high-precision control valve developed for high-pressure, low-flow fluid control. In the harsh conditions of special water treatment areas, such as waste leachate, seawater desalination, zero discharge of industrial wastewater and other mixed complex composition of the fluid, can provide high-performance regulation and control.

Concentrated water metering control valve in reverse osmosis RO membrane device, high-pressure reverse osmosis DTRO membrane device, high-pressure reverse osmosis STRO membrane device and so on. By controlling the pressure of the membrane in reverse osmosis, it improves the water production rate of the membrane separation equipment and completes the water quality standard treatment.

Electric concentrated water metering control valve is mainly used in the concentrated water discharge outlet of high pressure reverse osmosis membrane device, the product mainly plays the following roles in the whole process:

1. By adjusting the opening of the electric concentrated water control valve, it can control the flow rate of concentrated water discharge, regulate the pressure in the membrane, to ensure the pressure required for water separation in the reverse osmosis membrane, so improve the water production rate of the equipment, and reduce the discharge pressure after the concentrated water adjustment valve.

2. The electric adjustment is easy to realize remote control.

| Size(DN) | 3/8″、1/2″、3/4″、1″、1-1/4″ | |||||||||

| Seat Diameter(dn) | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 15 |

| Flow Coefficient CV | 0.006 | 0.016 | 0.16 | 0.25 | 0.4 | 0.63 | 1.0 | 1.6 | 2.5 | 4.0 |

| Nominal Pressure | PN16~PN320 | |||||||||

| Body Material | 304、316L、904L、2507、2205、HC276 | |||||||||

| Connection | Threaded Ends(G, NPT, ZG ), Flanged Ends(HG/T20592-2009) | |||||||||

| Rated Travel(mm) | 11 | 16.5 | ||||||||

| Bonnet Type | Standard Type, Cryogenic Type, extension Type, Bellows Type | |||||||||

| Plug Type | Needle, Cage Type | |||||||||

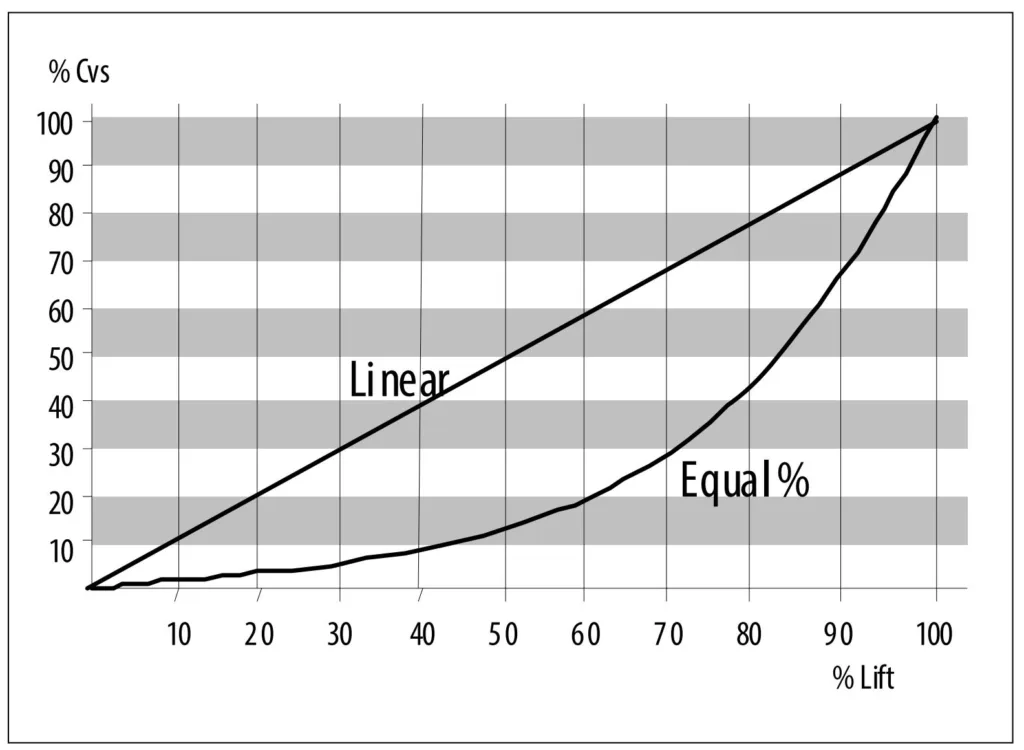

| Flow Characteristics | Equal Percentage, Linear Percentage | |||||||||

Flow Characteristic Curve