Description

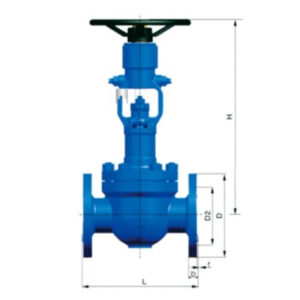

The axial nozzle check valve is the preferred solution for preventing return flow or shocks on critical process equipment. Typically used on rotating devices and systems where low-pressure loss, stable operation, and smooth dynamic behavior are essential.

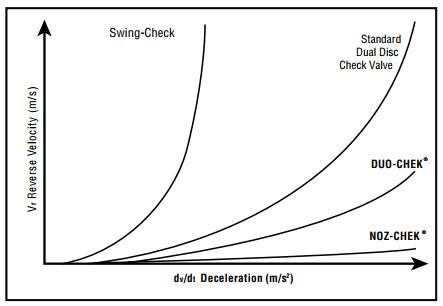

High-Performance Nozzle Type Non-Slam Check Valve delivers an effective dynamic response under various flow deceleration applications and compared to the dual plate check valve and swing check valve as below figure 1.

Features

- This nozzle check valve only has a few moving parts, the disc is the only moving part, which means minimizing wear.

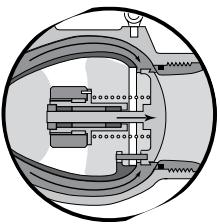

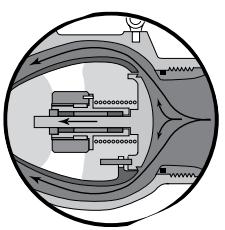

- Axial movement of the disc – Disc and seating configuration gives streamlined flow path with venturi effect, resulting in low-pressure drop.

- Short stroke of the spring-assisted disc – Inlet flow velocity moves the disc axially with a short stroke. In response to flow velocity reduction, a compressed spring initiates valve closure and provides a quick response.

- Spring options – Choice of spring affects the critical velocity and valve response. Selection is made on engineering evaluation of specific applications. In absence of this data, a standard spring will be provided.

Industry Standards |

|

| Valve Pressure Testing and Inspection | API 598 |

| Pressure/Temperature Ratings | ASME B16.34 |

| Pipeline Valves | API 6D |

| Production Valves | API 6A |

| Pressure Equipment Directive | 2014/68/EU |

| International Standards Organisation Cryogenic testing | ISO 28921 – 1 |

| British Valve Standard Cryogenic testing | BS 6364 |

| Manufacturing Standards Society | MSS SP-134 |