Description

Brief of API Globe Valve

THINKTANK API Globe Valve is engineered to comply with stringent API specifications, ensuring consistent quality and reliability. The innovative bellows design provides superior leak protection, extending the valve’s service life and reducing maintenance requirements.

Key Features of Our API Globe Valve

- Robust construction with high-quality materials for enhanced durability and long-lasting performance.

- Bellows seal technology for exceptional leak prevention, ensuring a safe and efficient operation.

- Streamlined flow path with minimal pressure drop, maximizing efficiency and reducing energy consumption.

- Easy-to-operate handwheel for precise flow control and straightforward adjustments.

- Available in a range of sizes and pressure ratings to suit diverse application requirements.

Advantage THINKTANK API Globe Valve

- The bellows component is a crucial element of below-sealed valves, which is securely attached to both the valve bonnet and valve stem through a sophisticated automatic roll welding process. This metal bellows construction ensures a 100% leak-free stem area.

- The double seal design incorporates both bellows and packing components. The metal bellows form a primary barrier to prevent leakage, while the packing serves as a secondary sealing mechanism in the event of bellows failure.

- The overlay welded seat guarantees reliable sealing performance, even in the most demanding conditions.

- The valve features an ergonomic handwheel, designed for enhanced durability and ease of operation.

Technical Specifications

- Design standard: ASME B16.34

- Face to face dimension: ASME B16.10

- Flanged ends: ASME B16.5

- Welded ends: ASME B16.25

- Test & inspection: API 598

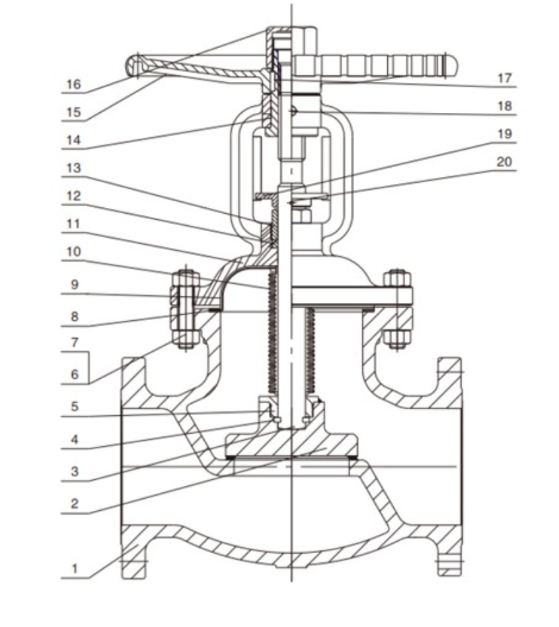

Parts of API Globe Valve with Bellows

| No. | Parts Name | Materials | No. | Parts Name | Materials |

| 1 | Body | A216WCB | 11 | Bonnet | A216WCB |

| 2 | Disc | F304 | 12 | Packing | Graphite |

| 3 | Stem | F304 | 13 | Packing gland | 1025 |

| 4 | Split loop | SS304 | 14 | Stem nut | QT400-15 |

