The process of manufacturing textiles begins with a plant or field where cotton is grown, picked, and processed. Cotton comes in different qualities. Different cotton types come in different sizes and colors.

A textile mill is a factory where cotton and other materials are made into textiles. Cotton fiber is separated from the seed and cotton is cleaned by various processes. The final product is the yarn which is then woven and knitted to make fabric. This is the entire process of making a textile mill. Every step is important and every aspect of this industry is covered in this article. The article starts with an explanation of the whole process. Then it discusses the equipment used in the process. This will be followed by the machinery and chemicals used in the process.

A textile mill is a production facility where different types of fibers, such as yarn or fabric, are produced and processed into usable products. This could be clothing, bed sheets, towels, textile bags, and much more. When textile mills were first created, the work was very labor-intensive, but technology has transformed some modern facilities into machine-intensive operations.

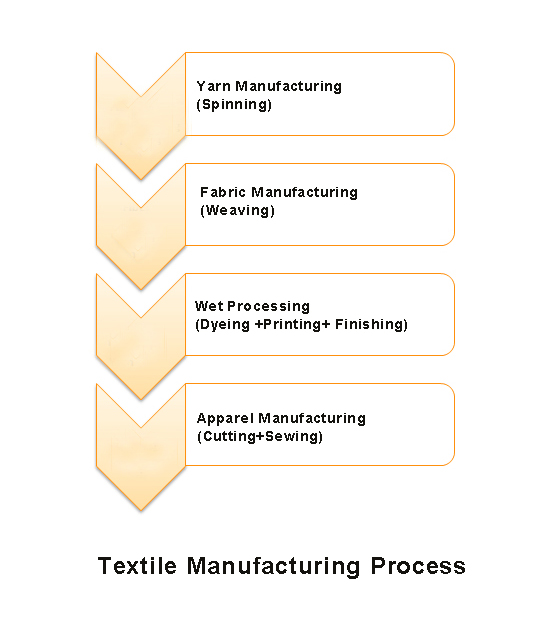

Textile mills use a multi-step process to turn raw materials into usable products. Here is a typical production cycle process.

There are various categories of textiles within the textile industry that can be transformed into functional products.

The textile manufacturing processes include yarn manufacturing, fabric manufacturing, dyeing, printing, finishing processing, and apparel manufacturing.

Textile manufacturing is an important part of the textile industry. Textile engineering uses science to develop a variety of fabrics and yarns and to analyze the polymers used to make fibers. There are many textile mills around the world. Some of the most popular places for the textile industry include Vietnam, China, Thailand, the Philippines, India, Indonesia, etc. most of these countries’ economies depend on it.

The term “textile” usually refers to a weave or textile network of overlapping threads, like the kind used on clothing. But this is just one of the many kinds of fabrics studied in textile engineering on the surface. Textile engineers also use plastics, vinyl, and other substances in their work to help design the special clothing materials needed for medical products, military materials, Firefighters and Police, and more. Broadly speaking, both industrial sewing and textile engineering involve any material that is flexible and non-rigid.

Textile technology is a branch of mechanical engineering, so many of the principles are similar. The study of textile engineering relates to the design and creation of fabrics. This usually includes the equipment and materials needed for manufacturing. Textile engineering involves determining the best way to develop fibers, process raw materials, and ensure accurate production.

Textile engineering relates not only to the use of existing materials but also to the development of entirely new materials. Textile engineers are discovering new high-tech methods of creating barriers and efficient structures that do not follow the same rules as rigid structures or devices. Some of these future uses include technologies that can transfer the energy generated by physical motion or convert sunlight into electricity. Whatever the future holds, fabrics will continue to become stronger, cheaper, and more durable.

Textile production is the process of manufacturing fibers, filaments, yarns, and threads, including natural and synthetic fibers.

A composite material is a combination of different materials, such as fiber and cotton. These two processes have their own production steps.

These textiles are both decorative and functional, such as clothing and home furnishings.

These textiles are created purely for functional rather than aesthetic purposes, such as protective clothing, military materials, medical implants, etc. They have different purposes but are manufactured in essentially the same way.

As mentioned earlier, many technical textiles are manufactured for specific purposes within specific industries. One of the most important of these purposes is safety. Some industries are extremely dangerous and garments must be protected from spills, fires, dangerous debris, etc. Some garments not only need to have special properties such as fire resistance, reflectivity, water resistance, etc., but also other accessories such as safety nets, waterproof fabrics, fire blankets, tarpaulins, reflective fabrics, and even anti-toxic fabrics are used in technical textiles for their protective properties.

