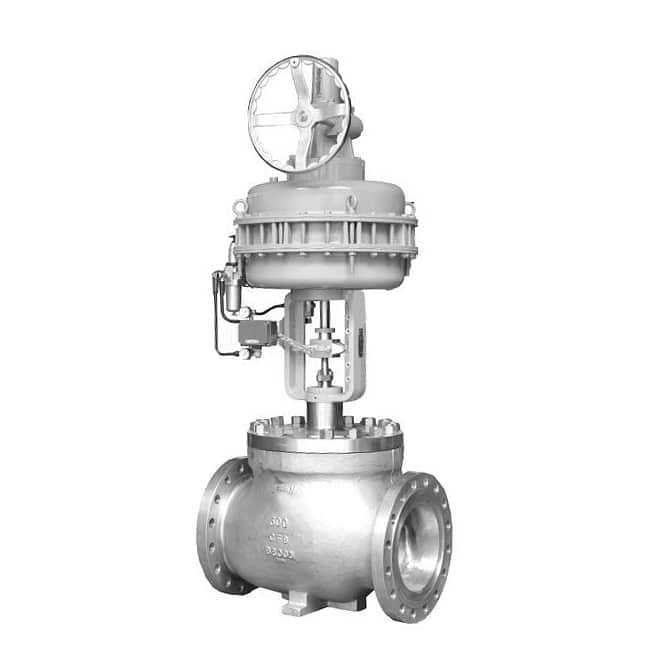

Description

This series is a fluid pressure balanced type cage guided high-performance control valve of large Cv value, and of excellent dynamic stability. It is suitable for heavy-duty services. Only a small operation force can achieve stability control due to the balanced fluid pressure structure on the plug. The series can be made with a special structure including bellows seal type, steam jacketed type, extended valve cover type to meet a variety of conditions.

Performance Characteristics

1. The third generation of S-type smooth casting body cavity gets greater circulation ability to reduce the initial investment, as it is now with more efficient average flow velocity by improving the second generation through CFD (Computational Fluid Dynamics)

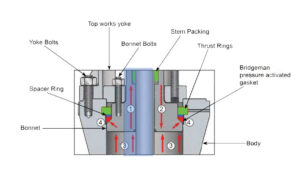

2. In accordance with ASME, the valve body and the upper bonnet are pressed together by the double-head stud bolt

3. The stability of plug movement is improved due to the strong cage guide and the unique balanced sealing ring (GF TFE structure for room temperature, graphite 1398 & Graph-lock structure for high temperature) so that the vibration and mechanical noise are reduced

4. With the solid cage, the valve body is protected from steam and cavitation damage. There was an S streamlined channel and this makes the small loss of pressure drop, high flow, a wide range of control.

Product Advantages

- Comparing the valve trim of the balanced structure with the unbalanced straight single seat valve, the configured actuator can be smaller, but it can overcome the higher drop pressure than the straight single-seat control valve. So the larger the diameter, the higher cost-effective.

- The flow characteristics are achieved by the shape of the sleeve window. Different flow characteristics only need to replace different sleeves to meet the requirements, which increases the versatility of parts.

- The noise is reduced by about 10dB compared with ordinary single and double seat control valves.

- Standard quick-change valve trims are more convenient for on-site maintenance. Even if the valve body is in the pipeline, all the valve trims can be easily removed from the valve body. The HCB series trim can also be easily replaced with an HCN Series multi-hole trim, which is suitable for different working conditions to ensure that the valve outlet flow rate is within a safe range, prevent cavitation and cavitation, and effectively reduce noise.

Actuator

Type

Single-acting diaphragm actuator, Spring type piston actuator, Double acting piton actuator

Diaphragm material

Cloth embedded nylon and ethylene-propylene rubber

Spring range

• 20 to 100 kPa(0.2 to 1.0 kgf/cm2)

• 40 to 200 kPa(0.4 to 2.0 kgf/cm2)

• 80 to 240 kPa(0.8 to 2.4 kgf/cm2)

Supply pressure

0.14, 0.16, 0.28, 0.4, 0.5 Mpa

Air connection

Rc1/4 or 1/4NPT internal thread

Ambient temperature

-30 to 70℃

Valve action

• FO: Air to close(Direct action actuator is combined.)

• FC: Air to open(Reverse action actuator is combined.)

Optional accessories

• P/P or I/P Positioner

• Air filter regulator

• Top-mounted or Side-mounted Handwheel

• Limit switch

• Solenoid valve

• Motion transmitter

• Booster relay

• Lock-up valve

• Airlock relay

• Others