| 5 | Disc cover | F304 | 15 | Handwheel | A216WCB |

| 6 | Nut | A194 2H | 16 | Lock nut | 1025 |

| 7 | Stud bolt | A193 B7 | 17 | Key | 1045 |

| 8 | Gasket | 304+Flexible graphite | 18 | Oil nipple | H62 |

| 9 | Bellows cover | SS304 | 19 | Spacer | 1025 |

| 10 | Bellows assembly | SS304 | 20 | Locating pin | 1045 |

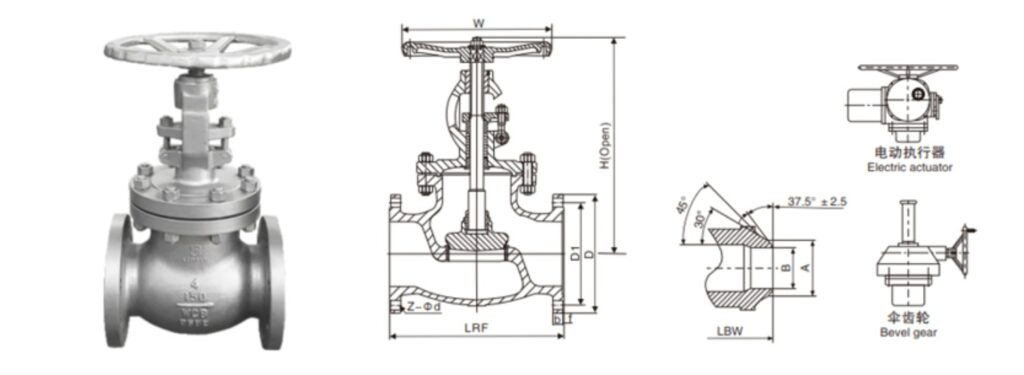

API Globe Valve Dimensions

| SIze Inch | DN | LRF | LBW | D | D1 | b | Z-φd | A | B | H | W |

| 150Lb | |||||||||||

| 2 | 50 | 203 | 203 | 150 | 120.5 | 14 | 4-19 | 60 | 52 | 368 | 200 |

| 21/2 | 65 | 216 | 216 | 180 | 139.5 | 16 | 4-19 | 75 | 63 | 687 | 200 |

| 3 | 80 | 241 | 241 | 190 | 152.5 | 17.5 | 8-19 | 91 | 78 | 410 | 250 |

| 4 | 100 | 292 | 292 | 230 | 190.5 | 22 | 8-22 | 117 | 102 | 454 | 250 |

| 5 | 125 | 356 | 356 | 255 | 216 | 22 | 8-22 | 144 | 128 | 455 | 355 |

| 6 | 150 | 400 | 400 | 280 | 241.5 | 24 | 8-22 | 172 | 154 | 540 | 355 |

| 8 | 200 | 495 | 495 | 345 | 298.5 | 27 | 8-22 | 223 | 203 | 650 | 450 |

| 10 | 250 | 622 | 622 | 405 | 362 | 28.6 | 12-25 | 278 | 255 | 800 | 450 |

| 12 | 300 | 698 | 698 | 485 | 432 | 30 | 12-25 | 329 | 305 | 1230 | 500 |

| 14 | 350 | 787 | 787 | 535 | 476 | 33.4 | 12-25 | 362 | 337 | 1450 | 600 |

| 16 | 400 | 914 | 914 | 595 | 540 | 35 | 16-29 | 413 | 387 | 1645 | 600 |

| 300Lb | |||||||||||

| 2 | 50 | 267 | 267 | 165 | 127 | 21 | 8-19 | 60 | 52 | 399 | 200 |

| 21/2 | 65 | 292 | 292 | 190 | 149.4 | 24 | 8-22 | 75 | 63 | 438 | 250 |

| 3 | 80 | 318 | 318 | 210 | 168.1 | 27 | 8-22 | 91 | 78 | 464 | 280 |

| 4 | 100 | 356 | 356 | 255 | 200.2 | 30 | 8-22 | 117 | 102 | 565 | 350 |

| 5 | 125 | 400 | 400 | 280 | 235 | 33 | 8-22 | 144 | 128 | 614 | 400 |

| 6 | 150 | 444 | 444 | 320 | 269.7 | 35 | 12-22 | 172 | 154 | 717 | 450 |

| 8 | 200 | 559 | 559 | 380 | 330.2 | 40 | 12-25 | 223 | 203 | 930 | 450 |

| 10 | 250 | 622 | 622 | 445 | 387.4 | 46 | 16-29 | 278 | 255 | 1012 | 500 |

| 12 | 300 | 711 | 711 | 520 | 450.9 | 49 | 16-32 | 329 | 305 | 1231 | 500 |

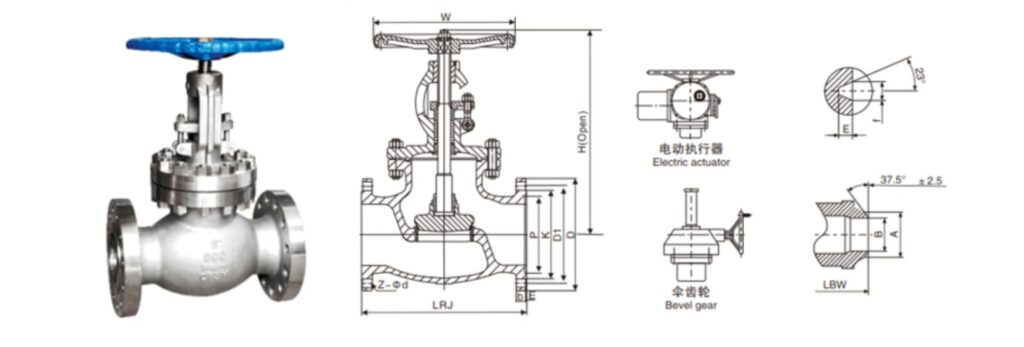

| SIze Inch | DN | LBW | LRJ | D | D1 | b | Z-φd | K | P | E | F | A | B | H | W |

