Description

Brief of API Ball Valve with Bellows

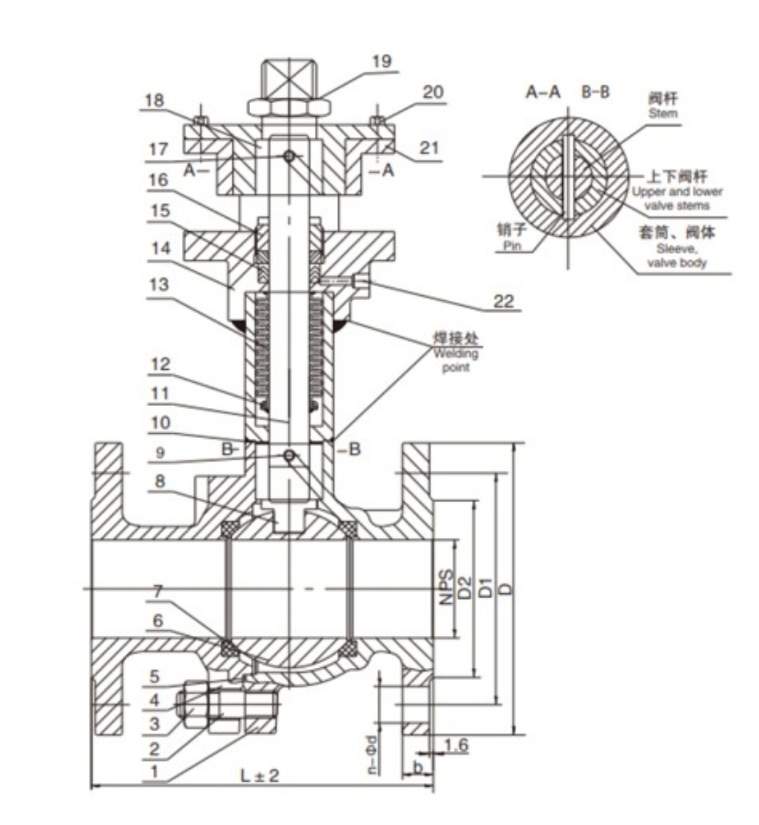

THINKTANK’s API ball valve with bellows features a three-stage sealing system. The primary seal is located at the lower end of the valve stem, utilizing a tapered seal that offers a metal-to-metal hard seal. The effectiveness of this seal increases with higher pressure. The second stage of sealing is provided by the bellows seal. As fluid enters the bellows through the first capillary-type seal, the pressure is significantly reduced, creating a stable and constant fluid environment. Consequently, the bellows experience a steady, unvarying force rather than alternating stress, which greatly enhances the working conditions and longevity of the bellows. The third stage of sealing is achieved through the use of conventional packing seals typically found in valves.

Key Features of Our API Ball Valve with Bellows

- Bellows Seal: The valve incorporates a bellows seal, a flexible, metallic component that ensures a tight, leak-free connection between the valve’s moving parts. This design significantly reduces fluid leakage and minimizes maintenance requirements.

- API Standard: Designed and manufactured according to the American Petroleum Institute (API) standards, this ball valve provides reliable performance and high-quality construction for various industries and applications.

- Durable Construction: Constructed from robust materials such as carbon steel, stainless steel, or alloy steel, the API Ball Valve with Bellows is built to withstand harsh industrial environments and provide a long service life.

- Full Port Design: The valve features a full port design, allowing for unrestricted fluid flow with minimal pressure drop, maximizing efficiency in fluid handling systems.

- Actuation Options: The API Ball Valve with Bellows can be operated manually using a lever or automatically using electric, pneumatic, or hydraulic actuators, depending on the application and system requirements.

- Versatile Applications: This ball valve is suitable for a wide range of applications, including oil, gas, water, steam, and other non-corrosive fluid handling systems in industries such as oil and gas, petrochemical, power generation, and more.

Advantage THINKTANK API Ball Valve with Bellows

- Superior Leak Protection: The bellows seal design provides an effective hermetic seal, minimizing fluid leakage and reducing the risk of fugitive emissions.

- Low Maintenance: The bellows seal design reduces the need for frequent maintenance and replacement of sealing components, lowering operational costs.

- Reliable Performance: The adherence to API standards ensures that the valve meets strict quality and performance requirements, providing reliable operation in demanding applications.

