Description

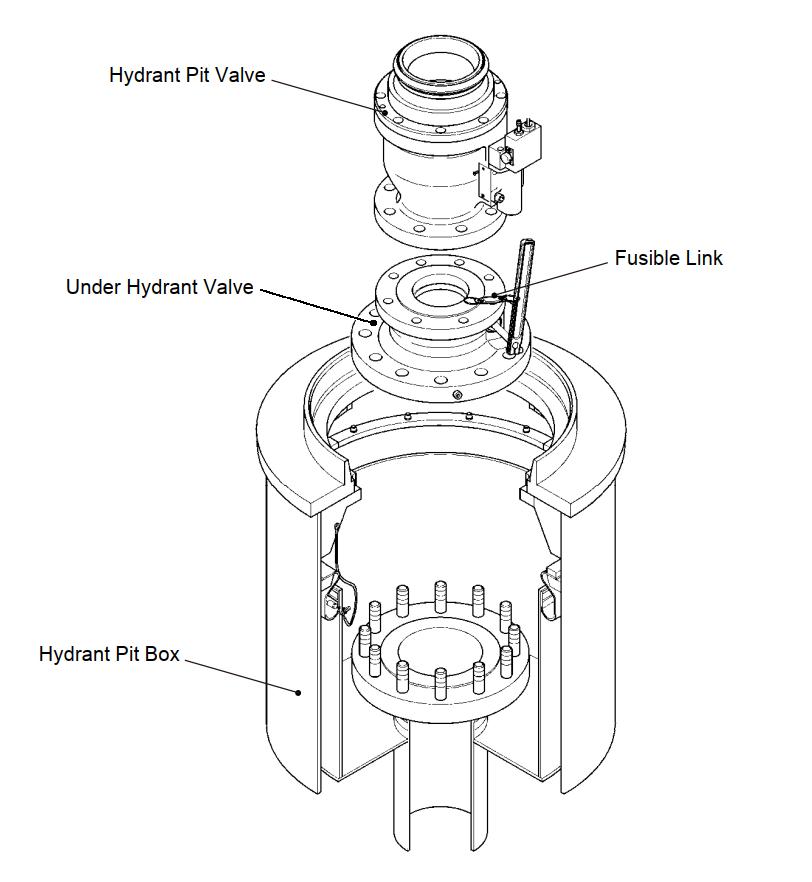

The UHSV1000 Under Hydrant Valve is one of the most essential piping system components in a hydrant system. When the isolation function of the under

hydrant valve fails to operate, the service valve can be shut off quickly on site, allowing the under hydrant valve to be disassembled or repaired without the need to completely or partially block the pipe system.

In the case of a fire, the valve also enables for fast automated immediate cutoff. At 95°C = 199.4°F, the fuse chain breaks, enabling an emergency shutdown mechanism.

Technical Parameters For Hydrant Shut-off Valve

Nominal Diameter: 101mm

Max. Working Pressure: 1.89MPa

Maximum Sheel Pressure Test: 2.84MPa

Fusing Temperature: 52°C, 70°C, 93°C, etc.

Applicable medium: Aviation Kerosene

Design

The valve body of this hydrant shut-off valve is made of ductile iron, and the internal inserts, valve plate, and air release structure are made of 304 stainless steel to ensure the cleanliness of oil delivery and improve the anti-corrosion performance.

Operation of Under Hydrant Valve

When it is installed, the flap valve is opened by spinning the handle and pushing against a custom internal torsion spring. Because of the design’s automatic pressure equalization function, the valve may be opened with ease even while the hydrant is under pressure. An arrangement of chains and fusible links keeps the valve open. The chain is simply decoupled, and the handle is turned until the flap touches the valve’s seat. The fusible connection will break in the event of a fire, enabling the valve to close by itself.

