Data Center Valve Solutions

Modern data centers run on more than servers and power. Behind every rack and cooling unit is a network of valves that must operate safely, predictably, and continuously. A single valve failure can interrupt cooling, threaten fuel systems, or disrupt emergency protection loops. For this reason, data center engineers expect industrial-grade valve solutions that match the reliability demands of 24/7 facilities.

This guide explains the key valve types used in data centers and shows how THINKTANK’s certified, engineered solutions support critical systems—from fuel supply and cooling loops to fire protection and tank safety.

What Are the Types of Valves Used in Data Centers?

The most common types of valves used in data centers include butterfly valves, ball valves, gate valves, globe valves, and pressure relief valves, breather valves c/w flame arresters, non-return valve, fusible link valves, solenoid valves, balanced globe valves, and air vent etc,. These are used for pump rooms, cooling systems, diesel backup lines, fuel tank systems, and fire protection.

Let’s break down these valve types, their functions, and why THINKTANK valves are trusted by global EPCs for critical infrastructure projects.

Key Valves Used in Data Centers

Pressure Relief Valves

Pressure relief valves are critical in maintaining system safety by automatically releasing excess pressure from pipelines, tanks, or closed systems. In data centers, they are commonly installed in chilled water systems, diesel fuel lines, and thermal storage tanks to prevent overpressure that could damage equipment or cause safety hazards.

THINKTANK’s pressure relief valves are engineered for precision activation, with options available for both low- and high-pressure systems, including configurations compliant with PED and ASME standards. Their compact design allows easy integration into tight utility spaces often found in pump rooms or backup system enclosures.

Butterfly Valves

Compact, cost-effective, and ideal for large-diameter lines, butterfly valves are widely used in chilled water systems. They allow fast shutoff and are often motorized for integration with BAS (building automation systems). THINKTANK’s high-performance resilient-seated butterfly valves are engineered for long-term stability under fluctuating flow conditions.

Ball Valves

Known for their tight shutoff capabilities, ball valves are commonly installed in diesel fuel systems, backup water loops, and equipment requiring zero leakage. THINKTANK offers both manual and actuated options, suitable for low- and high-pressure applications with FM or UL compliance.

Gate Valves

Gate valves offer full bore flow when open and minimal pressure loss, making them ideal for main water and diesel supply lines. While not used for throttling, they are excellent for isolation in sections that don’t require frequent actuation.

Globe Valves & Balanced Globe Valves

For precise flow regulation — particularly in secondary loops, CRAC units, and coil circuits — globe valves are a preferred choice. THINKTANK’s balanced globe valve designs ensure stable control performance even under fluctuating differential pressures, making them ideal for data center environments requiring thermal precision.