- Extended Service Life: The durable construction and materials used in the valve ensure a long service life, even in harsh industrial environments.

- Easy Operation: The various actuation options available allow for easy operation and integration into existing control systems.

Technical Specifications

- Design standard: ASME B16.34

- Face to face dimension: ASME B16.10

- Flanged ends: ASME B16.5

- Welded ends: ASME B16.25

- Test & inspection: API 598

Parts of API Ball Valve with Bellows

| No. | Parts Name | Materials | No. | Parts Name | Materials |

| 1 | Body | ASTMA216WCB | 12 | Bellows welding ring | ASTMA216WCB |

| 2 | Bolts | ASTMA193 B7 | 13 | Bellows | ASTMA182F316L |

| 3 | Nut | ASTM A194 2H | 14 | Sleeve | ASTMA216WCB |

| 4 | Bonnet | ASTMA216WCB | 15 | Packing | Expanded graphite |

| 5 | Gasket | PTFE | 16 | Packing gland | ASTMA216WCB |

| 6 | Ball | ASTMA182F316L | 17 | Pin | ASTMA182F6a |

| 7 | Seal ring | PTFE | 18 | Upper stem | 2Cr13 |

| 8 | Lower stem | 2Cr13 | 19 | Lock nut | ASTM A194 |

| 9 | Pin | ASTM A182 F6a | 20 | Bolts | ASTMA193B7 |

| 10 | Gasket | 316+Flexible Graphite | 21 | Sleeve | ASTMA216WCB |

