Karachi is one of the most populous cities in Pakistan, and it has become a major hub for industrial activity. As such, there is a significant demand for reliable and high-quality industrial valves that meet the strict safety standards set by the government. To cater to this need, numerous international and domestic valve manufacturers have established operations in Karachi.

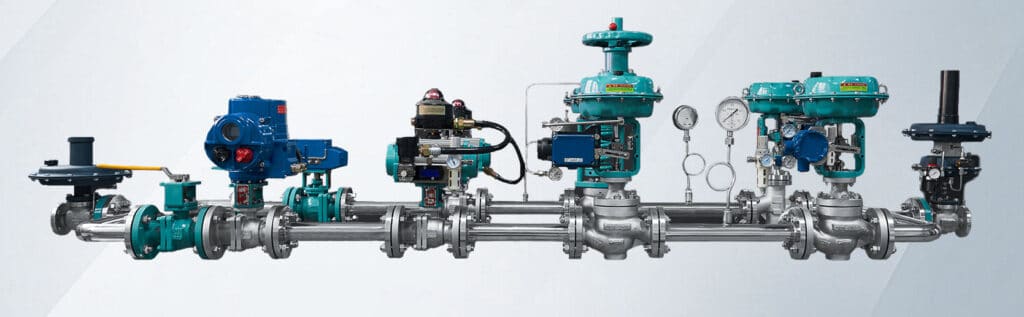

Here are some of the top industrial valve suppliers based in Karachi:

Dynaquip Controls

Founded in 1961, Dynaquip Controls has been an industry leader for over 50 years. They offer a wide range of products and solutions, from manual ball valves to automated control systems. With their own in-house engineering team and experienced technical support staff, they have established themselves as a reliable partner for businesses seeking quality valving solutions.

BWT Group (Pty) Ltd.

Established in 1965, BWT Group is another leading provider of quality valves and other related components across various industries. Their products range from water valves designed for corrosion protection to gas safety shutoff valves used in hazardous areas. They offer custom design services as well as specialized installation services.

BECO Valve Automation

A major player in the automation sector since 1997, BECO Valve Automation designs and manufactures customized solutions for process control applications such as slide gate valve automation, knife gate valve automation, isolation valve automation, and more. They provide end-to-end solutions with their unique product portfolio combined with local expertise and experience.

THINKTANK

THINKTANK is a traditional industrial valve family company, which has been active in various national industrial projects in Pakistan for the last decade. Over 30 years of experience in valve manufacturing and reliable valve quality have attracted many Pakistani trading companies, local valve distributors, and construction machinery companies to cooperate, which makes THINKTANK’s control valves, industrial valves, and regulators widely used in various industries around Pakistan.

Karachi is a bustling metropolis and the financial hub of Pakistan, with a thriving industrial sector that encompasses a wide range of businesses, from textile production to oil refining. This sector relies heavily on the smooth functioning of various types of industrial valves, which are used to control and regulate the flow of fluids and gases. In the following, we will take a closer look at the role that industrial valves play in the city’s industrial operations and why choosing the right valve for the job is so critical.

What are Industrial Valves?

Industrial valves are devices that are used to control, regulate, or shut off the flow of liquids, gases, and other fluids. They are designed to work in a wide range of harsh industrial environments and are typically made of high-quality materials that can withstand high temperatures, corrosive substances, and other harsh conditions. Industrial valves are used in a variety of applications, including chemical processing, oil and gas production, power generation, water treatment, and many others.