People in the military rely on camouflage fabrics and durable textiles to keep them hidden from the environment and to protect their bodies from pests. Sometimes special materials are also used to protect them from projectiles. Tents and parachutes in the military are also an important area of textile used in military applications.

Firefighters need fire-resistant clothing with flame retardant properties to do their jobs, while police officers often need defensive materials such as bulletproof clothing.

In the medical field, patients and medical personnel rely on technical textiles. Bandages, cotton gauze, mattresses, and pillows all contain technical textiles.

Agriculture is another industry that relies heavily on technical textiles. Special textiles are often used in greenhouses and ground coverings. Bags, nets, and twine are also often seen in agriculture.

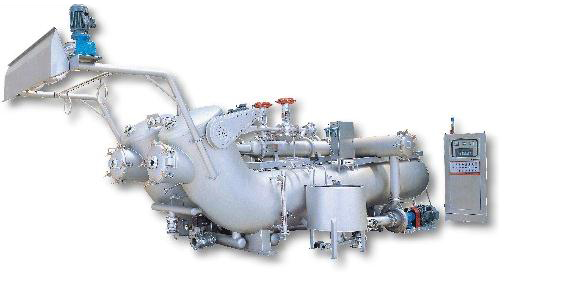

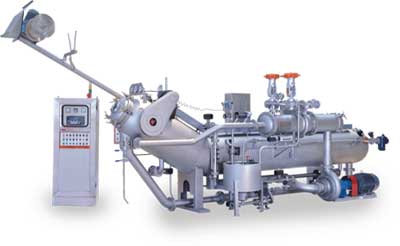

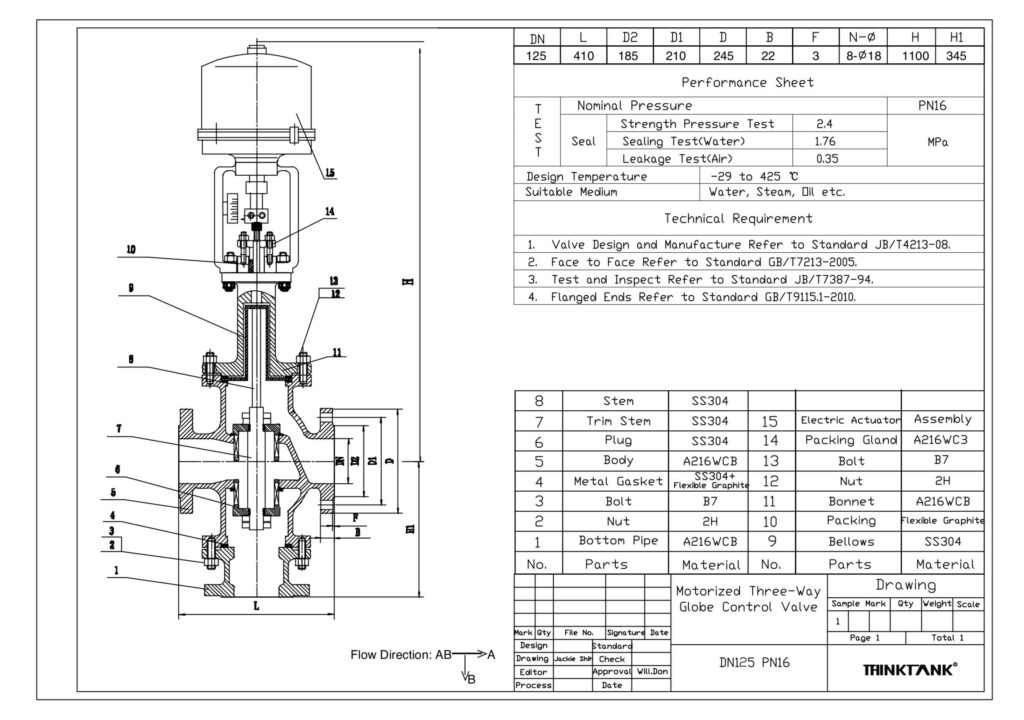

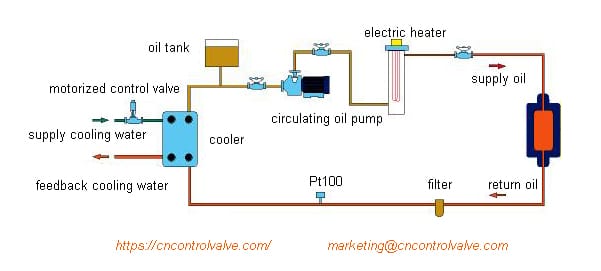

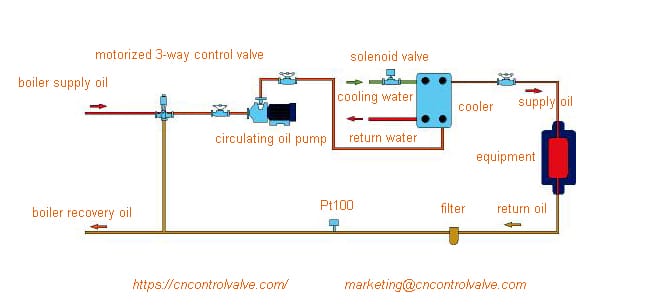

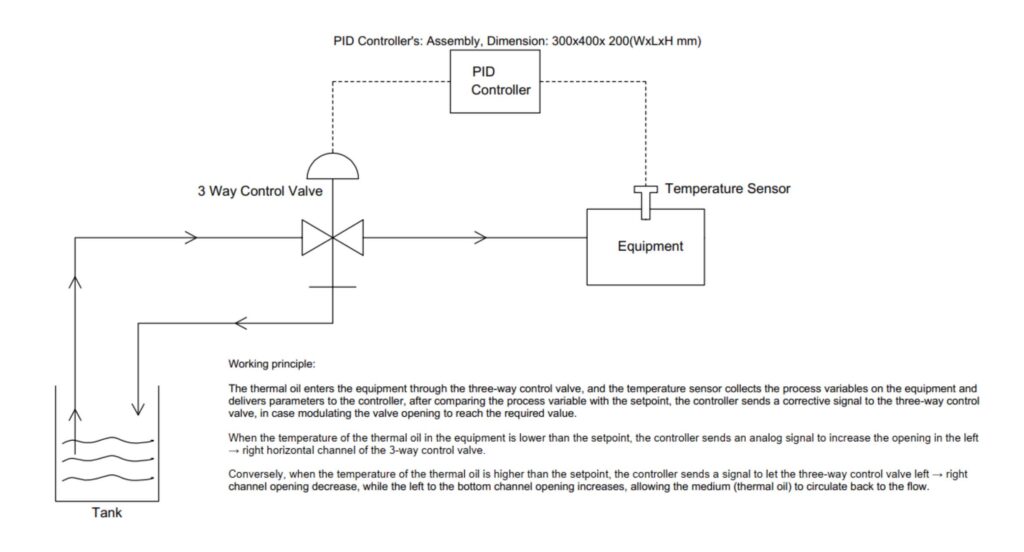