| 11 | Stem | 2Cr13 | 22 | Refueling nozzle | H62 |

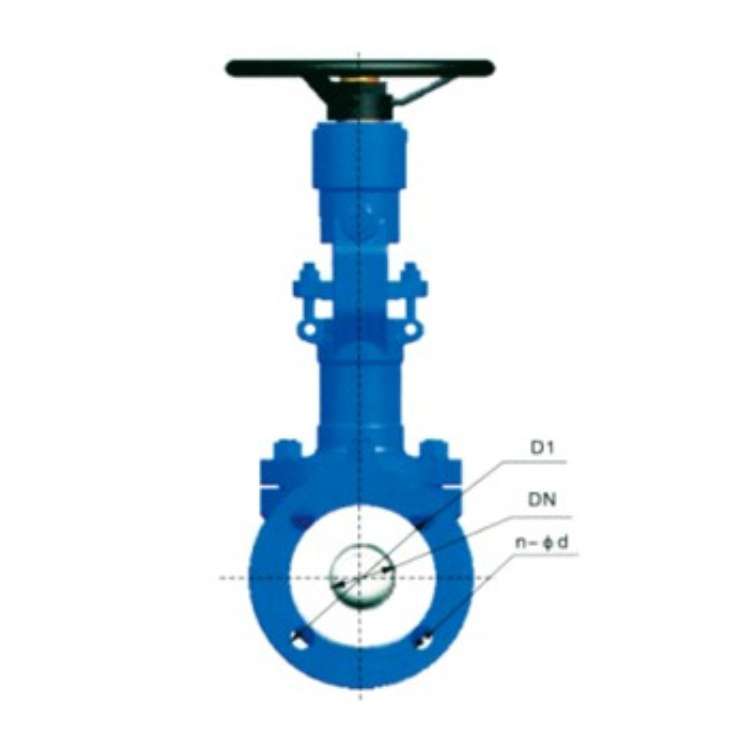

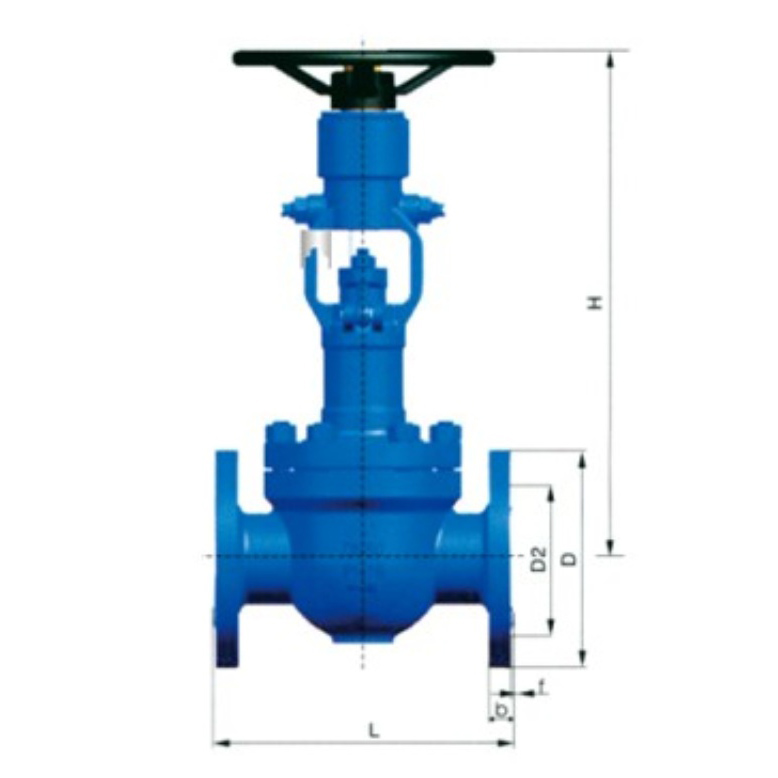

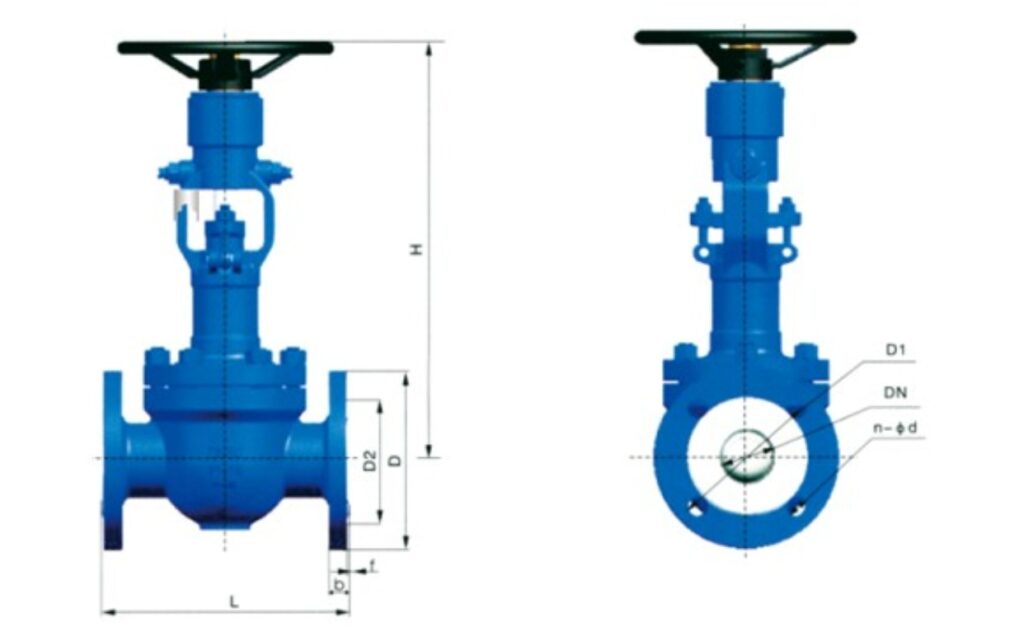

API Ball Valve with Bellows Dimensions

| DN | NPS | Dimensions(mm) | ||||||||

| L | D | D1 | D2 | b | f | n-φd | H | |||

| RF | BW | |||||||||

| 150LB | ||||||||||

| 100 | 4 | 229 | 305 | 229 | 190.5 | 157 | 24 | 1.6 | 8-19 | 330 |

| 125 | 5 | 356 | 381 | 254 | 216 | 186 | 24 | 1.6 | 8-22 | 360 |

| 150 | 6 | 394 | 457 | 279 | 241.5 | 216 | 25.5 | 1.6 | 8-22 | 392 |

| 200 | 8 | 457 | 521 | 343 | 298.5 | 270 | 29 | 1.6 | 8-22 | 492 |

| 250 | 10 | 533 | 559 | 406 | 362 | 324 | 31 | 1.6 | 12-25 | 548 |

| 300 | 12 | 610 | 635 | 483 | 432 | 381 | 32 | 1.6 | 12-25 | 688 |

| 350 | 14 | 686 | 762 | 533 | 476 | 413 | 35 | 1.6 | 12-29 | 722 |

| 400 | 16 | 762 | 838 | 597 | 540 | 470 | 37 | 1.6 | 16-29 | 722 |

| 450 | 18 | 864 | 914 | 635 | 578 | 533 | 40 | 1.6 | 19-32 | 804 |

| 500 | 20 | 914 | 991 | 699 | 635 | 584 | 43 | 1.6 | 20-32 | 952 |

| 600 | 24 | 1067 | 1143 | 813 | 749.5 | 692 | 48 | 1.6 | 20-35 | 1154 |

| 650 | 26 | 1143 | 1245 | 786 | 744.5 | 711 | 40 | 1.6 | 36-22 | 1300 |

