Control valves play a critical role in various industries, ensuring optimal process control and safety. However, these valves can generate significant noise during operation, which can cause damage to equipment and cause health risks to operators. In this article, we will explore the different noise reduction techniques for control valves and how manufacturers like Fisher, Emerson, Samson, THINKTANK, Flowserve, Spirax Sarco, KOSO, Azbil, Masoneilan, ARI, and ARCA are implementing these techniques in their products.

Sources of Control Valve Noise

Before diving into noise reduction techniques, it is essential to understand the sources of control valve noise. There are several sources of noise in control valves:

- Mechanical noise: Vibration and noise generated by the interaction of valve components such as the actuator, stem, and packing.

- Fluid flow noise: Caused by the fluid flow through the valve, including turbulence, cavitation, and flashing.

- Aerodynamic noise: Generated by high-velocity gas flow through the valve, leading to pressure fluctuations and vibrations in the valve body.

Noise Reduction Techniques

Several noise reduction techniques can be employed to minimize the impact of control valve noise:

1. Valve Sizing and Selection

Proper sizing and selection of control valves is crucial to minimize noise. Oversized valves can lead to excessive flow velocities and turbulence, while undersized valves may cause cavitation or flashing. It is essential to select the right type of control valve for the application and ensure that it operates within its specified range. For example, selecting a valve with a low Cv or a design that minimizes turbulence can help mitigate noise generation.

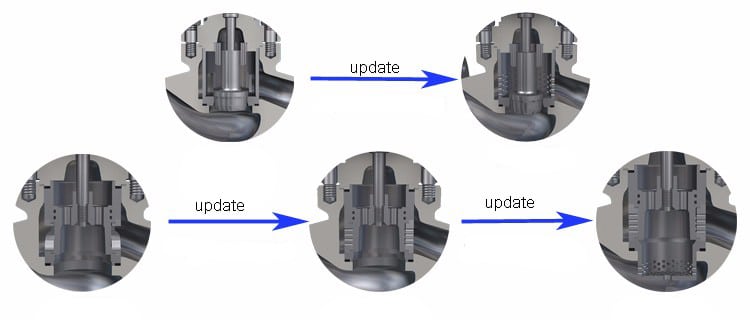

2. Valve Trim Design

Manufacturers design valve trims to minimize noise generation. Some popular trim designs include:

- Multi-stage trims: These trims divide the pressure drop across multiple stages, reducing the flow velocity and turbulence, thereby minimizing noise.

- Cage-guided trims: These trims use a cage to guide the plug and provide additional flow paths, which help distribute the pressure drop and decrease noise levels.

3. Anti-Cavitation and Flashing Solutions

Cavitation and flashing can generate significant noise and damage valve components. Manufacturers incorporate various design features to prevent or minimize these phenomena, such as:

- Anti-cavitation trims: These trims are designed to control the pressure drop and avoid conditions that may lead to cavitation.

- Diffusers: Diffusers can be installed downstream of the valve to help control the pressure recovery and minimize the risk of cavitation.

4. Noise Attenuators

Noise attenuators, such as silencers or mufflers, can be installed on the valve outlet to absorb and dissipate sound.

5. Piping design

Proper piping design, including the use of expansion joints and vibration isolators, can help minimize the transmission of noise through the piping system.

6. Insulation

Acoustic insulation or soundproof enclosures can be used to contain noise generated by control valves, helping to protect personnel and equipment.

Brands Offering Noise Reduction Solutions

Several well-known control valve manufacturers offer noise reduction solutions in their product portfolios:

- Fisher (Emerson): Offers a range of noise-attenuating valves and trims, including Whisper Trim and Cavitrol solutions.

- Samson: Provides noise-reducing trims and valve designs for various applications.

- THINKTANK: Offers control valves with low noise trim options and noise-reducing valve body designs.

- Flowserve: Provides noise reduction solutions, such as multi-stage trim and valve body designs, to minimize noise generation.

- Spirax Sarco: Offers control valves with noise-attenuating trim options for steam and condensate applications.

- KSB: Offers control valves with noise-reducing trims and valve designs for a variety of applications, including water, wastewater, and industrial processes.

- Metso (Neles): Provides control valves with noise-reducing trims, such as Q-Trim and C-Series, which help to minimize noise levels in demanding applications.

- IMI CCI: Offers control valves with advanced noise reduction technologies, such as DRAG and V-LOG, for high-pressure drop applications.

- Badger Meter: Provides control valves with noise-reducing trims and valve designs for water, chemical, and gas applications.

- Masoneilan (Baker Hughes): Offers control valves with noise-reducing trims and valve designs, such as the Lo-dB and Multi-Path trims, for a variety of applications.

Conclusion

In conclusion, noise reduction in control valves is an essential aspect to consider for the overall performance and reliability of your process systems. By selecting the right control valve, properly sizing it, and employing noise reduction techniques like specialized trim designs, piping designs, and insulation, you can minimize noise-related issues and improve the working environment for personnel and equipment. The aforementioned brands offer a range of noise reduction solutions, helping you choose the most appropriate control valve for your specific application.

Additionally, THINKTANK is a reliable control valve manufacturer in China, we have over three decades of history in this field. As a qualified vendor for ABB, THINKTANK has gained a reputation for providing high-quality control valves that can meet various industry needs. Be sure to explore our offerings as well when seeking a suitable control valve solution for your application.