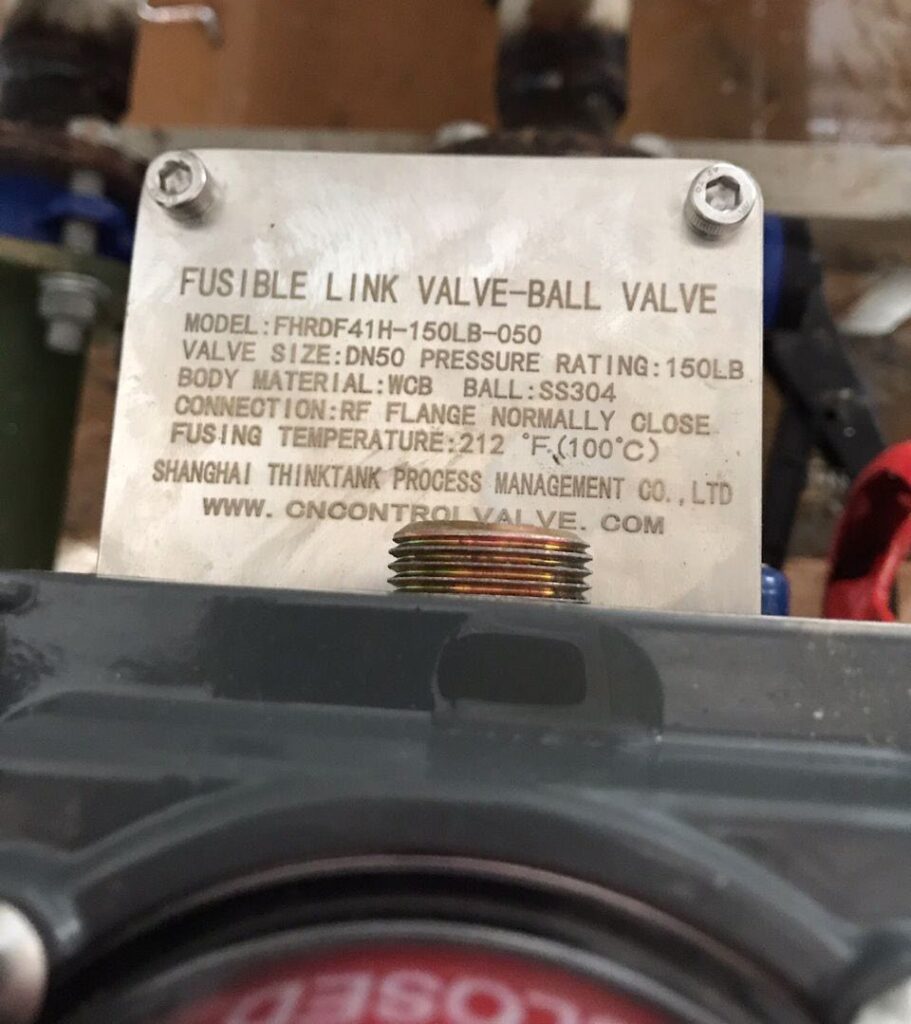

Fusible Link Valves

Designed for fire-critical applications, fusible link valves automatically shut off flow when ambient temperature exceeds a set threshold (typically around 72°C or 165°F). These are critical in diesel generator lines and fuel storage systems. THINKTANK is the only Chinese manufacturer producing these valves with FM/UL and API607 certification, ensuring compliance with international fire safety standards.

Breather Valves with Flame Arresters

Used primarily on diesel fuel tanks, breather valves allow safe venting while maintaining internal pressure integrity. When paired with flame arresters, they prevent external ignition sources from entering the tank. THINKTANK supplies ATEX-compliant assemblies suitable for explosive environments.

Non-Return Valves (Check Valves)

Preventing backflow is vital in chilled water pumps and fuel systems. A non-return valve ensures one-way flow, protecting equipment from reverse pressure damage. THINKTANK check valves are engineered for low cracking pressure and minimal head loss.

Solenoid Valves

Solenoid valves offer electrically actuated flow control — often used for emergency shutoff in fuel systems or integration with fire detection systems. These are fast-acting, programmable, and compatible with digital control environments. THINKTANK supplies explosion-proof and weatherproof solenoid valve options for outdoor or hazardous locations.

Air Vent Valves

Trapped air can impair heat exchange and lead to cavitation or corrosion. Automatic air vent valves remove air pockets from chilled water loops, especially during commissioning or after maintenance. THINKTANK’s brass and stainless steel vent valves are designed for fast installation and high reliability.

What Are the Most Common Valves in Cooling Towers?

Cooling towers rely heavily on:

- Control Valves

- Electronic Float Valves

- Isolation Valves

These valves regulate water levels, isolate sections for maintenance, and ensure balanced distribution. THINKTANK’s motorized butterfly valves and electronic float valves are ideal for this purpose.

What Is the Most Common HVAC System in Data Centers?

Most data centers use chilled water systems. This system requires a precise mix of pressure independent control valves (PICVs), ball valves, and check valves to maintain efficiency and avoid hot spots.

THINKTANK supplies reliable performance with corrosion-resistant valves options tailored for such systems.

What Are Fusible Link Valves and Why Are They Critical?

Fusible link valves are fire-safe valves equipped with a link that melts at a specific temperature, automatically closing the valve. They are vital in diesel supply lines or generator rooms.

🔥 THINKTANK is the only Chinese manufacturer of fusible link valves, and these are certified under FM/UL and API607, ensuring the highest fire protection standards.

How Do Flame Arresters and Breather Valves Improve Safety?

- Flame Arresters stop flame propagation in flammable gas systems, preventing explosions.

- Breather Valves control air and vapor exchange, preventing vacuum or pressure build-up in fuel tanks.

These are commonly used in diesel system designs. THINKTANK manufactures both with ATEX and PED certifications.

Why THINKTANK Valves Stand Out from Belimo and Other Brands

While brands like Belimo focus on actuators and HVAC automation, THINKTANK offers full valve solution packages, including:

- Manual + automated valves

- Custom pressure ratings

- Exclusive fire protection valve manufacturing

- Fast delivery from China to APAC and EMEA

With more control over design and certification, THINKTANK provides tailor-made solutions that EPCs can rely on.

THINKTANK Case Studies: NTT, Lumina, Edgenex & Damac

THINKTANK has proudly supplied valves to major data center projects:

- ✅ NTT Data Center(India)

- ✅ Lumina Data Center(India)

- ✅ Edgenex & Damac Projects in Malaysia & Thailand

With full certifications including ISO9001, ISO14001, ISO45001, ATEX, PED, FM/UL, and API607, THINKTANK is not just a valve supplier — we’re your engineering partner for data center success.

What Certifications Should Data Center Valves Have?

Valves used in mission-critical facilities like data centers must meet international standards. THINKTANK valves come with:

- ISO9001 – Quality Management

- ISO14001 – Environmental Compliance

- ISO45001 – Occupational Safety

- ATEX & PED – For explosive and pressure equipment

- FM/UL – For fire safety

- API607 – Fire testing for valves

With THINKTANK, you don’t just buy valves — you buy confidence.

Conclusion

Data centers demand valves that perform reliably under continuous load and emergency conditions. From diesel safety to cooling stability, the correct valve selection is essential for preventing downtime and protecting critical infrastructure.

THINKTANK provides engineered valve solutions built for these challenges, supported by technical expertise, flexible customization, and proven performance across global projects.

To discuss your next data center project or request a valve package proposal, our engineering team is ready to help.