| 700 | 28 | 1245 | 1346 | 837 | 795.5 | 762 | 43 | 1.6 | 40-22 | 1550 |

| 750 | 30 | 1295 | 1397 | 887 | 846 | 813 | 43 | 1.6 | 44-22 | 1650 |

| 800 | 32 | 1372 | 1524 | 941 | 900 | 864 | 44 | 1.6 | 48-22 | 1740 |

| 900 | 36 | 1524 | 1727 | 1057 | 1009.5 | 972 | 51 | 1.6 | 44-26 | 1950 |

| 300LB | ||||||||||

| 100 | 4 | 305 | 305 | 254 | 200 | 157 | 32 | 1.6 | 8-22 | 340 |

| 125 | 5 | 381 | 381 | 279 | 235 | 186 | 35 | 1.6 | 8-22 | 370 |

| 150 | 6 | 403 | 457 | 318 | 270 | 216 | 37 | 1.6 | 12-22 | 402 |

| 200 | 8 | 502 | 521 | 381 | 330 | 270 | 41.5 | 1.6 | 12-25 | 498 |

| 250 | 10 | 568 | 559 | 445 | 387.5 | 324 | 48 | 1.6 | 16-29 | 655 |

| 300 | 12 | 648 | 635 | 521 | 451 | 381 | 51 | 1.6 | 16-32 | 658 |

| 350 | 14 | 762 | 762 | 584 | 514.5 | 413 | 54 | 1.6 | 20-32 | 686 |

| 400 | 16 | 838 | 838 | 648 | 571.5 | 470 | 58 | 1.6 | 20-35 | 880 |

| 450 | 18 | 914 | 914 | 711 | 628.5 | 533 | 61 | 1.6 | 24-35 | 1050 |

| 500 | 20 | 991 | 991 | 775 | 686 | 584 | 64 | 1.6 | 24-35 | 1110 |

| 600 | 24 | 1143 | 1143 | 914 | 813 | 692 | 70 | 1.6 | 24-41 | 1400 |

| 650 | 26 | 1245 | 1245 | 867 | 803.5 | 737 | 87 | 1.6 | 32-35.5 | 1500 |