| 600Lb | |||||||||||||||

| 2 | 50 | 292 | 295 | 165 | 127 | 26 | 8-1 9 | 108 | 82.55 | 7.92 | 11.91 | 60 | 49 | 430 | 250 |

| 21/2 | 65 | 330 | 333 | 190 | 149.5 | 29 | 8-22 | 127 | 101.6 | 7.92 | 11.91 | 75 | 59 | 480 | 300 |

| 3 | 80 | 356 | 359 | 210 | 168 | 32 | 8-22 | 146 | 123.83 | 7.92 | 11.91 | 91 | 74 | 530 | 350 |

| 4 | 100 | 432 | 435 | 275 | 216 | 39 | 8-25 | 175 | 149.23 | 7.92 | 11.91 | 117 | 97 | 650 | 400 |

| 5 | 125 | 508 | 511 | 330 | 266.5 | 45 | 8-29 | 210 | 180.98 | 7.92 | 11.91 | 144 | 122 | 750 | 450 |

| 6 | 150 | 559 | 562 | 355 | 292 | 48 | 12-29 | 241 | 211.12 | 7.92 | 11.91 | 172 | 146 | 850 | 560 |

| 8 | 200 | 660 | 663 | 420 | 349 | 56 | 12-32 | 302 | 269.88 | 7.92 | 11.91 | 223 | 194 | 1050 | 640 |

| 10 | 250 | 787 | 790 | 510 | 432 | 64 | 16-35 | 356 | 323.85 | 7.92 | 11.91 | 278 | 243 | 1145 | 700 |

| 900Lb | |||||||||||||||

| 2 | 50 | 368 | 371 | 215 | 165.1 | 38 | 8-25 | 124 | 95.25 | 7.92 | 11.91 | 60 | 49 | 540 | 320 |

| 21/2 | 65 | 419 | 422 | 245 | 190.5 | 41 | 8-29 | 137 | 107.95 | 7.92 | 11.91 | 75 | 59 | 669 | 400 |

| 3 | 80 | 381 | 384 | 340 | 190.5 | 38 | 8-29 | 156 | 123.83 | 7.92 | 11.91 | 91 | 74 | 689 | 450 |

| 4 | 100 | 457 | 460 | 290 | 235 | 45 | 8-32 | 181 | 149.23 | 7.92 | 11.91 | 117 | 97 | 755 | 500 |

| 5 | 125 | 559 | 562 | 350 | 279.4 | 51 | 8-35 | 216 | 180.98 | 7.92 | 11.91 | 144 | 122 | 795 | 500 |

| 6 | 150 | 610 | 613 | 380 | 317.5 | 56 | 12-32 | 241 | 211.12 | 7.92 | 11.91 | 172 | 146 | 950 | 600 |

| 8 | 200 | 737 | 740 | 470 | 393.7 | 64 | 12-38 | 308 | 269.88 | 7.92 | 11.91 | 223 | 194 | 1150 | 700 |

| 10 | 250 | 838 | 841 | 545 | 469.9 | 70 | 16-38 | 362 | 323.85 | 7.92 | 11.91 | 278 | 243 | 1350 | 800 |