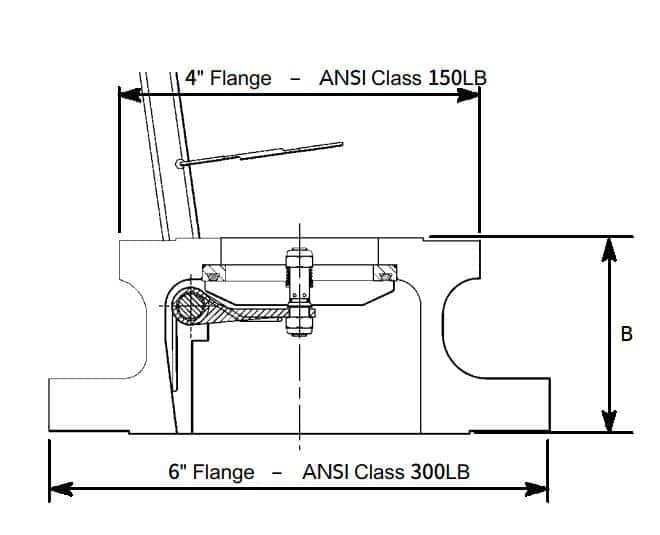

Features of Under Hydrant Valve

- ATEX and PED accreditation

- Carbon or stainless steel body options

- All components of valves are fabricated from stainless steel.

- Fire resistant to API 6A

- Three body lengths and four flange variants are available.

- Minimal face-to-face dimensions of only 124.50 mm for a compact design.

- Functions as an Emergency Shutoff Valve

Application of Under Hydrant Valve

The fused emergency under hydrant valve is installed in the ground well of the apron and connected to the ground well fuel plug for use. When the ambient temperature in the well exceeds a certain range, the fuse piece attached to the valve body chain buckle will fuse and the valve will be closed automatically to prevent fire. When the fuel plug maintenance, you can also manually close the valve by the handle, disassemble the fuel plug, and do not have to shut down the pump to unload pressure, does not affect the use of other oil wells.

Hydrant Valve

Technical Parameters

- Working Pressure 0.4-1 Mpa

- Maximum Working Pressure 1.89 Mp

- Max. Pressure Test: 2.84 MPa

- Applicable Medium: Aviation kerosene

- Flow Rate: 0.4 MPa 1200L/min ~ 1MPa 4000L/min

- Operating Temperature: -20~65℃

Application

Ground well refueling hydrant is designed with reference to the structure of foreign refueling hydrant and the relevant provisions of API Bulletin1584, installed in the ground well of the airport hydrant refueling system, the docking port is consistent with API Bulletin1584, and used with hose fittings to achieve pressure refueling of aircraft.

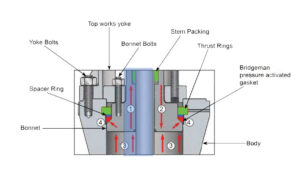

Structure

The ground well refueling hydrant consists of three parts, namely the bottom valve component, the top valve component (PAI outlet fitting), and the pilot valve. The bottom valve component contains an isolation valve, which can remove the top valve component and the pilot valve for maintenance under pressure at the ground well.

Vent or Drain Unit

This product is used in airport landing pads as high point bleed and bottom point drainage. It is an integral part of the oil pipeline system.

TechnicalParameters

- Nominal Diameter: 32mm

- Maximum Working Pressure: 1.89MPa

- Maximum Shell Pressure Test: 2.84MPa

- Flow Rate: 160L/min

- Working Temperature: -20~65℃

Suitable Medium: Aviation Kerosene, Gas, Water

Design

This device consists of a self-closing joint valve, regulating ball valve, flange, and drainage pipe (the bleeding device is not equipped with a drainage pipe). The main body and internal structure of the valve body are made of stainless steel, which improves the anti-corrosion performance. It has the characteristics of reasonable structure, safety and reliability, convenient operation, easy maintenance, and long service life.

Self-Closing Quick Connector

The self-closing quick connectors are used in airports, ports, petroleum, chemical, and other industries to drain and bleed the high and low points of the fluid transportation system of the pipeline.

Technical Parameters

- Nominal diameter: 32mm

- Maximum Working Pressure: 1.89MPa

- Maximum Shell Pressure Test: 2.84MPa

- Flow Rate: 160L/min

- Working Temperature: -20~65℃

Suitable Medium: Aviation kerosene, gas, water

Design

The main body and parts are uniformly made of stainless steel, with reasonable structure, compactness, safety and reliability, convenient operation, easy maintenance, long service life, etc.