| 700 | 28 | 1346 | 1346 | 924 | 857 | 787 | 87 | 1.6 | 36-35.5 | 1600 |

| 750 | 30 | 1397 | 1397 | 991 | 921 | 845 | 92 | 1.6 | 36-39 | 1720 |

| 800 | 32 | 1524 | 1524 | 1054 | 978 | 902 | 102 | 1.6 | 32-42 | 1800 |

| 900 | 36 | 1727 | 1727 | 1172 | 1089 | 1010 | 102 | 1.6 | 32-45 | 2200 |

| DN | NPS | Dimensions(mm) | ||||||||

| L | D | D1 | D2 | b | f | n-φd | H | |||

| RF | BW | |||||||||

| 600LB | ||||||||||

| 50 | 2 | 292 | 295 | 165 | 127 | 92 | 26 | 6.4 | 8-19 | 240 |

| 65 | 21/2 | 330 | 330 | 190 | 149 | 105 | 29 | 6.4 | 8-22 | 290 |

| 80 | 3 | 356 | 356 | 210 | 168 | 127 | 32 | 6.4 | 8-22 | 340 |

| 100 | 4 | 432 | 432 | 273 | 216 | 157 | 38 | 6.4 | 8-25 | 358 |

| 125 | 5 | 508 | 508 | 330 | 266.5 | 186 | 45 | 6.4 | 8-29 | 400 |

| 150 | 6 | 559 | 559 | 356 | 292 | 216 | 48 | 6.4 | 12-29 | 445 |

| 200 | 8 | 660 | 660 | 419 | 349 | 270 | 56 | 6.4 | 12-32 | 498 |

| 250 | 10 | 787 | 787 | 508 | 432 | 324 | 64 | 6.4 | 16-35 | 653 |

| 300 | 12 | 838 | 838 | 559 | 489 | 381 | 67 | 6.4 | 20-35 | 665 |

| 350 | 14 | 889 | 889 | 603 | 527 | 413 | 70 | 6.4 | 20-38 | 738 |

| 400 | 16 | 991 | 991 | 686 | 603 | 470 | 77 | 6.4 | 20-41 | 920 |