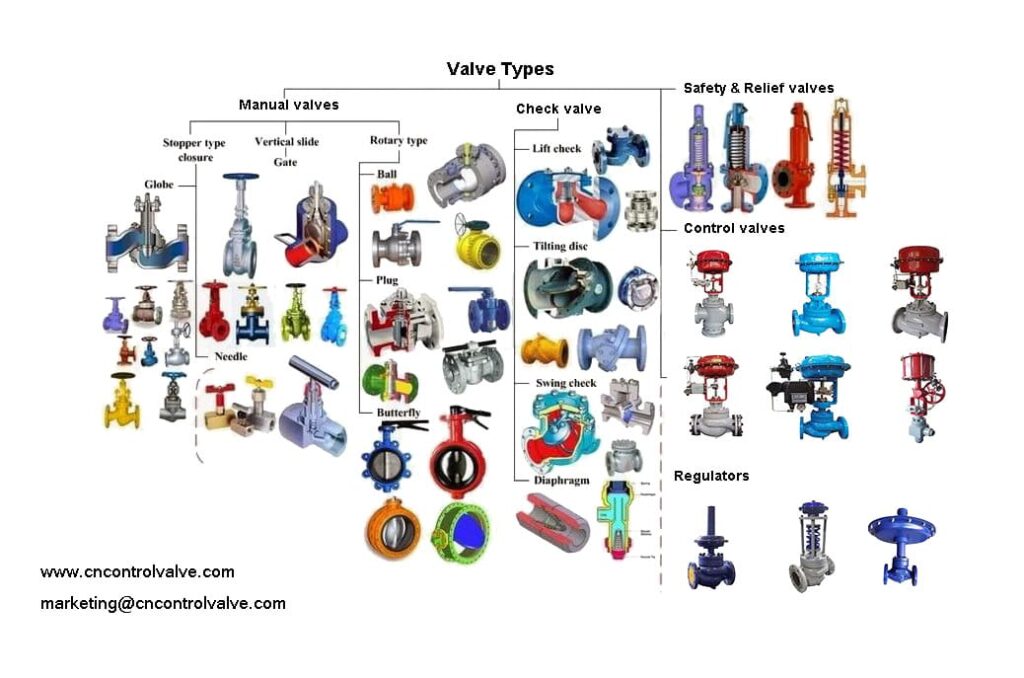

Types of Industrial Valves in Karachi

There are many different types of industrial valves, each designed to meet specific needs and requirements. Some of the most common types of industrial valves include:

Ball valves

These are quarter-turn valves that are used to control the flow of liquids and gases. They are easy to operate, reliable, and durable.

Butterfly valves

These are also quarter-turn valves that are used to control the flow of liquids and gases. They are commonly used in applications that require high flow rates.

Gate valves

These are linear valves that are used to regulate the flow of liquids and gases. They are commonly used in applications that require a tight shut-off.

Globe valves

These are linear valves that are used to regulate the flow of liquids and gases. They are commonly used in applications that require precise flow control.

Check valves

These are one-way valves that are used to prevent backflow in a piping system. They are commonly used in applications that require a high level of reliability.

The Importance of Choosing the Right Valve for the Application

Choosing the right valve for a specific application is critical to ensuring that the industrial process runs smoothly and efficiently. Factors to consider when selecting an industrial valve include:

Fluid Type: The type of fluid being handled will impact the selection of the valve. For example, corrosive fluids may require a valve made of materials that are resistant to corrosion.

Pressure and Temperature: The pressure and temperature of the fluid will impact the selection of the valve. High-temperature fluids may require a valve made of materials that can withstand high temperatures.

Flow Rate: The flow rate of the fluid will impact the selection of the valve. High-flow applications may require a valve with a large flow area.

Environment: The environmental conditions of the application will impact the selection of the valve. For example, a valve that is used in a high-temperature environment may require materials that can withstand high temperatures.

The Benefits of Using Industrial Valves in Karachi’s Industrial Operations

The use of industrial valves in Karachi’s industrial operations brings numerous benefits, including:

Improved Efficiency: By using industrial valves to control and regulate the flow of fluids and gases, industrial operations can become more efficient and streamlined.

Increased Safety: Industrial valves can help to prevent accidents and minimize the risk of injury in the workplace by controlling the flow of fluids and gases.

Enhanced Reliability: Industrial valves are designed to be durable and reliable, and their use can help to ensure that industrial operations run smoothly and with minimal downtime.

In conclusion

Industrial valves play a crucial role in the smooth functioning of Karachi’s industrial sector, providing control, regulation, and shut-off of the flow of liquids, gases, and other fluids. With the right valve for the job, industrial operations can become more efficient, safe, and reliable. When selecting an industrial valve, it is essential to consider factors such as fluid type, pressure and temperature, flow rate, and environment to ensure that the valve meets the specific needs and requirements of the application. By using high-quality industrial valves, the city’s industrial operations can continue to thrive and drive economic growth in the region. As a reliable industrial valve supplier, THINKTANK is always here to serve you. Please do not hesitate to contact us if you have any questions.