There are various types of machinery, and equipment used for textile mills, the most important machine is dyeing machinery, which is famously made in Taiwan, and most dyeing machine manufacturers use STONE valves.

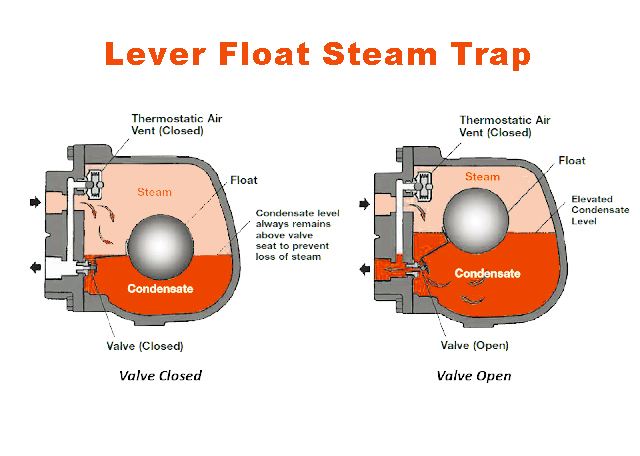

Above brand equipment manufacturers use STONE valves for their dyeing machines, which include ball valves, cylinder actuated control valves, diaphragm actuated control valves, butterfly valves, and angle seat valves.

Precision casting and full port stainless steel ball valves save operating time, and the control valves accurate proportional control of the flow capacity with tight shut-off.

The feeding system has the following properties

Avoid your inquiry is delay response, please enter your WhatsApp/Wechat/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 185 1656 9221, or WeChat: +86 199 2125 0077. or call +86 189 5813 8289 directly.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 199 2125 0077, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.

Just leave your name, email, and simple message or requirements, We will contact you within 1 hour.

WhatsApp: +86 199 2125 0077

Skype ID: sowell85

Wechat ID: +86 199 2125 0077