| 450 | 18 | 1092 | 1092 | 743 | 654 | 533 | 83 | 6.4 | 20-44 | 1100 |

| 500 | 20 | 1194 | 1194 | 813 | 724 | 584 | 89 | 6.4 | 24-44 | 1200 |

| 600 | 24 | 1397 | 1397 | 940 | 838 | 692 | 102 | 6.4 | 24-52 | 1480 |

| 900LB | ||||||||||

| 50 | 2 | 368 | 368 | 216 | 165.1 | 92 | 38.5 | 6.4 | 8-26 | 250 |

| 65 | 21/2 | 419 | 419 | 244 | 190.5 | 105 | 41.5 | 6.4 | 8-29 | 300 |

| 80 | 3 | 381 | 381 | 241 | 190.5 | 127 | 38.5 | 6.4 | 8-26 | 345 |

| 100 | 4 | 457 | 457 | 292 | 234.9 | 157 | 44.5 | 6.4 | 8-32 | 415 |

| 125 | 5 | 559 | 559 | 349 | 279.4 | 186 | 51 | 6.4 | 8-35 | 446 |

| 150 | 6 | 610 | 610 | 381 | 317.5 | 216 | 56 | 6.4 | 12-32 | 477 |

| 200 | 8 | 737 | 737 | 470 | 393.7 | 270 | 63.5 | 6.4 | 12-39 | 520 |

| 250 | 10 | 838 | 838 | 545 | 469.9 | 324 | 70 | 6.4 | 16-39 | 628 |

| 300 | 12 | 965 | 965 | 610 | 533.4 | 381 | 79.5 | 6.4 | 20-39 | 680 |

| 350 | 14 | 1029 | 1029 | 640 | 558.8 | 413 | 86 | 6.4 | 20-42 | 750 |

| 400 | 16 | 1130 | 1130 | 705 | 615.9 | 470 | 89 | 6.4 | 20-45 | 940 |

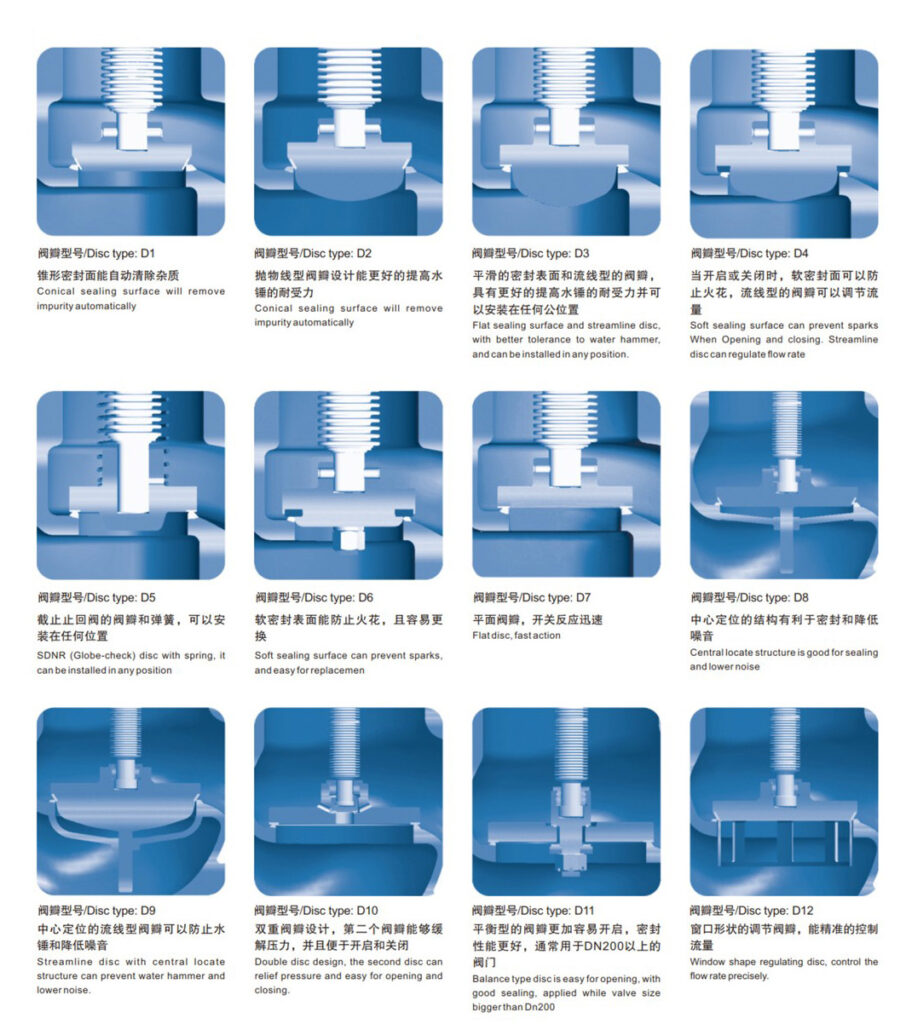

Available Dsic Types

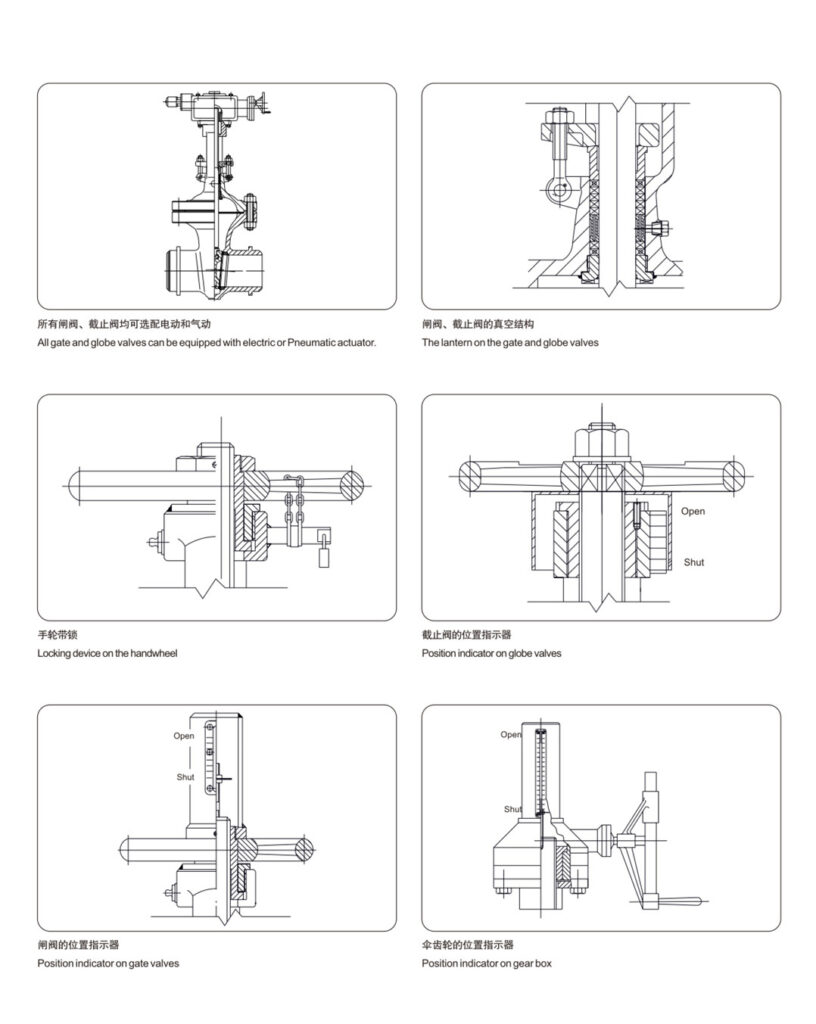

Special Design On Handwheel