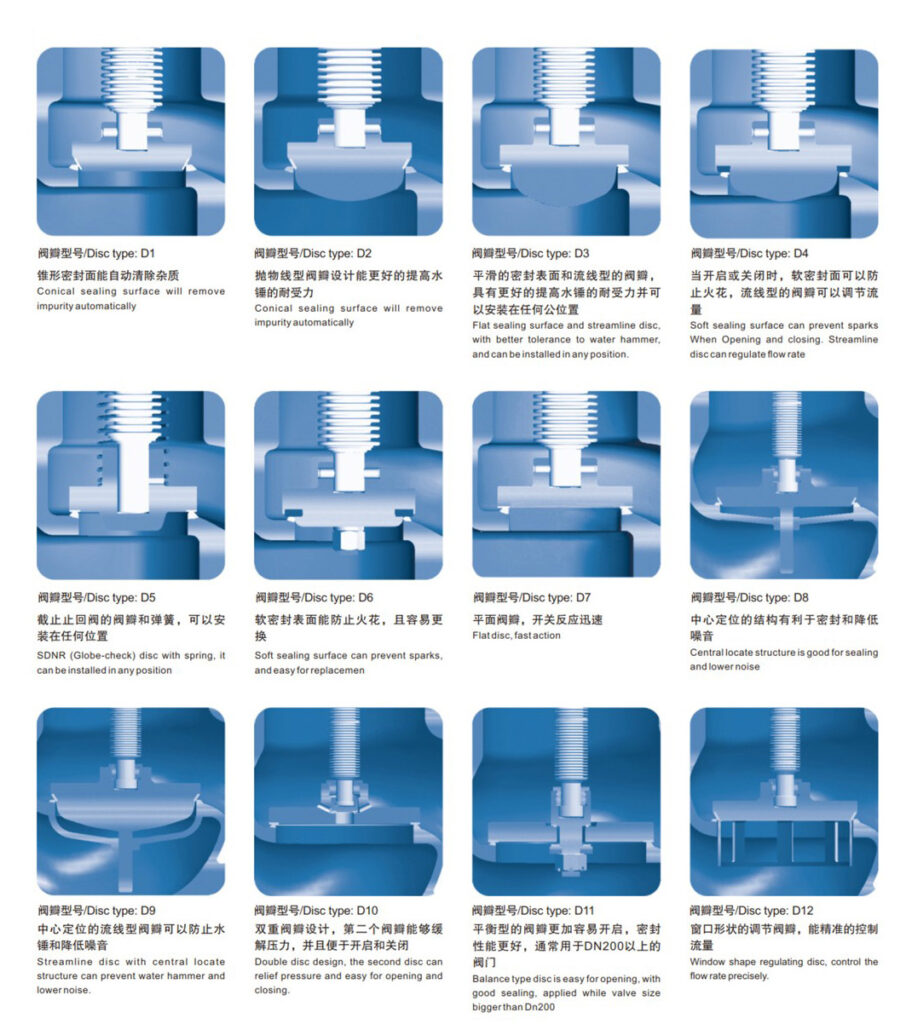

Available Disc Types

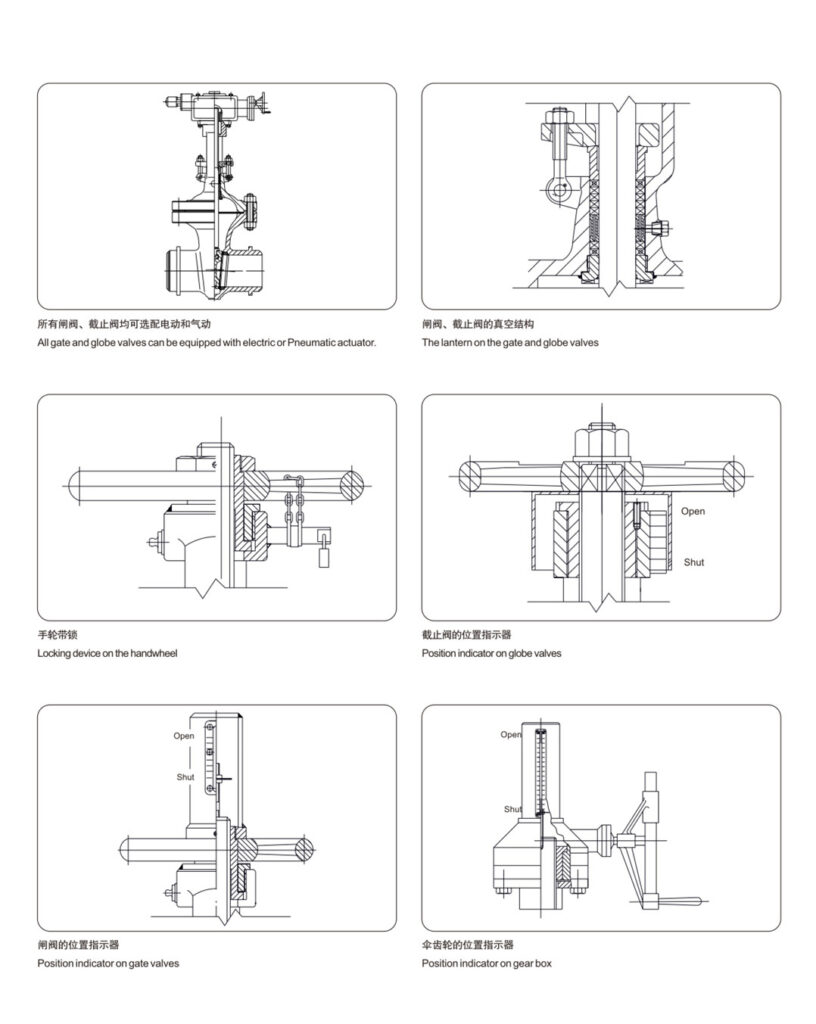

Special Design On Handwheel